- DL manuals

- Kalerm

- Coffee Maker

- KLM1601

- Service Manual

Kalerm KLM1601 Service Manual

Summary of KLM1601

Page 1

Klm1601 service manual intelligent fresh ground coffee machine klm1601-sm-en v003.

Page 3

English klm1601 service manual intelligent fresh ground coffee machine.

Page 4

Service manual intelligent fresh ground coffee machine klm1601 contents 1. Introduction 4 6 2. Structure 15 3. Troubleshooting 37 4. Repair 2.1 overview 2.2 description of internal components 2.3 water circuit 2.4 schematic circuit diagram 2.5 technical data general warnings symbol description 4 5 6...

Page 5

76 82 50 51 53 53 56 58 61 65 76 76 76 78 78 79 5. Function test and maintenance 6. Explosive view 4.3 precautions for maintenance and installation precautions for assembling 5.1 function test and test standards 5.2 coffee machine maintenance 4.2.15 disassemble thermoblock group 4.2.16 disassemble g...

Page 6

1. Introduction the manufacturer reserves the right to make product improvements. We guarantee that this manual respects the technological status at the time the machine is supplied. We are open to any suggestions from technicians which may improve the product and the manual. General warnings once t...

Page 7

Introduction 5 symbol description non-compliance with the operation, may cause electric shock, and threat to life. Non-compliance with the operation may cause coffee machine damaged, or personal injury. Non-compliance with the operation, may cause scalded or burned. This symbol, if prompted, please ...

Page 8

2. Structure 2.1 overview bean container lid top cover water tank cover water tank ornament cover water tank support elect power button front cover left cup support 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 9 10 11 12 13 14 15 16 17 18 structure 6 service manual intelligent fresh ...

Page 9

19 22 23 28 29 30 31 32 20 21 24 25 26 27 bean container grinder adjustment knob ground coffee container lid 19 20 21 back cover logo right side section 28 29 30 left side section power line 31 32 hot water export coffee export milk connector foam rubber light for coffee milk and foam export 22 23 2...

Page 10

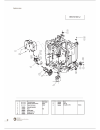

2.2 内部组件说明 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 structure 8 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 21 service manual intelligent fresh ground coffee machine klm1601 thermoblock dispenser valve 3w geared motor dispenser valve 2w dispenser valve condensator support pcba...

Page 11

2.3 water circuit 2.3.1 overview of water circuit structure 9 1 2 3 4 5 8 6 7 9 10 11 12 13 15 14 1 2 3 4 5 6 water tank sieve flowmeter condensator pump pressure maintaining valve steam thermoblock dispenser valve 3w 1 2 3 4 5 6 7 8 coffee thermoblock dispenser valve 2w drainage valve brew unit bev...

Page 12

2.3.2 water circuit for making coffee structure 10 1 10 2 3 7 4 5 6 9 8 service manual intelligent fresh ground coffee machine klm1601 valve support flowmeter condensator pump dispenser valve 3w coffee thermoblock dispenser valve 2w drainage valve brew unit export 1 2 3 4 5 6 7 8 9 10

Page 13

Valve support flowmeter condensator pump dispenser valve 3w steam thermoblock dispenser valve solenoid valve foam rubber 1 2 3 4 5 6 7 8 9 2.3.3 water circuit for making steam structure 11 1 9 8 2 7 3 6 5 4.

Page 14

2.3.4 water circuit for making hot water structure 12 1 8 2 7 3 4 5 6 service manual intelligent fresh ground coffee machine klm1601 valve support flowmeter condensator pump dispenser valve 3w coffee thermoblock dispenser valve export 1 2 3 4 5 6 7 8.

Page 15

2.4 schematic circuit diagram structure 13 n l 2 4 3 1 u u l n neutral line trans pump power steam coffee coffee steam p7 swv brew step ntc brew swv binwater milk bin water flow coffee lamp hmi - + + - + - 16 17 26 24 25 18 23 1 2 3 4 22 21 20 19 5 8 9 10 11 12 13 14 15 6 7 1 2 3 4 5 6 7 8 9 10 11 1...

