1 contents contents contents contents contents 1 user informa 1 user informa 1 user informa 1 user informa 1 user information tion tion tion tion 2 opera 2 opera 2 opera 2 opera 2 operator controls tor controls tor controls tor controls tor controls 3 boiler opera 3 boiler opera 3 boiler opera 3 boi...

2 boiler installed by:- tel: fax: email: the type of fuel required for the boiler is tank capacity oil suppliers ✍ ✍ to the householder. Thank you for purchasing a thermecon oil fired boiler. In the unlikely event of a problem arising with the boiler please first refer to:- page 41 section 12 ‘house...

3 select floor standing model s40/65 s60/80 s80/95 s90/120 btu/hr x 1000 40 to 65 60 to 80 80 to 95 90 to 120 kw 11.7 to 19.1 17.6 to 23.5 23.5 to 27.6 26.4 to 34.9 model s100/150 s140/190 s190/240 s240/270 btu/hr x 1000 100 to 150 140 to 190 190 to 240 240 to 270 kw 29.3 to 44.0 41.0 to 55.7 55.7 t...

4 90 70 55 heating limit heating hot water hw limit 2-1.1 boiler thermostat control the boiler thermostat control is used to control the temperature of the water within the boiler water chamber. The heat sensor phial of the thermostat is on the end of a capillary tube and placed in one of the tubes ...

5 opera opera opera opera operator controls 2 tor controls 2 tor controls 2 tor controls 2 tor controls 2 mains red lockout red red limit 2-1.2 mains switch o = off i = on the mains switch switches the boiler on and off. When power to the boiler is on and the mains switch is on the mains indicator l...

6 to remove plug press small screwdriver through hole in rear of plug 2-2 control panel - option 2-2.1 boiler thermostat control the boiler thermostat control is used to control the temperature of the water within the boiler water chamber. The temperature range of the control is 60°c to 90°c. The re...

7 opera opera opera opera operator controls 2 tor controls 2 tor controls 2 tor controls 2 tor controls 2 2-4 combistream and combi 65 expansion relief 2-4.1 tundish the combi boiler’s hot water system has two tpr valves, one for the hot water storage cylinder and one for the incoming cold supply. I...

8 3-3 burner ‘lockout’ the burner has its own control system that synchronises the burner ignition sequences. The safety system of the burner includes a flame detector (photoresistor) which senses the light of the flame. In the event of a failure of the flame, the burner control goes through a re-ig...

9 boiler opera boiler opera boiler opera boiler opera boiler operation 3 tion 3 tion 3 tion 3 tion 3 fig. 3-3a burner reset button in the event of a ‘lockout’, wait 45 seconds and restart the burner by pressing the reset button. If lockouts are more than occasional, consult your service engineer as ...

10 4-1 compliance inst inst inst inst installa alla alla alla allation general 4 tion general 4 tion general 4 tion general 4 tion general 4 the boiler and heating system must be installed to comply with the latest building regulations, british standards and oftec recommendations, refer to the appen...

11 inst inst inst inst installa alla alla alla allation 5 tion 5 tion 5 tion 5 tion 5 5-1 select and option internal floor standing 5-1.1 service access boiler models 40/65, 60/80, 80/95 and 90/120 can have the heat exchanger serviced from both the front or top of the boiler. The burner is serviced ...

12 205 35 45 1 bsp/f inst inst inst inst installa alla alla alla allation 5 tion 5 tion 5 tion 5 tion 5 5-2 select internal wall mounted - w40/50i & w50/80i 5-2.1 service access boilers have a quick release front panel enabling all routine servicing to be carried out without the necessity of removi...

13 18. Clear work space and carefully lift the boiler heat exchanger onto the 3 rawl bolts, fit nuts (the long nut is for the top bolt). Tighten nuts sufficiently to set rawl bolts in the wall. 19. Adjust for level and tighten the 3 rawl bolt nuts. 20. Fit the flue as per instructions supplied with ...

