- DL manuals

- Camcorp

- Dust Collector

- HVP

- Instruction, Operations & Maintenance Manual

Camcorp HVP Instruction, Operations & Maintenance Manual

Summary of HVP

Page 1

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 model hvp (high volume pulse) dust collector baghouse instruction, operations & maintenance manual.

Page 2

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 table of contents receiving & inspection of unit ....................................................................... 1-1 safety information ..............................................

Page 3

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 receiving your unit prior to accepting shipment, care must be taken to inspect all equipment received both for proper count and for damage. Any and all irregularities must be noted on the...

Page 4

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 *** safety information *** warning!!! - do not attempt to operate or maintain this piece of equipment until you have read and understand all of the safety information included in the manu...

Page 5

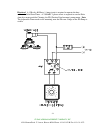

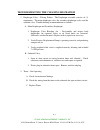

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 operation principle a. Solids laden air or gases enter the unit at the hopper or housing inlet. B. Air passes through the filter media. C. Solids are retained on the filter media surface....

Page 6

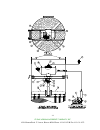

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 camcorp hvp (high volume pulse) cleaning mechanism components item quantity description 1a 1 pulse arm (size determined by model) 1b 1 pulse arm (size determined by model) 2 1 8” od rotar...

Page 7

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 3-3.

Page 8

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 3-4.

Page 9

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 on site storage recommendations i. Baghouse and housing 1. Housing can be stored outside. 2. Equipment must be blocked up to keep the flanges out of the dirt. 3. Many units are supplied w...

Page 10

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 on site storage recommendations (continued) iv. Fan and fan accessories 1. Fans can be stored outside on a pallet or skid to keep out of water and dirt. 2. Equipment should be covered wit...

Page 11

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 on site storage recommendations (continued) ix. Butterfly (wafer valve) 1. All limit switches, solenoids, and air cylinder ports must be capped and taped to prevent any moisture or dirt f...

Page 12

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 setting up your unit camcorp dust collectors are shipped in various states of assembly depending on the size and configuration of the unit. Before attempting to move the dust collector or...

Page 13

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 platform installation: the platform, ladder, handrail, and bracing are to be installed as shown on the special platform detail provided. Use the part id’s to locate the parts in the prope...

Page 14

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 electrical : a 120-volt, 60-hertz, 1-amp circuit is required to operate the dust collector’s solid state timer. A 230/460v 3-phase circuit is required to run the pulse arm drive motor and...

Page 15

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 gauges : check the pressure differential gauge to make sure that the high-pressure tap is connected below the tube sheet and the low-pressure tap is connected above the tube sheet. Verify...

Page 16

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 top load bag and cage installation 1. Inspect the cage for any signs of damage, warping, bent wires, or missing welds. 2. Inspect the filter bag for any signs of mold, mildew, ripped seam...

Page 17

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 start-up checklist 1. Installation make sure the unit is secured to grade. The ladder(s) and platform(s) must be tightened and set up according to osha requirements. Ducting and piping mu...

Page 18

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 5. Exterior of dust collector a. Access doors, inspection ports, and relief vents should seat effectively to prevent leakage. B. All bolts must be properly tightened. C. Operate any equip...

Page 19

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 start-up dust control systems 1. Fan or blower system a. Start the fan or blower and check rotation. B. Check dust pickup points for proper suction; balance airflow in individual ducts. C...

Page 20

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 h. Observe the manometer or magnahelic differential pressure gauge reading. As the new filter bags become coated with dust, the efficiency of the filtering action increases, and the diffe...

Page 21

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 shut-down procedures 1. Dust control systems reverse start-up procedure, shut down fan, then after 5 or 10 minute delay, shut down the pd pump and pulse arm drive motor. 2. Pneumatic syst...

Page 22

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 troubleshooting the dust collector i. Excessive pressure drop across filter bags the differential pressure gauge or manometer on your dust collector should read 6” w.G. Or less. Higher re...

Page 23

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 troubleshooting the dust collector (continued) visually inspect the bags for heavy caking; if caking is evident, see the note below and take the necessary action to clean the bags. Next, ...

