- DL manuals

- E-Bike

- Bicycle

- 36V

- Service Manual

E-Bike 36V Service Manual

Summary of 36V

Page 1

M a n u a l 3 6 v m o d e l s s e r v i c e.

Page 2: E-Bike

E-bike ® service manual 36v models ev global motors company 16201 stagg street van nuys, ca 91406 tel: 818/756-0566 fax: 818/756-0563 www.Ebike.Com.

Page 3

Copyright © 2000 ev global motors company first edition october, 2000 lit-82001-01-36 all rights reserved. No parts of this publication may be reproduced or transmitted in any form or by any means without the prior permission of ev global motors company. Although every precaution has been taken to a...

Page 4: Table of Contents

Table of contents chapter one: general information 1-1 beep/led codes vehicle identification number how to read the model code terms lubricants threadlock recommended maintenance schedule special tools chapter two: specifications 2-1 mechanical specifications gear ratios electrical specifications to...

Page 5: Chapter One

Code meaning beep leds good beep the system has been 1 continuous beep checked and is operational sounds for 1 second. Bad beep a problem exists in a 4 sets of 4 short system or component. Beeps pedal assist the system requests 3 short beeps every pedal assist. Sounds 16 seconds when on a steep hill...

Page 6

Code meaning beep leds battery state-of-charge 80% to 60% of run time none green and yellow remaining leds on. 60% to 40% of run time none yellow led on. Remaining. 40% to 15% of run time none yellow and red remaining. Leds on. Low battery 15% to 5% of run time none red led on. Remaining. Very low b...

Page 7

Oil always use oils made specifically for bicy- cle use. Bicycle oils need to be thin enough to penetrate tight places, they should be durable so they can withstand exposure to the ele- ments, and they must resist the accumulation of dirt. Suitable oils for the e-bike ® include alsop, bullshot, camp...

Page 8

Recommended maintenance schedule component or condition inspect before every ride inspect every 5 to 10 rides* brake pad adjustment x wheel quick release adjustment x tire pressure x tire wear/damage x head/tail/brake light operation x mirror position x controls and display x seatpost quick release ...

Page 9: Chapter Two

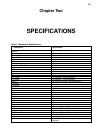

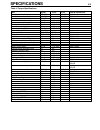

Table 1: mechanical specifications component specification headset stack height 33 mm (1.30 in.) dimensions 25.4 mm x 34 mm x 30 mm w/seal forks (le) type polyurethane allen key adjustable steerer tube 1-1/8 in. Travel 65 mm triple forks (sx/pe) type nitro dh steerer tube 1-1/8 in. Travel 75 mm stem...

Page 10: Chapter Two

Sx model 26 x 1.95 in., csk, puncture resistant pe model 26 x 1.95 in., black with reflective stripe, puncture resistant rims dh-17 front 26 x 1.5 in., 14g x 32h, double wall rear 26 x 1.5 in., 14g x 36h, double wall g3000 front 26 x 1.5 in., 14g x 32h, double wall rear 26 x 1.5 in., 14g x 36h, doub...

Page 11: Specifications

Table 4: torque specifications item kg-cm in.-lb. Ft.-lb. Special instructions handlebar-binder bolt 140~200 - 10~15 apply loctite handlebar-arm clamp bolts 140~200 - 10~15 apply loctite stem-binder bolt (stem-2 quill bolt) 180~250 - 13~18 headset locknut 40~50 34.7~43.4 accessory control clamp bolt...

Page 12

Frame specifications frame size (center to top) 419 cm (16.5 in.) wheel base 1062.3 mm (41.8 in.) rc 431.5 mm (17.0 in.) 72˚ head tube 163 mm (6.4 in.) table 5: performance specifications* item specification top speed 17.5 mph @ 36 volts in “p” performance mode. 12.5 mph @ 36 volts in “e” economy mo...

Page 13: Chapter Three

Charging the batteries the e-bike ® includes a charger that is an integral part of the battery pack. Batteries can be charged when the battery pack is on-board the e-bike ® or when the battery pack is removed for remote charging. To assure maximum battery life, always fully charge the battery after ...

Page 14: Chapter Three

Note when a battery is new, the led may rapidly flicker instead of turning to green. This is not a problem. The battery is fully charged and can be used. The flicking will cease after several use/recharge cycles. 5. Plug the male end of the charging cord into a standard 110v/60 cycle electrical outl...

Page 15: Battery Pack

(figure 3) sits in the bottom of the case (the end with the capacitor). Be sure the battery is properly seated in the battery case. Note perform the following when connecting a bullet connector. A. Press the male and female connector halves together. B. Roll the seal over the connector. 2a. On batte...

