Issue 3 original version june 2014 1 falcon magnetic drilling machine models cm/405/1 & cm/405/3 operator’s manual this machine (serial no ) is ce approved. Rotabroach ltd imperial works, sheffield road sheffield, south yorkshire united kingdom s9 2yl tel: +44 (0) 114 2212 510 fax: +44 (0) 114 2212 ...

Issue 3 original version june 2014 2 thank you for purchasing our falcon magnetic drill. We would really like your feedback on the machine. Other products by rotabroach™: thank you for your purchase of our product..

Issue 3 original version june 2014 3 contents page 1) general safety 4 2) machine specification 5 3) operational safety procedures 6 4) machine operation instructions 6 5) speed selection 7 6) arbor attachments 7 7) mounting of cutters 8 8) remedies for hole making problems 8 9) trouble shooting 9 1...

Issue 3 original version june 2014 4 1) general safety rules warning! When using electric tools basic safety precautions should always be followed to reduce the risk of fire, electric shock and personal injury, including the following. Read all these instructions before attempting to operate this pr...

Issue 3 original version june 2014 5 2) machine specification maximum hole cutting capacity in .2/.3c steel = 50mm dia. X 50mm deep arbor bore = 19.05mm (3/4”) dia. Motor unit cm/405/1 110v 11.5a, 1150w cm/405/3 230v 5.75a, 1150w overall dimensions machine 230 x 160 x 420mm magnet footprint 170mm x ...

Issue 3 original version june 2014 6 3) operational safety procedures read before using the machine all safety measures must be observed at all times when using magnetic core drills. Improper use and carelessness increase the risk of accidents. Read and carefully follow these recommendations in orde...

Issue 3 original version june 2014 7 5) speed selection the machine is equipped with gear ranges which can produce speeds up to 450rpm. Do not change the gear while the motor is in motion. The speed range for this gear is changed by the rotary change switch located on the gearbox side. The speed con...

Issue 3 original version june 2014 8 7) mounting of cutters the machine has been made to accept cutters having 19.05mm (3/4”) dia. Shanks. The following procedure is to be used when mounting cutters. • lay the machine on its side with feed handles uppermost, ensuring arbor is wound down to its lowes...

Issue 3 original version june 2014 9 9) trouble shooting magnet and motor do not function -‐ the magnet switch is not connected to the power supply -‐ damaged or defective wiring -‐ defective fuse -‐ defective magnet switch -‐ defective control unit -‐ motor forward/reverse switch set to o mag...

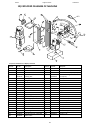

Issue 3 original version june 2014 10 10) exploded diagram of machine component identification for cm/405/1-‐3 falcon item no part no description. Item no part no description. 1 rd48153 frame 24 rd48196 screw+washer+nut 2 rd48174 screw ssm6x16 25 rd38001 info plate 3 rd48175 washer m6 26 rd48198 pa...

Issue 3 original version june 2014 11 11) exploded diagram of motor component identification for cm/405/1-‐3 falcon item no part no description. Item no part no description. 51 rd48215 screw 3,9x60 72 rd48236 end cover 52 rd48216 adaptor ring 22x0,2 73 rd48237 housing 53 rd48217 needle bearing 74 r...

Issue 3 original version june 2014 12 12) maintenance checks in order to ‘get the best life’ out of your rotabroach™ machine always keep it in good working order. A number of items must always be checked on rotabroach™ machines. Always before starting any job make sure the machine is in good working...

Issue 3 original version june 2014 13 2. Now lower the slide back to its lowest position. Bring the slide into the center of the dovetail slide housing and loosen screws thus allowing free movement of the arbor support bracket. 3. Commencing with the middle screws, gently feed in all the screws unti...

Issue 3 original version june 2014 14 13) cutter selection and speeds material material hardness cutter mild and free cutting steels rap or rapl mild and free cutting steels srcv or srcvl steel angle and joists rap or rapl steel angle and joists srcv or srcvl plate and sheet steel rap or rapl plate ...

Issue 3 original version june 2014 15 notes.

Issue 3 original version june 2014 16 14) warranty statement rotabroach™ warrants its machines to be free from faulty materials, or workmanship under normal use for a period of 12 months from initial date of purchase and 90 days for all other parts (excluding cutters), provided that the warranty reg...