Page 24

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 troubleshooting the dust collector (continued) ii. Extremely low pressure drop a. Pressure gauge check the differential pressure gauge or manometer and the tubing leading to the dust coll...

Page 25

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 troubleshooting the dust collector (continued) b. Residual dust if dust has gotten into the clean air plenum because of a dropped or torn bag, hole in tube sheet, etc., the pulse air may ...

Page 26

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 troubleshooting the cleaning mechanism 1. Diaphragm valve – pulsing failure. The diaphragm assembly consists of (3) components. The main diaphragm valve, the secondary diaphragm valve, an...

Page 27

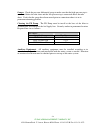

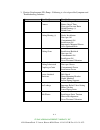

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 3. Positive displacement (pd) pump - following is a list of possible symptoms and troubleshooting solutions. Symptom possible causes possible sources noisiness rotor-to-rotor contact rust...

Page 28

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 symptom possible causes possible sources poor performance restricted inlet clogged filter element collapsed inlet hose erroneous pressure loose gauge connection gauge movement damaged gau...

Page 29

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 symptom possible causes possible sources overheating excessive pressure ratio clogged filter element collapsed inlet hose clogged dust vent filter undersized dust vent filter clogged diff...

Page 30

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 safety recommendations because this unit may be under pressure, do not attempt to open any device doors or panels while fans or blowers are running. If your unit is equipped with a discha...

Page 31

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 routine maintenance a. Inspection frequency will vary as widely as there are operating conditions. In general proceed as follows: 1. Daily – check unit differential pressure. 2. Weekly – ...

Page 32

Clean air management company, inc. 8224 nieman road i lenexa, kansas 66214 phone: 913-831-0740 fax: 913-831-9271 component iom manuals morse raider worm gear speed reducer (maintenance)......................... 1-8 martin torque limiter clutch ...........................................................

Page 33: Center Distances

Center distances 1.33, 1.54, 1.75, 2.06, 2.37, 2.62, 3.00, 3.25 3.75, 4.50, 5.16 and 6.00 ® emerson power transmission p o box 687 maysville, ky 41056 phone: 800-626-2093 www.Emerson-ept.Com f o r m maintenance instructions for worm gear speed reducers 8721 march 2003 ™.

Page 34

2 © emerson power transmission manufacturing, l.P. Or affiliates 2003. All rights reserved. To change output shaft direction to change the hand of a unit from left hand to right hand, or vice versa, the following instructions apply: 1. Remove drain plug and drain oil from unit. 2. Remove end cover a...

Page 35

3 © emerson power transmission manufacturing, l.P. Or affiliates 2003. All rights reserved. Figure 3 figure 4 figure 1 figure 2 sheet metal screws 3. High speed shaft (worm shaft) removal: c-flange units 1.33 c.D. Through 3.25 c.D.: use a small chisel to make a groove in the stamped steel cover oppo...

Page 36

4 © emerson power transmission manufacturing, l.P. Or affiliates 2003. All rights reserved. D. Work seal loose. Be careful to keep all metal or dirt particles from entering unit. Remove old sealing compound from seal seat if it is present. Also remove burrs and sharp edges from shaft. Clean with rag...

Page 37

5 © emerson power transmission manufacturing, l.P. Or affiliates 2003. All rights reserved. Disconnect all power before adjusting units lubricate bearing bores of housing. Sub-assemble the rear bearing onto worm shaft. Lock rear bearing onto shaft with external snap ring. Insert shaft assembly from ...

Page 38

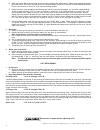

6 © emerson power transmission manufacturing, l.P. Or affiliates 2003. All rights reserved. 1/6 of facewidth clear on entering side 1/3 1/3 1/3 ideal runs from center towards leaving edge move gear runs to entering edge does not enter center third move gear 4. Seals - to reassemble seals to unit, se...

Page 39: Sprocket & Gear, Inc.

Martin sprocket & gear, inc. Bulletin tl-1 torque limiter clutch drive overload protection now in stock at all martin facilities also stock plate sprockets bored to size and face ground for torque limiters.

