- DL manuals

- Kalmar

- Tractor

- Ottawa t2

- Maintenance Manual

Kalmar Ottawa t2 Maintenance Manual

Summary of Ottawa t2

Page 2

Maintenance manual ottawa t2 4x2 a. Foreword ........................................................................................................................... 1 about this manual ................................................................................................... 1 additiona...

Page 3

Maintenance manual ottawa t2 4x2 vehicle serial number ..................................................................................... 32 engine serial number ..................................................................................... 32 component location ..............................

Page 4

Maintenance manual ottawa t2 4x2 trailer brake air lines ................................................................................................ 53 description ................................................................................................. 53 anti-lock brake system (option...

Page 5

Maintenance manual ottawa t2 4x2 windshield wipers ...................................................................................................... 86 description ................................................................................................. 86 diagnosis .......................

Page 6

Maintenance manual ottawa t2 4x2 cab tilt pump and motor .......................................................................................... 106 diagnosis (cab tilt pump) ....................................................................... 106 repair (pump and motor removal) .................

Page 7

Maintenance manual ottawa t2 4x2 common pneumatics ....................................................................................................... 137 air system and brakes ................................................................................................. 137 description ........

Page 8

Maintenance manual ottawa t2 4x2 differential axle lock option circuit ......................................................... 169 additional 7.35 cu. In. Air reservoir ......................................................................... 170 air lines — additional 7.35 cu. In. Air reservoir o...

Page 9

Maintenance manual ottawa t2 4x2 air system tank pressure senders ......................................................... 218 battery power distribution ........................................................................ 219 cab tilt system control wiring ........................................

Page 10: A. Foreword

– a. Foreword 1 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm a. Foreword page – about this manual this service manual covers the ottawa t2 4x2 and 6x4 termi- nal (yard) tractors produced by kalmar solutions llc, kalmar terminal tractors. You will find here descriptions of the fea- tures, locat...

Page 11

2 – a. Foreword maintenance manual ottawa t2 4x2 • trw steering components - www.Trw.Com • chelsea pto - www.Chelseaproduct.Com • parker hydraulic pump - www.Parker.Com • cab tilt pump - www.Bucherhydraulics.Com • denso starter - www.Densoheavyduty.Com • remy alternator - www.Delcoremy.Com • bostrom...

Page 12: B. Safety

– b. Safety 3 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm b. Safety page – hazardous condition signs the following signs accompanied by an explanation are used to advise the reader of the degree of hazard associated with the procedure being described. Note information that is important withou...

Page 13: Do’S and Dont’S

4 – b. Safety maintenance manual ottawa t2 4x2 page – do’s and dont’s • do use care when removing the radiator filler cap. When the engine is hot, rotate the cap to the first detent, allow the pressure to dissipate and then remove it. • do stay clear when lowering the cab. • do set the parking brake...

Page 14: C. Preventive

0.1 lubrication points – c. Preventive maintenance 5 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm c. Preventive maintenance 0.1 lubrication points page – lubrication points chassis lubrication diagram — left-hand drive 1. Coolant/antifreeze 2. Engine oil 3. Slack adjusters brake cam pivot 4. F...

Page 15: 0.2 Inspections

6 0.2 inspections – c. Preventive maintenance maintenance manual ottawa t2 4x2 0.2 inspections page – every day perform the inspections listed in the daily inspection checklist on page 7 and page 8. At each inspection, add fluids and lubricants as indicated. Re- pair all leaks. Replace cracked, dama...

Page 16: 0.3 Checklists

0.3 checklists – c. Preventive maintenance 7 maintenance manual ottawa t2 4x2 0.3 checklists page – page – daily inspection checklist ❒ fuel tank ❒ engine oil level (engine stopped) ❒ coolant level ❒ windshield washer fluid level (if applicable) ❒ fuel water separator ❒ transmission fluid level (eng...

Page 17

8 0.3 checklists – c. Preventive maintenance maintenance manual ottawa t2 4x2 ❒ clean the cab interior. ❒ clean the windows. ❒ clean and adjust the mirrors..

Page 18: Daily Inspection Form

0.3 checklists – c. Preventive maintenance 9 maintenance manual ottawa t2 4x2 daily inspection form daily inspection form truck # ________________ driver name __________________________________________ date _____________ perform the following complete complete complete l e v e l l i o k n a t c i l ...

Page 19

10 0.3 checklists – c. Preventive maintenance maintenance manual ottawa t2 4x2 page – preventive maintenance forms preventative maintenance form – non-synthetic transmission lubrication kalmar terminal tractor preventative maintenance form non-synthetic (non – tes-295) lube used in the transmission ...

Page 20

0.3 checklists – c. Preventive maintenance 11 maintenance manual ottawa t2 4x2 preventative maintenance form – synthetic transmission lubrication with high capacity filters kalmar terminal tractor preventative maintenance form synthetic (tes-295) lube and allison high-capacity filters used in the tr...

Page 21: 0.4 Preventive

12 0.4 preventive maintenance technique – c. Preventive maintenance maintenance manual ottawa t2 4x2 0.4 preventive maintenance technique page – general the following is more detailed information for preventive main- tenance. See the lubrication points page 5 provided in this manual. Refer to the pr...

Page 22

0.4 preventive maintenance technique – c. Preventive maintenance 13 maintenance manual ottawa t2 4x2 0.4.2 cab interior page – maintenance check operation of neutral start — move the gear selec- tor to any position other than "n" and attempt to start the engine. The engine should not crank with the ...

Page 23

14 0.4 preventive maintenance technique – c. Preventive maintenance maintenance manual ottawa t2 4x2 • defroster operation with the engine running and the defroster control turned on, confirm air flow from the defroster vents. • air conditioner operation with the engine running and the air condition...

Page 24

0.4 preventive maintenance technique – c. Preventive maintenance 15 maintenance manual ottawa t2 4x2 inspect latch for proper operation by inserting into buckle. Latch must insert smoothly and you must hear an audible click. Verify proper latching by tugging on belt. Latch must not be worn, deformed...

Page 25

16 0.4 preventive maintenance technique – c. Preventive maintenance maintenance manual ottawa t2 4x2 check trailer light cord (if applicable) — inspect light cord for cuts and abrasions. As the lights of the truck are checked confirm that a trailer connected with the light cord also has lights. This...

Page 26

0.4 preventive maintenance technique – c. Preventive maintenance 17 maintenance manual ottawa t2 4x2 check coolant level and concentration — check cool- ing system level. Coolant should be visible in radiator sight glass. It is not necessary for the coolant to be at the top of the sight glass. Test ...

Page 27

18 0.4 preventive maintenance technique – c. Preventive maintenance maintenance manual ottawa t2 4x2 0.4.5 under vehicle page – maintenance check steering gear — inspect steering gear for fluid leaks and excessive play. Inspect the steering linkage for wear or looseness. Check brake linings and drum...

Page 28

0.4 preventive maintenance technique – c. Preventive maintenance 19 maintenance manual ottawa t2 4x2 check differential oil level — check the differential oil level per the component manufacturer's instructions. Change differential oil — drain and replace differential oil. Use oil meeting, at least,...

Page 29

20 0.4 preventive maintenance technique – c. Preventive maintenance maintenance manual ottawa t2 4x2 inspect platforms — inspect the platforms for proper mounting and the absence of cracks and trip points. Check frame for cracks — inspect frame rails and cross- members for cracks and bending. Check ...

Page 30

0.4 preventive maintenance technique – c. Preventive maintenance 21 maintenance manual ottawa t2 4x2 check/lubricate 5th wheel top plate — clean and in- spect the 5th wheel top plate for cracks or other damage. Apply lithium grease to the surface of the top plate. Check/lubricate 5th wheel pivot pin...

Page 31

22 0.4 preventive maintenance technique – c. Preventive maintenance maintenance manual ottawa t2 4x2.

Page 32: 0. Machine Complete

0.1 the ottawa t2 terminal tractor – 0. Machine complete 23 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 0. Machine complete 0.1 the ottawa t2 terminal tractor page – description the ottawa t2 terminal tractor by kalmar is designed to suit the operator and the tasks. Ottawa t2 tractors are pur...

