- DL manuals

- Golden Skies

- Toy

- Bampf 3D Extreme

- Final Assembly Manual

Golden Skies Bampf 3D Extreme Final Assembly Manual

1

For Your Ultimate Enjoyment and Safety:

If this is your first ARF or RC model, Golden Skies R/C Aircraft, Inc. (GSRC) recommends that

you seek the knowledge and help of a long time, experienced modeler to assist you in the assembly

of this kit and to assist you in the preflight safety checks and first flights, during which you will be

trimming the plane for safety and performance. Your local hobby shop or the AMA association

(http:www.modelaircraft.org ) can assist you in finding a club, local expertise and a local flying

field. Seek a flying field with an AMA authorized club charter and one that has qualified flying

instructors. This is absolutely mandatory for your safety and the safety of others.

Golden Skies R/C Aircraft, Inc.

30882 Rivera Place, Laguna Niguel, CA 92677

949-429-2910; http://www.goldenskiesrc.com

Rev. 1.0 (2-16-06)

Bampf

Bampf

Bampf

Bampf

Bampf

3D Extreme

3D Extreme

3D Extreme

3D Extreme

3D Extreme

Unlimited Sport Aerobatics and 3D Extremes

Final Assembly Manual

(Check www.goldenskiesrc.com for the most updated manuals)

Specifications:

Wing Span: 64 in, Area: 936 sq-in; Loading: 18.5 oz/sqft

(@7.5 lbs)

Length: 60-1/2 in;

Weight: 7-1/2 to 8-1/2 pounds

(Depending upon equip used)

Engine: 60 - 90 2/s or 90 4/s Sport Flying; 1.08 - 160 2/s or 120 to 140 4/s 3 D Flying

90-1.08 2/S or 110 - 180 4/S

Almost Ready to Fly (ARF)

Summary of Bampf 3D Extreme

Page 1

1 for your ultimate enjoyment and safety: if this is your first arf or rc model, golden skies r/c aircraft, inc. (gsrc) recommends that you seek the knowledge and help of a long time, experienced modeler to assist you in the assembly of this kit and to assist you in the preflight safety checks and f...

Page 2

Optional equipment and accessories order these optional parts through: http://www.Goldenskiesrc.Com 1-866-429-2910 bampf 3d extreme kit components.

Page 3

3 kit components optional equipment - accessories ............................. ...... 2 table of contents ...................................................................................... 3 introduction ..............................................................................................

Page 4

4 introduction we are sincerely pleased that you have purchased the golden skies r/c aircraft (gsrc), bampf 3d extreme arf and we are sure you will thoroughly enjoy the bampf’s ease of assembly and flight performance. The final assembly manual is written in two sections: 1) for the very experienced ...

Page 5

5 safety warning, disclaimer and assumption of risk golden skies r/c aircraft, inc. Legal agreements warning the radio controlled (r/c), almost ready to fly aircraft (“arf”) is not a toy and is potentially dangerous to property and individuals within several miles of your flying area. It is capable ...

Page 6

3) release i hereby voluntarily release, and forever discharge golden skies r/c aircraft, inc., a california corporation, on its behalf and on the behalf of its successors and assigns, and each of them (“golden skies”) and its subcontractors, and all other persons or entities associated with it, inc...

Page 7

7) venue t he venue of any dispute that may arise out of this agreement or otherwise between the parties to which golden skies or its agents is a party shall be superior court for the state of california located in the county of orange. Return policy if you are not prepared to: 1) obtain adequate in...

Page 8

8 warranty golden skies r/c aircraft (gsr/c) warrants the arf to be free from defect in both materials and arf assembly workmanship for six (6) months from the date of purchase or the first flight, which ever comes first. Gsr/c warranty does not cover the whole or any component parts thereof damaged...

Page 9

9 gsrc general recommendations - work area : keep the work area clean and free of debris and unused tools. This will help prevent damage to your model. If you set the kit components on tools or debris you can damage the parts. Cover the work area with a soft cloth (bath towels work well) to prevent ...