Page 16: Chapter Three

6. Fit the cover onto the battery pack. Be sure no wire is pinched beneath the cover. 7. Apply loctite 242 (blue) to the threads of the two cover screws, and secure the cover in place. Replacing the charger two types of chargers are used on these models: an ic charger and a non-ic charger. To determ...

Page 17: Battery Pack

If there are no intermittent connections, replace the battery. Charger output test 1. Remove the cover from the battery pack. 2. Connect a digital voltmeter’s positive (+) test probe to the positive (+) battery terminal, and connect the voltmeter’s negative (-) test probe to the battery negative (-)...

Page 18: Chapter Three

Battery voltage test, after charging note the charger must be operational for this test to be valid. Perform the charger output test before performing this test. 1. Charge the battery as described in this chapter. 2. Unplug the charger, and let the battery stand for one hour. 3. Remove the cover fro...

Page 19: Chapter Four

Handlebar position note the handlebar may be adjusted to suit the rider’s preference. The following procedure describes how to set the handlebar to the stock position. 1. Loosen the handlebar-binder bolts (a, figure 1). 2. Rotate the handlebar so the ends point down slightly. The handlebar grip shou...

Page 20: Chapter Four

Warning the "minimum insert" mark on the handlebar stem must not sit above the top of the headset. 2. Raise or lower the stem within the fork col- umn until the handlebar is at the desired height. 3. Rotate the handlebar from side to side, and align the handlebar with the wheel or fork dropouts. 4. ...

Page 21: Handlebar and Controls

7. Disconnect the front brake cable from the s-hook (c, figure 1). Note how the front brake cable is routed around the headlight (le and sx models) or around the battery holder (pe models). The cable will have to be routed along the same path during assembly. 8. Loosen the right-brake-lever clamp bo...

Page 22: Chapter Four

6. Loosen the mirror-mounting bolt (figure 10), and remove the mirror from the handlebar end. 7. Roll the left handlebar grip from the han- dlebar. Do not lose the shim that sits between the handlebar grip and the shifter body. 8. Disconnect the shifter cable from the s- hook (c, figure 1). Note how...

Page 23: Handlebar and Controls

5. Slide the shifter body onto the left handle- bar. Guide the shifter cable around the head- light (le or sx models) or battery holder (pe models). 6. Slide the shim onto the handlebar. Roll the handlebar grip onto the handlebar until the grip is flush with the handlebar end. 7. Slide the shifter a...

Page 24: Chapter Four

10. Visually inspect the position of cone in the adjustable race and in the fork crown. Note how far each cone protrudes from its respec- tive cup (figure 17). This will help during assembly. 11. Remove the headset locknut with the park 36 mm wrench (figure 18), and then remove the washer. 12a. On l...

Page 25: Handlebar and Controls

Assembly 1. Clean the bearings, head-tube races, fork- crown race, and adjustable race with solvent. 2. Lightly coat the upper head-tube race and the lower head-tube race with grease. A 1-mm bead in each race should be sufficient. 3. Pack the bearings with grease. Note the grease in the lower head-t...

Page 26: Chapter Four

Er with the other. On pe and sx models, grasp a stanchion between the upper and lower fork bridges with one hand and grasp the lower slider with the other. B. Try to move the forks back and forth. You should not notice any play in the head set. C. If free play is noticed, adjust the headset by tight...

Page 27: Chapter Five

5-1 chapter five brakes v-brakes note when working on the brake calipers and pads, the terms "left" and "right" refer to the techni- cian’s point of view when standing in front of the e-bike ® and looking at the front brake caliper or when standing behind the e-bike ® and looking at the rear brake c...

Page 28: Chapter Five

Caution do not set the caliper-arm spring tension too high. C. If necessary, balance the caliper arms by turning the spring-tension adjuster (b, figure 4) on either arm. 11. Adjust the brake lever free play as described in this chapter. Brake lever removal 1. Remove the handlebar grip from the handl...

Page 29: Brakes

3. Squeeze the caliper arms together, and dis- connect the cable guide from the bracket on the left caliper arm (a, figure 1). 4. Loosen the adjuster locknut at the brake lever. 5. Turn the adjusting barrel and the adjuster locknut until their slots align with the slot in the brake lever body. 6. Pu...

Page 30: Chapter Five

Connect the cable guide from the bracket on the left caliper arm. 2. Remove the brake pad nut (f, figure 8) from the pad stud . 3. Remove the plain washer (e, figure 8), the concave washer (d, figure 8), and the convex washer (c, figure 8) from the pad stud. 4. Remove the brake pad from the caliper ...

Page 31: Brakes

Plane relative to the brake surface of the rim (figure 10). The pad’s vertical plane should parallel the vertical plane of the brake surface of the rim. Tangent alignment sets the position of the horizontal axis of the pad relative to the wheel rim. The distance between the top of the wheel rim and ...