Page 40: Torque-Limiter

Martin torque-limiter clutch offers thrifty overload protection that’s easy to adjust. Here is low cost protection for your machinery . . . A torque limiting clutch that is easy to install. Torque-limiter clutches feature an exclusive “easy-set adjustment.” with “easy-set,” torque adjustment is acco...

Page 41: Torque-Limiter

3 torque-limiter clutches stock plate sprockets with ground face and bored to fit the martin torque limiter sprocket size 35tta25-25 35tta26-25 40tta20-25 40tta22-25 40tta24-25 40tta28-25 40tta30-25 50tta17-25 50tta21-25 50tta22-25 sprocket size 35tta35-35 35tta40-35 40tta28-35 40tta30-35 40tta32-35...

Page 42: Coupling

7 coupling safety warning & safety reminder safety must be considered a basic factor in machinery operation at all times. Most accidents are the result of carelessness or negligence. All rotating power transmission products are poten- tially dangerous and must be guarded by the contractor, installer...

Page 43: Made-to-Order and

8 made-to-order and stock products angle flanged “u” trough form flanged “u” trough mild steel and galvanized mild steel and galvanized trough ends tubular housing discharge gate with and without feet mild steel and galvanized flat rack and pinion mild steel and galvanized thrust assembly type e inl...

Page 44: Made-to-Order and

9 made-to-order and stock products stock qd v-belt sheaves “3v” hi-cap® “5v” hi-cap® “8v” hi-cap stock tapered bushed v-belt sheaves conventional c section “3v” hi-cap® conventional b section taper bushed taper bushed taper bushed stock couplings/covers rubber element roller chain jaw coupling marti...

Page 45: Service Centers Worldwide

Usa general offices sales and manufacturing arlington, tx 3100 sprocket drive 76015-2898 p.O. Box 91588 • arlington, texas 76015-0088 817-258-3000 (fax 817-258-3333) sales and manufacturing danielsville, pa 3376 delps road 18038 p.O. Box 267 • danielsville, pa 18038-0267 610-837-1841 (fax 610-837-73...

Page 46: 606

American control products a div. Of precision timer co., inc. 47 westbrook industrial park road westbrook, ct. 06498 phone: (860)399-6253 fax:(860)399-5619 email:info@precisiontimer.Com web site: precisiontimer.Com technical bulletin solid state timing module page 1 of 2 date 6-4-01 606 rev b timing...

Page 47: 606

American control products a div. Of precision timer co., inc. 47 westbrook industrial park road westbrook, ct. 06498 phone: (860)399-6253 fax:(860)399-5619 email:info@precisiontimer.Com web site: precisiontimer.Com technical bulletin solid state timing module page 2 of 2 date 6-4-01 606 rev b calibr...

Page 48: Parts List

Parts list operating and service manual d--9--610 version 10 november, 2005 models: ggb_ _b ggg_ _c_ series: 30 & 70 blowers.

Page 49

D--9--610 page i maintain blower reliability and performance with genuine duroflow parts and support services from gardner denver factory genuine parts, manufactured to design toler- ances, are developed for optimum dependability ------ specifically for your blower. Design and material innova- tions...

Page 50

D--9--610 page ii gardner denver lubricant order information re--order part numbers for factory--recommended lubricants. Aeon pd synthetic lubricant or aeon pd--food grade synthetic lubricant aeon pd synthetic lubricant description part number 1 quart 28g23 case/12quarts 28g24 5 gallon pail 28g25 55...

Page 51

D--9--610 page iii foreword duroflow r blowers are the result of advanced engineering and skilled manufacturing. To be assured of receiving maximum service from this machine, the owner must exercise care in its operation and maintenance. This book is written to give the operator and maintenance depa...

Page 52

D--9--610 page iv safety precautions safety is everybody’s business and is based on your use of good common sense. All situations or circumstances cannot always be predicted and covered by established rules. Therefore, use your past experience, watch out for safety hazards and be cautious. Some gene...

Page 53

D--9--610 page v table of contents page maintain blower reliability and performance with genuine duroflow parts and support services i . . . . . . . . . . . . Remanufactured blower program (see page 19 for complete details) i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 54

D--9--610 page vi index aeon pd food grade lubricant part numbers 10 . Aeon pd lubricant part numbers 10 . . . . . . . . . . . . Air seal vent systems 12 . . . . . . . . . . . . . . . . . . . . . . . Alignment, belt drive 9 . . . . . . . . . . . . . . . . . . . . . . . . . Base and foundation 7 . . ...

