- DL manuals

- G&F Manufacturing

- Heat Pump

- R-410A

- Service Manual

G&F Manufacturing R-410A Service Manual

Summary of R-410A

Page 1

G&f manufacturing service manual version 2.0 april 2010 any tech working on these units must read this manual. Any questions, please call service department from the job site. 954-318-6900

Page 2

Topics page • introduction to 410a 3 • sequence of operation 4 • control board operation 4 • control board service menu 4 • service menu options 4 language select 4 remote t-stat 5 pool heat/cool 5 pool- cool 5 solar control 5 time delay 5 spa timer 5 even heat 6 temperature scale 6 defrost mode 6 e...

Page 3: Warning:

Warning: only certified service providers to work on unit. Anyone else will void warranty. Only put your refrigerant gauges on these units as a last resort. It is a package unit that has had many steps taken at the factory to assure the system is contaminant free. Almost all problems can be diagnose...

Page 4: Sequence Of Operation

Sequence of operation in order to properly diagnose a problem you must understand the sequence of operation. When the pool pump comes on and the water flows through the heater, the water pressure closes the normally open pressure switch. When the switch closes, the control board then checks the ther...

Page 5: Attention:

Attention: you will find the pool/spa remote is no longer necessary; the board is programmed to automatically recognize the switch and self-program. 2 nd option: remote t- stat (disable) this option is used for external controller systems with its own thermostat such as an aqua logic! Or aqua link!....

Page 6: Board Diagnostics

8 th option: even heat (disabled) will periodically turn pool pump on according to delay setting. Options are: off, 0 hr (for testing), 1 hr, 2 hr, 3 hr, 4 hr, default is off 9 th option: temperature scale (f) sets display for centigrade or fahrenheit. Use arrows to toggle. 10 th option: defrost mod...

Page 7: Attention:

Low refrigerant pressure low pressure cut out is 37 pounds cut in is 80 pounds. Unless the defrost sensor is way out of calibration, you should never see this code because of low ambient temperatures. You should only see this code if there is a refrigerant leak. Find and repair the leak. Water flow ...

Page 8: Attention:

Charge the system holds 4 pounds for turbotec r-410a unit, because the sub cooling & super heat vary greatly with air and water temperature. For field charging we use a condensing temperature of 24 degrees. After power is on and water has been running through unit for at least 5 minutes your high si...

Page 9: Remove And Replace Parts

Remove and replace parts attention: although the components of this system are the product of an engineer, the design of the unit was created by a service technician of 35 years. Therefore, wherever possible, the unit was put together with ease of service in mind. Time is important to both your comp...

Page 10: Attention:

R&r txv and/ or filter turn off power. Start refrigerant recovery. Remove 4 screws holding top on unit. Cut wire tie holding fan wires bundled at side of control box. Lift top off, flip over and lay on end next to unit. After recovery has finished remove component from system. Replace with new filte...

Page 11: Warning:

R&r fan motor turn off power. Remove front cover. Disconnect fan wires from contactor, capacitor and ground. Remove strain relief bushing and holding wires where they penetrate control box. Feed wires out of control box. Cut wire ties holding wires in a bundle. Remove plastic fan motor cap from fan ...

Page 12

R&r defrost sensor turn off power. Remove front cover. Disconnect connectors from t-7 and t-8 on control board. Remove strain relief bushing where wires penetrate side of control box and feed sensor wires out of control box. On the suction line cut the cork tape and peel back exposing txv bulb and s...

Page 13: Installation

Installation attention: before installing this heater there are several things to consider for performance, serviceability and warranty. Direction of placement: access panel should always face out away from wall. If you must face the service panel toward the wall, leave a minimum of 24” between the ...

Page 14

Page 14.

Page 15

Bill of materials page 15 drawing no. Component description part no. 1 compressor plug 1001001 2 fan motor, 2/5hp, 825 rpm 1001002 3 control 1001003 4 temp sensor, suction 1001004 5 temp sensor, water 1001005 6 contactor, 2 pole, 40a 1001006 7 transformer, 40va 1001007 8 capacitor, 80uf, 370v 100102...

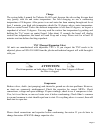

Page 16: 10K Sensor Ohms Chart

10k sensor ohms chart f ohm f ohm f ohm f ohm f ohm 20 46225 40 26100 60 15310 80 9297 100 5827 21 44879 41 25391 61 14921 81 9076 101 5697 22 43577 42 24704 62 14543 82 8861 102 5570 23 42318 43 24037 63 14176 83 8651 103 5446 24 41099 44 23391 64 13820 84 8447 104 5326 25 39919 45 22764 65 13473 8...

Page 17: Warning:

Warning: using any company that is not certified by g&f manufacturing will cause the warranty on the unit to void. Service all service must be handled by an authorized service center. Warranty may be void if a non- authorized service representative does service. Do not return the heater to your deal...