- DL manuals

- IBC Technologies

- Boiler

- SL 20-115

- Installation And Operating Instructions Manual

IBC Technologies SL 20-115 Installation And Operating Instructions Manual

INST

ALLA

TION AND OPERA

TING INSTR

UCTIONS

www.ibcboiler.com

SL 20-115

Modulating gas Boiler

(Natural Gas or Propane)

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

this Manual is also available in French - contact iBC or visit our web site www.ibcboiler.com

Summary of SL 20-115

Page 1

Inst alla tion and opera ting instr uctions www.Ibcboiler.Com sl 20-115 modulating gas boiler (natural gas or propane) warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Do not store or use gas...

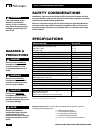

Page 2: Safety Considerations

Installation and operation instructions 2 sl 20-115 modulating gas boiler safety considerations specifications warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Installation, start-up and servi...

Page 3: Contents

3 installation and operating instructions sl 20-115 modulating gas boiler 1.0 installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

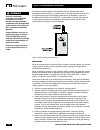

Installation and operation instructions 4 sl 20-115 modulating gas boiler the installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel and termination, gas supply, condensate removal and...

Page 5: Installation

1-1 installation sl 20-115 modulating gas boiler installation 1.0 general slseriesgas-firedmodulatingboilersarelowpressure,fullycondensingunits having variable input ranges (see specification chart - inside, front cover). The boilers are approved as “category iv” vented appliances using either direc...

Page 6

Installation and operation instructions 1-2 sl 20-115 modulating gas boiler code requirements thesl20-115modelwastestedtoandcertifiedundercsa4.9-2010/ansi z21.13-2010. Installation must conform to local codes, or in the absence of these, with the latest editions of can/cga b149 and the canadian elec...

Page 7

1-3 installation sl 20-115 modulating gas boiler contaminants; combustion air should be drawn from a clean source (e.G. Outdoors) and the boiler should be isolated from interior dust sources. Surface distance from combustible surfaces recommended distance for installation and service front 2" 24" re...

Page 8

Installation and operation instructions 1-4 sl 20-115 modulating gas boiler all venting must be installed in accordance with the requirements of the jurisdiction having authority: in canada, part 8, venting systems of the b149.1- 10 code and any other local building codes are to be followed. In the ...

Page 9

1-5 installation sl 20-115 modulating gas boiler • any improper operation of the common venting system should be corrected so the installation conforms with the national fuel gas code, ansi z223.1 - latest edition. In canada, all installations must conform with the current can/ cga - b149.1-10 insta...

Page 10

Installation and operation instructions 1-6 sl 20-115 modulating gas boiler by the respective pps manufacturers centrotherm / innoflue tm (their part # isaa0303)orm&gduravent/polypro(#3pps-ad).For2”venting,useinnoflue part # isrd0302 or polypro # 3pps-r2 (within the pps piping, after adapting with #...

Page 11

1-7 installation sl 20-115 modulating gas boiler overcome gravity on 1/4” / foot vent slope – leaving a pool of condensate at the nextupturnedelbow.Poolingcanimpairtheachievementoffullhigh-firerating plate performance. Exhaustpipingisinserteddirectlyintothe3”femalestainlesssteelfittingon the top, le...

Page 12

Installation and operation instructions 1-8 sl 20-115 modulating gas boiler figure 4: rooftop vent terminal configurations 1.4.5 rooftop vent termination rooftop vents must terminate as follows: • the exhaust pipe can terminate in an open vertical orientation without concern aboutraininfiltration;ra...

Page 13

1-9 installation sl 20-115 modulating gas boiler • use a 45° elbow on the exhaust termination to launch the plume up and off the sidewall, for protection of wall. • bird screen of 1/4” stainless steel or plastic mesh (ipex system 636 drain grate) is useful to guard against foreign objects. Sidewall ...

Page 14

Installation and operation instructions 1-10 sl 20-115 modulating gas boiler vent terminal clearance minimums are as follows: • clearance above grade, veranda, porch, deck or balcony – 12” (0.3m), but check local code also (anticipated snow levels may supersede). • clearance to openable window or do...

Page 15

1-11 installation sl 20-115 modulating gas boiler • clearance above paved sidewalk or paved driveway located on public property: - 7’ (2.2m) note: cannot terminate directly above a paved sidewalk or paved driveway that is located between two single family dwellings and serves both dwellings • cleara...