Page 33: 0.2

24 0.2 diesel fuel requirements – 0. Machine complete maintenance manual ottawa t2 4x2 0.2 diesel fuel requirements page – precautions use only the fuel specified by the engine manufacturer. Improp- er fuel can result in corrosion, damaging deposits and prema- ture wear. Avoid using smoke suppressan...

Page 34

0.2 diesel fuel requirements – 0. Machine complete 25 maintenance manual ottawa t2 4x2 the following are other common names used for def: • urea • aus 32 (aqueous urea solution 32) • adblue • nox reduction agent • catalyst solution regardless of what the diesel exhaust fluid is called, the die- sel ...

Page 35: 0.3 Emergency

26 0.3 emergency starting – 0. Machine complete maintenance manual ottawa t2 4x2 0.3 emergency starting page – precautions when jump starting one vehicle from another, both electrical systems must have the same voltage rating and polarity. Due to the higher torque requirements for starting diesel en...

Page 36: W A R N I N G

0.3 emergency starting – 0. Machine complete 27 maintenance manual ottawa t2 4x2 7. Remove the jumper cables by reversing the above installa- tion sequence exactly. While removing each clamp be sure that it does not touch any other metal while connected to the other battery. W a r n i n g batteries ...

Page 37: 0.4 Vehicle

28 0.4 vehicle towing – 0. Machine complete maintenance manual ottawa t2 4x2 0.4 vehicle towing page – precautions use proper equipment to prevent damage to vehicles during towing. Conform to applicable state and local laws for towing vehicles. Vehicles should not be towed at speeds in excess of 55 ...

Page 38

0.4 vehicle towing – 0. Machine complete 29 maintenance manual ottawa t2 4x2 when the vehicle has arrived at its destination, ensure it is safely positioned. 1. Block the rear wheels. 2. Install the axle shafts. 3. Remove the covers from the hub openings. 4. Align the universal joints and connect th...

Page 39: 0.5 Vehicle

30 0.5 vehicle modifications – 0. Machine complete maintenance manual ottawa t2 4x2 0.5 vehicle modifications page – approval do not modify your ottawa t2 tractor without approval in writing from kalmar solutions llc, kalmar terminal tractors. Unau- thorized modifications may void the vehicle warran...

Page 40: 0.6 Vehicle

0.6 vehicle identification – 0. Machine complete 31 maintenance manual ottawa t2 4x2 0.6 vehicle identification page – identification plate a vehicle may be specifically identified by referring to the vehicle identification plate. The plate is located inside the cab on the top corner of the rear doo...

Page 41

32 0.6 vehicle identification – 0. Machine complete maintenance manual ottawa t2 4x2 – vehicle serial number the serial number is located on top of the left frame rail inboard of the cab air spring (above the rear spring hanger) and also on the identification plate (see page 31). Always refer to thi...

Page 42: 0.7 Component

0.7 component location – 0. Machine complete 33 maintenance manual ottawa t2 4x2 0.7 component location 0.7.1 chassis/cab, left side page – ottawa t2, left side (4x2 hhd chassis shown) 1. Cab air ride air spring 2. Height control valve assembly 3. Cab tilt switch 4. Boom lift cylinder upper mount 5....

Page 43

34 0.7 component location – 0. Machine complete maintenance manual ottawa t2 4x2 12. Tow hook 13. Fuel tank 0.7.2 chassis/cab, right side page – ottawa t2, right side (4x2 hhd chassis shown) 1. Fifth wheel pivot 2. Boom lift cylinder upper mount 3. Vertical muffler and exhaust pipe 4. Tow hook 5. Ca...

Page 44

0.7 component location – 0. Machine complete 35 maintenance manual ottawa t2 4x2 0.7.3 chassis/cab, front/rear page – ottawa t2, front/rear (4x2 hhd chassis shown) 1. Front panel (removable) 2. Rear door 3. Glad hands (air brake) 4. Trailer electrical connector (7-pin) 5. Air brake chambers 6. Fifth...

Page 45

36 0.7 component location – 0. Machine complete maintenance manual ottawa t2 4x2 0.7.4 chassis, plan view page – ottawa t2 plan view (4x2 hhd chassis shown) 1. Fifth-wheel boom 2. Hydraulic fluid tank 3. Hydraulic fluid filter 4. Air tank, service (air brakes) 5. Battery box 6. Boom pivot 7. Fuel fi...

Page 46: 0.8 Electrical

0.8 electrical instruments – 0. Machine complete 37 maintenance manual ottawa t2 4x2 0.8 electrical instruments page – guide to troubleshooting this guide is provided for diagnosis of problems in kalmar elec- trical instruments. The sequence presented is intended to min- imize duplication. Follow th...

Page 47

38 0.8 electrical instruments – 0. Machine complete maintenance manual ottawa t2 4x2.

Page 48: 1 Engine

– 1 engine 39 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 1 engine page – description the ottawa t2 yard tractor is designed to utilize the benefits of a diesel engine of the type customarily found in fire engines, dump trucks and refuse haulers. Engine options are provided for off-highway an...

Page 49: 1.1

40 1.1 controls and instruments – 1 engine maintenance manual ottawa t2 4x2 1.1 controls and instruments 1.1.7 fuel gauge page – diagnosis fuel gauge components • cab accessory circuit breaker • gauge cluster • fuel level sending unit • headlight switch • ignition switch • panel dimmer switch (optio...

Page 50: 1.2

1.2 fuel system – 1 engine 41 maintenance manual ottawa t2 4x2 1.2 fuel system 1.2.1 fuel tank page – description fuel tank and fittings brackets bolted to the rail hold the 50-gallon (190 liter) rectan- gular step fuel tank. Two-inch (51 mm) wide straps secure the tank to the two mounting brackets....

Page 51: 1.3

42 1.3 diesel exhaust fluid (def) – 1 engine maintenance manual ottawa t2 4x2 1.3 diesel exhaust fluid (def) 1.3.1 def tank and pump page – description def tank the def tank is locate on the left side of the tractor at the rear of the fuel tank. It is a 5-gallon size tank constructed of cross-link p...

Page 52: 1.11 Start/stop

1.11 start/stop – 1 engine 43 maintenance manual ottawa t2 4x2 1.11 start/stop page – diagnosis (starting and charging diagnosis) components • alternator • batteries • ignition switch • starter • starter relay • starter solenoid starting and charging circuit diagnosis observation cause action batter...

Page 53

44 1.11 start/stop – 1 engine maintenance manual ottawa t2 4x2.

Page 54: 2 Transmission

– 2 transmission 45 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 2 transmission page – description the standard transmission is an automatic allison, rds series. For service and maintenance information, consult the manuals included with your vehicle, contact the kalmar dealer or the manufactur...

Page 55

46 – 2 transmission maintenance manual ottawa t2 4x2.

Page 56: 3 Driveline/axle

– 3 driveline/axle 47 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 3 driveline/axle page – description an ottawa t2 tractor will be equipped with one of several man- ufacturer’s rear axles. Special features, such as a locking or a “no-spin” differential, are optional. Contact your kalmar deale...

Page 57

48 – 3 driveline/axle maintenance manual ottawa t2 4x2.

Page 58: 4 Brakes

4.1 controls and instruments – 4 brakes 49 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 4 brakes 4.1 controls and instruments 4.1.1 foot pedal (treadle valve) page – description this foot-actuated valve is actually two valves that operate in quick sequence. It is connected in the front and rea...

Page 59: 4.3 Brake

50 4.3 brake system – 4 brakes maintenance manual ottawa t2 4x2 4.3 brake system page – description major components of the air brake system include the following items. • air compressor and governor • air control valves • air dryer (optional) • air reservoirs (air storage) • brake chambers and park...

Page 60

4.3 brake system – 4 brakes 51 maintenance manual ottawa t2 4x2 4.3.1 air compressor and governor page – description air compressor governor pressure is supplied by a reciprocating piston-type compressor mounted on the engine. The compressor shares engine lubri- cation and coolant systems. Running c...

Page 61

52 4.3 brake system – 4 brakes maintenance manual ottawa t2 4x2 4.3.10 brakes page – description brake chambers and parking brakes — in the front are two single chamber units at the wheel ends. These operate the foundation brakes described below. In the rear are two dual chamber units at the wheel e...

Page 62

4.3 brake system – 4 brakes 53 maintenance manual ottawa t2 4x2 4.3.11 trailer brake air lines page – description trailer electrical connector and brake hoses coiled service (blue) and supply (red) lines provide trailer brak- ing controls. Both air lines must be connected in order to re- lease the t...