Page 32: Chapter Five

4. Inspect the caliper-mounting boss in the frame. A. Be sure the threads of the caliper-mount- ing boss are clean. B. The mating surface of the caliper-mount- ing boss should also be clean. Dress the area with emery cloth if necessary. C. Inspect the caliper-mounting boss for cracks or other signs ...

Page 33: Brakes

4. Thread the caliper-pivot bolt into the caliper- mounting boss. As you tighten the pivot bolt, be sure the pin engages then indexing hole in the boss. 5. Torque the caliper pivot bolt to the specifica- tion in table 4. 6. Align the brake pads as described in this chapter. 7. Squeeze the caliper ar...

Page 34: Chapter Five

5. Hold the adjuster with the allen wrench, and tighten the locknut (b, figure 16) securely. 6. Set the pads by sharply apply the brakes four or five times. Note: a slight amount of pad scraping is normal, especially with new brakes or new brake pads. 7. Spin the wheel and check for brake pad/disc s...

Page 35: Chapter Six

Shifter removal 1. Remove the shift cable from the s-hook (figure 1) that holds the cable to the front brake cable. 6-1 chapter six shifter and derailleur fig. 1 2. Loosen the mounting screw in the mirror housing, and remove the mirror from the end of the handlebar (figure 2). 3. Remove the handleba...

Page 36: Chapter Six

3. Slide the shim onto the handlebar. Install the handlebar grip so the grip end is flush with the handlebar end. 4. Slide the shifter body against the grip shim. 5. Rotate the shifter body so the adjusting bar- rel is below the brake lever. Tighten the shifter clamp bolt to the specification in tab...

Page 37: Shifter And Derailleur

11. Remove the shifter from the handlebar as described in this chapter. 12. Gently pry the cover plate from the inside face of the shifter housing (figure 7). 13. Pull the twist unit from the shifter housing. Slide the shifter housing down the inner wire and remove it. 14. Push the inner wire into t...

Page 38: Chapter Six

5. Feed the inner wire along the cable groove (figure 12) in the shifter housing and out through the barrel adjuster. 6. Fit the twist unit into the shifter housing. Pull firmly on the inner wire while pressing the twist unit into the shifter housing. Be sure the end of the twist unit engages the cl...

Page 39: Shifter And Derailleur

Fig. 16 17. Loosen the pinch-mechanism nut, and use the fourth-hand tool to pull the slack from the inner wire. 18.Torque the pinch-mechanism nut (b, figure 4) to the specification in table 4. Check that the inner cable is still contained within the groove in the pinch-mechanism plate. 19. Fit an en...

Page 40

3. Turn the shifter barrel adjuster to its fully-in position, and then back out the adjuster one full turn. Note do not pull the inner wire so much that the derailleur begins to move. 4. Use a fourth-hand tool to pull the slack out of the inner wire. 5. Torque the pinch-mechanism nut to the specific...

Page 41: Chapter Seven

B. Chain length is acceptable if the tension pulley is 1.75 in. Or less forward or rear- ward of the guide pulley. 4. Examine the chain. A. The chain is too long if it sags in the upper chain run as shown in figure 2. B. The chain is too long if the chain con- tacts itself or any part of the deraill...

Page 42: Chapter Seven

5. Shift the derailleur so the chain rides on the innermost cog. 6. Examine the chain as it passes through the derailleur. A. If the chain passes through the derailleur without bending twice, the chain is too short. See figure 4. Removal a chain breaker (park ct-3) is required for removing and insta...

Page 43: Chain and Crankset

2. Take the non-riveted end of the chain and feed it under and around the rear of the tension pulley on the derailleur. Following the derailleur cage, route the chain up the front and over the top of the guide pulley. Once the chain emerges from the derailleur cage, route it under and around the out...

Page 44: Chapter Seven

4. Inspect the position of the spindle end. The end of the spindle should be recessed within the crank-arm square hole. If the spindle end is flush with the surface of the crank-arm square hole, the crank arm is excessively worn and must be replaced. 5. If you intend to reinstall the crank arm, mark...

Page 45: Chain and Crankset

2. Inspect the square hole in the crank arm (figure 12). The flats of the hole should be straight and even. Replace the crank arm if its square hole shows signs of wear or damage. 3. Inspect the crank arm for cracks or other signs of wear. Pay particular attention to the area around the mounting hol...

Page 46: Chapter Seven

5. Set your hand against the frame down tube with the end of your forefinger touching the inside of the chainring (figure 14). 6. Rotate the crank arm and note the amount of wobble in the chainring. 7. Remove the crank arm by striking the arm with the rubber mallet. 8. Rotate the spindle so the refe...