Page 16

Installation and operation instructions 1-12 sl 20-115 modulating gas boiler intake pipe size maximum equivalent length sched.40; rigid pps 2” 100’ 3” 240’ 90° long sweep elbow allow 5’ equivalent 90° vent elbow allow 8’ equivalent 45° elbow allow 3’ equivalent pps 87-90° elbows use 8’ equivalent ai...

Page 17

1-13 installation sl 20-115 modulating gas boiler air intake filter assembly, ibc part #sc-100a an “indoor combustion air installation”, as described herein, is one in which air for combustion is taken from the ambient air around the boiler. To support combustion, an ample air supply is required. Th...

Page 18

Installation and operation instructions 1-14 sl 20-115 modulating gas boiler condensate removal ibc’sspecifiedventconfigurationpromotesthesafedrainageofmoisturefrom theboilerandexhaustventingwithoutflowingliquidsbackthroughtheheat exchanger (as done by some other condensing boilers). Reliable system...

Page 19

1-15 installation sl 20-115 modulating gas boiler 1.5.3 condensate trap assembly - cleaning procedure 1. Turn off the power to the boiler and allow it to cool down. 2. Remove the trap from the boiler (reverse the installation procedure above). 3. Remove the trap cleanout assembly (h), from the trap ...

Page 20

Installation and operation instructions 1-16 sl 20-115 modulating gas boiler figure 18: condensate trap drainage figure 19: condensate neutralization tank warning if condensates are to be discharged into building drain piping materials that are subject to corrosion, a neutralization package must be ...

Page 21

1-17 installation sl 20-115 modulating gas boiler figure 20: overview of piping options water piping 1.6.1 general piping issues the sl 20-115 boiler was designed to be easy to install in almost any application. Its unique multi-port piping design allows connection from either side or both sides at ...

Page 22

Installation and operation instructions 1-18 sl 20-115 modulating gas boiler the sl modulating series boilers are designed for use within a closed loop, forced circulation, low pressure system. A 30 psi pressure relief valve (3/4” npt) issuppliedforfieldinstallationatoneofthelocationsshowninthefollo...

Page 23

1-19 installation sl 20-115 modulating gas boiler system piping is connected to the boiler using the 1” npt female threaded fittingsontherightorleftsideconnectionports,orbottom(orderbottom connection kit). Unions and gate or ball valves at the boilers supply and return water connections are recommen...

Page 24

Installation and operation instructions 1-20 sl 20-115 modulating gas boiler the sl series modulating boilers are designed to supply three different heating loads with temperatures within the range 34°f to 180°f - to meet three separately piped loads. Use closely spaced tees to connect each pumped “...

Page 25

1-21 installation sl 20-115 modulating gas boiler schematics for several piping layouts are provided herein, and additional drawings are available at www.Ibcboiler.Com. Installers shall conform the piping designtooneoftheprovidedconfigurationstosimplifythecontrolapplication, promotegoodloadsandflowm...

Page 26

Installation and operation instructions 1-22 sl 20-115 modulating gas boiler figure 28: important primary/secondary piping details with hydraulic separator figure 27: basic primary/secondary piping with hydraulic separator concept.

Page 27

1-23 installation sl 20-115 modulating gas boiler figure 29: primary/secondary piping to a hydraulic separator / distribution manifold figure 30: parallel piping connection to one side.

Page 28

Installation and operation instructions 1-24 sl 20-115 modulating gas boiler figure 31: parallel piping connection to two sides warning do not use automotive-type ethylene or other types of automotive glycol antifreeze, or undiluted antifreeze of any kind. This may result in severe boiler damage. It...

Page 29

1-25 installation sl 20-115 modulating gas boiler for optimal performance, place pumps on the supply side of secondary loops to facilitate air evacuation. Use pumps with internal check valves to avoid ghost flowsandthermalsiphoning. The primary loop temperature may need to transition from a 180°f do...

Page 30

Installation and operation instructions 1-26 sl 20-115 modulating gas boiler parallell load piping - benefits and installation rules compared with the primary/secondary approach, the design below saves one pump.Lostisthesimplicityofconstantheadandflowattheboiler. Wiring: in a parallel piping applica...