14 5-3 select external wall mounted w40/50e & w50/80e 5-3.1 service access external wall mounted boilers have a large hinged front door that gives access to the control panel and enables all routine servicing to be carried out without the necessity of removing main case or flue. The door can be lift...

15 5-3.4 fixing the boiler - suggested procedure 1. Remove carton. 2. Open boiler door and remove flue components. 3. Remove control panel by unplugging burner plug and unbolt two nuts. 4. Remove main casing - 3 screws each side. 5. Remove access door and lift out all baffles from heat exchanger. 6....

16 flow fig. 5-4a heating connections inst inst inst inst installa alla alla alla allation 5 tion 5 tion 5 tion 5 tion 5 5-4 select free standing external - fe40/50 & fe50/80 5-4.1 free standing external boilers the thermecon external free standing range of boilers are based on the external wall mou...

17 5-4.4 oil connection free standing external boilers are supplied with a pump set for single pipe oil system. The oil pipe and electric cable should also enter through the cut-outs provided in the bottom panel - see fig 5-4c. Inst inst inst inst installa alla alla alla allation 5 tion 5 tion 5 tio...

18 5-5.3 pump the pump is a standard 3 speed central heating circulating pump which pumps the hot water through the system. The unique design of the boiler enables the pump direction to be the same for both left hand and right hand flow connection. 5-5.4 pressure gauge the pressure gauge is provided...

19 inst inst inst inst installa alla alla alla allation 5 tion 5 tion 5 tion 5 tion 5 5-5.5 pressure relief valve the pressure relief valve is provided to vent excess pressure from the system. The valve will open when the pressure exceeds 3 bar ± 10%. The pressure relief valve can be manually opened...

20 l n pump electrical connections fig. 5-5f wiring connections note older systems need careful checking as they will be operating at a higher pressure. Note the expansion vessel is factory set at 1.5 bar. 5-5.9 wiring the wiring of the pump should be done by the installer to best suit the system ti...

21 inst inst inst inst installa alla alla alla allation - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 6-1 combistream system and combi 65 6-1.1 the combi boiler design the burner (8) heats th...

22 impormpormpormpormpor tant notestant notestant notestant notestant notes do not modify any of the pipework insidedo not modify any of the pipework insidedo not modify any of the pipework insidedo not modify any of the pipework insidedo not modify any of the pipework inside the boiler case.The boi...

23 inst inst inst inst installa alla alla alla allation - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 6-2.1 accumulator (supplied with combistream only) the accumulator may be installed at an...

24 fig. 6-2a static head note the plate heat exchanger is not guaranteed against corrosion or blockage caused by excessive scale. Fig. 6-2b filling loop mains supply isolating valve supplied flexible hose supplied double check valve supplied hose must be disconnected when not in use heating return 6...

25 ✓ supplied with combistream ✓✓ supplied with combistream and combi 65 cold water storage (accumulator) 3 stop cock double check valve 33 pressure regulating valve 33 outside tap cleanstream 3 drinking water servicing valves inst inst inst inst installa alla alla alla allation - combistream & comb...

26 300 min continuous fall discharge pipe to tundish - 15mm fixed grating tundish 500 m ax discharge pipe d2 metal from tundish trapped gully thermecon 6-2.12 hot water tpr discharge tundish one tundish is supplied with the boiler, this should be fitted to the hot water tpr valve discharge pipe at t...

27 m i x c0ld hot inst inst inst inst installa alla alla alla allation - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 tion - combistream & combi 65 6 6-3.2 thermostatic mixing valve a thermstatic mixing valve is supplied wit...

28 a s n o it p o m e t s y s li o s e t o n r e n r u b e v o b a k n a t m 5 o t 0 m e t s y s li o e p i p e l g n i s 1 . 3 - 7 o t r e f e r r e n r u b w o l e b k n a t m 1 o t 0 e v l a v n r u t e r - n o n h ti w m e t s y s li o e p i p e l g n i s 2 . 3 - 7 o t r e f e r m 0 . 4 o t 1 ) ...

