P e-tac (gb series) ackaged terminal air conditioner / heat pump 7,000 --- 15,000 btuh installation and operating instructions unit information model # ______________________________ serial # ______________________________ installation information date installed __________________________ dealership...

2 unit inspection examine unit for damage incurred during shipment. File a claim immediately with the transit company if damage is found. Table of contents page safety considerations 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

3 read all instructions before installation or use safety considerations recognize safety information. This is the safety--alert symbol . When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury. Understand these signal words: danger, warning...

4 unit features fig. 2 – e-tac front panel are different than those found on standard ptac models. The owner must be familiar with these features in order to fully understand the operation and capability of the unit. Computer that utilizes real time diagnostics to prolong the life of your unit. Ther...

5 unit features continued • unit configuration – there are many different configuration possibilities, through both dipswitches and the digital keypad, that allow you to configure the unit for your exact application. See section on unit configuration for more details. Following are the configuration...

6 electrical data electrical shock hazard failure to follow this warning could result in personal injury or death and/or property damage do not alter cord or plug or use an extension cord. ! Warning important: for 265v units, if power cord long and must plug into the accessory electrical 265v subbas...

7 installation proper installation is the responsibility of the installer. Product failure due to improper installation is not covered under the warranty. Chassis installation units are shipped without a sleeve. In applications where unit is a replacement, it is recommended that a gree sleeve be use...

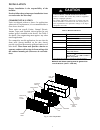

8 retrofit sleeve preparation important: inspect wall sleeve thoroughly prior to installation. Manufacturer does not assume responsibility for costs or damages due to defects in sleeve or for improper installation. Electrical shock hazard failure to follow this warning could result in personal injur...

9 install unit into wall sleeve 1. Carefully remove shipping tape from the front panel and vent door. See fig. 8. 2. Remove shipping screw from the vent door, if present. See fig. 9. 3. Remove front panel. See fig. 10. 4. Lift unit level and slide unit into wall sleeve until foam seal rests firmly a...

10 system configuration ventilation control the ventilation control lever is located at left side of unit, behind front panel. Note: the vent door shipping hardware must be removed before using vent control lever. See see figure 9. When set at close, only the air inside the room is circulated and fi...

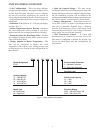

11 dip switches auxiliary dip switch controls are located behind front panel, through an opening below the control panel. To access, remove front panel. See fig. 10. Dip switches are accessible without opening the control box. Unit must be powered off to effectively change their status. Dip switches...

12 keypad configuration keypad configuration allows further configuration of system to desired application. Changes do not take affect until power is cycled on the unit. To enter keypad configuration cycle power to unit. Press and hold the fan speed button and the cooler button for 5 continuous seco...

13 auxiliary controls wall thermostat terminal important: only trained, qualified personnel should access electrical panel on unit and install electrical accessories. Please contact your local electrical contractor, dealer, or distributor for assistance. Thermostat wire routing thermostat wire is fi...

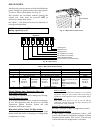

14 terminal connections the wall thermostat terminal block is located behind the front panel and is easily accessible on front of control panel. Fig. 24 – terminal connector and status led location unit damage hazard failure to follow this caution may result in equipment damage or improper operation...

15 operation important: when unit is first started, high humidity conditions can cause condensation to form on discharge grille. Keep doors and windows closed. Room humidity will decrease and moisture will evaporate. Fig. 26 – e-tac controls about the controls on your unit note: in case of a power f...

16 care and cleaning front panel and case turn unit off and disconnect power supply. To clean, use water and a mild detergent. Do not use bleach or abrasives. Some commercial cleaners may damage the plastic parts. Outdoor coil coil on outdoor side of unit should be checked regularly. Unit will need ...

17 preventative maintenance preventative maintenance is essential to proper unit operation, efficiency and longevity. To ensure equipment operates properly, it must be properly maintained. Equipment operation should be checked and verified several times during each year. During regular unit inspecti...

18 troubleshooting possible causes solutions unit does not start • unit may have become unplugged • fuse may have blown • circuit breaker may have been tripped •unit may be off or in wall thermostat mode. Check section on dipswitch settings to verify dipswitches are set properly. • unit may be in a ...

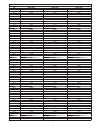

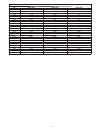

19 r---t conversion table r25 :20.0k Ω (tolerance 1% ) t[f] rmin.[k Ω] rnom.[k Ω] rmax.[k Ω] 32.0 64.46 65.89 67.34 33.0 62.68 64.03 65.40 34.0 60.95 62.23 63.53 35.0 59.27 60.48 61.71 36.0 57.65 58.80 59.96 37.0 56.07 57.16 58.26 38.0 54.54 55.58 56.62 39.0 53.06 54.04 55.03 40.0 51.63 52.55 53.49 ...

20 r---t conversion table (cont.) r25 :20.0k Ω (tolerance 1% ) t[f] rmin.[k Ω] rnom.[k Ω] rmax.[k Ω] 97.0 12.30 12.45 12.60 98.0 12.02 12.17 12.32 99.0 11.75 11.90 12.04 100.0 11.48 11.63 11.77 101.0 11.22 11.37 11.51 102.0 10.97 11.11 11.26 103.0 10.72 10.87 11.01 104.0 10.48 10.62 10.77 105.0 10.2...

21 gb series –typical wiring schematic for standard units (except models with 5kw elec. Heaters).

22 gb series –typical wiring schematic for models with 5kw elec. Heaters.

Gree gb series p ac kaged t er minal air conditioner limited w ar ranty t w o-year p a r ts and labor limited w arranty – du ring the first t w o years after purchas e, gree will, through its autho riz ed independent se rvicing dealer or se rvice stations*, and free of charge to the user or subseque...

Cat alo g number: 4 90 04dp 58 e dit io n da te : 10 /11 if y o ur a ir c o nd it io ne r d o es n o t w o rk, f o ll o w t h es e st ep s i n o r de r : 1. Check the th ings y o u c a n do y o urse lf . These include being sure the air conditioner is plugged in firml y in an approp riate receptacle...