Page 63: D A N G E R

54 4.3 brake system – 4 brakes maintenance manual ottawa t2 4x2 4.3.15 automatic traction control (optional) page – description some vehicles that are equipped with abs may also be equipped with full-time automatic traction control (atc). The atc indicator lamp blinks when atc is working. Atc uses t...

Page 64: C A U T I O N

4.3 brake system – 4 brakes 55 maintenance manual ottawa t2 4x2 internal caging tool the following steps can be used to release the standard brake chambers used on most kalmar tractors. If your vehicle is equipped with other optional brake chambers, refer to that manufacturer’s operation or service ...

Page 65: 4.9 Diagnosis

56 4.9 diagnosis (mechanical) – 4 brakes maintenance manual ottawa t2 4x2 4.9 diagnosis (mechanical) page – brakes components • brake drums • brake shoes brakes — mechanical diagnosis observation cause action pulls to one side brakes out of adjustment adjust slack adjusters. Poor front end alignment...

Page 66

4.9 diagnosis (mechanical) – 4 brakes 57 maintenance manual ottawa t2 4x2 slow release treadle valve return slowed by dirt and grime clean and lubricate as needed. Poor adjustment or poor lubrication inspect. Adjust or lubricate as needed. Air line(s) restricted inspect. Repair or replace as need- e...

Page 67

58 4.9 diagnosis (mechanical) – 4 brakes maintenance manual ottawa t2 4x2 no pressure buildup refer to brake air system diagno- sis table. Low air pressure warning pressure drops quickly: engine stopped, brakes applied pressure drops: engine stopped, brakes applied pressure does not reach normal pre...

Page 68: 5 Steering

5.2 steering system – 5 steering 59 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 5 steering 5.2 steering system page – description (power steering components) the standard power steering system uses an integral power steering gear and the transmission-mounted hydraulic pump. The system operate...

Page 69: 5.3

60 5.3 diagnosis (power steering) – 5 steering maintenance manual ottawa t2 4x2 5.3 diagnosis (power steering) page – power steering components • power steering gear • power steering pump • reservoir the following guide covers symptoms that may be remedied by adjustments outside of the steering gear...

Page 70

5.3 diagnosis (power steering) – 5 steering 61 maintenance manual ottawa t2 4x2 c. Close the flow valve on the steering analyzer and record the pressure _________ psi. The pressure needs to be 2100 to 2200 psi at pump relief. D. If pump pressure is less than 2100 psi, the pressure relief on the pump...

Page 71

62 5.3 diagnosis (power steering) – 5 steering maintenance manual ottawa t2 4x2 • 1/2” end wrench • allen wrench 5/16”.

Page 72: 5.4 Diagnosis

5.4 diagnosis (hydrostatic steering) – 5 steering 63 maintenance manual ottawa t2 4x2 5.4 diagnosis (hydrostatic steering) page – hydrostatic steering hydrostatic steering is optional. Components • orbital control valve • power steering pump • steering cylinders • reservoir the following guide cover...

Page 73

64 5.4 diagnosis (hydrostatic steering) – 5 steering maintenance manual ottawa t2 4x2.

Page 74: 6 Suspension

– 6 suspension 65 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 6 suspension page – description (vehicle suspension) leaf spring suspension the front suspension consists of parabolic leaf springs. There are 3 steel leaves on each side. Rubber blocks mounted on each axle reduce the shock of bott...

Page 75: 6.2 Front

66 6.2 front springs – 6 suspension maintenance manual ottawa t2 4x2 6.2 front springs page – repair (springs removal) 1. Park the vehicle on level ground and chock the rear wheels. 2. Raise the front of the vehicle high enough to relieve all ten- sion on the front springs while allowing the front w...

Page 76: 7 Load

7.2 lift and lower – 7 load handling 67 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 7 load handling 7.2 lift and lower page – description (boom components) elevated boom with fifth wheel 1. Boom pivot 2. Boom 3. Boom lift cylinder pivots 4. Fifth-wheel pivot 5. Fifth-wheel plate the standard ...

Page 77

68 7.2 lift and lower – 7 load handling maintenance manual ottawa t2 4x2 7.2.1 boom lift cylinders page – description the standard configuration utilizes two 4-inch (100 mm) diam- eter lift cylinders with a capacity of 48,500 pounds (22,000 kg) and a lifting height of 17.7 inches (450 mm). The cylin...

Page 78: 7.11 Diagnosis

7.11 diagnosis (boom) – 7 load handling 69 maintenance manual ottawa t2 4x2 7.11 diagnosis (boom) page – diagnosis components • boom lift cylinders • control valve • filter • hydraulic pump • hydraulic relief valve • reservoir • wet line kit connection maximum pressure — hydraulic relief valve boom ...

Page 79

70 7.11 diagnosis (boom) – 7 load handling maintenance manual ottawa t2 4x2 – hydraulic pump with priority valve tests – boom issue – boom slow to lift 1. Check control valve pressure setting. A. Install 3000 psi pressure gauge at the test port in the cyl- inder hose bulkhead fitting located at the ...

Page 80

7.11 diagnosis (boom) – 7 load handling 71 maintenance manual ottawa t2 4x2 – issue – boom not lifting 1. Check that the fifth wheel control valve cable is operating freely. 2. Check for full movement of control valve lever. 3. Install a flow meter or steering analyzer between the pump and the contr...

Page 81

72 7.11 diagnosis (boom) – 7 load handling maintenance manual ottawa t2 4x2.

Page 82: 8 Control

– 8 control system 73 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 8 control system page – introduction - general information not available..

Page 83

74 – 8 control system maintenance manual ottawa t2 4x2.

Page 84: 9 Frame, Body, Cab and

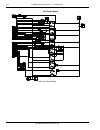

9.1 controls and instruments – 9 frame, body, cab and accessories 75 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 9 frame, body, cab and accessories 9.1 controls and instruments page – 4 30 32 31 33 1 2 3 5 6 7 9 10 11 12 8 22 25 27 13 14 14 21 29 23 24 28 26 18 17 16 15 20 19.

Page 85

76 9.1 controls and instruments – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 s=standard a=assigned options u=unassigned options pos name standard dot/epa tractor off-highway tractor 1 air diffuser s s 2 radio a a 3 main gauge panel s s 4 headlight switch s s 5 dimmer switch ...

Page 86

9.1 controls and instruments – 9 frame, body, cab and accessories 77 maintenance manual ottawa t2 4x2 description left dash panel gauges, controls and indicators appear in four panels in front and to the side of the driver as shown. The left dash panel and main gauge panel are mounted in front of th...

Page 87

78 9.1 controls and instruments – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 main gauge panel main gauge panel — displays the following gauges and indi- cator lights. • gauges 1. Def gauge, dot tractors only volt meter, off-highway only 2. Speedometer 3. Fuel gauge 4. Rear b...

Page 88

9.1 controls and instruments – 9 frame, body, cab and accessories 79 maintenance manual ottawa t2 4x2 center dash panel — displays the following gauges, controls and indicators. Center dash panel • controls – fan speed control – mode selector – temperature control – air recirculation switch – air co...

Page 89

80 9.1 controls and instruments – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 driver controlled differential lock driver controlled differential lock if equipped, the driver controlled differential lock control rock- er switch is located on the right dash panel. Turn signal, ...

Page 90

9.1 controls and instruments – 9 frame, body, cab and accessories 81 maintenance manual ottawa t2 4x2 9.1.36 low air warning page – diagnosis the vehicle will be equipped with one of two air braking sys- tems. Vehicles that travel on the roads are made to comply with the regulations in federal motor...

Page 91

82 9.1 controls and instruments – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.1.39 speedometer page – diagnosis the speedometer may include an optional connection to the pulse generator. Components • cab accessory circuit breaker • gauge cluster • headlight switch • ignitio...

Page 92

9.1 controls and instruments – 9 frame, body, cab and accessories 83 maintenance manual ottawa t2 4x2 9.1.41 voltmeter page – diagnosis components • cab accessory circuit breaker • circuit breaker • headlight switch • ignition switch • panel dimmer switch (optional) • gauge cluster voltmeter circuit...