29 oil suppl oil suppl oil suppl oil suppl oil supply 7 y 7 y 7 y 7 y 7 7-2.2 oil supply pipe in all oil systems the vertical lift of the oil line should be 10mm diameter. Horizontal runs should also be 10mm diameter, however it is good practice to use 15mm diameter, on the horizontal sections only,...

30 7-3.3 single pipe system - deaerator (tigerloop) when the burner is over 1 metre above the tank the installation normally requires a two pipe system, however, a ‘tigerloop’ deaerator can be used which removes air from a single pipe lift oil feed. Higher lift heights can be achieved than are possi...

31 conventional fl conventional fl conventional fl conventional fl conventional flue 8 ue 8 ue 8 ue 8 ue 8 8-1 conventional flue all floor standing boilers are supplied with an adaptor and flexible air duct fitted for conventional flue connection. Note the chimney must comply with current building r...

32 9-1 balanced flue selection balanced fl balanced fl balanced fl balanced fl balanced flue 9 ue 9 ue 9 ue 9 ue 9 wall mounted w40/50i, w50/80i 75mm 100mm floor standing o40/65, o60/80, o80/95, o90/120, s40/65, s60/80, s80/95, s90/120, c40/65 combi o100/150, o140/190, o190/240 s100/150, s140/190, s...

33 balanced fl balanced fl balanced fl balanced fl balanced flue 9 ue 9 ue 9 ue 9 ue 9 9-2 suggested flue siting g g n j h c,d l a k f g e a b b c c,d b f p f m o closer than 750 h fig. 9-2a suggested flue siting note *when the terminal is within 1 metre of any plastic material this should be protec...

34 balanced fl balanced fl balanced fl balanced fl balanced flue 9 ue 9 ue 9 ue 9 ue 9 9-3 burner air supply 9-3.1 combustion air supply boiler in room. No combustion air inlet is required. Boiler in compartment/small room. Ventilation air supply is required as shown in fig. 9-3a. Oftec information ...

35 commissioning 10 commissioning 10 commissioning 10 commissioning 10 commissioning 10 10-1 commissioning checks it is recommended that an o.F.T.E.C. Trained and registered technician be used. It is the responsibility of the installer to ensure that the boiler is properly commissioned, see bs5410 p...

36 10-2 extra procedures for system boilers 10-2.1 expansion vessel pressure check that the expansion vessel is adequate for the system as follows:- operate the system at normal temperature (80°c) with all radiators on and hot water on. The system pressure will rise above the cold fill pressure. If ...

37 commissioning 10 commissioning 10 commissioning 10 commissioning 10 commissioning 10 10-3.2 check pressure relief valve to check operation of the pressure relief valve temporarily increase the system pressure. The valve should operate when the pressure increases to 3 bar ± 10%. Reduce the pressur...

38 servicing 11 servicing 11 servicing 11 servicing 11 servicing 11 11-1 routine service fuel fuel fuel fuel fuel 28 second class c k 28 second class c k 28 second class c k 28 second class c k 28 second class c ker er er er erosene - once a year. Osene - once a year. Osene - once a year. Osene - on...

39 11-3 extra procedure for combi boilers servicing 11 servicing 11 servicing 11 servicing 11 servicing 11 11-3.1 cold fill pressure check the cold fill pressure is as recorded, reset the red pointer if required. A drop in the cold fill pressure indicates that the system requires topping up. If regu...

40 servicing 11 servicing 11 servicing 11 servicing 11 servicing 11 11-4.2 floor standing boilers s40/65 s40/65 s40/65 s40/65 s40/65 c40/65 c40/65 c40/65 c40/65 c40/65 o40/65 o40/65 o40/65 o40/65 o40/65 s100/150 s100/150 s100/150 s100/150 s100/150 o100/150 o100/150 o100/150 o100/150 o100/150 s60/80 ...

