BaltGaz NEVALUX 7224 User Manual

User’s manual

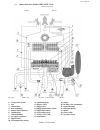

TABLE OF CONTENTS

1. SAFETY MEASURES...................................................................................................................................................4

2. Technical description

........................................................................................................................................................................................... 5

2.1.Boiler’s purpose........................................................................................................................................................... 5

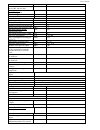

2.2. Technical characteristics............................................................................................................................................. 5

2.3. Overall and connection

dimensions………………………..................................................................................................................................... 6

3. USER’S MANUAL....................................................................................................................................................... 7

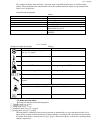

3.1. Control Panel.............................................................................................................................................................. 7

3.2. Boiler’s operating

modes………………......................................................................................................................................................... 8

3.2.1. Standby

mode...................................................................................................................................................................................8

3.2.2. DHW mode.............................................................................................................................................................. 8

3.2.3. Combined

mode………….................................................................................................................................................................. 9

3.2.4. Heating

mode…….......................................................................................................................................................................... 9

3.3. Additional

functions…….................................................................................................................................................................... 9

3.3.1. Antifreeze

functions………................................................................................................................................................................ 9

3.3.2. Anti-blocking

functions…………............................................................................................................................................................ 9

3.3.3. Boiler’s operation in heating mode with an external (outdoor) temperature

sensor................................................................................................................................................................................ 9

3.3.4. Boiler’s operation at low /high source

voltage............................................................................................................................................................................. 10

4. BOILER SERVICE…................................................................................................................................................. 10

4.1.Examination............................................................................................................................................................... 10

4.2. Boiler Treatment…….............................................................................................................................................. 10

4.3. Operations effectuated at technical

service.............................................................................................................................................................................. 11

5. STORAGE

PRECAUTIONS.............................................................................................................................................................. 11

6. GENERAL

REQUIREMENTS.......................................................................................................................................................... 11

7. OPERATIONS BEFORE

INSTALLATION............................................................................................................................................................ 12

7.1. DHW system............................................................................................................................................................. 12

7.2. Heating system......................................................................................................................................................... 12

7.2.1. New heating

system……...................................................................................................................................................................... 12

7.2.2. Existing heating

system………………...................................................................................................................................................... 12

7.3. Selection of an additional expansion

tank.................................................................................................................................................................................. 12

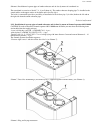

8. BOILER INSTALLATION......................................................................................................................................... 13

8.1. Mounting the boiler to the

wall……………………….............................................................................................................................................. 13

8.2. Connecting the boiler to the CH and the DHW

system.............................................................................................................................................................................. 13

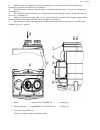

8.3. Connecting the boiler to the gas

system.............................................................................................................................................................................. 13

8.4. Connecting the boiler to the balloon with liquefied

gas.................................................................................................................................................................................... 14

8.5. Connecting the boiler to the power

line................................................................................................................................................................................... 14

9. SMOKE EXHAUSTER

INSTALLATION……………........................................................................................................................................ 15