Page 16

14 structure service manual intelligent fresh ground coffee machine klm1601 2.5 technical data total voltage/power china europe 220v/50hz 1200w 230v/50hz 1400w approvals ccc,cb,gs,ce power ratings thermoblock pump grinder motor drive motor dispenser valve motor solenoid valve 220v 1200w 230v/50hz 48...

Page 17

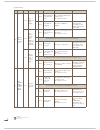

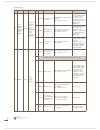

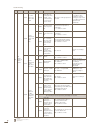

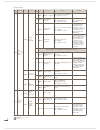

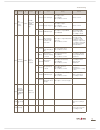

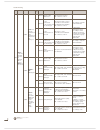

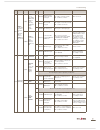

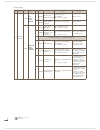

Troubleshooting 15 3. Troubleshooting check list 3.1 3.2 3.1.1 3.2.1.1 3.2.1.2 3.2.1.3 3.2.2.1 3.2.2.2 3.2.2.3 3.1.2 3.2.1 3.2.2 3.2.3 3.1 troubleshooting check list item confirmation no. No. Cause remedy remarks problem prob- ability the following should be repaired by disassembling the machine the...

Page 18

16 service manual intelligent fresh ground coffee machine klm1601 troubleshooting item confirmation no. No. Cause remedy remarks problem prob- ability 3.2 3.2.4 3.2.4.1 3.2.4.2 3.2.5.1 3.2.5.2 the following should be repaired or replaced water tank group the following should be repaired or replaced ...

Page 19

Troubleshooting 17 item confirmation no. No. Cause remedy remarks problem prob- ability the connector between pcb and powder switch does not work yes - connect or repair power switch connector no - continue to 3.3.1.6 1. Disassemble control panel according to 4.2.8; 2. Disassemble control panel,repa...

Page 20

18 troubleshooting service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- ability yes - replace or repair pcba, item: 78000006 yes - clean rest coffee powder no - continue to 3.3.3.2 yes - take out coffee grounds container, reinsta...

Page 21

Troubleshooting 19 item confirmation no. No. Cause remedy remarks problem prob- ability inside pipe connector damaged- water leakage(lots of water on the table) yes - repair damaged pipe or connector no - continue to 3.3.5.3 1. Disassemble drainage valve group according to 4.2.10; 2. Replace or repa...

Page 22

Troubleshooting 20 3.3 3.4 3.3.6 3.3.6.4 3.3.6.5 3.3.6.6 3.4.1.1 3.4.1.2 3.4.1.3 3.4.1.4 3.4.1.5 3.4.1 service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- ability contropistone seal damaged yes - replace brew unit seal, item: 73...

Page 23

3.4 3.4.2.1 3.4.2.2 3.4.2.3 3.4.2 troubleshooting 21 3.4.3.1 3.4.3.2 3.4.3.3 3.4.3.4 3.4.3.5 3.4.3 3.4.2.4 3.4.2.5 item confirmation no. No. Cause remedy remarks problem prob- ability refer to 3.4.2.1 refer to 3.4.2.1 1. Disassemble control panel according to 4.2.8; 2. Disassemble control panel comp...

Page 24

Troubleshooting 22 3.5 3.5.1.1 3.5.1.2 3.5.1.3 3.5.1.4 3.5.1 3.5.2.5 3.5.2.6 3.5.2.7 3.5.2.8 3.5.2.1 3.5.2.2 3.5.2.3 3.5.2.4 3.5.2 service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- ability use coffee beans to make coffee the g...