Page 10

10 recommendations continued - batteries : 4.8 v, 600 mah batteries are typical in sport model aircraft, however, gsrc prefers to use 6.0 v, 1100 mah batteries for higher torque and greater servo actuation speed. The 6.0 v battery is heavier by one “cell” (5- vs 4-cells), but gsrc believes in highly...

Page 11

11 tools and supplies needed: the following items will be needed to complete the final assembly of the bampf 3d extreme arf. The assembler should acquire all needed supplies prior to starting assembly and become familiar with each item by thoroughly reading the manufacturer’s directions. Materials: ...

Page 12

12 table 1: english to metric conversion chart quick build step sequence: for very experienced builder, follow the building sequence below and refer to the appropriate pictures or narrative as needed for assistance. 1. Epoxy hinges into all control surfaces 2. Construct the aileron wing servos 3. In...

Page 13

13 caution: do not use oil ! Insert the hinge: insert the hinges into the control surface’s hinge hole. Press the hinge sufficiently into the hole so that the metal hinge pin is in-line with the control surface’s hinge point or line. Bend the hinge as shown in the picture (left) so that the free hin...

Page 14

14 step 2: wing servos & servo-wire extensions: in this step you will be installing the wing-servos onto the wing-servo access covers and placing the wing and elevator servo-extension cables in the wings and fuselage respectively. Hardwood mounting blocks: locate the four hardwood servo-mounting blo...

Page 15

15 step 3: join wing panels: gather together the following items: wing panels (2); dihedral brace; 2-part, 30- minute epoxy; epoxy brush; mixing cup, clamps (4); rubber bands #64; 2 ea 6” bar clamps; 2 pieces of scrap lite plywood (~ 1” x 8”), wax paper. Be sure you have placed the wing servo-extens...

Page 16

16 step 4: assemble the engine mount: although gsrc had intended to have the engine mount blind-nuts pre-mounted, but in order to provide the assembler with the most engine mounting flexibility we allow the assembler to decide the engine mount orientation. We will show how to side-mount an engine. W...

Page 17

17 locate engine position: with the spinner’s backplate on the engine shaft, clamp the engine to the mount-rails, as shown. Position the engine so that the rear edge of the spinner backplate is 5-5/8” from the firewall front surface. Be sure to measure all the way around the backplate to be sure the...

Page 18

18 step 5: preliminary pitch-balance check now is a good time to consider the layout options for your “movable” and discretionary com- ponents, such as engine, servos and battery. The allowable pitch c/g range is set by the planes wing plan and your style of flying. We will temporarily mount these c...

Page 19

19 mark the hs at the fuselage edge: using a felt tip pen, mark the hs at four points at the intersection of the hs and fuselage at the trailing and leading edges. Remove the hs (if the oracover is not already removed in the mounting area ..... Using a straight edge and a razor blade, score a line i...

Page 20

20 step 7: elevator & rudder hinge installation: gather elevator & rudder hinges, 30-minute epoxy, thin ca glue, masking tape, elevators and rudder, tailwheel. Gsrc has provide the bampf with two types of hinge: 1) ca-type & 2) metal pin hinges select hinge type you wish to use: for typical sport pi...

Page 21

21 step 8: fuel tank assembly: open the prepackaged fuel tank components and inventory the parts. Handy tools for this assembly step are: 1) dremel© tool with cut of wheel, tubing bender (see supple- mental pictures 4 and 5) fuel tank parts: the fuel tank parts are: tank, metal tubes (2), stopper, f...

Page 22

22 step 9: install ailerons: gather the ailerons, you pre-assembled in step 1, 30-minute epoxy, toothpicks, mix- ing cup, masking tape (blue), the wing-bolt brace, clamps to complete the installation of the control surfaces and the wing. Test fit and install ailerons: test each aileron by sliding th...

