- DL manuals

- Balboa Instruments

- Control Systems

- Poolux

- Installation And Configuration Manual

Balboa Instruments Poolux Installation And Configuration Manual

Summary of Poolux

Page 1

1 installation and configuration manual.

Page 2: Warning

2 save these instructions important notices this equipment has been tested and complies with the limits for a class b digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equi...

Page 3

3 important water safety instructions danger - to reduce the risk of drowning from hair or body entrapment, assure that the suction fittings, skimmers and main drains in the spa or pool connected to this control system are approved for the application. Danger - to reduce the risk of injury, do not r...

Page 4

4 important electrical safety instructions 1. Danger - risk of electric shock. Before making any electrical connections, make certain that the main power breaker from the house breaker box has been turned off. 2. Danger - risk of electric shock. Do not permit any electric appliance, such as a light,...

Page 5

5 table of contents this manual assumes that the poolux control system has been installed and configured according to this installation manual. Important notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 important water safety instruct...

Page 6

6 table of contents connecting high voltage components to the system control center . . . . . . . . . . . . . . . . . . . . . . 28 general requirements for high voltage equipment wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 pumps . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

7 table of contents configuring the system: step 1 - training the first wireless panel . . . . . . . . . . . . . . . . . . . . . . 46 configuring the system: step 2 - entering configuration mode . . . . . . . . . . . . . . . . . . . . . . . . . 47 configuring the system: adding a device . . . . . . ...

Page 8

8 fig. 1 poolux system overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 fig. 2 pool/spa system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 fig. 3 pool/spa system with pump operated pool cleane...

Page 9

9 fip: female iron pipe connection there are two types: 1) a female straight thread fitting or slip joint connection may be attached to a tapered male thread, as long as a gasket or seal is included into the female fitting design. A thread sealant alone will not seal. In this case, a thread sealant ...

Page 10

10 poolux system overview caution: the equipment and controls shall be located not less than 3 meters horizontally from the pool/spa. Attention: maintenir une distance minimale, m esuree dans un plan horizontal, de 3 m entre la cuve de relaxation et les appareils et commandes. Fig. 1 poolux system o...

Page 11

11 power requirements 120/240vac, 50/60 hz, 80 amps max outputs 6 - motorized valve actuators 24 vac, 0.75a max 8 - 30 amp relays 2 - dimmable light circuits - 120 vac, 8.3a max (1000w) each, gfci protected 1 - fill valve 24 vac, 0.5a max (in place of valve actuator #6) 1 - low voltage relay - (dry ...

Page 12

12 package content • determine that you have everything necessary to complete the installation. • find a suitable mounting location for the system control center, receivers and panels. • plan and determine where components will be plumbed. • plan wire runs and wiring connections. What is included: s...

Page 13

13 plumbing schematic suggestions j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd w a ter analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com ports wi...

Page 14

14 plumbing schematic suggestions (cont’d) j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd wa t e r analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure co...

Page 15

15 j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd w a ter analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com ports wireless transceiver fuse 4a 250v...

Page 16

16 plumbing schematic suggestions (cont’d) j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd wa t e r analog digit al in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com...

Page 17

17 j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd wa t e r analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com ports wireless transceiver fuse 4a 250...

Page 18

18 plumbing schematic suggestions (cont’d) j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd w a ter analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com...

Page 19

19 j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd w a ter analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com ports wireless transceiver fuse 4a 250v...

Page 20

20 plumbing schematic suggestions (cont’d) j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd w a ter analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com...

Page 21

21 j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd wa t e r analog digit a l in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com ports wireless transceiver fuse 4a 250...

Page 22

22 plumbing schematic suggestions (cont’d) j12 j33 j13 from gfci load lt 2 wht light 1 light 2 lt 1 j14 tb12 s1 in1+ in1- in2+ v+ in grd wa t e r analog digit al in2- in3+ in3- tb1 tb2 j8 j1 j11 gnd b a 9v j7 tb5 j2 icsp poc modules 5v 9v air j9 solar j10 setup run dip switch aux inputs pressure com...

Page 23

23 mounting the system control center important: please read the following mounting con- siderations before installing the system control center the system control center is contained in a rainproof enclosure. It is suitable for indoor or outdoor mounting. It should mount on a flat vertical wall and...

Page 24

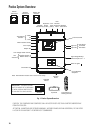

24 the poolux control system j12 j33 d36 1 j13 from gfci load chlorine gen. Control lt 2 wht light 1 light 2 relay 8 relay 7 relay 6 relay 5 relay 4 relay 3 relay 2 relay 1 fill valve valve 6 valve 5 valve 4 valve 3 valve 2 valve 1 lt 1 j14 1 1 1 1 1 1 1 1 1 1 1 1 lt 1 lt 2 j22 j21 j20 j19 j18 j17 j...