Page 93: 9.3 Seating

84 9.3 seating – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.3 seating page – description the tractor is fitted with a seat suspended on an air spring. The firmness of the ride is adjusted by changing the air pressure. Driver's seat — side view seat height adjusts by changi...

Page 94: 9.4

9.4 heating, ventilation and air conditioning – 9 frame, body, cab and accessories 85 maintenance manual ottawa t2 4x2 9.4 heating, ventilation and air conditioning page – description a heater is standard equipment. Air conditioning is optional. Air diffusion is provided through ducts in the instrum...

Page 95: 9.5

86 9.5 wiping and cleaning of windows – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.5 wiping and cleaning of windows 9.5.1 windshield wipers page – description the windshield wiper is electrically driven. A rotary switch on the instrument panel also controls its operating s...

Page 96

9.5 wiping and cleaning of windows – 9 frame, body, cab and accessories 87 maintenance manual ottawa t2 4x2 9.5.4 windshield washer page – description a windshield washer system is an available option. Page – diagnosis the windshield washer is optional equipment. Components • accessory relay • ignit...

Page 97: 9.6 Lighting

88 9.6 lighting system – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.6 lighting system page – description kalmar provides a dome light, instrument panel lighting, head- lights, marker lights and a trailer electrical connector with circuit breakers. A work area floodlight an...

Page 98

9.6 lighting system – 9 frame, body, cab and accessories 89 maintenance manual ottawa t2 4x2 9.6.3 clearance, marker and tail lights page – diagnosis clearance and marker lights are standard only on vehicles as- sembled to meet fmvss and cmvss requirements. Trailer marker and trailer tail light circ...

Page 99

90 9.6 lighting system – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.6.4 brake lights page – diagnosis components • brake light switch • flasher circuit breaker 30a • stop/tilt circuit breaker 20a • trailer circuit breakers 15a • turn signal flasher • turn signal switch • t...

Page 100

9.6 lighting system – 9 frame, body, cab and accessories 91 maintenance manual ottawa t2 4x2 9.6.5 backup light page – diagnosis this circuit may contain an optional circuit breaker between the accessories relay and the flood light switch/backup flood relay. Components • accessory relay • backup ala...

Page 101

92 9.6 lighting system – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.6.6 turn signal page – diagnosis components • brake light switch • flasher circuit breaker 30a • stop/tilt circuit breaker 20a • trailer circuit breakers 15a • turn signal flasher • turn signal switch • tu...

Page 102

9.6 lighting system – 9 frame, body, cab and accessories 93 maintenance manual ottawa t2 4x2 9.6.8 beacon light page – diagnosis this circuit may contain an optional circuit breaker between the accessories relay and the beacon light switch. Components • accessory relay • beacon light • beacon light ...

Page 103

94 9.6 lighting system – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.6.12 daytime running lights page – diagnosis daytime running lights are optional equipment. Components • daytime running light module • headlights • ignition switch • module fuse 10a daytime running lights...

Page 104

9.6 lighting system – 9 frame, body, cab and accessories 95 maintenance manual ottawa t2 4x2 9.6.15 transmission shifter/fifth-wheel control and panel lighting page – diagnosis components • electroluminescent lamps • incandescent lamps • headlight switch • parking light circuit breaker 10a • panel d...

Page 105: 9.7 Signal

96 9.7 signal system – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.7 signal system 9.7.1 horn page – diagnosis components • horn • horn button (switch) • horn circuit breaker 15a • horn relay horn circuit diagnosis 9.7.2 emergency flasher page – diagnosis components • brake...

Page 106

9.7 signal system – 9 frame, body, cab and accessories 97 maintenance manual ottawa t2 4x2 9.7.5 backup alarm page – diagnosis this circuit may contain an optional circuit breaker between the accessories relay and the flood light switch/backup flood relay. Components • accessory relay • backup alarm...

Page 107: 9.8 Maintenance

98 9.8 maintenance and communication – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.8 maintenance and communication 9.8.1 radio page – description a radio is an available option. Page – diagnosis components • accessory relay • radio • radio circuit breaker 15a • speakers rad...

Page 108: 9.9 Glass/window/mirrors

9.9 glass/window/mirrors – 9 frame, body, cab and accessories 99 maintenance manual ottawa t2 4x2 9.9 glass/window/mirrors page – description windows and ventilation — the window in the side panel moves up and down via a regulator handle on the door. A fixed window ahead of the side panel window per...

Page 109: 9.10 Construction

100 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.10 construction and suspension of cab/deck 9.10.1 cab frame page – description ottawa 4x2 — rear view with tilted cab the cab four walls are constructed of 14-gauge steel for stre...

Page 110

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 101 maintenance manual ottawa t2 4x2 9.10.2 door page – description the rear door slides and latches in open or closed position and gives quick access to the walkway and frame decking. The ori- entation of the door in ...

Page 111

102 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.10.3 roof and door mouldings page – description the roof of the standard cab rises at an angle from the wind- shield permitting a rear door opening approximately 68 inches (1.73 m...

Page 112

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 103 maintenance manual ottawa t2 4x2 electric pump motor — cab tilt system the cab tilt system electric pump motor is mounted on the hydraulic tank. It serves only the cab’s tilting system on the tractor. Cab tilt cont...

Page 113

104 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 page – cab tilt (hydraulic) components cab tilt cylinder and safety prop the cab tilt system is an electro/hydraulic system that utilizes the tractor battery to power an electric mo...

Page 114: D A N G E R

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 105 maintenance manual ottawa t2 4x2 cab tilt control switch and lanyard a — cab tilt control switch b — safety prop release cable cab tilt safety prop — an additional mechanical safety de- vice is used to ensure that ...

Page 115: W A R N I N G

106 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.10.6 cab tilt pump and motor page – diagnosis (cab tilt pump) components • stop/tilt circuit breaker 20a • tilt pump control switch • tilt pump motor • tilt pump solenoid cab tilt...

Page 116

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 107 maintenance manual ottawa t2 4x2 1. Disconnect the negative cable from the battery. 2. Locate and disconnect the two wires (1) at the solenoid un- der the pump motor. 3. Locate and disconnect the battery cable (2) ...

Page 117

108 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 6. With the cab raised all the way up, hold the tilt control switch in the “up” position. Note the reading on the hydrau- lic pressure gauge. 7. Turn the adjusting screw in or out a...

Page 118: W A R N I N G

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 109 maintenance manual ottawa t2 4x2 9.10.7 cab tilt cylinder page – repair (cylinder removal) 1. Raise the cab using the cab tilt system. Note if unable to raise the cab using the cab tilt system due to component fail...

Page 119

110 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 8. Remove the cab tilt cylinder from the vehicle as follows: 2000 year model and newer trucks — remove the cotter key (1) from the support pin securing the lower end of the cylinder...

Page 120: W A R N I N G

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 111 maintenance manual ottawa t2 4x2 9.10.8 cab pivot bushing page – repair (pivot bushing removal) w a r n i n g make sure all safety devices are in place while the cab is in the raised position..

Page 121

112 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 1. Raise the cab to the full-tilt position and make sure the safe- ty arm is in place. 2. Remove the snaptrac ® bolts from the left front corner of the frame cross member and from t...

Page 122

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 113 maintenance manual ottawa t2 4x2 repair (pivot bushing installation) 1. Install new bushings into the cab pivot blocks. Note the bushings are a light press-fit. 2. Remove the additional blocks placed in position to...

Page 123

114 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 diagnosis (cab air suspension) components • cab leveling valve • cab shock absorbers cab leveling valve and shock absorber diagnosis 9.10.11 air ride suspension (three-point) page –...

Page 124

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 115 maintenance manual ottawa t2 4x2 – repair (cab suspension assembly installation) 1. From the inner side of the frame rail, insert bolts into the two lower suspension mounting holes. These bolts will support the sus...

Page 125

116 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 repair (air ride level adjustment) 1. Park the vehicle on firm level ground. 2. Start and run the engine until the air system has a minimum of 100 psi of air pressure. 3. Shut the e...

Page 126

9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories 117 maintenance manual ottawa t2 4x2 9.10.13 shock absorbers page – repair (shock removal) replacement of the shock absorber is necessary if the cab ride becomes too bouncy under normal operating conditions. 1. Raise t...

