- DL manuals

- ECD

- Controller

- 100-181

- Manual

ECD 100-181 Manual

Summary of 100-181

Page 1

100-181 controller manual revision date: feb 22, 2017 ecd system manual.

Page 2

E l e c t r o n i c c i r c u i t d e s i g n s p t y . L t d . Operation guide this manual covers all versions of 100-181 hardware and software. Some features and operative descriptions mentioned in this manual may differ or not be available on earlier 100-181 versions electronic circuit designs pt...

Page 3

Table of contents table of contents............................................................................................ I section 1: safety regulations & introduction .............................................. 4 1.2.1 following operating instructions. .......................................

Page 4

Cfss - car fire service start input...................................................... 28 dcbf - door close button (front doors) input................................... 28 dcbr - door close button (rear doors) input.................................... 28 dcf - door close (front doors) relay outp...

Page 5

Lift gets out of step ................................................................................. 68 lift does not answer car calls................................................................. 68 lift does not answer hall calls..................................................................

Page 6

S a f e t y r e g u l a t i o n s & i n t r o d u c t i o n 4 section 1: safety regulations & introduction section 1.1 safety regulations elevator controllers and other electrical components can cause serious harm or death if installation guides are not met. It is the responsibility of the installer...

Page 7

S a f e t y r e g u l a t i o n s & i n t r o d u c t i o n 5 1.2.4 hazards associated with the equipment. The equipment is built with state-of-the-art technology and recognized safety regulations. Nevertheless, use of the equipment can result in dangers to life and limb for the installer, user or a...

Page 8

S a f e t y r e g u l a t i o n s & i n t r o d u c t i o n 6 1.2.7 protective equipment. • at all times, prior to putting the machine into operation, all protective equipment must be correctly installed and in proper working condition. • protective equipment may only be removed - after the machine ...

Page 9

S a f e t y r e g u l a t i o n s & i n t r o d u c t i o n 7 • if work has to be carried out on live parts, do this only in the presence of a second person who can switch off the master switch in an emergency. • the machine causes electromagnetic interference sources. For this reason, do not use an...

Page 10: Introduction

E e p r o m s e t t i n g s 1.2.16 introduction he 100-181 controller enables independent control of the front and rear doors at each floor. The 100-181 controller can operate up to 8 floors. The controllers can be grouped up to a 6 car group and may be inter-connected using 3 wire serial communicat...

Page 11

E e p r o m s e t t i n g s section 2: eeprom settings eeprom how to read and modify settings this eeprom holds settings for the particular contract data including number of floors, door type and drive types. The eeprom holds values for various contract settings which may be altered on site. Each se...

Page 12

E e p r o m s e t t i n g s eeprom version 4.02 summary the eeprom holds values for various contract settings which may be altered on site. Each setting has a definition followed by its value in hex and then its value in bit format. Note: refer to eeprom definitions (full description) for more infor...

Page 13

E e p r o m s e t t i n g s rpt run protection timer setting example:-rpt 01: 00000001 (25s) drv drive control type. Setting example:-drv 02: 00000010 (3010/2ch/s block) st2 star delta time. (value) setting example:-st2 08: 00001000 (= 800ms) sdx star delta exchange time. (value) setting example:-sd...

Page 14

E e p r o m s e t t i n g s dtrf door time hr recall . (value) setting example:-dtrf 32: 00110010 (= 5000ms, “5 seconds”) dtrr door time hrr recall . (value) setting example:-dtrr 32: 00110010 (= 5000ms, “5 seconds”) hrf hosp / hall recall mask. Setting example:-hrf 40: 01000000 hrr hosp / hall reca...

Page 15

E e p r o m s e t t i n g s eeprom definitions (full description) ado - advanced door opening setup sets the doors to open whilst traveling into the floor. The doors shall commence opening when the lift is within the door zone and the msu or msd vane pending direction. Ado eeprom advanced door openi...