Page 31

1-27 installation sl 20-115 modulating gas boiler multiple boiler piping - benefits and installation rules multiple ibc boilers can be installed in a single heating system to provide redundancy, increased output, and greater heating plant turn-down capabilities. Primary/secondary piping must be empl...

Page 32

Installation and operation instructions 1-28 sl 20-115 modulating gas boiler 1.7 gas piping the boiler requires an inlet gas pressure of at least 3.0" w.C. For natural gas or propane. For either fuel, the inlet pressure shall be no greater than 14.0" w.C. Confirmthispressurerangeisavailablewithyourl...

Page 33

1-29 installation sl 20-115 modulating gas boiler electrical connections all electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or national electrical code, ans/nfpa no. 70 – latest edition, or the canadian electrical code, c22.1 - part 1. 1.8.1 120vac l...

Page 34

Installation and operation instructions 1-30 sl 20-115 modulating gas boiler note the ibc control only recognizes a true dry contact closure as a call for heat on terminals “therm. 1, therm. 2 or term. 3. Thermostats and other devices that use a “triac” output cannot be used as a call for heat witho...

Page 35

1-31 installation sl 20-115 modulating gas boiler 1.8.6 thermostat heat anticipator ibc “therm.” contacts draw no power, so an anticipator setting for the thermostat is not applicable with the sl modulating series boilers. In the case of a single temperature / heat load where zone valves are used to...

Page 36

Installation and operation instructions 1-32 sl 20-115 modulating gas boiler.

Page 37

2-1 boiler systems and operation sl 20-115 modulating gas boiler 2.0 boiler systems and operation general residential sl series modulating boilers are designed to service three separate, directly piped heating loads using different pre-selected water temperatures and heat regulation routines. Extern...

Page 38

Installation and operation instructions 2-2 sl 20-115 modulating gas boiler 2.3.2 lcd display uponpower-up,thelcdscreeninitiallyflashesasoftwarereleasenumber then switches to a standby- display mode, showing real time data plus key temperature target settings. Whenthereisacallforheatfromanyload,that...

Page 39

2-3 boiler systems and operation sl 20-115 modulating gas boiler 2.4.1 user setup the occupant has access to a number of practical settings. The most meaningful include adjustment of the indoor temperature target plus the temperature setback and occupied / unoccupied modes. The user menu also provid...

Page 40

Installation and operation instructions 2-4 sl 20-115 modulating gas boiler sequence of operation the control module has 5 cycles during normal operation, as well as an error mode for problem detection: 1. Standby cycle 2. Purging 3. Ignition cycle 4. Heating cycle 5. Circulating cycle 6. Error mode...

Page 41

2-5 boiler systems and operation sl 20-115 modulating gas boiler the pump remains on for 5 minutes (adjustable) after the heating cycle ends. If the heating cycle ends as a result of water temperature exceeding the load specificbandlimit,the postpurge will continue as normal, but the boiler will ent...

Page 42

Installation and operation instructions 2-6 sl 20-115 modulating gas boiler until the loop drops ½ the differential below the new load target temperature. Note: if there is no place to sink heat during such circ. Mode, this phase will continueindefinitely,affectingheatdelivery. Thermal shock avoidan...

Page 43

2-7 boiler systems and operation sl 20-115 modulating gas boiler runningofaradiantfloor.Thelargethrottleturndownrangecoupledwithoutdoor reset means that several loads can receive heat in-turn, with less on/off duty cycling than would occur with other heat sources. The boiler is shipped with default ...

Page 44

Installation and operation instructions 2-8 sl 20-115 modulating gas boiler contacts are provided for connection of an outdoor sensor (a tekmar 070 or similar sensor is shipped with each boiler) to be placed in an appropriate outdoor position.Thetemperaturemanagementalgorithmflexestheboilersupply te...

Page 45

2-9 boiler systems and operation sl 20-115 modulating gas boiler if outdoor reset is selected and there is no signal received from the sensor, the controller assigns a provisional 0°c value and will adopt the appropriate temperature target from the relevant reset curve. See section 2.7 set up & load...

Page 46

Installation and operation instructions 2-10 sl 20-115 modulating gas boiler from the main installer setup menu, select “heat load configuration”, then “configure load (use the load number tagged as space heating)”, and drop down to “summer shutdown”. Press enter to select, then use the keys to move...