Page 127

118 9.10 construction and suspension of cab/deck – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 repair (shock installation) 1. Place the shock absorber in position between the mounting brackets at the side of the suspension assembly. 2. Install the 7/16-inch bolts and nuts to ...

Page 128: 9.12 Chassis

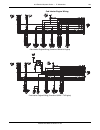

9.12 chassis – 9 frame, body, cab and accessories 119 maintenance manual ottawa t2 4x2 9.12 chassis page – description frame construction 1 2 3 4 5 6 7 8 9 10 1. Front crossmember weldment 2. Front spring hanger and bumper mount weldment with two hook (2) 3. Main rail(2) 4. Fifth-wheel boom pivot 5....

Page 129: W A R N I N G

120 9.12 chassis – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 the frame rails (3) are reinforced c channels. Front and rear crossmember weldments (1) (10) are bolted to the frame rail ends forming a box structure. A rear tie bar angle bracket (9) is bolted inside the rails b...

Page 130: W A R N I N G

9.12 chassis – 9 frame, body, cab and accessories 121 maintenance manual ottawa t2 4x2 frame diagnosis w a r n i n g do not cut the rails or holes in the rails using a weld- ing torch. Do not drill holes in top or bottom rail flanges. Failure to heed this warning may result in se- vere property dama...

Page 131

122 9.12 chassis – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 page – equipment added beyond vehicle capacity load shift (e.G., surging liquid) in a loaded trailer vehicle fire vehicle collision rails weakened by added holes, notches, extraordinary welding or cutting misalign...

Page 132: C A U T I O N

9.12 chassis – 9 frame, body, cab and accessories 123 maintenance manual ottawa t2 4x2 repair (frame damage analysis) this section is not intended to cover the causes of all possible frame problems; however, it should be of valuable assistance in preparing complete, concise reports. The purpose of t...

Page 133

124 9.12 chassis – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 4. Make reinforcements long enough so that they can be ta- pered and still extend beyond the critical area. Page – repair (making reinforcements, attachment) reinforcements must be attached with grade 8 bolts, loc...

Page 134

9.12 chassis – 9 frame, body, cab and accessories 125 maintenance manual ottawa t2 4x2 good smooth radius. If extensive damage is incurred to a cross member, the cross member should be replaced. It may be nec- essary to align the frame and level the rails before repairing the frame. The following pr...

Page 135: 9.13 Bodywork

126 9.13 bodywork – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.13 bodywork 9.13.3 footstep page – description cab access ladders and decking a two-step ladder is attached to the cab deck by the back door. In addition, three steps made from 10-gauge perforated steel are mou...

Page 136: 9.16

9.16 accessories and options – 9 frame, body, cab and accessories 127 maintenance manual ottawa t2 4x2 9.16 accessories and options 9.16.1 accessory relay page – diagnosis components • accessory circuit breakers • accessory relay • ignition switch accessory relay circuit diagnosis 9.16.2 heater/air ...

Page 137

128 9.16 accessories and options – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2 9.16.3 mirrors (heated/motorized) page – diagnosis heated and motorized (remotely controlled) mirrors are option- al equipment. Components • mirrors • mirror heat switch • motorized mirror switch (...

Page 138

9.16 accessories and options – 9 frame, body, cab and accessories 129 maintenance manual ottawa t2 4x2 inoperative motor defective wiring inspect connections and wires. Test circuits. Repair or replace as needed. Observation cause action.

Page 139

130 9.16 accessories and options – 9 frame, body, cab and accessories maintenance manual ottawa t2 4x2.

Page 140: 10 Common Hydraulics

10.3 tanks and accumulators – 10 common hydraulics 131 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 10 common hydraulics page – system description the hydraulic system of the current production ottawa tractors is composed of three subsystems. They are the boom (hoist), cab tilt and power steer...

Page 141: 10.6 Temperature

132 10.6 temperature control, cleaning and hydraulic oil – 10 common hydraulics maintenance manual ottawa t2 4x2 10.6 temperature control, cleaning and hydraulic oil 10.6.8 return filter page – description the return filter is located in the hydraulic tank, where it is con- tinuously filtering fluid...

Page 142: 11 Common Electric

11.1 controls and instruments – 11 common electric 133 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 11 common electric 11.1 controls and instruments page – description (wiring harness) the wiring harness can accommodate several items of optional equipment. Contact your dealer for information a...

Page 143: 11.2 Safety

134 11.2 safety – 11 common electric maintenance manual ottawa t2 4x2 11.2 safety 11.2.2 fuses, relays and circuit breakers page – description fuses, relays and circuit breakers — the kalmar tractor is equipped with two power boards. One power board is located in the cab under the center panel of th...

Page 144

11.2 safety – 11 common electric 135 maintenance manual ottawa t2 4x2 cab power board dash_10 pwr_pt_bat2 power_pt_ign pwr_pt_bat gauges_10 drl_10 lube_ign wipe/wash_15 hvac_30 trlr_lights_30 park_lights_10 ext_lights_25 radio/accy_15 mirrors_15 foglights_10 cab_light_10 park_lps_10 diag_10 headligh...

Page 145

136 11.2 safety – 11 common electric maintenance manual ottawa t2 4x2 chassis power board.

Page 146: 12 Common Pneumatics

12.1 air system and brakes – 12 common pneumatics 137 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm 12 common pneumatics 12.1 air system and brakes page – description the main function of the vehicle air system is to provide com- pressed air to operate the brakes. Compressed air also oper- ates...

Page 147

138 12.1 air system and brakes – 12 common pneumatics maintenance manual ottawa t2 4x2 • reservoirs (dot/epa: primary, front and rear) • stoplight switch • tractor protection valve brakes — air system diagnosis observation cause action frequent air dryer purging (cycling) excessive system leakage in...

Page 148

12.1 air system and brakes – 12 common pneumatics 139 maintenance manual ottawa t2 4x2 water in reservoirs desiccant saturated replace desiccant cartridge. Refer to medium duty truck unit repair manual. External charge air did not pass through air dryer ensure charge air enters filter valve at compr...

Page 149

140 12.1 air system and brakes – 12 common pneumatics maintenance manual ottawa t2 4x2 desiccant expelled through purge valve air dryer vibration inspect. Repair or replace as needed. Defective desiccant cartridge inspect. Repair or replace as needed. Defective compressor piston rings inspect supply...

Page 150

12.1 air system and brakes – 12 common pneumatics 141 maintenance manual ottawa t2 4x2 pressure does not reach normal reservoir drain cocks open inspect and close as needed. Excessive system leakage inspect system connections and valves. Repair or replace as needed. Poor governor adjustment inspect....

Page 151: 12.4 Valves

142 12.4 valves – 12 common pneumatics maintenance manual ottawa t2 4x2 12.4 valves page – tractor protection valves located in the circuitry between the tractor and the trailer, a special valve responds to the trailer air supply knob, or to a bro- ken trailer air line, by cutting off the air supply...

Page 152: 12.5 Air

12.5 air dryer – 12 common pneumatics 143 maintenance manual ottawa t2 4x2 12.5 air dryer page – description an air dryer for the brake system is available as optional equip- ment. In the circuit between the compressor and the reservoir, it removes water vapor from the air. It also removes any oil v...

Page 153

144 12.5 air dryer – 12 common pneumatics maintenance manual ottawa t2 4x2.

Page 154: D. Error Codes

– d. Error codes 145 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm d. Error codes page – description this section is not applicable for this vehicle. Note error codes for the engine and transmission can be found in the engine and transmission manufacturer's manuals..

Page 155

146 – d. Error codes maintenance manual ottawa t2 4x2.

Page 156: E. Schematics

0.1 air system circuits – e. Schematics 147 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm e. Schematics 0.1 air system circuits 0.1.1 air brakes page – components • abs electronic control unit • abs modulator valve • air compressor • air dryer (optional) • air pressure governor • air reservoirs...

Page 157

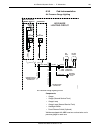

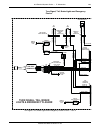

148 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 on-highway air system on-highway air system – part a cab inside cab e-7 tp-3dc pp-1 pp-7 qr-1 dc-4 quick trailer air - r14 valve option 5th wheel interlock option tractor/trailer park brake valve option trailer hand brake o...

