- DL manuals

- Ice

- Air Conditioner

- ECUA120

- Installation & Operation Manual

Ice ECUA120 Installation & Operation Manual

Chapter 1 Description ........................... 5

Chapter 2 Installation ......................... 12

Chapter 3 Start-Up ............................. 21

Chapter 4 Troubleshooting ................. 22

Chapter 5 Maintenance ....................... 25

Chapter 6 Warranty ............................ 26

Chapter 7 Start-Up Checklist .............. 27

ECU Installation & Operation Manual

Vertical Air Conditioners

Part Number 02118 04/2015 rev.3

Models ECUA90/120/150/180/240

Manufactured By:

Industrial Climate Engineering™ Division of AIRXCEL

®

, Inc.

P.O. Box 5104 • Cordele, Georgia 31010

2002 Hoover St. • Cordele, Georgia 31015

(229) 273-9558 • Fax (229) 273-5154

E-mail: icesales@airxcel.com • Internet: www.acice.com

The most current version of this manual can be found at www.acice.com.

Summary of ECUA120

Page 1

Chapter 1 description ........................... 5 chapter 2 installation ......................... 12 chapter 3 start-up ............................. 21 chapter 4 troubleshooting ................. 22 chapter 5 maintenance ....................... 25 chapter 6 warranty ............................ ...

Page 2

2 ecu 04/2015 rev.3 how to use this manual this manual is intended to be a guide to industrial climate engineering's line of vertical air conditioners. It contains installation, troubleshooting, maintenance, warranty, and application information. The information contained in this manual is to be use...

Page 3: Table of Contents

3 ecu 04/2015 rev.3 warning • if the information in these instructions are not followed exactly, a fire may result causing property damage, personal injury or loss of life. • read all instructions carefully prior to beginning the installation. Do not begin installation if you do not understand any o...

Page 4: Table of Contents

4 ecu 04/2015 rev.3 table of contents chapter 5 maintenance 5.1 scheduled maintenance .........................................................................................................................25 chapter 6 warranty 6.1 limited product warranty .............................................

Page 5

5 ecu 04/2015 rev.3 chapter 1 description & specifications 1.1 general description industrial climate engineering's (ice) environmental control units (ecu) are a series of vertical wall-mounted air conditioning systems that provide heating, cooling, and ventilation for electronic equipment shelters,...

Page 6

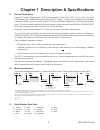

6 ecu 04/2015 rev.3 1.4 weights and filter sizes complete electrical and performance specifications and dimensional drawings are in the product data sheet. Model number ecua90 ecua120 ecua150 ecua180 ecua240 cooling btuh 1 94,000 125,000 150,000 170,000 235,000 rated air flow (cfm 2 ) 3,500 4,000 5,...

Page 7

7 ecu 04/2015 rev.3 1.6 electronic control board mode of operation normal 24 vac power must be continuously applied to “r” and “c”. Upon a call for cooling “y” and with the high pressure switch (hps) closed, the compressor will be energized. (note: see the delay on make feature.) the compressor will...

Page 8

8 ecu 04/2015 rev.3 reset is necessary to prevent harmful short-cycling. To reset switch, turn primary power off, then back on or turn thermostat system switch off, then back on. Low pressure switch the low pressure switch is mounted on the compressor suction line. It is designed to open if the refr...

Page 9

9 ecu 04/2015 rev.3 fresh air damper allows introduction of outside air into the building to provide positive pressurization. Field installed on either the left or right hand side of the unit. Dual compressors with lead/lag operation freeze sensor on indoor coil prevents frost on the indoor coil cau...

Page 10

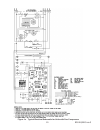

10 ecu 04/2015 rev.3 figure 1a. Typical electrical schematic for units with one compressor.

Page 11

11 ecu 04/2015 rev.3 figure 1b. Typical electrical schematic for units with two compressors notice: models 180-240 have two independent electrical circuits and each electrical circuit is wired the same as shown..

Page 12: Chapter 2 Installation

12 ecu 04/2015 rev.3 chapter 2 installation warning failure to observe and follow warnings and cautions and these instructions could result in death, bodily injury or property damage. Read this manual and follow its instructions and adhere to all cautions and warnings in the manual and on the ice un...

Page 13

13 ecu 04/2015 rev.3 the national fire protection association standards 90a and 90b before designing and installing duct work. The duct system must be engineered to insure sufficient air flow through the unit to prevent over-heating of the heater element. This includes proper supply duct sizing, suf...

Page 14

14 ecu 04/2015 rev.3 kit components: accessories: the package may include other factory-supplied items (optional): p/n description s/04581 commstat 3 controller, solid state lead/lag controller s/07846 commstat 4 controllers, solid state lead/lag controller 50123 digital thermostat. 1 stage heat, 1 ...