Page 23

23 step 10: install servos, horns & push-rods: (aileron, elevator, rudder) gather together, all servos, control linkages (push-rods & clevises (3 ea sets), pull-pull hardware, control horns, etc). You will need 1) drill & 1/ 16” bit, # 2 phillips head screwdriver, locktite®, ca glue, ruler, felt-tip...

Page 24

24 install elevator horn & push-rod & pull-pull: like the aileron horn alignment , the elevator horn requires two alignments, 1) with the elevator hinge line and 2) in straight line with the elevator servo-arm. Again, using the elevator push-rod and a piece of blue masking tape, may help you align t...

Page 25

25 crimp the tube: crimp the copper tube using either a crimping tool or pliers. Take care not to over crimp the tube and split its sides. Test for security and strength. Slide on and shrink the optional heat-shrink tubing if used. Attached the clevis to the rudder control horn. Hint: slightly enlar...

Page 26

26 turn the belly-pan over and secure the tips of the covering to the underside of the belly-pan. Spray the entire belly-pan underside with a clear, fuel proof spray paint. Do not over-soak the wood as warpage may occur. Colored paint may be used, but take care not to get any on the outside of the b...

Page 27

27 install fuel tank: slide the fuel tank into the forward fuselage area such that the front tubes protrude through the firewall in the round hole provided. Orient pieces of foam rubber between the tank sides and fuselage former (f2) to cushion the tank from vibration. (window sealing foam, that com...

Page 28

28 install the throttle push-rod: using the plastic push-rod and guide sleeve for the throttle control. Depending upon the engine you choose to use, you may be able to run the push-rod directly from the throttle servo to the carburetor control-arm. In the case of a 4/stroke engine you may need to se...

Page 29

29 step 14: install the cowl: you will install the cowl by cutting a hole in the cowl that is specific to your engine, muffler and way you mounted the engine to the firewall. You will need the cowl, masking tape, dremel tool w/cutting disk & sanding drum, ruler, cowl mounting screws. Locate hole in ...

Page 30

30 test fit the cowl: reinstall the engine and slip the cowl back in place. Install the spin- ner back plate and adjust the cowl to be about 1/16” back of the spinner backplate. Observe the cowls position for proper alignment with the lines of the fuselage. Check the engine hole clearance. There sho...

Page 31

31 step 15: wheel & landing gear installation: gather the main landing gear, wheels, wheel collars, stand-off bushings from the wheel assembly package. You will need: 1) # 2 phillips head screwdriver, install main landing gear: from the landing gear assembly package, gather the main aluminum landing...

Page 32

32 step 16: install receiver, battery & switch: you will need a 4 or 5 channel receiver; 4.8 or 6.0 volt, 1100 mah battery and a electrically compatible switch; velcro strips, foam rubber, rubberbands, # 11 blade. Attach switch: thread the switch leads through the hole and position the switch so tha...

Page 33

33 foam wrap receiver: attach the servo and switch wires to the receiver, then wrap your radio receiver in the foam provided by the receiver manufacturer. Secure with a rubber band and attach velcro© to the bottom, as shown. Attach receiver: attach the wrapped receiver to the velcro© on the receiver...

Page 34

34 decals: apply the decals: retrieve the bampf 3d extreme decal sheet and locate the specific decals that are placed on the fuselage-side , the fuselage-cowl, the rudder and the wingtip as shown in the set of pictures at left. Separate each decal using a pair of scissors by cutting a “rough-cut” li...

Page 35

Optional assembly procedures: the following are optional assembly steps/processes that are referred to through- out the assembly manual. Whether or not one performs these steps is completely up to the builder and how the builder might feel these procedures will enhance the strength or performance of...

Page 36

36 “receiver safe-box” installation (optional) radio-safe-box®: it may be elected to install a “radio-safe-box” to protect the receiver and possible the battery from damage during crashes or other mishaps. The “radio-safe-box” is available from sonictronics www.Sonictronics.Com. The receiver-safe-bo...