Page 16

E e p r o m s e t t i n g s this signal can be used when a lift in the group doesn’t go all the way to the bottom. 01: 00000001 (level 1) 02: 00000010 (level 2) 03: 00000011 (level 3) 04: 00000100 (level 4) 05: 00000101 (level 5) bst – brake switch time for brake switch monitoring. Bst sets the time...

Page 17

E e p r o m s e t t i n g s 08: 00001000 not used. Default to 0. 10: 00010000 not used. Default to 0. 20: 00100000 dcbr. Door close rear input inverted 40: 01000000 dobr. Door open rear input inverted 80: 10000000 edpr. Light ray rear input inverted eg. 42: 01000010 = both dobf and dobr door open bu...

Page 18

E e p r o m s e t t i n g s doors midway – dfcf/dfcr led will be off. Dfof/dfor led will be off dlm - door limit setup this signal sets up the door limits inputs. See also eeprom setting dli, dfcf/dfcr, dfof/dfor. Dlm eeprom door limit mask. Setting example: dlm 00: 00000000 (door open and close lim...

Page 19

E e p r o m s e t t i n g s 32: 00110010 = 5000ms, “5 seconds” 90: 10010000 = 14400ms, “14.4 seconds” (01 to ff valid values.) dthf - door time hall call (front doors) close setup sets the amount of time before the front doors close for a hall call whilst on normal operation. Lobby time (dtl) overri...

Page 20

E e p r o m s e t t i n g s eqk n/a. Do not adjust. Fs - fire service type australia: set to 00: 00000000 usa only. Fire service code 17.1. Fs eeprom setting must be set to 01: 00000001 hfaf - hall fire alternate (front doors) floor setup usa only. Fire service code 17.1. Fs eeprom setting must be s...

Page 21

E e p r o m s e t t i n g s hfsr - hall fire service (rear doors) return floor setup this sets the hall fire service return rear doors floor activated when hfs input is active whilst in normal mode and hfsr has a setting floor. Hfsr…eeprom hall fire service (rear doors) floor. (mask) 00: 00000000 (n...

Page 22

E e p r o m s e t t i n g s l.#…eeprom…lift # (value). Set value to lift number. (01 to 06 valid values.) 01: 00000001 (lift 1) 02: 00000010 (lift 2) 03: 00000011 (lift 3) 04: 00000100 (lift 4) 05: 00000101 (lift 5) 06: 00000110 (lift 6) mod - mode inputs setup enables the 3 mode inputs to be invert...

Page 23

E e p r o m s e t t i n g s rpt - run protection timer setup if the lift is given run signals from controller and lift does not move, (no msu or msd input received) the controller turns off all run signals after a certain time, (e.G. 25s) depending on value of the rpt setting. If this process is cyc...

Page 24

E e p r o m s e t t i n g s spares --1 eeprom spare --2 eeprom spare --3 eeprom spare --4 eeprom spare --5 eeprom spare stf - start fast number of pulses (in hex) it takes to reach fast speed stf eeprom start fast pulses. (value) eg. 30: 00110000 (30 pulses in hex or 48 in decimal) see also section ...

Page 25

E e p r o m s e t t i n g s 20: 00100000 (level 3) 10: 00010000 (level 4) 08: 00001000 (level 5) 04: 00000100 (level 6) top - top floor setup top eeprom top floor number (value) set value to number floors served. (02 to 06 are valid values). Lift resets to “top” value when tsl limit is activated. 02...

Page 26

E e p r o m s e t t i n g s recommend to set zon to the same value in all lifts belong to the group. A lift shall zone to floor defined by lob and ignore zon, when working in simplex. Zon eeprom zone floor. (mask) zoning floors for other lifts. 00: 00000000 (no zoning). To disable zoning set “lob” a...