Page 25

25 fig. 13 system control center main panel j12 j33 d36 1 j13 fr om gfci lo ad chlorine gen. Contr ol lt 2 wht light 1 light 2 relay 8 relay 7 relay 6 relay 5 relay 4 relay 3 relay 2 relay 1 fill valve valve 6 valve 5 valve 4 valve 3 valve 2 valve 1 lt 1 j14 1 1 1 1 1 1 1 1 1 1 1 1 lt 1 lt 2 j22 j21...

Page 26

26 system control center wiring routing of the wires the high voltage and low voltage wiring must be run separately, never sharing the same conduit or installed in the same compartment. The high voltage wires must be copper conductors sized for the required equipment current draw. Note: all of the e...

Page 27

27 circuit breaker installation the circuit breaker sub-panel has space for up to 8 single position or 4 double position circuit breakers. The installer is responsible for providing circuit breakers of appropriate ratings. See the table below for a list of the approved breakers that can be used. Thi...

Page 28

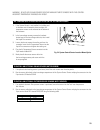

28 1. Check to see that all equipment motors have built-in thermal protection before installing. 2. Pull appropriately sized wires for each piece of equipment from the equipment to the enclosure. 3. Each piece of equipment requiring high voltage should have its own high voltage relay. If using one r...

Page 29

29 connecting high voltage components to the system control center (cont’d) filter pump relay #1 is configured by default for use with a single-speed pump. While this function can be moved to another relay during system configurations, it is rarely practical to do so. If the filter pump is a two-spe...

Page 30

30 connecting low voltage components to the system control center valve actuators the system control center is capable of controlling six (6) 24vac valve actuators. Run the valve actuator cable into the low voltage raceway. For pool/spa installations, valve 1 and valve 2 have dedicated functions. Co...

Page 31: Heater Tb3

31 connecting low voltage components to the system control center (cont’d) low voltage control circuit for heaters this section applies to all heaters or heat pumps that have control circuitry of 24vac or less. An internal relay with low voltage dry contacts is provided to connect to the low voltage...

Page 32

32 temperature sensors attention: the water temperature sensor is 25’ long. Consider the sensor mounting locations before mounting the system control center. 1. Locate the air temperature sensor so that it will be exposed to the outside ambient temperature but not influenced by direct sunlight. If t...

Page 33

33 1. If the system control is not installed in a building and is otherwise not influenced by direct sunlight, the temperature sensor can be mounted to the bottom of the enclosure. 2. In the low-voltage raceway, remove the knockout located next to the low-voltage cable slot, then install the liquid-...

Page 34

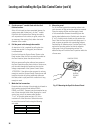

34 1. Determine the exact location of the panel. Warning: it is important to position the panel so that it cannot be submerged at any time! Occasional splashing is permissible so long as the water can drain off the panel. While the panel is designed to get wet, constant water contact must be avoided...

Page 35

35 3. Provide a 1" conduit. Provide a 1" conduit through the concrete/gunite at the location selected for the panel. The panel will extend into the inside diameter of the conduit and the cable will be routed through it. Before concrete/gunite is placed, securely fasten the 1" conduit so that it will...

Page 36

36 8. Mount the panel. Dry fit the panel against the mounting surface to be sure there are no high points that need to be removed. Clean the mating surfaces and then apply a bead of silicone adhesive. Remove the masking from the double sided adhesive strips. Carefully push the extra 6" to 8" of cabl...

Page 37

37 installing spa-side and optional dolphin base transceiver modules 1. Position both receivers away from any cables (such as power lines, extension cords, cable lines, and phone lines). 2. Mount the rf module far away from large metallic objects (such as fences, aluminum siding, metal piping, and r...

Page 38

38 ph/orp/conductivity 1. Splice in one reducing tee for each sensor (ph, orp and conductivity) with pipe dimensions as required by existing pool plumbing. Sensors should be located after the filter and before the heater or electrolytic chlorine generator. Each sensor requires 1/2 inch npt female pi...

Page 39

39 dislodging air from within the ph bulb tip during shipping or storage, the electrolyte within the sealed ph bulb tip may have been replaced by entrained air bubbles. This may cause erroneous readings. To dislodge the air and to force the electrolyte back into the ph bulb tip, grasp the electrode ...

Page 40

40 optional chlorine generation cell installation the chlorine generator option contains: factory-installed control electronics with display (installed in the system control center) esc24/36/48 chlorine generator cell chlorine generator cell cord installation summary this is a quick guide as to how ...

Page 41

41 water flow in most cases (for 1.5” and 2” pvc) the total water flow can be directed through the cell housing as shown in sketch 3a) without significantly affecting the flow rate and/or back- pressure on the filter, etc. However, if flow rate is a concern (high horse-power pump, large diameter pip...