Page 25

3.5 3.5.2 3.5.2.9 3.5.2.10 troubleshooting 23 3.5.3.1 3.5.3.2 3.5.3.3 3.5.3.4 3.5.3.5 3.5.3.6 3.5.3 item confirmation no. No. Cause remedy remarks problem prob- ability if conical burr and upper burr is stucked by foreign object, there will be different regular noise when the conical buur and upper ...

Page 26

Troubleshooting 24 3.5 3.5.4 3.5.4.2 3.5.4.3 3.5.4.4 3.5.5.1 3.5.5.3 3.5.6.1 3.5.6.2 3.5.6.3 3.5.6.4 3.5.5 3.5.6 service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- ability 1. Disassemble brew unit according to 4.2.3; 2. Replace...

Page 27

25 troubleshooting item confirmation no. No. Cause remedy remarks problem prob- ability 3.5 the following should be repaired by dismatling the machine drainage valve group damaged, no water comes to brew unit, dropped to drip tray from drainage valve directly yes - replace drainage valve group no - ...

Page 28

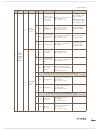

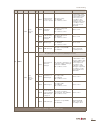

Troubleshooting 26 3.6 3.6.1 3.6.1.1 3.6.1.2 refer to 3.5.3 3.6.2 3.6.3 3.6.4 3.6.5 3.6.7 3.6.6 3.7.1 3.7 service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- ability use coffee powder to make coffee lack of powder displays on th...

Page 29

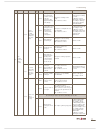

Troubleshooting 27 3.7 3.7.2.1 3.7.2.2 3.7.2.3 3.7.3.1 3.7.3.2 3.7.2 3.7.3 3.10.1.1 3.10.1.2 3.7.4 3.8 3.8.1 3.8.2 3.8.3 3.9 3.9.1 3.10 3.10.1 item confirmation no. No. Cause remedy remarks problem prob- ability 1. Disassemble dispenser valve according to 4.2.9; 2. Disassemble dispenser valve accord...

Page 30

Troubleshooting 28 3.10 3.10.1.3 3.10.1.4 3.10.1.5 3.10.1.6 3.10.1 3.10.1.7 3.10.1.8 3.10.2.1 3.10.2.2 3.10.2 3.10.3.1 3.10.3.2 3.10.3 3.11 3.11.1 3.11.2.1 3.11.2.2 3.11.2 service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- abil...

Page 31

Troubleshooting 29 3.11 3.11.2.3 3.11.2.4 3.11.2 3.11.2.5 3.13 3.14 3.15 3.12.1.1 3.12.1.2 3.12.1.3 3.12.1.4 3.12.1.5 3.12.1.6 3.12.1.7 3.12 3.12.1 item confirmation no. No. Cause remedy remarks problem prob- ability the process to make cream it is milk instead of cream inside the cup yes - replace ...

Page 32

Troubleshooting 30 3.16 3.16.1 3.16.1.2 3.16.1.3 3.16.1.4 3.16.1.5 3.16.2.1 3.16.2.2 3.16.2.3 3.16.2.4 3.16.3.1 3.16.3.2 3.16.3.3 3.16.2 3.16.3 3.16.1.1 service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- ability error 1~7coffee...

Page 33

Troubleshooting 31 3.16 3.16.3 3.16.3.6 3.16.3.4 3.16.3.5 3.17 3.17.1 3.17.2 3.17.2.1 3.17.2.2 3.17.2.3 3.17.3 3.17.4 3.16.4 3.16.7.1 3.16.7.2 3.16.7.3 error3 (valve reset restart 3.17.4.3 3.17.4.1 3.17.4.2 3.17.4.4 item confirmation no. No. Cause remedy remarks problem prob- ability yes - replace d...

Page 34

Troubleshooting 32 3.17.4.5 3.17.4.6 3.17.4 3.17 3.17.5 brew unit reset restart machine 3.17.5.1 3.17.5.3 3.17.5.2 3.17.5.4 3.17.5.5 3.17.5.6 service manual intelligent fresh ground coffee machine klm1601 item confirmation no. No. Cause remedy remarks problem prob- ability information reminding refe...