41 fffffaul aul aul aul ault finding 12 t finding 12 t finding 12 t finding 12 t finding 12 12-1 householders fault finding - also see www.Gah.Co.Uk k c e h c r e d l o h s u o h n o it u l o s e l b i s s o p ? N o p m a l s n ia m si o n tl u a f .R e li o b e h t o t r e w o p o n s i e r e h t ....

42 fffffaul aul aul aul ault finding 12 t finding 12 t finding 12 t finding 12 t finding 12 12-4 engineers fault finding - also see www.Gah.Co.Uk k c e h c r e e n i g n e n o it u l o s e l b i s s o p t o n ll i w r o t o m r e n r u b tr a t s .L e n a p l o rt n o c n o s t h g il t u o k c o l ...

43 fffffaul aul aul aul ault finding 12 t finding 12 t finding 12 t finding 12 t finding 12 12-5 engineers fault finding - system boilers 12-6 engineers fault finding - combi boilers k c e h c r e e n i g n e n o it u l o s e l b i s s o p g n it r a t s n e h w t u o k c o l d l o c m o rf . Y ll a...

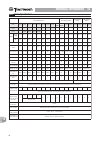

44 la n r e t ni g n i d n a t s r o o l f la n r e tx e g n i d n a t s e e r f d e t n u o m ll a w la n r e t ni d e t n u o m ll a w la n r e tx e t c e l e s 5 6 / 0 4 s 0 8 / 0 6 s 5 9 / 0 8 s 0 2 1 / 0 9 s 0 5 1 / 0 0 1 s 0 9 1 / 0 4 1 s 0 4 2 / 0 9 1 s 0 7 2 / 0 4 2 s i b m o c 5 6 / 0 4 c i...

45 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-2 boiler output options t c e l e s t c e l e s t c e l e s t c e l e s t c e l e s 5 6 / 0 4 s 5 6 / 0 4 s 5 6 / 0 4 s 5 6 / 0 4 s 5 6 / 0 4 s 0 8 / 0 6 s 0 8 / 0 6...

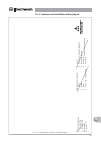

46 13-3.2 floor standing select & option range factory setting technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13 13 13 13 13 note there is no facility for blast tube adjustment on the ecoflam max burner range. L e d o ...

47 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-4 burner settings 13-4.1 combustion air setting - minor series burners ;; ;; ;; ;; note the recommended settings for the combustion head and combustion air are shown...

48 13 13 13 13 13 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-4.5 combustion air setting - max series burners note the recommended settings for the combustion head and combustion air are shown on pages 45 & 46. S...

49 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-4.6 burner oil pressure the burner pump oil pressure is measured using a pressure gauge fitted into the bleed/ pressure gauge port of the pump. An allen key is used ...

50 13 13 13 13 13 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-5 panel wiring diagrams 13-5.1 floor standing select and wall mounted internal 13-5.2 floor standing option range 1 4 2 limit stat mains switch contro...

51 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-5.3 wall mounted and free standing external range boiler mains pl ug connections programmer mains 5a fused sp ur permanent live neutral ear th switched live programm...

52 13 13 13 13 13 13-5.4 combistream and combi 65 internal wiring diagram technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 heating control stat mains limit e n/o blk blk blk blk blk bl r yg heating limit st at chassis ea...

53 13-5.4 combistream and combi 65external wiring diagram fig. 13-5e combistream and combi 65 external wiring diagram time clock connections 1. Hot w ater on 2. Hot w ater off ht g heating n. Neutral terminal block connections 1. Spar e 2. Neutral 5. Ear th 6. Time clock - t imed heating remoemoemoe...

54 13 13 13 13 13 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 1 2 3 4 5 6 7 fig. 13-6a floor standing m e ti tr a p s e t o n 1 e s o h s i e s o h a rt x e n a n o it a ll a t s n i e p i p o w t r o f .T s o c a r...