Page 42

42 expansion controller connection this section only includes instructions on connecting the expansion controller(s) to the system control center. A single installation may utilize up to four expansion boxes. 1. Install the expansion controller following the installation instructions that are includ...

Page 43

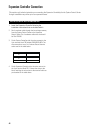

43 dip switch settings set the dip switch settings on the circuit board as shown. When looking at the dip switches on the service panel, the on position is to the right. Before powering up the system identify the default configuration that most closely matches the plumbing and equipment installed. N...

Page 44

44 start up: configuration parameters default settings filter cycles all disabled chemistry ph 7.2 to 7.8 orp 500 to 800 tds 1000 to 8000 pool set temperature 80°f spa set temperature 100°f pool mode heat disable spa mode heat disable spa filter heat disable spa panel button map light 1, light 2 con...

Page 45

45 start up: configuration parameters (cont’d) filter pumps most configurations have a single filter pump, configured as filter pump 1. A two-water-body, two-pump system has two filter pumps, with filter pump 1 being the pool pump and filter pump 2 the spa pump. Heaters the system can support four t...

Page 46

46 important: the first thing you must do before making changes to the configuration is to create communication between the system and the panel by “training” the panel as described below: the system should be powered up. You will need to be standing in front of the system box within reach of the se...

Page 47

47 configuring the system: step 2 - entering configuration mode to configure the system, move the setup-run switch (s1) on the circuit board to the setup position. The system will enter configuration mode. (the first wireless panel must be trained prior to use. See previous page.) read page 45 regar...

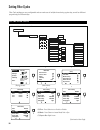

Page 48

48 configuring the system: adding a device disable unassigned external aux device 1 mode device type maximum speed output 1 expansion boxes --- device no. --- pool + spa aux device 1 mode device type maximum speed output 1 expansion boxes device no. Spa relay on/off internal unassigned 2 (4) mode: p...

Page 49

49 configuring the system: heater control heater add device delete device edit device setup devices filter pump pool light spa light heater cleaner pool fill assigned assigned assigned unassigned unassigned unassigned disable unassigned external heater mode device type maximum speed output 1 expansi...

Page 50

50 add device mode device type maximum speed output 1 expansion boxes device no. Output 2 expansion boxes device no. Freeze protect valves drain time rename device solar valve setup devices configuring the system: configuring a solar heater configuring a heater at-a-glance disable unassigned externa...

Page 51

51 configuring the system: exiting configuration mode after configuration is complete, left arrow to exit configuration and enter automatic mode. Change s1 to run position on the pool control and press ‘select’ button on the panel exit from configuration panel display will indicate a reset and will ...

Page 52

52 configuration at-a-glance system information your system information (accessories and settings) can be viewed within a few screens, beginning with the check configuration menu (menu 4 below). The basic equipment installed is shown: 1) pool and/or spa, 2) expansion boxes, and 3) other features (me...

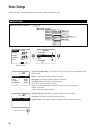

Page 53

53 setting day and time at-a-glance setting day and time day of the week and am/pm settings cannot be set separately. Day of the week changes automatically according to the date input, and the am/pm setting is changed with the hour setting. Day and time setup main menu mode pool pool light spa light...

Page 54

54 setting filter cycles setting filter cycles at-a-glance (5) filter: press select to turn enable or disable. (6) mode: press select to choose mode, pool or spa. (7) days to run: right arrow. (continued on next page) pool 12:00 am 12:00 am high filter 1 setup filter mode days to run timer 1 start t...

Page 55

55 9 for a second filter cycle press select to enable or disable a second run time for filter cycle 1. If enabled, arrow down and set start time 2 and stop time 2 in the same way described above for start time 1 and stop time 1. Program additional filter cycles in the same way. Two separate bodies o...

Page 56

56 set pool temp set spa temp heater heat pump pool mode heat spa mode heat solar heat spa filter heat heater enable disable polling heat in filter manaul disable disable enable disable enable disable enable disable enable set polling main menu heater settings at-a-glance mode pool pool light spa li...

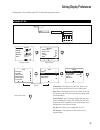

Page 57

57 display backlight (min) sleep time (min) assign display2 key tone lcd contrast setup main menu display set up at-a-glance mode pool pool light spa light filter pump heater pool temp air temp 10/09/06 pool set 80f monday 12:42 pm alert / error (display screen) 1 3b left arrow to exit. Setting disp...

Page 58

58 renaming devices at-a-glance renaming devices mode pool pool light spa light filter pump heater pool temp air temp 10/09/06 pool set 80f monday 12:42 pm alert / error (display screen) 1 5 left arrow to exit. A g m s exit abc save clear back b h n t c i o u d j p v e k q w f l r x y 5 shift space ...

Page 59

59 panel leds led 1 thru 7 device list scene list mode chemistry unassigned setup main menu assigning panel leds at-a-glance assigning panel leds mode pool pool light spa light filter pump heater pool temp air temp 10/09/06 pool set 80f monday 12:42 pm alert / error (display screen) 1 you may choose...