Page 35

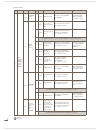

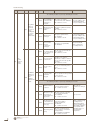

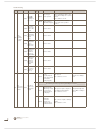

33 troubleshooting 1 1 1 3.2.1.1 reed sensor function if there is water in water tank, but the screen displays fill water tank,put a magnet in left side section as the picture shows: if the screen does not display fill water tank anymore- water tank components damaged- replace components;if the scre...

Page 36

34 troubleshooting service manual intelligent fresh ground coffee machine klm1601 3.2.2.4 check all the connection lines 3.2.2 circuit 3.2.2.1 check fuse inside line pencil connector if the fuse is damaged, machine can not be started on. 3.2.1.4 press button operation all the function buttons on the...

Page 37

35 1 1 1 1 1 troubleshooting 3.2.2.5 check all switches the picture shows off-state. When touch microswitch contactor, it is on-state. 3.2.3. Leakage take off drip tray layer board as the picture shows, fill drip tray microswitch with paper, and press rinse button check leakage of brew unit.

Page 38

36 troubleshooting check leakage of connectors service manual intelligent fresh ground coffee machine klm1601.

Page 39

Repair 4. Repair 4.1 tools preparation torx screwdriver ( t6,t10,t15,t20,t25 ) slotted type screwdriver (3mm series) needle-nose pliers electronic scale temperature tester multimeter 37.

Page 40

4.2 disassemble process for components 1. Take out drip tray 2. Take out bean container lid group 4.2.1 disassemble exterior parts 4.2.1.1 take out movable parts 1 2 3. Take out water tank group 3 1. Rotate the logo support according to the direction of the arrow 2. Dismantle 2 screws from the botto...

Page 41

39 repair 3. Take out back cover according to the arrow direction 3 1. Disassemble the 2 screws from the bottom 2. Take out front cover right and front cover left separately according to the direction of the arrow 4.2.1.3 disassemble front cover right and front cover left 1 2 1. Take out right side ...

Page 42

40 1 1 repair 1. Disassemble 2 screws from the left side of the top cover 2. Loose top cover and hook of the frame 4.2.1.6 disassemble top cover 1 2 3. Take out top cover according to the direction of the arrow 3 1. Disassemble 4 screws from the coffee bean container, and take the coffee bean contai...

Page 43

41 repair 4.2.2 disassemble power cord 1. Disassemble left side section according to the direction of the arrow 1. Refer to 4.2.1- disassemble the exterior parts of the machine 4.2.1.7 disassemble left cover 1 2. Disassemble 2 screws from the cable rack 3. Disassemble 1 screw from support, loose 3 s...

Page 44

42 repair 4.2.3 disassemble brew unit 1. Refer to 4.2.1- disassemble exterior parts of the machine 2. Disassemble 3 screws, and take out frame support 3. Pull out silicon pipe from brew unit 2 3 4. Disassemble 3 screws from brew unit 4 4 5. Pull the brewing unit outward and rotate the gear clockwise...

Page 45

43 1. Refer to 4.2.1-disassemble exterior parts repair 4.2.4 disassemble valve support group 2. Take out valve support according to the direction of the arrow and pull out silicon pipe note : there are 4 hooks between valve support and base 2 4.2.5 disassemble flowmeter 1. Refer to 4.2.1- disassembl...

Page 46

44 repair 4.2.6 disassemble solenoid valve group 1. Refer to 4.2.1-disassemble exterior parts 2. Disassemble hooks from support 3. Pull out terminal and silicon pipe and take out solenoid valve group 2 3 4.2.7 disassemble grinder group 1. Refer to 4.2.1.1-4.2.1.6-disassemble top cover 2. Disassemble...