Page 55

D--9--610 page vii list of illustrations figure 1--1 blower configuration changes 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Figure 1--2 outline 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 56

D--9--610 page 1 column 1 -- basic designator column 2 -- product family g. Industrial blower column 3 -- gear diameter b. 3”-- 30 series g. 7” -- 70 series column 4 -- case length 30 series 70 series a. 4” 9” b. 6” 12” c. 15” d. 18” e. 23” f. 28” column 5 -- construction a. Vertical--top hand--cent...

Page 57

D--9--610 page 2 introduction your key to trouble free service thank you for investing in duroflow quality. The duro- flow reputation for rugged dependability has been earned by over 70 years of service in demanding, industrial operations where downtime cannot be toler- ated and efficient blower per...

Page 58

D--9--610 page 3 section 1 general information inspection before uncrating, check the packing slip carefully to be sure all the parts have been received. All accessories are listed as separate items on the packing slip, and small important accessories such as relief valves can be overlooked or lost....

Page 59

D--9--610 page 4 figure 1-- 1 -- blower mounting configurations vertical top rotates right to become hor- izontal right vertical bottom ro- tates right to become horizontal left vertical top rotates left to become hor- izontal left vertical bottom ro- tates left to become horizontal right shaft rota...

Page 60

D--9--610 page 5 fig u r e 1 --2 -- o u tlin e.

Page 61

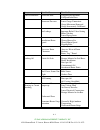

D--9--610 page 6 f igure 1 --3 -- bl ow e r out l ine di m e ns io n chart bl o w e r o u t l ine di m e ns io n chart d im ens ions 3004 3006 7009 7012 7015 7018 7023 7028 a 16. 64 18. 64 32. 42 35. 43 38. 44 41. 44 46. 44 51. 44 b 11. 62 11 .6 2 23. 62 23. 62 23. 62 23. 62 23. 62 23. 62 c 8. 81 8....

Page 62

D--9--610 page 7 section 2 installation location whenever possible, install the blower in a clean and dry place that is both well lighted and well ventilated. Provide plenty of room for easy inspection and maintenance. Foundation and base for permanent installations we recommend concrete foundations...

Page 63

D--9--610 page 8 figure 2--1 -- belt drive overhung load calculations dimensions maximum gear (inches) allowable diameter moment series (inches) a b c (lb--in) 30 3 4.75 1.87 .94 1449 70 7 9.45 3.82 .63 14469 z ac z ac z ac z ac z ac z ac 0.000 1.000 0.250 0.966 0.500 0.926 0.750 0.879 1.000 0.823 1...

Page 64

D--9--610 page 9 driver location -- to properly balance the air load stress on the blower drive shaft, locate the driver on the inlet side for a vertical mounted blower and on the shaft side for a horizontal mounted blower. Belt drive alignment -- belt drives must be carefully aligned, with the moto...

Page 65

D--9--610 page 10 section 3 lubrication all duroflow blowers are splash oil lubricated at both the gear and drive ends. Oil is distributed around the gear housing and drive end chamber by the gears and specially designed oil flingers. Approximate oil sump capacities are listed in figure 3--1 below. ...

Page 66

D--9--610 page 11 failure to add oil to each end of the blower on 70 series models will result in damage to the blower. The 70 series “c” design version with a column gauge indicates the actual oil level during operation. The column gauge before start--up should be filled to the middle of the glass....

Page 67

D--9--610 page 12 flush the oil whenever a change is made from one type of oil to another. Flush the oil whenever a change is made from one type of oil to another. Drain the current lubricant as thoroughly as possible. Refill with the new lubricant. Fill to normal level of the blower, which is at th...

Page 68

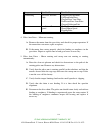

D--9--610 page 13 blower ambient temperature discharge temperature less than10 _ f * 10 _ f to 32 _ f ** 32 _ f to 90 _ f greater than 90 _ f less than 32 _ f iso 100 } iso 100 } (0 _ c) 32 _ f to 100 _ f iso 100 } iso 100 } iso 150 } (0 _ c to 38 _ c) 100 _ f to 225 _ f iso 100 } iso 100 } iso 150 ...