Page 60

60 creating scenes scenes are used to assign one or more devices to a preset timer. For example, a scene named “evening” could be created that turns on a pool or spa light, and an auxiliary device such as a waterfall at the same time each evening. Scene 1 off on scene 2 -20 select devices scene time...

Page 61

61 12 12:00 am disable 12:00 am scene 1 select devices scene timout timers timer 1 start timer 1 stop days to run 12 12:00 am disable 12:00 am scene 1 select devices scene timout timers timer 1 start timer 1 stop days to run 12 12:00 am disable 12:00 am scene 1 select devices scene timout timers tim...

Page 62

62 vacation mode vacation mode is used to disable scene timers when going on vacation. Each scene has an option in its setup called “run in vacation.” if set to yes, the scene timers will continue to operate even though vacation mode is turned on or off. Vacation mode main menu 2 mode pool pool ligh...

Page 63

63 set low orp set high ph set low ph set high tds set low tds chlorine gen. Chemical feeder chemical feeder duration in min ecomatic orp threshold extend filter cycle set high orp chemistry enable disable enable disable enable disable main menu chemistry settings at-a-glance (display screen) chemis...

Page 64

64 device timeout pool fill 30 min setup main menu device timeout at-a-glance mode pool pool light spa light filter pump heater pool temp air temp 10/09/06 pool set 80f monday 12:42 pm alert / error (display screen) 1 3 left arrow to exit. Device timeout a device timeout is the length of time a devi...

Page 65

65 check alerts main menu check alerts at-a-glance mode pool pool light spa light filter pump heater pool temp air temp 10/09/06 pool set 80f monday 12:42 pm alert / error (display screen) 1 no alerts ! Alerts & errors 3 alerts & errors check air sensor check air sensor 4 if there is no error, this ...

Page 66

66 spa-side panel set up you may choose the equipment that you would like to associate with the first two spa panel buttons. The temp and mode buttons cannot be reassigned. Choose the piece of equipment from the device list, then press select when the piece of equipment you desire is highlighted as ...

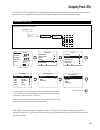

Page 67

67 optional dolphin remote set up you must designate the equipment that you would like the jet and the aux buttons to operate from the dolphin remote. Choose the piece of equipment from the device list, then press select when the piece of equipment you desire is highlighted as illustrated below. Lef...

Page 68

68 poolux wireless panel cradle installation option the wireless panel comes with a charging cradle that can be installed on a wall inside the home for a convenient display while charging. Installing the cradle is not necessary to charge the panel; it can be charged independently from the cradle wit...

Page 69

69 faults a fault is an indication of a serious error that can affect the operation of the pool system. One of the following messages will blink on the lower right side of the wireless pool control display when a fault occurs. Air sensor fault the air temperature sensor has failed or has been discon...

Page 70

70 having a chemical tank provides a convenient way to dispense acid into your pool or spa to maintain the proper ph. A chemical tank system also reduces overall maintenance time for the owner, and optimizes the pool chemistry over time. The chemical solution (diluted muriatic acid) is contained in ...

Page 71

71 12. Once the filter is suspended at the proper height, route the outside tubing to the motor to determine how much is to be cut off when inserted into the suction (“in”) side of the motor. Note: the recessed “in” and “out” ports for the tubes in the motor are approx 3/4” deep. Note: do not instal...

Page 72

72 the service panel operation controls and displays for the poolux and an optional chlorine generator are found on the service panel inside of the poolux system box. The chlorine generator control and display are located on the top portion of the panel, and the poolux and display are located on the...

Page 73

73 fig. 35 service display panel button functions--quick overview s a n i t i z a t i o n select min 1 2 on off operation mode fi lter au xi liar y au xi liar y au xi liar y au xi liar y au xi liar y au xi liar y au xi liar y lcd contrast system control max stand by winter mode cell output force fil...

Page 74

74 to enter service mode, press mode once. In service mode, all devices shut off, and the wireless controller is disabled. Service mode stays on until manually terminated unless a service time out period is set. Press mode at any time from within the service mode to enter service time out. When serv...

Page 75

75 replacement poolux parts list 40499 . . . . . . . . . . . . . . . . Actuator 24va 53963 . . . . . . . . . . . . . . . . Panel pool display 54186 . . . . . . . . . . . . . . . . Dolphin ii pool 53770 . . . . . . . . . . . . . . . . Dolphin rf receiver 71004 . . . . . . . . . . . . . . . . Ecs24/36...

Page 76

76 balboa instruments, inc. 1382 bell avenue tustin, ca 92780 www.Balboa-instruments.Com t 714-384-0384 f 714-384-0338 pn: 40627_a february 12, 2007.