Page 47

45 2. Pull out two silicon pipes from the dispenser valve on the right side of the machine 3. Pull out two silicon pipes from the left side of the machine 4. Disassemble 5 cable racks 5. Pull out terminal on pcba which connected to control panel 4 5 6. Disassemble 2 screws from the support 7. Disass...

Page 48

46 note:there is one hook between the dispenser valve and base repair 4.2.9 disassemble dispenser valve group 1. Refer to 4.2.1.1-4.2.1.4-disassemble right side section 2. Disassemble 1 screw from dispenser valve 3w so that the wire can be taken out from the cable rack 3. Pull out dispenser valve te...

Page 49

47 note:there is a sealing element left at the bottom after taking out drainage valve group 3. Disassemble 1 screw from dispenser valve 3w, so that the wire can be taken out from the cable rack 4. Pull out terminal from stepper motor on pcba 3 4 5. Pull out teflon pipe between dispenser valve 2w and...

Page 50

48 2 3 4. Take out all of line pencil from cable rack, disassemble 3 screws from cable rack and take out cable rack 5. Pull out silicon pipe on condensator that connected to pump 4 5 7. Pull out pump clamp from the support and take out pump group 6 1. Refer to 4.2.1.1-4.2.1.4-disassemble right side ...

Page 51

49 2. Pull out all the terminals on pcba 3. Disassemble 4 screws on pcba, and take out pcba 2 3 1. Refer to 4.2.1.1-4.2.1.4-disassemble right side section repair 4.2.12 disassemble pcba 1 2. Disassemble 1 screw 3. Pull out teflon pipe on dispenser valve 2w that connected to pump, and take out dispen...

Page 52

50 service manual intelligent fresh ground coffee machine klm1601 2. Disassemble 1 screw from dispenser valve 3w 3. Pull out 3 teflon pipes which connected to dispenser valve 3w, and take out dispenser valve 3w 2 3 1. Refer to4.2.1.1-4.2.1.4-disassemble right side section 4.2.14 disassemble dispense...

Page 53

51 5. Move dispenser valve group , and pull out teflon pipe which connected thermoblock 5 6. Move dispenser valve group , and pull out teflon pipe which connected thermoblock 7. Disassemble hooks from support, and take out thermoblock group 6 7 1 1. Refer to4.2.1.1-4.2.1.4-disassemble top cover 4.2....

Page 54

52 4. Disassemble 2 screws from support and take out geared motor group 4 1 repair service manual intelligent fresh ground coffee machine klm1601.

Page 55

Repair 4.3 precautions for maintenance and installation 1. Disassemble the spool gear group according to the arrow direction 2. Disassemble the wiper, notice the hooks showed by the arrow 4.3.1 brew unit group 1 2 3. Disassemble the 4 screws from the left and right cover 3 3 4. Disassemble 4 hooks f...

Page 56

Service manual intelligent fresh ground coffee machine klm1601 54 repair 5. Disassemble five hooks at the back of the left and right cover , and take out the left and right cover 6. Take out connect part and reset base 5 6 7. Take out left and right pull plate and pull plate sleeve 8. Rotate the gea...

Page 57

Repair 11. Deform brew unit frame with strength according to the arrow direction, and take out coffee brewing group 11 12. Disassemble release link , and take out piston 12 13. Disassemble the screw from contropistone, and take out filter screen 13 14. Disassemble seal from contropistone 14 note: th...

Page 58

Repair 1. Take out 2 screws from dispenser valve 2. Loose the hook , and separate gear box for dispenser valve from the water dispenser box 4.3.2 dispenser valve 6w 1 2 3. Disassemble the 2 screws from the dispenser valve 3 4. Take out water distributor and get out ceramic plate sheet gasket 4 1 1 1...