Page 47: Chain and Crankset

A bottom-bracket-cartridge tool (park tool bbt-2) is required for removing and installing the bottom-bracket cartridge. Removal 1. Remove both crank arms. 2. Remove the left bottom-bracket cover (figure 16). 3. Install the bottom-bracket cartridge tool onto the adapter ring, and remove the ring from...

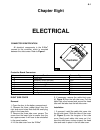

Page 48: Controller

8-1 connector identification all electrical components in the e-bike ® connect to the controller, which is mounted between the side covers. Refer to figure 1. Right side cover removal 1. Open the door to the battery compartment. 2. Remove the three rubber plugs from the right side cover holes. Note ...

Page 49: Chapter Eight

5. Remove the three left-side-cover screws. One is located behind the steering head (b, figure 2), one is above the controller (a, figure 4), and the third is toward the rear of the side cover (b, figure 4). 6. Carefully, pivot the right side cover away from the e-bike ® until the battery-compartmen...

Page 50: Electrical

Each left-side-cover mounting screw, and install each screw finger tight. See (b, figure 2 and a & b, figure 4) along with the washer. 5. Torque the three side-cover mounting screws and the three battery-compartment screws to the specifications in table 4. 6. If the brake cable was disconnected from...

Page 51: Chapter Eight

10. Gently pull the left side cover away from the frame, and pull the controller half of the qr connector between the frame and side cover. See figure 10. 11. Remove the two controller-plate mounting screws (c, figure 4), and remove the con- troller assembly from the e-bike ® . Installation 1. Fit t...

Page 52: Electrical

1. Shift the chain to the outermost rear cog on the freewheel. 2. Squeeze the top of rear brake arms togeth- er and free the rear brake cable from the bracket on the left arm (a, figure 5). 3. Disconnect the qr connector (a, figure 12) as described above in this chapter. 4. Remove the hardware that ...

Page 53: Chapter Eight

6. If removed, loosely reinstall the axle nuts and washers. Be sure the textured side of the washers faces inward toward the hub. 7. Finger tighten the axle nuts. 8. Secure the motor torque arm to the frame seat stay. Apply loctite 242 (blue) to the threads of the mounting bolt, and tighten the nut ...

Page 54: Electrical

Headlight bulb replacement 1. Remove the reflector from the headlight housing as described above in this chapter. 2. Release the arms (c, figure 16) of the bulb clip from the clasp on the reflector housing. 3. Rotate the clip up and lift the bulb from the reflector housing. See figure 18. Note do no...

Page 55: Chapter Eight

2. Disconnect the taillight/brake light connector under the seat (figure 20). 3. Remove the two taillight mounting nuts (figure 21), and remove the taillight assembly from the seat bracket. 4. Fit a new taillight assembly in place, and secure it with the two taillight mounting nuts. Torque the nuts ...

Page 56: Electrical

E. The system turns on, but the headlight does not operate. 1. Remove the battery, and turn the power knob to on to discharge the capacitor in the controller. 2. Remove the lens from the headlight and visually inspect the bulb. Replace the bulb if it is blown. 3. Perform the headlight bulb resistanc...

Page 57: Chapter Eight

Battery voltage test 1. Remove the battery pack from the e-bike ® . 2. Use a digital volt ohmmeter to measure the voltage across the terminals at the bottom of the battery pack. A. The battery is good if the voltage is 31- 39 voltage. B. If battery voltage is 0 volts, perform the battery fuse test. ...

Page 58: Electrical

Horn resistance test. 1. Disconnect the horn connector (g, figure 1) from the controller. 2. Connect the positive (+) probe of a digital volt ohmmeter to pin 1 on the connector and connect the meter’s negative (-) probe to pin 2. 3. Note the reading on the ohmmeter. Horn resistance: approximately 11...

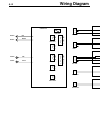

Page 59: Wiring Diagram

Controller 5 amp fuse headlight 1 2 3 1 2 3 1 2 3 4 1 2 3 4 5 6 1 2 3 4 5 6 7 1 2 1 2 horn left tail lamp right brake left brake right power + red power - black red motor + brown motor - 1 2 3 1 2 3 1 2 3 4 1 2 1 2 headlight horn tail lamp brake left brake right 8-12 wiring diagram.

Page 60

Right brake switch left brake switch taillight horn headlight 1 2 3 4 5 6 1 2 3 4 5 6 7 horn switch cruise switch economy switch head light led head lamp switch accessory control (left) throttle control (right) throttle power knob green led amber led red led.

Page 61

Ev global motors company 16201 stagg street van nuys, ca 91406 www.Ebike.Com 818-756-0566 tel / 818-756-0563 fax p/n: lit-82001-01-36 a lee iacocca enterprise.