- DL manuals

- L&W

- Air Compressor

- LW 225 E

- Operating Instructions Manual

L&W LW 225 E Operating Instructions Manual

C H A P T E R O V E R V I E W

Operating Instructions

..............................................................................................................

Spare Parts Lists

..........................................................................................................................

Options

(if equipped)

................................................................................................................

Attachment

....................................................................................................................................

A

B

C

D

Manufacturer in terms of 97/23/EC

The full name and address of the manufacturer is:

Lenhardt & Wagner GmbH

An der Tuchbleiche 39

68623 Hüttenfeld / Germany

Phone: +49 (0) 62 56 - 85 88 0 - 0

Fax: +49 (0) 62 56 - 85 88 0 - 14

E-Mail: service@lw-compressors.com

Internet: www.lw-compressors.com

Version: 11/12-E

Summary of LW 225 E

Page 1

C h a p t e r o v e r v i e w operating instructions .............................................................................................................. Spare parts lists .........................................................................................................................

Page 2

S e r v i c e i n f o r m a t i o n / w a r r a n t y compressor information type designation serial number date of construction purchase information purchase date first commissioned on warranty period dealer's stamp warranty l&w will uphold warranty claims made during a period of 12 months from the...

Page 3: Operating Instructions

A operating instructions breathing air compressor lw 225 e lw 245 b version: 02/14-e.

Page 4

Page a - 2 a lw 225 e / lw 245 b version: 19.11.2015 general information and technical data general information / description of warning symbols .................................................................... 4 drive motors ..........................................................................

Page 5

Page a - 3 a lw 225 e / lw 245 b version: 19.11.2015 maintenance and service service, repair and maintenance ..................................................................................................... 43 maintenance lists / maintenance intervals ...............................................

Page 6

Page a - 4 a lw 225 e / lw 245 b version: 19.11.2015 warning indicates a potentially hazardous situation which, if not avoided, could result in physical injury or damage to the product or environment. Caution indicates an imminently hazardous situation which, if not avoided, could result in serious ...

Page 7

Page a - 5 a lw 225 e / lw 245 b version: 19.11.2015 drive motors lw 245 b high performance 4 gear motor (6 kw) with integrated fuel tank. Pull start, auto cut off at low oil level. Lw 225 e 5.5 kw e-motor / 400v / 3 phase / 50 hz (or 60 hz). Start/stop switch, phase selector switch, ready to connec...

Page 8

Page a - 6 a lw 225 e / lw 245 b version: 19.11.2015 scope of delivery lw 225 e user-friendly compressor with electric motor and in a compact design. The portable lw 225 e is ideal for mobile applications or occasional filling operations. Versions filling pressure versions: • pn 225 bar • pn 330 bar...

Page 9

Page a - 7 a lw 225 e / lw 245 b version: 19.11.2015 scope of delivery lw 245 b user-friendly compressor with 4-stroke power and in a compact design. The portable lw 245 b is ideal for mobile applications or occasional filling operations. He is a popular compressor for expeditions and safaris. Versi...

Page 10

Page a - 8 a lw 225 e / lw 245 b version: 19.11.2015 b e s c h r e i b u n g technische daten technical data lw 225 e lw 245 b capacity [l/min]: 225 245 max. Operating pressure [bar]: 330 330 rpm [min -1 ]: 1850 2000 number of pressure stages: 3 3 cylinder bore 1st stage [mm]: Ø 75 Ø 72 cylinder bor...

Page 11

Page a - 9 a lw 225 e / lw 245 b version: 19.11.2015 unit assembly lw 225 e no. Designation 1 pressure gauge 2 filling hose with filling valve 3 filter housing 4 phasen selector switch 3 2 1 4 d e s c r i p t i o n.

Page 12

Page a - 10 a lw 225 e / lw 245 b version: 19.11.2015 phase selector switch lw 225 e no. Designation 1 switch position 0 - off 2 switch position 1 - on - rotation 1 3 switch position 2 - on - rotation 2 2 3 1 d e s c r i p t i o n.

Page 13

Page a - 11 a lw 225 e / lw 245 b version: 19.11.2015 d e s c r i p t i o n unit assembly lw 245 b no. Designation 1 pressure gauge 2 filling hose with filling valve 3 filter housing 4 hand start 1 4 3 1.