Page 27

G r o u p section 3. Group group connections and communication • +24v and 0v, up and down hall calls, hfs and hfa (if usa) inputs must be looped between all elevators in the group. • group serial communication uses rs485 3-wire system. • controllers in the group are linked at the serial tx terminals...

Page 28: Group/duplex Faults

G r o u p group checks to ensure all the lifts in the group are communicating with each other, check the ram address which shows the position of each lift. Each lift has its position shown at the following ram addresses. • lift 1. - ram location 81 • lift 2. - ram location 91 • lift 3. - ram locatio...

Page 29

I n p u t s – o u t p u t s section 4. Inputs – outputs all inputs except lr, saf, hv1 and hv2 switch low to 0v in respect to +24v. The input shall draw approx 12ma. The input led is in series with the input. All inputs are opto isolated to avoid noise-related problems. Darlington outputs (uln2803) ...

Page 30

I n p u t s – o u t p u t s 1cr - i/o - 1 st floor rear car call/tell tale light 2cr - i/o - 2 nd floor rear car call/tell tale light 3cr - i/o - 3 rd floor rear car call/tell tale light 4cr - i/o - 4 th floor rear car call/tell tale light 5cr - i/o - 5 th floor rear car call/tell tale light 6cr - i...

Page 31

I n p u t s – o u t p u t s toggle switch also provided on board. When switch is on (down) ddo is activated. Allows the lift to be sent to floors via car calls without the doors opening. Useful for testing/adjusting etc. Os output shall be activated. Lift shall be taken out of the group. Do button, ...

Page 32

I n p u t s – o u t p u t s dli eeprom setting shall be ignored . . See dli in eeprom settings. Dfcr input is switched via the external rear door close relay n/o contacts. The rear doors close relays drop out via the rear door fully closed limit switches. When the external rear door close relay is i...

Page 33

I n p u t s – o u t p u t s dfof - door fully open (front doors) input dfof input must change state when the front doors reach the fully open limit/position. Single front door: input state can be inverted with dli setting. See dli in eeprom settings. To open the front door, dof relay shall pull up a...

Page 34

I n p u t s – o u t p u t s did inputs dfc and lrx change state? Do command did dfc input change state? Did lrx input change state? Wait 25 secs. Os output on. Drop do relay, yes no yes yes no no wait 25 secs. Os output on. Drop do relay, wait 25 secs os output on drop do relay, wait "x" secs. Dc re...

Page 35

I n p u t s – o u t p u t s 3dr i/o 3 rd floor dn call/tell tale light 4dr i/o 4 th floor dn call/tell tale light 5dr i/o 5 th floor dn call/tell tale light 6dr i/o 6 th floor dn call/tell tale light dn - down relay output dn relay output down relay output see section 6: motion, for more on the rela...

Page 36

I n p u t s – o u t p u t s edpr - electronic door protection (rear doors) input led is off when light ray is interrupted unless inverted with cnt setting. The edpr shall reopen the rear doors whilst on normal and independent modes. Ep - emergency power input ep – for hydraulic elevator operation on...

Page 37

I n p u t s – o u t p u t s hfs - hall fire service input hfs initiates the fire service recall operation australia: hfs led shall be on when hfs recall is activated. (unless inverted with mod setting) via the fireman’s hall fire service key switch if lift is on normal operation mode and hfs is acti...

Page 38

I n p u t s – o u t p u t s lev - leveling relay output lev relay output relay pulls up when lift leveling or re-leveling to floor lr – lock relay input. Lr - lock relay input for lr relay. High voltage input. Lr input controls lr relay. The lr n/o contacts are used in the safety circuit. (see page ...

Page 39

I n p u t s – o u t p u t s remain the same until the lift passes through dz. At floor level the msu magnets must be within the dz magnet or a dual advance count may occur. Re-leveling operation – if the lift is stationary at a floor and msu is off with dz and msd on then the lift shall re- level do...

