- DL manuals

- Cadel

- Pellet stove

- aquos 24 h2O

- Installation, Use And Maintenance Manual

Cadel aquos 24 h2O Installation, Use And Maintenance Manual

Summary of aquos 24 h2O

Page 2

2 aquos 24 h 2 o en summary 1 introduction .................................................... 3 1.1 revisions to the publication.....................3 1.2 care of the manual and how to consult it ...3 1.3 symbols used in the manual .....................3 2 warnings and warranty terms ................

Page 3

3 aquos 24 h 2 o en 1 introduction dear customer, our products are designed and manufactured in compliance with european reference standards for construction products (en13240 wood-burning stoves, en14785 pellet-burning appliances, en13229 fireplaces/ wood-burning inserts, en 12815 wood-burning cook...

Page 4

4 aquos 24 h 2 o en • only use the fuel recommended by the manufacturer. The product must not be used as an incinerator. • it is strictly forbidden to use alcohol, petrol, liquid fuel for lanterns, diesel, bio-ethanol, fluids for lighting charcoal or similar liquids to light/rekindle the flame in th...

Page 5

5 aquos 24 h 2 o en rest and provide suitable insulation if it is made of flammable material (e.G. Wood, fitted carpet or plastic). • live electrical parts: only power the product after completing assembly. • disconnect the product from the 230v power supply before performing any maintenance operati...

Page 6

6 aquos 24 h 2 o en the hearth. • variations in colour of the painted or ceramic/serpentine parts and craquelure ceramics as they are natural characteristics of the material and product use. • masonry work. • plant parts (if present) not supplied by the manufacturer. Any technical interventions on t...

Page 7

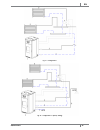

7 aquos 24 h 2 o en installation must be carried out with reference to the diagram of the heating system prepared in accordance with the standards and local recommendations in force: in any case, respect: for the heating appliance local requirements concerning the chimney connection. Local requireme...

Page 8

8 aquos 24 h 2 o en 5.2 precautions regarding installation important! Product installation and assembly must be carried out by qualified personnel. The product must be installed in a suitable place for it to be regularly opened and routine maintenance to be performed. The site must be: • compliant f...

Page 9

9 aquos 24 h 2 o en the product cannot be installed (except for sealed or closed operation appliances with external ducted combustion air intake): - in bedrooms or bathrooms; - in rooms where there are liquid fuel appliances with continuous or intermittent operation that draw the combustion air from...

Page 10

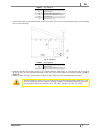

10 aquos 24 h 2 o en fig. 3 - rear view of a pellet stove (example) 5.7 introduction this chapter about the chimney flue has been drawn up in cooperation with assocosma (www.Assocosma.Org) and is based on european standards (en 15287 - en 13384 - en 1856 - en 1443 - uni 10683:2012). It provides inst...

Page 11

11 aquos 24 h 2 o en legend fig. 4 page 10 1 chimney flue with insulated stainless-steel pipes 2 chimney flue on the existing chimney 3 inspection plug 4 inspection door 5 ≥ 3,5 mt • the chimney flue or chimney is of great importance for the correct running of the heating appliance. • it is fundamen...

Page 12

12 aquos 24 h 2 o en fig. 6 - example of label 5.10 maintenance • the fumes extraction pipes (fumes conduit + chimney flue + chimney pot) must always be cleaned, scrubbed and checked by an expert stove-repairer, in compliance with current regulations, with the instructions of the stove-manufacturer ...

Page 13

13 aquos 24 h 2 o en legend fig. 8 page 12 1 chimney pot 2 fume outlet 3 chimney flue 4 termal insulation 5 external wall 6 chimney union 7 fume pipe 8 heat generator 9 inspection door 10 t-union with inspection plug 5.13 external air inlet fig. 9 - direct air inflow fig. 10 - indirect air inflow le...

Page 14

14 aquos 24 h 2 o en system type Ø80 mm pipe Ø100 mm pipe maximum number of unions 3 3 level section (minimum inclination 3%) 2 mt 2 mt installation at a height above 1200 m a.S.L. No obligatory • use a plate pipe for stoves of Ø80 mm or Ø100 mm depending on the type of system and with silicone gask...

Page 15

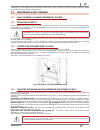

15 aquos 24 h 2 o en legend fig. 12 page 14 1 insulating material 2 inspection plug 3 chimney inspection entrance 4 minimum safety distance = 0,5 mt 5 inclination ≥ 3° 6 level section ≤ 1 mt • old chimney flue with an inserted pipe of minimum Ø100/120 mm and with an external door which enables the c...

Page 16

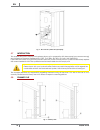

16 aquos 24 h 2 o en 6 technical drawings and characteristics 6.1 dimensions fig. 14 - aquos 24 h2o dimensions.