Page 158

0.1 air system circuits – e. Schematics 149 maintenance manual ottawa t2 4x2 – on-highway air system – part b rear brakes reservoir front brakes reservoir wet tank cab air suspension qr-1c bp-r1 pr-4 air dryer option 7.35 cu. In. Reservoir option diff lock option inter axle lock option 1/2" gn 1/2" ...

Page 159

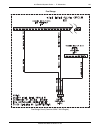

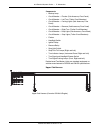

150 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 – on-highway air system circuit on-highway air system circuit – part a tractor/trailer park brake valve option abs front brakes option 5th wheel interlock option grease jockey lube pump option air horn option air dryer opti...

Page 160

0.1 air system circuits – e. Schematics 151 maintenance manual ottawa t2 4x2 on-highway air system circuit – part b – quick trailer air - r14 valve option trailer hand brake option traction control option abs rear brakes option 7.35 cu. In. Reservoir option trailer hose connection diff lock option 4...

Page 161

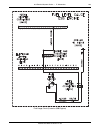

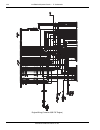

152 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 off-highway air system off-highway air system – part a cab inside cab tp-3dc e-7 qr-1 pp-1 pp-7 dc-4 quick trailer air - r14 valve option 5th wheel interlock option tractor/trailer park brake valve option trailer hand brake...

Page 162

0.1 air system circuits – e. Schematics 153 maintenance manual ottawa t2 4x2 – off-highway air system – part b qr-1 service brakes qr-1 spring brakes rear brakes reservoir front brakes reservoir cab air suspension diff lock option 3rd air tank option air dryer option 7.35 cu. In. Reservoir option in...

Page 163

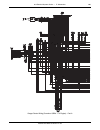

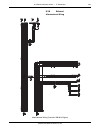

154 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 – off-highway air system circuit off-highway air system circuit – part a 5th wheel interlock option tractor/trailer park brake valve option grease jockey lube pump option 3rd air tank option air horn option air dryer option...

Page 164

0.1 air system circuits – e. Schematics 155 maintenance manual ottawa t2 4x2 off-highway air system circuit – part b trailer hose connection quick trailer air - r14 valve option trailer hand brake option 7.35 cu. In. Reservoir option diff lock option 1 2 4 psi 23 11 12 24 1-4 21 22 1 2 1 2 0 - 150 p...

Page 165

156 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.1.2 cab seating page – air lines — driver's seat components • air control valve • air reservoir • air spring the adjustable driver's seat cushion rides on an air bag. A lock- ing mechanism allows the driver to stop fore a...

Page 166

0.1 air system circuits – e. Schematics 157 maintenance manual ottawa t2 4x2 0.1.4 fifth-wheel coupling page – air lines — fifth-wheel latch air lines — fifth-wheel latch components • air control valve • air cylinder • air reservoir pressing the control valve button on the instrument panel opens the...

Page 167: Tr-3

158 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 air lines — fifth-wheel unlatch tr-3 3/8" bk 3/8" vl 3/8" vl 3/8" bl 3/8" rd 3/8" rd sup del 5th wheel unlatch sup del con.

Page 168

0.1 air system circuits – e. Schematics 159 maintenance manual ottawa t2 4x2 – 5th wheel interlock option circuit 5th wheel interlock option 5th wheel interlock option 1 2 3 3 2 1 4.

Page 169

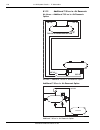

160 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.1.5 tractor/trailer park brake page – air lines — tractor/trailer park brake option air lines — tractor/trailer park brake option 3/8" bl 3/8" rd 3/8" yw 3/8" gn 3/8" oe trailer park (red) del sup exh sup del tractor park...

Page 170

0.1 air system circuits – e. Schematics 161 maintenance manual ottawa t2 4x2 – tractor/trailer park brake valve option circuit tractor/trailer park brake valve option tractor/trailer park brake valve option 12 11 3 21 22.

Page 171

162 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.1.6 quick trailer air/r14 valve page – air lines — quick trailer air/r14 valve option air lines — quick trailer air/r14 valve option tp-3dc dc-4 quick trailer air - r14 valve option 5/8" oe 5/8" gn 3/8" rd 3/8" rd 5/8" rd...

Page 172

0.1 air system circuits – e. Schematics 163 maintenance manual ottawa t2 4x2 – quick trailer air/r14 valve option circuit quick trailer air/r14 valve option 0.1.7 trailer hand brake page – air lines — trailer hand brake option air lines — trailer hand brake option quick trailer air - r14 valve optio...

Page 173

164 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 – trailer hand brake option circuit trailer hand brake option – trailer hose connection coiled air lines circuit trailer hose connection coiled air lines trailer hand brake option 3 1 11 2 12 trailer hose connection.

Page 174

0.1 air system circuits – e. Schematics 165 maintenance manual ottawa t2 4x2 – trailer hose connection glad hands both ends coiled air lines circuit trailer hose connection glad hands both ends coiled air lines – trailer hose connection straight rubber air lines circuit trailer hose connection strai...

Page 175

166 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.1.8 air horn page – air lines — air horn option air lines — air horn option – air horn option circuit air horn option air horn option 3/8" vl air horn option.

Page 176

0.1 air system circuits – e. Schematics 167 maintenance manual ottawa t2 4x2 0.1.9 inter axle lock page – air lines — inter axle option air lines — inter axle option – inter axle lock option circuit inter axle lock option inter axle lock option 3/8" vl 3/8" vl inter axle lock option 3 2 1.

Page 177

168 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.1.10 grease jockey lube pump page – air lines — grease jockey lube pump option air lines — grease jockey lube pump option – grease jockey lube pump option circuit grease jockey lube pump option grease jockey lube pump opt...

Page 178

0.1 air system circuits – e. Schematics 169 maintenance manual ottawa t2 4x2 0.1.11 differential axle lock page – air lines — differential axle lock option air lines — differential axle lock option – differential axle lock option circuit differential axle lock option diff lock 3/8" vl 3/8" vl differ...

Page 179

170 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.1.12 additional 7.35 cu. In. Air reservoir page – air lines — additional 7.35 cu. In. Air reservoir option air lines — additional 7.35 cu. In. Air reservoir option – additional 7.35 cu. In. Air reservoir option additional...

Page 180

0.1 air system circuits – e. Schematics 171 maintenance manual ottawa t2 4x2 0.1.13 air dryer page – air lines — air dryer option air lines — air dryer option air dryer option 5/8" bk 1/4" bk air comp. Resv unl.

Page 181

172 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 – air dryer option air dryer option air dryer option 2 3 4 1.

Page 182

0.1 air system circuits – e. Schematics 173 maintenance manual ottawa t2 4x2 0.1.14 abs brakes page – air lines — abs brakes option – on-highway only air lines — abs brakes option – on-highway only abs front brakes abs front brakes abs rear brakes abs rear brakes traction control option 1/2" gn 1/2"...

Page 183

174 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 – abs brake option circuit abs brake option traction control option abs rear brakes option traction control option abs front brakes option 42 41 1 2 11 2 12 r + c - h + 1 2 3 r + c - h + 1 2 3 1 2 r + c - h + 1 2 3 r + c - ...

Page 184

0.1 air system circuits – e. Schematics 175 maintenance manual ottawa t2 4x2 0.1.15 traction control page – air lines — traction control option for abs brakes – on-highway only air lines — traction control option for abs brakes – on-high- way only traction control option 3/8" gn 3/8" gn 3/8" gn.

Page 185

176 0.1 air system circuits – e. Schematics maintenance manual ottawa t2 4x2 – traction control option for use with abs brake option circuit traction control option for use with abs brake option traction control option traction control option 42 41 1 2 3 2 1.

Page 186

0.1 air system circuits – e. Schematics 177 maintenance manual ottawa t2 4x2 0.1.16 3rd air tank page – air lines — 3rd air tank option – off-highway only air lines — 3rd air tank option – 3rd air tank option circuit 3rd air tank option wet tank 3rd air tank option 5/8" bk 3/8" vl 5/8" bk 3rd air ta...

Page 187: 0.2

178 0.2 hydraulic system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.2 hydraulic system circuits page – hydraulic systems one electric motor with integral pump and one hydraulic fluid reservoir are shared by the fifth-wheel boom, cab tilt and power steering systems. Each system opera...