Page 40

I n p u t s – o u t p u t s this signal is the advanced lift position count. Front doors: 1pf transistor output position 1 output 2pf transistor output position 2 output 3pf transistor output position 3 output 4pf transistor output position 4 output 5pf transistor output position 5 output 6pf transi...

Page 41

I n p u t s – o u t p u t s safety circuit input saf must be on for normal operation. Saf input is supplied from the end of the safety circuit (normally terminal 16 - see page 2 of ecd circuit diagrams). If this input is lost then the saf led shall be off and the lcd lift status shall show saf. Saf ...

Page 42

I n p u t s – o u t p u t s sp3 - multi purpose output 3 sp3 relay output spare relay output 3 sp3 may be used for inspection speed input, depending on drv setting sp3 may be used for auxiliary leveling pump operation, depending on drv setting. See also eeprom settings alp see section 6: motion, for...

Page 43

I n p u t s – o u t p u t s us - up slow relay output us relay output up slow output see section 6: motion, for more on the relay operation.

Page 44

L i q u i d c r y s t a l d i s p l a y section 5. Liquid cr ystal display understanding the lcd reading the liquid crystal display modes, position, address’ and status note: lcd contrast is set via pot located to the upper left of lcd. (pot 2.) lcd status line lcd position & direction the lift posi...

Page 45

L i q u i d c r y s t a l d i s p l a y lcd lift status the lift status is shown to the top right centre of the lcd display. The left side example shows the lift running down • bdl bridged door lock. Doors shall remain open until bridge is removed. See dfof/dfor input • dcp fail door close protectio...

Page 46

L i q u i d c r y s t a l d i s p l a y lcd control buttons the control buttons are used for accessing and programming the second line of the lcd display > > > > ∧ ∧ ∧ ∧ ∨ ∨ ∨ ∨ ent buttons - • > > > > =forwards • = backwards • ∧ = up • ∨ = down • ent = enter lcd display options use the forwards and...

Page 47

L i q u i d c r y s t a l d i s p l a y number of runs or front door/rear operations the counting value is in decimal. > > > > forwards floor positioning see motion. Counting method 01. 02- nor idl ][][ log run/door ops 02- nor idl ][][ flr positioning.

Page 48

M o t i o n section 6. Motion motion control outputs drive settings and their output status. The controller may output to various different drives as per the list below depending on the drv eeprom setting. The following diagrams only indicate the drive outputs but do not show re-leveling functions a...

Page 49

M o t i o n d o w n u p " d f " f u ll d o w n " u p " u p " u f " f u ll u p dynahyd "da valve" setting "01" " b r k " l o c k " d n " d o w n note: 1. On inspection sp3 turns on for inspection speed 2. To initiate a run, prv input must be on d o w n u p " b r k " v m d " d f " v m l " u s " v m p ...

Page 50

M o t i o n d o w n u p " d s " d o w n s lo w " u s " u p s lo w " u p " u p " u f " u p f a st 2 speed ac setting "04" " b r k " b ra k e " d n " d o w n " u d " u p /d o w n " b r k " b ra k e " d f " d o w n f a st " u d " u p /d o w n note: 1.To initiate a run, "prv" must be active prior to run...

Page 51

M o t i o n d o w n u p " b r k " l o c k " d f " v m l " d s " v m d " u s " v m p /s " s p 2 " d el ta " s p 1 " s ta r " u f " v m l 100 ms 400ms gmv 3010/s, blain ev100, maxton, bucher lrv, eeco. Setting "05" note: 1. On inspection sp3 turns on for inspection speed d o w n u p vf drive type 2 c....

Page 52

M o t i o n d o w n u p " s p 1 " l ev el in g " d s " d o w n s lo w " d f " d o w n f a st vf drive type 3 setting "07" abb-vf, pdl vf note: 1. To initiate a run, "prv" must be active prior to run. "prv" is not required on inspection. The end of the run is initiated by loss of leveling. Brk then h...