Page 69

D--9--610 page 14 section 4 operation future operating problems can be avoided if proper precautions are observed when the equipment is first put into service. Before starting under power, the blower should be turned over by hand to make certain there is no binding, or internal contact. Limitations ...

Page 70

D--9--610 page 15 maximum operating limitations differential dry * pressure vacuum discharge size rpm psi in hg temperature _ f 3004 4000 15 15 350 3006 4000 15 15 350 7009 2650 15 15 350 7012 2650 15 15 350 7015 2650 15 15 350 7018 2650 15 15 350 7023 2600 12 16 325 7028 2600 10 16 325 do not excee...

Page 71

D--9--610 page 16 blower startup checklist this startup procedure should be followed during the initial installation and after any shutdown periods or after the blower has been worked on or moved to a new location. It is suggested that the steps be followed in sequence and checked off ( ) in the box...

Page 72

D--9--610 page 17 section 5 maintenance and troubleshooting your duroflow blower has been designed, manufac- tured and tested to precise specifications. Every duroflow blower is backed by over 70 years of proven performance in the most demanding applications that modern industry can produce. Duroflo...

Page 73

D--9--610 page 18 problem possible causes solution 1. Insufficient assembled 1. Return for warranty. (see page 19.) clearances. 2. Case or frame distortion. 2. Remove all mounting and pipe strains. 3. Excessive operating pressure. 3. Remove cause. 4. Excessive operating temperature. 4. Remove cause....

Page 74: Stop

D--9--610 page 19 section 6 service options factory remanufactured blower program stop you have turned to the service section because you have a blower problem that requires the blower to be mechanically adjusted or repaired. First determine if the blower is still under warranty. Contact your durofl...

Page 75

D--9--610 page 20 advancements . . . Manufactured in our state--of--the-- art blower factory under exacting quality standards. Prepackaged overhaul kits are available for immediate shipment for all duroflow blowers. Kits include all the normal wearing parts needed to overhaul your duroflow blower: o...

Page 76

D--9--610 page 21 section 7 parts lists and exploded views 30 series duroflow blower exploded view 200ggb810 (ref. Drawing).

Page 77

D--9--610 page 22 order by part number and description. Reference numbers are for your convenience only. Size size 3004 3006 ref. Ggba_b_ ggbb_b_ no. Name of part qty. Part no. Part no. 1 cover--gear 1 df145949 df145949 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 78

D--9--610 page 23 70 series duroflow blower exploded view 201ggg810--f (ref. Drawing).

Page 79

D--9--610 page 24 order by part number and description. Reference numbers are for your convenience only. Size size size 7009 7012 7015 ref. Ggga_c_ gggb_c_ gggc_c_ no. Name of part qty. Part no. Part no. Part no. 1 cover--gear 1 300ggd602 300ggd602 300ggd602 . . . . . . . . . . . . . . . . . . . . ....

Page 80

D--9--610 page 25 order by part number and description. Reference numbers are for your convenience only. Size size size 7018 7023 7028 ref. Gggd_c_ ggge_c_ gggf_c_ no. Name of part qty. Part no. Part no. Part no. 1 cover--gear 1 300ggg602 300ggg602 300ggg602 . . . . . . . . . . . . . . . . . . . . ....

Page 81

D--9--610 page 26 general provisions and limitations gardner denver (the “company”) warrants to each origi- nal retail purchaser (“purchaser”) of its new products from the company or its authorized distributor that such products are, at the time of delivery to the purchaser, made with good material ...

Page 82

Warranty registration your duroflow blower has been designed and manufactured to provide continuous, trouble--free service, year in and year out. Follow the simple maintenance procedures outlined in this manual and you will be assured of superior blower performance and years of dependable blower lif...

Page 83

Specifi cations subject to change without notice © copyright 2005 gardner denver, inc. Litho in u.S.A. For additional information, contact your local representative or gardner denver compressor division 1800 gardner expressway, quincy, illinois 62305 phone (800) 682-9868 • fax (217) 221-8780 e-mail:...