Page 188

0.2 hydraulic system circuits – e. Schematics 179 maintenance manual ottawa t2 4x2 0.2.2 fifth-wheel boom page – hydraulic lines — fifth-wheel boom hydraulic lines — fifth-wheel boom components • boom • control valve • hydraulic cylinders • hydraulic relief valve although engine speed controls the s...

Page 189

180 0.2 hydraulic system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.2.3 power steering page – hydraulic lines — power steering hydraulic lines — power steering system components • integral steering gear the power steering system shares the hydraulic fluid reservoir with the cab tilt...

Page 190

0.2 hydraulic system circuits – e. Schematics 181 maintenance manual ottawa t2 4x2 0.2.4 optional hydrostatic steering page – hydraulic lines — hydrostatic steering hydraulic lines — hydrostatic steering system components • orbital control valve • power steering pump • reservoir • steering cylinders...

Page 191: 0.3

182 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.3 electrical system circuits 0.3.1 starting and charging page – starting and charging circuit starting and charging circuit components • alternator • batteries • circuit breaker — ignition switch (cab accessory fus...

Page 192

0.3 electrical system circuits – e. Schematics 183 maintenance manual ottawa t2 4x2 0.3.2 cab accessory components page – wire color codes be = blue bk = black bn = brown gn = green oe = orange pe = purple pk = pink rd = red tn = tan we = white yw = yellow – anti-lock braking system (abs) for inform...

Page 193

184 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – heater and air conditioning heating and air conditioning circuits components • accessory relay #1 • air conditioner switch • cab fan (optional) • cold control (ac optional) • fan switch • fuse — hvac (cab accessory...

Page 194

0.3 electrical system circuits – e. Schematics 185 maintenance manual ottawa t2 4x2 – horn horn circuit components • circuit breaker — horn (cab accessory fuse panel) • horn • horn button • horn relay the horn operates independently of the ignition switch. – ott0037 remove positive stud cab acc fuse...

Page 195

186 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 mirrors heated (optional) heated mirror circuit components • circuit breaker — optional accessory • heater switch • left-hand mirror heater • right-hand mirror heater an indicator lamp illuminates when the mirror hea...

Page 196

0.3 electrical system circuits – e. Schematics 187 maintenance manual ottawa t2 4x2 heated and motorized (optional) heated and motorized mirror circuit components • circuit breaker — optional accessory • heater switch • left-hand mirror heater • left-hand mirror motor • left-hand motor switch • righ...

Page 197

188 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – radio (optional) radio circuit o tt0040 positive pass-thru stud positive pass-thru stud ba2000 rd radio circuit ig1000 rd/we ig1000 rd/we cab acc ignition switch fuse ignition switch ignition switch connector 10 a ...

Page 198

0.3 electrical system circuits – e. Schematics 189 maintenance manual ottawa t2 4x2 – radio circuit — hot wire radio circuit — hot wire components • accessory relay #1 • circuit breaker — radio battery (cab accessory fuse panel) • fuse — ignition switch (cab accessory fuse panel) • fuse — radio (cab...

Page 199

190 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – windshield washer (optional) windshield washer circuit components • accessory relay #1 • circuit breaker — wiper/washer (cab accessory fuse panel) • windshield washer motor • windshield wiper switch the ignition sw...

Page 200

0.3 electrical system circuits – e. Schematics 191 maintenance manual ottawa t2 4x2 – windshield wiper windshield wiper circuit components • accessory relay #1 • circuit breaker — wiper/washer (cab accessory fuse panel) • windshield wiper motor • windshield wiper switch the ignition switch must be o...

Page 201

192 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – cab power board cab power board wiring.

Page 202

0.3 electrical system circuits – e. Schematics 193 maintenance manual ottawa t2 4x2 – cab interior engine wiring cab interior engine wiring (cummins isb 2013 engine) – cab interior engine wiring (cummins qsb 6.7 t3 engine).

Page 203

194 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – cab interior engine wiring (cummins qsb t4f engine).

Page 204

0.3 electrical system circuits – e. Schematics 195 maintenance manual ottawa t2 4x2 0.3.3 cab instrumentation page – air pressure gauge lighting air pressure gauge lighting circuit components • gauge • gauge (second service tank) • gauge lamp • gauge lamp (second service tank) • headlight switch • p...

Page 205

196 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – engine hourmeter engine hourmeter circuit components • circuit breaker — ignition switch (cab accessory fuse panel) • fuse — gauge (cab accessory fuse panel) • hourmeter • ignition relay • oil pressure (hourmeter) ...

Page 206

0.3 electrical system circuits – e. Schematics 197 maintenance manual ottawa t2 4x2 – fuel gauge fuel gauge circuit (cummins isb 6.7 2013 engine).

Page 207

198 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 components • fuse — gauge (cab accessory fuse panel) • gauge • gauge lamp • headlight switch • ignition relay • panel dimmer switch (optional) • sender (fuel level — variable resistance) the fuel level gauge displays...

Page 208

0.3 electrical system circuits – e. Schematics 199 maintenance manual ottawa t2 4x2 fuel gauge circuit (cummins qsb engines).

Page 209: Low Air Warning Circuit

200 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – low air warning alarm low air warning alarm circuit components • fuse — gauge (cab accessory fuse panel) • ignition relay • low air alarm buzzer • low air switch • low air switch (optional) ott0072 cab acc fuse gau...

Page 210

0.3 electrical system circuits – e. Schematics 201 maintenance manual ottawa t2 4x2 – speedometer speedometer circuit components • fuse — gauge (cab accessory fuse panel) • gauge (speedometer) • gauge lamp • headlight switch • ignition relay • panel dimmer switch (optional) some tractor speedometers...

Page 211

202 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – voltmeter voltmeter circuit components • fuse — gauge (cab accessory fuse panel) • gauge lamp • headlight switch • ignition relay • panel dimmer switch (optional) • voltmeter the voltmeter detects the voltage at th...

Page 212

0.3 electrical system circuits – e. Schematics 203 maintenance manual ottawa t2 4x2 – gauge cluster wiring gauge cluster wiring (cummins isb 2013 engine) – part a.

Page 213

204 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 gauge cluster wiring (cummins isb 2013 engine) – part b.

Page 214

0.3 electrical system circuits – e. Schematics 205 maintenance manual ottawa t2 4x2 – gauge cluster wiring (cummins qsb 6.7 t3 engine) – part a.

Page 215

206 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 gauge cluster wiring (cummins qsb 6.7 t3 engine) – part b.

Page 216

0.3 electrical system circuits – e. Schematics 207 maintenance manual ottawa t2 4x2 – gauge cluster wiring (cummins qsb t4f engine) – part a.

Page 217

208 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 gauge cluster wiring (cummins qsb t4f engine) – part b.

Page 218

0.3 electrical system circuits – e. Schematics 209 maintenance manual ottawa t2 4x2 0.3.4 chassis circuits page – chassis power board chassis power board wiring 6 7 10 3 1 5 2 4 8 9 16 15 14 12 11 13 input ignition signal input reverse signal output reverse signal backup alarm chassis backup lights ...

Page 219

210 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – air dryer (optional) air dryer circuit components • air dryer • chassis options relay • circuit breaker — air dryer (cab accessory fuse panel).

Page 220

0.3 electrical system circuits – e. Schematics 211 maintenance manual ottawa t2 4x2 – cab tilt pump cab tilt pump circuit components • batteries • fuse — tilt (cab accessory fuse panel) • ignition relay • starter with solenoid • tilt pump control switch • tilt pump motor (up) • tilt solenoid (down) ...

Page 221

212 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – cab exterior/front chassis wiring cab exterior/front chassis wiring (cummins isb 2013 engine).

Page 222

0.3 electrical system circuits – e. Schematics 213 maintenance manual ottawa t2 4x2 – cab exterior/front chassis wiring (cummins qsb 6.7 t3 engine).

Page 223

214 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – cab exterior/front chassis wiring (cummins qsb t4f engine).

Page 224

0.3 electrical system circuits – e. Schematics 215 maintenance manual ottawa t2 4x2 – chassis wiring chassis wiring (cummins isb 2013 engine).

Page 225

216 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – chassis wiring (cummins qsb 6.7 t3 engine).

Page 226

0.3 electrical system circuits – e. Schematics 217 maintenance manual ottawa t2 4x2 – chassis wiring (cummins qsb t4f engine) –.