Page 53: Vf Drive Type 4

M o t i o n d o w n u p d s d f vf drive type 4 setting "08" bucher vf hydraulic note: prv must be active prior to run. Prv is not required on inspection. Sp3 turns on for insp speed. The end of the run is initiated by loss of leveling. Brk then holds up for sdx time and then ud is held up for st2 t...

Page 54: Vf Drive Type 5

M o t i o n d o w n u p " s p 2 " " d f " vf drive type 5 thy cpik-vf. Setting "09" note: 1. To initiate a run, "prv" must be active prior to run. "prv" turns off during entire run and becomes active to complete the run. "prv" is not required on inspection. " d n " d o w n " u d " u p /d o w n " b r...

Page 55: Vf Drive Type 6

M o t i o n d o w n u p " s p 1 " l ev el in g " d f " d o w n f a st vf drive type 6 setting "0a" gefran with db similar to "03" with ud delay off for synch gearless ac. (drop db contactor) note: 1. To initiate a run, "prv" must be active prior to run. "prv" turns off during entire run and becomes ...

Page 56

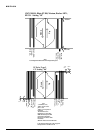

M o t i o n counting method “00” - magnet counting. Eeprom msl setting “00” the controller counts its position within the lift shaft using the dz – door zone input, msu – magnet switch up input, msd – magnet switch down input, tsl – top slowing limit and bsl – bottom slowing limit. If the lift is st...

Page 57

M o t i o n 1 0 0 m a g n e t s x x see note: g x -5 0 x -5 0 l im it c a m 4 0 t o p f l o o r b o t t o m f l o o r y y 4 0 m s d v a n e s e n s o r m s u v a n e s e n s o r bottom slowing & reset limit dn final up final limit limit slowing top limits 2 5 0 d z v a n e s e n s o r c h 2 c h 1 c ...

Page 58

M o t i o n counting method “01” - pulse counting. Also used for short floors that requires an intermediate speed, to avoid long creep times. Long creep times can be caused on a shorter floor where the lift does not reach rated speed before receiving a slow down signal. As the lift has not reached r...

Page 59

M o t i o n • once the lift has reached the top floor the lift shall revert to normal operation. • the hex value/count of each floor can be viewed by pressing the “∧” button to scroll through to the various levels “pos count” displays the current lift position in hex level 1 stored hex position coun...

Page 60

M o t i o n pulse distance table: level hex diff. In diff. In multiply by = count hex decimal pulse distance floor height in mm in mm 12. ___________ (11 to 12) > ────────────────────────────────────────────────────── 11. ___________ (10 to 11) > ─────────────────────────────────────────────────────...

Page 61

M o t i o n variable speed selection: all values are referred to in hex. Before a run, the speed (fast, medium or slow) is selected after calculating the distance to the selected floor. • rated (max) speed is selected when (stf + slf) • medium speed is selected when (stf + slf) > the commencing floo...

Page 62

M o t i o n as explained by fig 6a, fast speed can be selected. After stf distance of 5a hex pulses lift is at full speed. Lift stays at full speed for distance of 38 hex pulses at a distance of slf (5a hex pulses) from level 2, the fast speed relay is dropped to initiate the slowdown (5a + 38 + 5a ...

Page 63

M o t i o n therefore a fast speed run cannot be selected (not enough distance) between these 2 floors. The required distance for a medium speed run is now checked. 4c(stm) + 4c(slm) = 98. 98 is less than a6 so a medium speed run is now selected. Ie, the medium speed is selected when stf + slf (b4) ...

Page 64

M o t i o n npt: no pulse time out mode. (msl = 01, 02) during an up run, if the controller loses the pulse input, the lift shall travel to the top floor and stop, then perform a correction run down to the bottom floor and display npt on the lcd. During a down run, if the controller loses the pulse ...