55 ;;;;; ;;;;; ;;;;; technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 fig. 13-6c combistream & combi 65 m e ti tr a p s e t o n 5 6 i b m o c d n a m a e rt s i b m o c 5 6 i b m o c d n a m a e rt s i b m o c 5 6 i b m ...

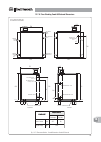

56 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-7 boiler dimensions 13-7.1 select and option range thermecon c b d f e g a f.F.L. 50 50 socket for conventional flue not 190/240 & 240/270 flow h return h oil pipe /...

57 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 175 205 Ø125 vertical balanced flue return - 1 bsp flow - 1 bsp 45 35 88 138 plan return flow 825 45 298 133 88 r Ø125 balanced flue (rear) 105 35 k x 3 35 703 465 36...

58 13 13 13 13 13 88 k x 2 r k = 315 = 40 200 r w40/50e w50/80e 800 min - 925 max 687 90 205 35 flow - 1 bsp return - 1 bsp 320 585 r - 3 mounting holes 12Ø for m10 rawl bolts k - knockouts for electric / oil pipes 980 865 135 420 45 recommended pipe arrangement technical informa technical informa...

59 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-7.4 free standing external dimensions fig. 13-7d thermecon boilers - overall dimensions external fully pumped systems only all dimensions are nominal flow - 1 bsp 3...

60 13 13 13 13 13 fig. 13-7e thermecon boilers - overall dimensions combistream and combi 65 fully pumped systems only all dimensions are nominal technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-7.5 floor standing com...

61 135 545 100 70 855 75 50 oil pipe / cable entry heating flow 1 bsp 575 635 100 40 855 75 50 oil pipe / cable entry 745 hot water flow 22mm hot water tpr (to tundish) 15mm cold feed 22mm heating return 1 bsp f.F.L. F.F.L. Right side left side 135 f.F.L. Rear 700 f.F.L. Hot water flow 22mm cold f...

62 13 13 13 13 13 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-8 balanced flue dimensions 13-8.1 floor standing internal inc. Combi - high level side & rear flues cannot be cut to length fig. 13-8a floor standing ...

63 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 13-8.2 floor standing internal inc. Combi - rear 135 plan Øa f.F.L. D c b minimum Øa d c b f.F.L. Plan minimum l e d o m t e lt u o r a e r e u l f a Ø b c d ti k d r a...

64 13 13 13 13 13 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 telescopic extensions available flues cannot be cut to length terminal section (vtl) l ength 1120 ffl 615 c 135 Ø200 vs extensions 300, 600 & 950mm 525 3...

65 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 fig. 13-8e internal wall mounted - standard balanced flue dimensions fig. 13-8f internal wall mounted - high level balanced flue dimensions standard kit 170 to 360 160 ...

66 13 13 13 13 13 615 a screws 88 138 plan flue brackets 300mm (exs-075) extension included terminal section (vtl) l ength 1120 Ø125 Ø200 120 technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 fig. 13-8g internal wall moun...

67 fig. 13-8h combi - low level rh side balanced flue dimensions telescpic extensions available 300mm, 600mm and 950mm flues cannot be cut to length technical informa technical informa technical informa technical informa technical information 13 tion 13 tion 13 tion 13 tion 13 160 b a 135 a minimum ...

68 appendix appendix appendix appendix appendix ap1-1 building regulations the following standards and codes of practice should be considered when installing thermecon boilers. Bs5449 - 1990 forced circulation hot water central heating systems for domestic use. Bs5410 part 1:1977 oil installations u...

69 important health and safety information for installers and service engineers seals and insulation seals and insulation seals and insulation seals and insulation seals and insulation fibreglass insulation, glass rope, mineral wool, insulation pads and ceramic fibre. 1. Avoid inhalation of fibres o...