Page 227

218 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 air system tank pressure senders air system tank pressure senders (cummins isb 2013 engine) – air system tank pressure senders (cummins qsb 6.7 t3 engine) – air system tank pressure senders (cummins qsb t4f engine) –.

Page 228

0.3 electrical system circuits – e. Schematics 219 maintenance manual ottawa t2 4x2 battery power distribution battery power distribution (cummins isb 2013 engine) – battery power distribution (cummins qsb 6.7 t3 engine).

Page 229

220 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – battery power distribution (cummins qsb t4f engine) –.

Page 230

0.3 electrical system circuits – e. Schematics 221 maintenance manual ottawa t2 4x2 cab tilt system control wiring cab tilt system control wiring (cummins isb 2013 engine).

Page 231

222 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – cab tilt system control wiring (cummins qsb 6.7 t3 engine).

Page 232

0.3 electrical system circuits – e. Schematics 223 maintenance manual ottawa t2 4x2 – cab tilt system control wiring (cummins qsb t4f engine).

Page 233

224 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 0.3.5 lighting circuits (cab and chassis) page – backup light and alarm backup light and alarm circuit components • backup alarm • backup lamp • circuit breaker — reverse (cab accessory fuse panel) • ignition relay •...

Page 234

0.3 electrical system circuits – e. Schematics 225 maintenance manual ottawa t2 4x2 – beacon/strobe light (optional) beacon/strobe light circuit components • accessory relay #2 • beacon light switch (optional) • beacon/strobe lamp.

Page 235

226 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 • flood light switch • fuse — exterior lighting (cab accessory fuse panel) the flood light switch is mounted on the instrument panel. – clearance lights (optional) clearance lights circuit components • cab clearance ...

Page 236

0.3 electrical system circuits – e. Schematics 227 maintenance manual ottawa t2 4x2 – daytime running lights (optional) daytime running lights circuit components • daytime running lights module • fuse — daytime running lights (cab accessory fuse panel) • head lamps • ignition relay ott0060 lh headli...

Page 237

228 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – dome light dome light circuit components • accessory relay #2 • dome lamp with switch • fuse — cab lighting (cab accessory fuse panel) the lamp on/off switch is on the dome light fixture. – fifth-wheel control refe...

Page 238

0.3 electrical system circuits – e. Schematics 229 maintenance manual ottawa t2 4x2 – flood light flood light circuit components • accessory relay #2 • flood light.

Page 239

230 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 • flood light switch • fuse — exterior lighting (cab accessory fuse panel) – headlights headlight circuit components • circuit breaker — head lights (cab accessory fuse panel) • headlamps • headlight relay (high/low)...

Page 240

0.3 electrical system circuits – e. Schematics 231 maintenance manual ottawa t2 4x2 – tail lights refer to turn signal, tail, brake lights and emergency flasher. – trailer auxiliary power trailer auxiliary power circuit components • circuit breaker — trbk (trailer breaker) • ignition switch jumper •...

Page 241

232 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – transmission shifter, fifth-wheel control and panel lighting transmission shifter, fifth-wheel control and panel lighting circuit components • headlight switch • lamps (2 — fifth-wheel control) • light bar — heater...

Page 242: Turn Signal, Tail, Brake

0.3 electrical system circuits – e. Schematics 233 maintenance manual ottawa t2 4x2 – turn signal, tail, brake lights and emergency flasher turn signal, tail, brake lights and emergency flasher circuit — part a turn sig & dimmer sw turn signal switch connector a b c d e f tl2000 tn/we tl1000 oe/bk b...

Page 243

234 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 turn signal, tail, brake lights and emergency flasher circuit — part b ott0064 sl2000 bk sl2000 bk rd yw – lh turn rd – st op gn – rh turn sl2000 bk tl2001 tn tl2001 tn tl2002 gn tl2002 gn bu1000 bk bu2000 bk/rd bu20...

Page 244

0.3 electrical system circuits – e. Schematics 235 maintenance manual ottawa t2 4x2 components • backup lamp • circuit breaker — flasher (cab accessory fuse panel) • circuit breaker — left turn (trailer circuit breakers) • circuit breaker — parking lights (cab accessory fuse panel) • circuit breaker...

Page 245

236 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – upper cab harness (cummins qsb 6.7 t3 engine) – upper cab harness (cummins qsb t4f engine) – headlight/dimmer switch wiring headlight/dimmer switch wiring (cummins isb 2013 engine).

Page 246

0.3 electrical system circuits – e. Schematics 237 maintenance manual ottawa t2 4x2 – headlight/dimmer switch wiring (cummins qsb 6.7 t3 engine) – headlight/dimmer switch wiring (cummins qsb t4f engine).

Page 247

238 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – auxiliary lighting and air horn auxiliary lighting and air horn (cummins isb 2013 engine) – auxiliary lighting and air horn (cummins qsb 6.7 t3 engine).

Page 248

0.3 electrical system circuits – e. Schematics 239 maintenance manual ottawa t2 4x2 – auxiliary lighting and air horn (cummins qsb t4f engine) – tail light/backup light wiring tail light/backup light wiring (cummins isb 2013 engine).

Page 249

240 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – tail light/backup light wiring (cummins qsb 6.7 t3 engine) – tail light/backup light wiring (cummins qsb t4f engine).

Page 250

0.3 electrical system circuits – e. Schematics 241 maintenance manual ottawa t2 4x2 0.3.7 engine controls page – throttle pedal (tps) wiring throttle pedal (tps) wiring (cummins isb 2013 engine) – throttle pedal (tps) wiring (cummins qsb 6.7 t3 engine) – throttle pedal (tps) wiring (cummins qsb t4f ...

Page 251

242 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 engine wiring engine wiring (cummins isb 2013 engine).

Page 252

0.3 electrical system circuits – e. Schematics 243 maintenance manual ottawa t2 4x2 – engine wiring (cummins qsb 6.7 t3 engine).

Page 253

244 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – engine wiring (cummins qsb t4f engine).

Page 254

0.3 electrical system circuits – e. Schematics 245 maintenance manual ottawa t2 4x2 0.3.8 exhaust page – aftertreatment wiring aftertreatment wiring (cummins isb 2013 engine).

Page 255

246 0.3 electrical system circuits – e. Schematics maintenance manual ottawa t2 4x2 – aftertreatment wiring (cummins qsb t4f engine).

Page 256: F. Technical Data

0.1 standard vehicle data – f. Technical data 247 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm f. Technical data 0.1 standard vehicle data page – ottawa t2 series terminal tractor standard features, dimensions and performance specifications are presented below for three typical chassis configu...

Page 257

248 0.1 standard vehicle data – f. Technical data maintenance manual ottawa t2 4x2 gawr front rear 12,000 lbs. (5,443 kg) 30,000 lbs. (13,608 kg) 12,000 lbs. (5,443 kg) 30,000 lbs. (13,608 kg) gcwr 81,000 lbs. (43,545 kg) 81,000 lbs. (36,287 kg) wheelbase 116 inch (2,794 mm) 116 inch (2,794 mm) leng...

Page 258: 0.2 Hydraulic

0.2 hydraulic system – f. Technical data 249 maintenance manual ottawa t2 4x2 0.2 hydraulic system page – ottawa t2 series 4x2 the hydraulic system includes three sub-systems. • fifth-wheel boom • power steering • cab tilt all three draw and use fluid from a common 16-gallon reservoir. Specification...

Page 259: 0.3

250 0.3 fluids, lubricants and sealants – f. Technical data maintenance manual ottawa t2 4x2 0.3 fluids, lubricants and sealants page – ottawa t2 series 4x2 following are the specified fluids, lubricants and sealants by component. These are to be used in accordance with the rec- ommended maintenance...

Page 260: 0.4

0.4 fastener torque values – f. Technical data 251 maintenance manual ottawa t2 4x2 0.4 fastener torque values page – ottawa t2 series 4x2 following are the specified torque values required for sched- uled maintenance operations and typical repair and/or adjust- ment procedures covered in this manua...

Page 261

252 0.4 fastener torque values – f. Technical data maintenance manual ottawa t2 4x2.

Page 262: G. Appendix

– g. Appendix 253 maintenance manual ottawa t2 4x2 mm mm mm mm mm mm g. Appendix page – description this section is not applicable for this vehicle..