Page 65

M o t i o n see note: g x -5 0 x -5 0 l im it c a m 4 0 t o p f l o o r b o t t o m f l o o r y 4 0 m s d v a n e s e n s o r m s u v a n e s e n s o r bottom slowing & reset limit dn final up final limit limit slowing top limits 2 5 0 d z v a n e s e n s o r c h 2 c h 1 c h 3 l r steel tape viewed ...

Page 66

M o t i o n npt: no pulse time out mode. (msl = 01, 02) during an up run, if the controller loses the pulse input, the lift shall travel to the top floor and stop, then perform a correction run down to the bottom floor and display npt on the lcd. During a down run, if the controller loses the pulse ...

Page 67

M o t i o n counting method “02” - pulse counting. Refer to the following explanation and “counting method 02 shaft layout” diagram; if the fast speed slowdown distance for level 1 exceeds the distance from level 2 to level 1, bsl would need to be placed above level 2. This creates a problem, as the...

Page 68

M o t i o n see note: g 50 level 1 y m s d m s u bsl - bottom slowing / reset limit to bsl input down final limit d z l r 1 0 0 1 0 0 y 1 0 0 y 1 0 0 y 1 0 0 y 1 0 0 y level 2 level 4 level 5 1 0 0 y 1 0 0 y level 3 tsl-2 drops uf input tsl - top slowing / reset limit up final limit bsl-2 drops df i...

Page 69

Section 7: faults – fault finding. Upgrade controller software. Controller software may be required to be updated depending on the version installed and the options the lift has. While we try to make it as simple as possible for software upgrades, unfortunately some eeprom address’ may be required t...

Page 70

On board fuse blows there are 2 fuses mounted on the controller board. The 2a fuse protects the 5vdc supply to all the logic on board. The 4a fuse protects the 24vdc supply. If 2a (5v) fuse blows check that the 6v zener diode is not short circuited. (return for repairs) if 4a (24v) fuse blows. 1. Te...

Page 71

1. Ensure sis unit is mounted firmly. 2. Some magnets may have dead spots. Change faulty magnets. 3. Ensure software is latest version. 4. On terminal floors – ensure that msu/msd initiates slowing before tsl/bsl respectively. Re-leveling won’t operate check rlv setting. Red3 led is not blinking the...

Page 72

Section 8. Upgrades, changes & technical infor mation upgrades, changes and modifications when contacting us please have the board’s part number (printed in white on pcb), software version and software build date (see section 5). Section 8.

Page 73

Controller id. D e c 2 0 0 3 c o n tr o ll er i d d at e d ra w in g n o : d ra w n r ev : d a t e : 1 0 0 -1 7 0 1 0 0 -1 7 2 1 0 0 -1 7 3 1 0 0 -1 7 4 1 0 0 -1 7 7 c a r _ s r 0 1 - 0 0 -1 0 k w ( 1 4 h p ) 0 2 - 1 0 -2 0 k w ( 2 7 h p ) 0 3 - 2 0 -3 0 k w ( 4 0 h p ) 0 4 - 3 0 -4 0 k w ( 5 4 h p ...

Page 74

Terminal screw torque settings. Tightening torques for 3 pole contactors type contactor terminal screw size torque (nm) torque (ft-lbs) gmc-9 m4 2.3 1.7 gmc-12 m4 2.3 1.7 gmc-18 m4 4.0 3.0 gmc-22 m4 4.0 3.0 gmc-32 m5 4.0 3.0 gmc-40 m5 4.0 3.0 gmc-50 m6 5.0 3.7 gmc-65 m8 5.0 3.7 gmc-75 m8 5.0 3.7 gmc...

Page 75

E l e c t r o n i c c i r c u i t d e s i g n s p t y . L t d . Operation guide electronic circuit designs pty. Ltd. Factory 11/30 perry street • matraville • nsw • australia • 2036 phone 61 2 9316 6909 • fax 61 2 9316 6797 email sales@ecd.Com.Au web www.Ecd.Com.Au.