Page 59

Repair 5. Take out the top cover of the dispenser valve 5 6. Separate dispenser valve from sheave permanent seat, take out sheave and disassemble microswitch. 6 7. Take out the sheave and disassemble the microswitch 7 note: when installing, the microswith with two lines should be in the upside and t...

Page 60

4.3.3 grinder group repair 8. Disassemble the hook on gear box lid, and take out gear box lid 9. Take out dispenser valve gear a and dispenser valve gear b 8 9 10. Disassemble 2 screws inside the gear box, and take out the motor for dispenser valve 10 1. Disassemble the 3 hooks from the grinder adju...

Page 61

Repair 3. Disassemble the three hooks from the motor support for grinder, and take out the grinder adjustment ring 4. Disassemble 1 middle screw 3 4 5. Take out the line pencil and conical burr group 6. Take out 1 screw from the coffee powder hopper 5 6 7. Disassemble 3 screws from grinder support, ...

Page 62

Repair 9. Take out the 3 hooks from the gearbox, and then take out the coffee powder container 10. Disassemble steel ball support and 34 pcs steel ball 9 10 11. Take out the epicyclic gear group b 12. Take out filler piece and the epicyclic gear group a 11 12 13. Disassemble the 2 screws inside the ...

Page 63

Repair 1. Take out foam rubber group 2. Pull out the rotary according to the arrow direction 4.3.4 control panel group 1 2 3. Disassemble 4 screws from the backside of control panel 4. Pull out 4 screws from the backside of the control panel, and pull out the terminal, then take out the decorative p...

Page 64

Repair 7. Disassemble 4 screws from the export group, and take out the sliding group 8. Take out the led 7 8 9. Separate coffee export sliding panel and coffee export support, and take out magnet sliding panel and shell fragment magnet 10. Disassemble 1 screw inside the coffee export base, and take ...

Page 65

Repair 13. Disassemble 2 screws from the handle, and take out the handle 14. Disassemble 2 screws from the backside of the touch screen decorative cover; take out decorative plate and smokebell 13 14 15. Disassemble 2 screws from the rotary, and take out the bottom terminal, and then take out the ro...

Page 66

Repair 19. Disassemble the 2 screws at both sides of the switch support, and then take out 2 microswitch 20. Disassemble 5 screws from the hmi, pull out two terminals, and take out hmi 19 20 21. Take out silica gel, clean buttons and smokebell, and clean the power button decorative cover 22. Take ou...

Page 67

65 repair precautions for assembling 1. Assemble the drain valve support, pin, pin sleeve, pin reset spring, pin seal together as the picture shows. Pay attention to the direction of the pin seal. 2. Assemble the drainage export and pin seal together. 1 2 3. Assemble the pin seal, pin and drainage v...

Page 68

Repair 1. Press the gear pin into the hole of the gearbox, and put the dispenser valve motor to gearbox . The screws need a few loctite. 2. Install dispenser valve gear a and dispenser valve gear b into dispenser valve gearbox after coat oil(mi-setral-61b). 1 2 3. Install the gear box lid and sheave...

Page 69

67 repair 7. Install the ceramic plate a into the dispenser valve. The upper side should be the side of slot, and it should be covered with oil(syn-setral-al/c 2-fd). 8. Install the ceramic plate b into the dispenser valve. Both sides should be covered with oil((syn-setral-al/c 2-fd). 7 8 9. Install...

Page 70

Repair 13. Assemble the water distributor to the dispenser valve, and lock the screws on both sides uniformly, the head of the screws need loctite. 14. Assemble the water dispenser box and the gear box together, and then lock the screw. 13 14 1. When installing the support seal, the downside should ...

Page 71

69 repair 2. Install the coffee brewing unit into the brew unit frame, and install reset base and connect part. 2 3. Assemble the pin seal and pin together to drainage valve connection. Note: the direction of the pin seal. 4. Coating the contropistone seal with lubricating oil(syn-setral-al/c 2-fd) ...