Page 47

2-11 boiler systems and operation sl 20-115 modulating gas boiler 5. Eachoftheboiler’s3loadpositionscanbeconfiguredforanytypeof heating. Sl boilers are factory shipped with default settings as follows: load 1 set as space heating or reset heating, with high mass radiant floor set as the terminal typ...

Page 48

Installation and operation instructions 2-12 sl 20-115 modulating gas boiler 11. Avoid situations where the maximum is close or below the potential target, or the boiler will cycle off its (software) water high limit. 12. Priority:- where more than one load is present, it is critical that a value be...

Page 49: Startup and Commissioning

3-1 startup and commissioning sl 20-115 modulating gas boiler startup and commissioning 3.0 3.1 lighting and shutting down the boiler.

Page 50

Installation and operation instructions 3-2 sl 20-115 modulating gas boiler 3.2 prior to start-up 3.2.1 pre-ignition checks 1. Ensureventingsystemiscompleteandsealtested.Confirmanycommon venting system at the installation site is isolated and independent of the sl boiler, that any holes left from re...

Page 51

3-3 startup and commissioning sl 20-115 modulating gas boiler toverifytheproperoperationofthegasvalveinthefield,thefollowingprocedure canbecarriedoutbyaqualifiedtechnician(see figure 38). 1. Withasmall(1/8”or3mm)flatscrewdriver,opentheinletgassupply pressure test port by turning its center-screw 1 f...

Page 52

Installation and operation instructions 3-4 sl 20-115 modulating gas boiler note the safety warning regarding burner refractory on page 4-2 of this manual must be observed. 3.3.1 gaining access to combustion chamber, burner removal instructions 1. Remove fan and gas valve assembly. See “fan and gas ...

Page 53: Maintenance

4-1 maintenance sl 20-115 modulating gas boiler maintenance 4.0 boiler maintenance 4.1.1 general care • keepcombustiblematerialsandflammableliquidsandvapoursawayfromthe boiler. • keep vent terminals clear of obstructions (snow, dirt, etc.). 4.1.2 inspection inspection of the boiler is to be performe...

Page 54

Installation and operation instructions 4-2 sl 20-115 modulating gas boiler 4.1.6 heat exchanger during annual inspection (with the burner removed), examine the heat exchanger for signs of contamination and clean if necessary. In areas of poor gas quality, there may be a buildup of black plaque (typ...

Page 55

4-3 maintenance sl 20-115 modulating gas boiler 4.1.11 freeze protection checkfreezeprotection.Useonlyantifreezemadespecificallyforhydronic systems. Inhibited propylene glycol is recommended. Antifreeze volume must not exceed 50% of the total volume of water in the system. 4.1.12 boiler treatment • ...

Page 56

Installation and operation instructions 4-4 sl 20-115 modulating gas boiler removing top service cover removing front cover gas inlet connection on bottom gas valve connection block gas valve gas supply line ignition wire boot fan housing fan pressure sensing tube fan pressure sensor fan motor ignit...

Page 57

4-5 maintenance sl 20-115 modulating gas boiler outlet (supply) water temperature sensor upper vessel high limit switch vent temperature sensor bracket inlet (return) water temperature sensor ignition electrode/flame sensor removing vent stack test port plug fan coupler block water pressure sensor w...

Page 58

Installation and operation instructions 4-6 sl 20-115 modulating gas boiler 4.2.1 fan and gas valve removal instructions 1. Turn off electric power and gas supply to the boiler. 2. Ensure boiler cools down to ambient temperature. Do not drain the boiler unless freezing conditions are expected during...

Page 59: 5.0 Troubleshooting

5-1 troubleshooting sl 20-115 modulating gas boiler 5.0 troubleshooting the troubleshooting section is divided into 3 sections: 5.1 preliminary checks 5.2 electronic components 5.3 troubleshooting guide often,aproblemcanbeidentifiedandsolvedthroughsimplechecksofthe basics:confirmingtheelectricalpowe...

Page 60

Installation and operation instructions 5-2 sl 20-115 modulating gas boiler electronic components this section details the method for troubleshooting the non-standard electronic components on the boiler including the electronic differential air pressure sensor and the temperature sensors. 5.2.1 temp...

Page 61

5-3 troubleshooting sl 20-115 modulating gas boiler 5.2.2 fan/blower operating power is provided by means of a separate 120 vac connector at the bottom of the fan (white/black/green). Control of the fan is provided via a four lead connector at the top of the fan. This connector feeds a pwm control s...