Page 37

Seal control hinge gaps: cut oracover seals: cut the following strip of oracover to seal the listed control surfaces: o ailerons 29-1/2” x 5/8” 2 ea white o elevators 8-3/8” x 5/8” 2 ea white o rudder 9- 3/8 ” x 5/8” 1 ea white fold each strip in the middle along its length with the oracover’s outer...

Page 38

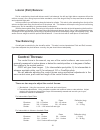

Balancing the bampf 3d (pitch, roll & yaw) it is critical that you balance the airplane correctly. An improperly balanced plane, particularly in pitch, will be unstable, causing loss of control and crashing. Pitch balance: the center of gravity (c/g) for pitch is located 10 - 1/16” back from the fro...

Page 39

39 lateral (roll) balance: roll is controlled by the aircraft ailerons and if not balanced, the left and right aileron response will not be uniform or equal. Also, during loops and other aerobatics, one of the wings is likely to droop and cause an adverse and undesired flight path. In this procedure...

Page 40

40 for advance 3-d and freestyle pilots: up down deflection (deg) elevators: 1.5 - *** inches 1.5 - *** inches 30-40 deg *** ailerons: 1 - 1.25 inches 1 - 1.25 inches rudder: maximum, to the point just short of touching the elevators (***) as much as you want and can safely handle. To mechanically a...

Page 41

41 3. With a experienced builder/pilot, check every electrical connection: a. Battery and receiver mounting to fuselage b. Battery to switch connection c. Switch to receiver connection d. Receiver to servo connections (elevator, rudder, ailerons, throttle) 4. Recheck the balance: ( check with the fu...

Page 42

42 radio controls: the transmitter controls setup are totally dependant upon the radio system you are using and the mode you are flying. In the usa, the mode is generally “mode - 2”. Mode two (2) and will assumed. A briefly description of the transmitter control functions and how they relate to the ...

Page 43

43 at the field, first and subsequent flights: perform the pre-flight checks and tests as described in the pre-flight section. One should get in the habit of doing these checks before each flight. Flying the bampf 3d extreme take off: the bampf will taxi and track straight forward, if one has set up...

Page 44

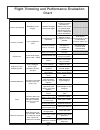

44 flight trimming and performance evaluation chart 000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000 000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000 000000000000000000000000000000000000000000...

Page 45

45 supplemental pictures and figures figure 2: wing and tail alignment with respect to fuselage figure 3: wing leveling diagram figure 4: dremel tool with sanding drums and cutting disc. Figure 5: tube bending tools.

Page 46

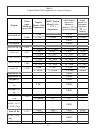

46 engine crank case width (@ mount tabs) engine mount - rail separation gsrc engine mount holes ( c/c ) separation gsrc engine mount c/c separation dimension "a" on eng mount drawing gsrc engine mount c/c separation dimension "b" on drawing 1.744 2.044 2.044 1.022 ~1-3/4" ~2-3/64" ~2-3/64" ~1-1/32"...

Page 47

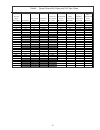

47 table3: typical screw-bolt sizes and drill-taps sizes 0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000 0000000000000...

Page 48

48 engine drawings engine top profiles for make the template to cut out the cowl for engine access. Os-91 4/s outlie.

Page 49

49 product evaluation request: golden skies r/c aircraft, inc. Is dedicated to the highest quality products and superior customer service. Gsrc seeks and values our customer’s feed back. It is our customer’s thoughts and ideas that assist gsrc to achieve continued product and customer service improv...

Page 50

50

Page 51

51 notes:.

Page 52

52 this page, intensionally left blank..

Page 53

53 read and accept disclaimer, liability, indemnification, and assumption of risk before purchasing the product see pages 5 - 7 for full text the back page of this assembly manual is an overview of the assumption of risk legal agreement only..

Page 54

54 safety warning and disclaimer (partial) and assumption of risk see full statement, pages 5 - 7 warning the radio controlled (r/c), almost ready to fly aircraft (“arf”) is not a toy and is potentially dangerous to property and individuals within several miles of your flying area. It is capable of ...