Page 72

70 repair 7. Rotate the gear onto the brew unit frame, install the sleeve pipe, the small head of sleeve pipe should be inward. 7 8. Install the left and right pull plate and left and right cover on brew unit frame, oil (mi-setral-61b) coating position for left and right pull plate should be as the ...

Page 73

71 repair 10. Lock the left side and right side cover screws. 10 10 11. Install wiper and spool gear group. 11 1. When installing microswitch and power microswitch support, please pay attention to the connection position between microswitch and connector. 2. When installing silicon pipe, please note...

Page 74

72 repair 1. When install the ntc on the thermoblock, cover ntc with silicone grease and fasten it. 1 1. Assemble the grinder motor and gearbox together, and screw them tightly. The screw should be covered with loctite. The teeth of the gearbox should be coated with oil(mi-setral-61b). The red mark ...

Page 75

Repair 4. Put the already installed epicyclic gear frame a into the gearbox, put 1 filler piece onto epicyclic gear frame a. 5. Put the already installed epicyclic gear frame b into gearbox. 4 5 6. Put the steel ball support and 34 roll steel ball into gearbox. 7. Install 3 grinder antivibration pad...

Page 76

Repair 10. Insert the already installed grinder motor in the grinder support, and lock screws. 11. Install the coffee powder hopper on the coffee powder container, and lock the screw. 10 11 12. Install 3 spring sleeves into the hole of the support lower grinder. 13. Install the screw pin worm drive ...

Page 77

Repair 16. Put the already installed support lower grinder into the coffee powder container and lock the screw. 17. Install the grinding adjustment spring and steel ball into the coffee powder container pillar. 16 17 18. Install the grinder adjustment ring in the motor support for grinder. 19. Assem...

Page 78

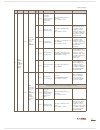

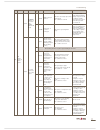

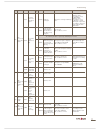

1. Empty tray 2. Dissolve decalcifier in the clean water, and pour into the water tank- the water inside the water tank should be half of the water tank. 2 function test and maintenance methods 5. Function test and maintenance methods 5.1 function test and test standards 5.2 coffee machine maintenan...

Page 79

2 3. Press rotary for 3 seconds to enter in the program menu, rotate the rotary to maintaince. 4. Enter in decalcifying program and operation as the screen displays ( put a container which is over than 1l under the coffee export ) . 5. After the first cleaning, take out water tank and pour the rest ...

Page 80

78 5.2.2 rinse the brew unit 1.When machine in ready state, press rotary for 3 seconds to enter in the program menu, rotate the rotary to maintaince. 2. Press the rotaryl to enter the coffee machine maintenance menu, jog shuttle dial to " clean brew unit " page. 3. Press the rinse button to confirm ...

Page 81

79 1 1 1 1 2 2. Clean water tank clean water tank by flowing water. Function test and maintenance methods 5.2.4 wipe the coffee machine power off and pull out plug before clean the inside machine. Do not put the machine in the water to avoid electric shock do not use metal object to clean the machin...

Page 82

3 4 5 5 function test and maintenance methods 3. Clean coffee bean container and the hopper use dry rag or tissue clean rest oil inside bean container. Do not use water to wash bean container. 4. Clean hopper use dry rag clean the channel of hopper. Do not use water to wash hopper channel. 5. Clear ...

Page 83

6 7 1 1 2 3 81 function test and maintenance methods 6. Clean the internal machine clean base 7. Clean coffee machine. Use dry and soft rag to clean the appearance of the coffee machine. Clean brew unit-coffee brewing box( position 1) and contropistone( position 3 and position 2 is the back side).

Page 96

Suzhou industrial park kalerm electric appliances co., ltd www.Kalerm.Com +86-4006-800-866 add: #100 sumu rd, sip suzhou,215021,jiangsu china t e l : +86-512-68180758 fax: +86-512-68181050