Page 62

Installation and operation instructions 5-4 sl 20-115 modulating gas boiler next,confirmthatthecircuitisproperlypowered.Thesupplyvoltagetothesensor should be 13.8 vdc; to check, the simplest technique is to measure the circuit on the face of the controller circuit board (vs. An attempt to splice int...

Page 63

5-5 troubleshooting sl 20-115 modulating gas boiler 5.3 troubleshooting guide symptom diagnosis remedy airflow error lcd screen message: error – insufficient air flow insufficient combustion airflow; soft error; will retry in 5 minutes check fan operation • checkleadisattachedatfan. • cyclepoweroff/...

Page 64

Installation and operation instructions 5-6 sl 20-115 modulating gas boiler symptom diagnosis remedy maximum ignition trials error lcd screen message: error – ignition failure after 3 tries boiler has failed to ignite on 3 successive attempts. Boiler in lockout for 1 hour, then repeats 3-try seq. Co...

Page 65

5-7 troubleshooting sl 20-115 modulating gas boiler symptom diagnosis remedy vent hi-limit error lcd screen message: error - vessel/vent high-limit exceeded *** call for service! Vent temperature has exceeded the vent limit switch or the upper vessel high limit has been tripped. Boiler in lockout. C...

Page 66

Installation and operation instructions 5-8 sl 20-115 modulating gas boiler 5.3.3 cycling problems symptom diagnosis remedy rapid cycling improper values entered via keypad. Check load maximum temps are above target temps, by 1/2 of the selected boiler differential. Ensure boiler differential is ok ...

Page 67

5-9 troubleshooting sl 20-115 modulating gas boiler symptom diagnosis remedy rapid cycling insufficient water flow due to undersized pump. Check manufacturer’s rating charts/check temperature differential across heat exchanger. Insufficient water flow due to restrictions in water pipe. Check tempera...

Page 68

Installation and operation instructions 5-10 sl 20-115 modulating gas boiler 5.3.5 miscellaneous symptom diagnosis remedy fumes and high humidity improperly installed condensate trap refer to installation/operation instructions leak in vent piping inspect using soap solution flue gas leak within boi...

Page 69: 6.0 Diagrams

6-1 diagrams sl 20-115 modulating gas boiler 6.0 diagrams 6.1 - parts diagrams 6.2 - wiring diagrams 6.3 - sequence of operation.

Page 70

Installation and operation instructions 6-2 sl 20-115 modulating gas boiler 6.1 parts diagrams diagram 6.1-1: boiler assembly parts sl 20-115 modulating boiler - parts assembly.

Page 71

6-3 diagrams sl 20-115 modulating gas boiler diagram 6.1-3: intake air filter assembly, ibc part #sc-100a (filter element alone is ibc part #p-102a) item part no. Description qty 10 240-027 fan 1 15 180-017 air intake housing base 1 20 180-010 fan adapter plate 1 25 180-018 air intake housing cover ...

Page 72

Installation and operation instructions 6-4 sl 20-115 modulating gas boiler 6.2 wiring diagrams diagram 6.2-1: pictorial wiring diagram.

Page 73

6-5 diagrams sl 20-115 modulating gas boiler diagram 6.2-2: ladder wiring diagram.

Page 74

Installation and operation instructions 6-6 sl 20-115 modulating gas boiler diagram 6.2-3: internal wiring diagram.

Page 75

6-7 diagrams sl 20-115 modulating gas boiler 6.3 sequence of operation diagram 6.3: sequence of operation diagram.

Page 76

Installation & commissioning report boiler details: model number _____________________ serial number ______________________________________________ date of installation ______________ address of installation __________________________________________ _________________________________________________...

Page 77

Service record date licensed contractor description of work done installer set-up load definition - load #1 _______________________________________________________________________ load configuration - load #1 ___________________________________________________________________________________________...

Page 78

Notes.

Page 79: Important

Revision history r1 (dec 2010) initial release r2 (sept 2012) polypropylene venting, fuel mixture table 8 and us energy act disclosures added important this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equ...

Page 80

Ibc technologies inc. 1445 charles street, vancouver, bc canada v5l 2s7 tel: 604.877.0277 fax: 604.877.0295 www.Ibcboiler.Com 120-116e-a-r2 september 2012.