Page 17

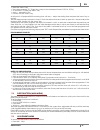

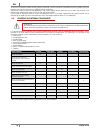

17 aquos 24 h 2 o en technical characteristics aquos 24 h 2 o nominal output power:: 24,8 kw (21328 kcal/h) nominal output power (water):: 22,7 kw (19522 kcal/h) minimum output power: 6,0 kw (5160 kcal/h) minimum output power (water): 5,0 kw (4300 kcal/h) efficiency at max 91.6% efficiency at min 95...

Page 18

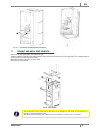

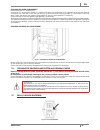

18 aquos 24 h 2 o en 7 installation and assembly 7.1 preparation and unpacking fig. 15 - removing the package screws fig. 16 - hook for handling the stove is supplied complete with all its electrical and mechanical components and factory-tested: open the package and remove the two screws between the...

Page 19

19 aquos 24 h 2 o en fig. 17 - 1. Turn the feet clockwise to lower the product. 7.2 ceramic and metal sides insertion remove, on the upper part, the metal top (a). Take the ceramic sides (b) or the metal side (b1) from the box and insert them onto the profile (c) in correspondence of the guide, from...

Page 20

20 aquos 24 h 2 o en 8 plumbing connection 8.1 plumbing connection important! If installation of the product involves interaction with another, pre-existing system complete with heating equipment (gas boiler, methane boiler, diesel boiler, etc.), contact qualified personnel, who subsequently will be...

Page 21

21 aquos 24 h 2 o en • pipes and fittings for connection the kit comes preassembled by the manufacturer and it is designed to heat domestic water directly from the home water supply system. When hot water is required and the tap is turned, the internal water flow switch will send a signal to the div...

Page 22

22 aquos 24 h 2 o en fig. 21 - hydraulic kit legend a domestic water outlet b domestic water inlet c heating return d heating delivery e exchanger return f exchanger delivery the safety valve (6) is always connected to a water draining pipe. The pipe must be adequate to support the water's high temp...

Page 23

23 aquos 24 h 2 o en level must be inspected regularly every 14 days to maintain the water content almost constant. In the event one needs to add water one must carry out the filling process when the boiler has cooled down to room temperature. These precautions aim to prevent the onset of a thermal ...

Page 24

24 aquos 24 h 2 o en 9 electrical connections 9.1 general precautions electrical safety of the system is ensured only when it is properly connected to an efficient earthing system made in compliance with the safety standards in force: gas, water or heating systems pipes are not suitable as earth con...

Page 25

25 aquos 24 h 2 o en fig. 24 - check the brazier after a long period of inactivity, remove any pellets left in the hopper (using a vacuum cleaner with a long pipe ), as they could have absorbed moisture, thereby altering their original characteristics and no longer being suitable for combustion. The...

Page 26

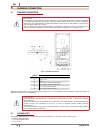

26 aquos 24 h 2 o en 10.2 opening/closing the door attention! The door must be closed properly for the boiler to work correctly. Use suitable protective clothing (such as gloves) to open the boiler door. To open the door, lift the hook, as shown in the figure. Fig. 25 - door opening 10.3 settings to...

Page 27

27 aquos 24 h 2 o en fig. 27 - lift the cover. Insert the pellets. No other type of fuel other then pellets, in compliance with above-mentioned specifications, is to be inserted into the hopper. 10.5 duct for additional tank (optional) fig. 28 - duct for additional tank one can purchase a duct to be...

Page 28

28 aquos 24 h 2 o en fig. 29 - display legend 1 boiler lighting/shutdown 2 scrolling of programming menu to decrease. 3 menu 4 scrolling of programming menu to increase. 5 decrease set temperature/programming functions. 6 increase set temperature/programming functions. 7 display. 11.2 main menu it i...

Page 29

29 aquos 24 h 2 o en • press the “menu” key • the system proposes “p1” (press the keys for the subsequent timers p2,p3, p4, p5, p6) • to activate “p1” press the “menu” key • press + - and select “on” • confirm with the “menu” key at this point it will propose 00:00 as starting time, with key + - adj...

Page 30

30 aquos 24 h 2 o en • scroll with the arrows and select “set room t” or “set water t” or “exchanger speed" • press "menu" to enter the chosen option. • modify with the + - keys. • press "menu" to confirm and "esc" to exit. 11.6 settings menu the settings menu allows to act on the stove operating mo...

Page 31

31 aquos 24 h 2 o en fig. 30 - electrical thermostat connection legend pos.1-2 external thermostat pos.3-4 puffer/boiler probe pos.5 earthing pos.6-7 additional boiler (max 100 ma) pos.8 three-way valve neutral pos.9 three-way valve neutral (domestic) pos.10 three-way valve neutral (heating) (*) dis...

Page 32

32 aquos 24 h 2 o en • scroll to "settings" using the arrows • press "menu" to confirm. • scroll to "eco - shutdown t" using the arrows. • press "menu" to confirm. • enter the minutes with the + - keys. • press "menu" to confirm and "esc" to exit. 11.7 auto eco mode to activate the “auto eco” mode a...