Page 15

15 ecu 04/2015 rev.3 2.4 porting and duct work general information note: the following instructions are for general guidance only. Due to the wide variety of installa- tion possibilities, specific instructions will not be given. When in doubt, follow standard and accepted installation practices, or ...

Page 16

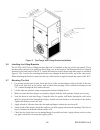

16 ecu 04/2015 rev.3 figure 2. Top flange and lifting bracket installation 2.6 installing the lifting brackets the ecu90/120/150 have lifting brackets that can be installed on the top of the side panels. These brackets allow the unit to be picked up thru lifting eyes in the brackets.The lifting brac...

Page 17

17 ecu 04/2015 rev.3 for units with electric heat, a one inch clearance is required around the duct extensions. The duct extensions must be constructed of galvanized steel with a minimum thickness of .019” as per the nfpa standards 90a & 90b. Figure 3. Air conditioner wall mount detail 2.8 electrica...

Page 18

18 ecu 04/2015 rev.3 that the suction pressure drops and the discharge pressure rises when the compressor is energized. An alternate method of verification for self contained system with small critical refrigerant charges, where the installation of gauges may be objectionable, can be made by monitor...

Page 19

19 ecu 04/2015 rev.3 dual unit phasing for applications where one controller operates two units, e.G., the commstat 4. 1. Wire each unit as described in steps 1 through 4 above. 2. Test for proper phasing as follows: a. Power up the units. B. Using an ac volt meter set to the 300 volt scale, measure...

Page 20

20 ecu 04/2015 rev.3 figure 4a. Thermostat connection diagram figure 4b. Commstat 3 wiring diagram.

Page 21: Chapter 3 Start-Up

21 ecu 04/2015 rev.3 chapter 3 start-up 3.1 check-out of cooling cycle important: be sure that the crankcase heater (if used) has been energized for at least 24 hours before starting the unit(s). Double-check all electrical connections before applying power. All air conditioners with scroll compress...

Page 22: Chapter 4 Troubleshooting

22 ecu 04/2015 rev.3 chapter 4 troubleshooting 4.1 overview the middle front panel provides access to the electrical/control box and to the filters. This panel has hinges on the left and right hand side. This panel should only be opened by using the two hinges on the left side or the two hinges on t...

Page 23

23 ecu 04/2015 rev.3 problem/symptom likely cause(s) correction b. Unit runs for long periods or continu- ously; cooling is insufficient. 1. Dirty filter or reduced airflow 2. Low refrigerant. 3. Component failure. 4. Unit undersized for job. 1. Check air filter(s). Check blower operation. Remove ai...

Page 24

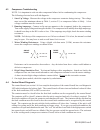

24 ecu 04/2015 rev.3 4.3 compressor troubleshooting note: it is important to rule out other component failures before condemning the compressor. The following electrical tests will aid diagnosis: 1. Start-up voltage: measure the voltage at the compressor contactor during start-up. The voltage must e...

Page 25: Chapter 5 Maintenance

25 ecu 04/2015 rev.3 chapter 5 maintenance the middle front panel provides access to the electrical/control box and to the filters. This panel has hinges on the left and right hand side. This panel should only be opened by using the two hinges on the left side or the two hinges on the right side. Ne...

Page 26: Chapter 6 Warranty

26 ecu 04/2015 rev.3 chapter 6 warranty 6.1 limited product warranty if any part of your industrial climate engineering™ environmental control unit (ecu) fails because of a manufacturing defect within eighteen months from the date of original shipment by ice or within twelve months from the date of ...

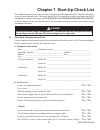

Page 27

27 ecu 04/2015 rev.3 chapter 7 start-up check list the middle front panel provides access to the electrical/control box and to the filters. This panel has hinges on the left and right hand side. This panel should only be opened by using the two hinges on the left side or the two hinges on the right ...

Page 28

28 ecu 04/2015 rev.3 condensate section has water been placed in drain pan to confirm proper drainage? ❒ yes ❒no are correct filters in place? ❒ yes ❒no refrigerant piping if leaks are found, report any leaks to ice warranty service dept. C. Check rated voltage at terminal block for imbalance before...

Page 29

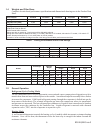

29 ecu 04/2015 rev.3 d. Heating mode check & record readings circuit 1 circuit 2 (if applicable) room temperature ________ ________ outside temperature ________ ________ evap. Entering air db temp ________ ________ evap. Entering air wb temp ________ ________ evap. Leaving air db temp ________ _____...

Page 30

30 ecu 04/2015 rev.3 after 10 minutes of compressor operation, record the following: circuit 1 circuit 2 (if applicable) room temperature ________ ________ outside temperature ________ ________ suction pressure ________ ________ suction line temperature ________ ________ discharge pressure ________ ...