Page 33

33 aquos 24 h 2 o en and ash expulsion speed can be increased. This change resolves all the potential problems related to pellets clogging in the brazier and deposits forming at the bottom of the brazier itself caused by poor quality fuel or fuel that produces a lot of ashes. The values available ar...

Page 34

34 aquos 24 h 2 o en to change the function act as follows: • press the “menu” button. • scroll to "settings" using the arrows • press "menu" to confirm. • scroll to "season" using the arrows. • press "menu" to confirm. • select "summer" or "winter" with the + - keys. • press "menu" to confirm and "...

Page 35

35 aquos 24 h 2 o en fig. 31 - configuration 1 fig. 32 - configuration 2.1 (factory setting).

Page 36

36 aquos 24 h 2 o en fig. 33 - configuration 2.2 (*) (*) disconnect internal three-way valve and flow switch fig. 34 - configuration 3 (*) (*) disconnect internal three-way valve and flow switch.

Page 37

37 aquos 24 h 2 o en fig. 35 - configuration 4 fig. 36 - configuration 5 legend 1 stove 2 heating delivery 3 heating return 4 zone valves.

Page 38

38 aquos 24 h 2 o en legend 5 heating bodies 6 hot domestic water 7 cold domestic water 8 domestic water boiler 9 diverter valve 10 boiler thermostat 11 thermostatic mixing valve 12 domestic water 10 kΩ β3434 ntc probe 13 heating puffer 14 heating system circulator 15 puffer thermostat 16 puffer 10 ...

Page 39

39 aquos 24 h 2 o en 12.3 smoke temperature probe detects the temperature of the smoke, thereby enabling start-up or stopping the product when the temperature drops below the preset value. 12.4 contact thermostat in the fuel hopper if the temperature exceeds the preset safety level, it immediately s...

Page 40

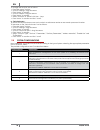

40 aquos 24 h 2 o en the control panel gives information on the reason of the alarm in progress. A sound signal is not envisioned for alarms a01-a02 only so to panel alertnot disturb the user in the event of pellets running out in the hopper during the night. Panel alert type of problem solution a01...

Page 41

41 aquos 24 h 2 o en meanwhile. This last stage can be skipped by pressing key 1 (esc) (it goes into start-up) and by pressing it again (it recognises that the boiler is switched off). 13 maintenance and cleaning 13.1 daily or weekly cleaning performed by the user 13.2 before each start-up using a s...

Page 42

42 aquos 24 h 2 o en fig. 39 - cleaning 1 fig. 40 - cleaning 2 13.5 periodic cleaning performed by a qualified technician cleaning the exchanger and pipe unit cleaning the upper compartment when the boiler is cold lift the ceramic top; remove screws “o” to the right and left and remove cover “a”. Th...

Page 43

43 aquos 24 h 2 o en cleaning the lower compartment remove ash pan “d” and empty it. Lower lever “e” and extract drawer “f”. Remove the ash from the drawer and if needed use a vacuum cleaner to remove any other ash or soot that has built-up under the drawer. Remove brazier “g” and clean it every 2/3...

Page 44

44 aquos 24 h 2 o en at the end of season, before shutting down the boiler, we recommend completely removing pellets from the hopper with the use of a vacuum cleaner with an extension. The service fuse may have to be replaced if the control panel display does not go on when the product is re- starte...

Page 45

45 aquos 24 h 2 o en 14 faults/causes/solutions 14.1 checking the internal components attention: guide for the exclusive use of the specialised technician. Attention: all repairs must be carried out exclusively by a specialised technician, with the boiler switched off and the plug disconnected. The ...

Page 46

46 aquos 24 h 2 o en anomaly possible causes solutions pellets accumulate in the brazier, the glass of the door gets dirty and the flame is weak insufficient combustion air clean the brazier and check that all the holes are clear. Perform a general cleaning of the combustion chamber and smoke duct. ...

Page 47

47 aquos 24 h 2 o en anomaly possible causes solutions radiators cold in winter room thermostat (local or remote) set too low. If remote thermostat, check if it is defective. Set it at a higher temperature or replace it. (if remote) circulator does not run because blocked. Free up the circulator by ...

Page 48

48 aquos 24 h 2 o en motherboard wiring key 1 fuse 2 board phase 3 board neutral 4 smoke expulsion fan 5 room fan 6 pellets safety thermostat 7 water temperature overload protector 8 spark plug 9 water pressure switch 10 air pressure switch 11 auxiliary boiler connection (terminal block) 12 feed scr...

Page 49

Note.

Page 50

Note.

Page 51

Note.

Page 52

Pellet stoves · wood stoves · wood cooking stoves thermostoves · pellet fireplace inserts cadel srl freepoint by cadel via foresto sud, 7 31025 santa lucia di piave (tv) - italy tel. +39.0438.738669 fax +39.0438.73343 www.Cadelsrl.Com partner of: rev.00 - 2015.