Page 14

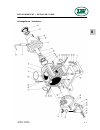

Page a - 12 a lw 225 e / lw 245 b version: 19.11.2015 1. Air intake filter 2. 1st pressure stage 3. Safety valve 1st stage 4. Cooling pipe 1st stage 5. 2nd pressure stage 6. Safety valve 2nd stage 7. Cooling pipe 2nd stage 8. Condensate release hose 9. Condensate release valve 10. Oil-/water separat...

Page 15

A s a f e t y p r e c a u t i o n s.

Page 16

Page a - 14 a lw 225 e / lw 245 b version: 19.11.2015 intended use only use the unit in perfect condition for its intended purpose, safety and intended use and observe the operating instructions! In particular disorders that may affect safety have to be eliminated immediately! Use the unit exclusive...

Page 17

Page a - 15 a lw 225 e / lw 245 b version: 19.11.2015 safety instructions on the unit importance of notes and warning signs that are affixed to the compressor according to the application or its equipment. S a f e t y p r e c a u t i o n s warning high voltage! Note ensure correct direction of rotat...

Page 18

Page a - 16 a lw 225 e / lw 245 b version: 19.11.2015 s a f e t y p r e c a u t i o n s general safety precautions • read the operating instructions of this product carefully prior to use. • read the operating instructions of the petrol engine carefully prior to use. (lw 245 b versions) • strictly f...

Page 19

Page a - 17 a lw 225 e / lw 245 b version: 19.11.2015 s a f e t y p r e c a u t i o n s unit customised safety notices organisational measures • in addition to the instruction manual, observe and comply with universally valid legal and other obligatory regulations regarding accident prevention and e...

Page 20

Page a - 18 a lw 225 e / lw 245 b version: 19.11.2015 s a f e t y p r e c a u t i o n s maintenance instructions • hoses have to be checked by the operator (pressure and visual inspection) at reasonable intervals, even if no safety-related defects have been detected. • immediately repair any damage....

Page 21

Page a - 19 a lw 225 e / lw 245 b version: 19.11.2015 s a f e t y p r e c a u t i o n s transportation instructions • parts which need to be dismantled for transport purposes must be carefully replaced and secured before taking into operation. • the transport may only be carried out by trained perso...

Page 22

A i n s t a l l a t i o n.

Page 23

Page a - 21 a lw 225 e / lw 245 b version: 19.11.2015 installation in closed rooms - lw 225 e for installation in closed rooms, observe the following: • install the unit horizontally and level. The floor must be vibration-free and capable of taking the load of the system weight. • the compressor roo...

Page 24

Page a - 22 a lw 225 e / lw 245 b version: 19.11.2015 installation lw 245 b for outside installation observe the following: • install the unit horizontally and level. The floor must be vibration-free and capable of taking the load of the system weight. • on units employing petrol or diesel motors, i...

Page 25

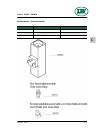

Page a - 23 a lw 225 e / lw 245 b version: 19.11.2015 3 9 0 5 6 0 780 4 5 0 dimensions lw 225 e fig. Dimensions i n s t a l l a t i o n.

Page 26

Page a - 24 a lw 225 e / lw 245 b version: 19.11.2015 3 9 0 5 7 0 920 4 5 0 dimensions lw 245 b fig. Dimensions i n s t a l l a t i o n.

Page 27

Page a - 25 a lw 225 e / lw 245 b version: 19.11.2015 minimum distances • make sure that the compressor always has a sufficient amount of fresh air available. • to prevent serious damage, ensure that the cooling air flow can flow freely. • the following minimum distances must be adhered: front side ...

Page 28

Page a - 26 a lw 225 e / lw 245 b version: 19.11.2015 ventilation lw 225 e • make sure that the compressor always has a sufficient amount of fresh air available for cooling. • to prevent serious damage, ensure that the cooling air flow can flow freely. • the necessary cooling air flow can be calcula...

Page 29

Page a - 27 a lw 225 e / lw 245 b version: 19.11.2015 electrical installation lw 225 e for installation of electrical equipment, observe the following: • if control devices are delivered by the factory, refer to the appropriate wiring diagram. • ensure correct installation of protective conductors. ...

Page 30

Page a - 28 a lw 225 e / lw 245 b version: 19.11.2015 recommended fuses for 360 - 500 v operating voltage nominal motor power fusing start a connection in mm² [kw] [a] direct star/delta contactor supply s/d* to motor 4 8,5 20 16 2,5 1,5 5,5 11,3 25 20 2,5 1,5 electrical installation lw 225 e the com...

Page 31

A o p e r a t i o n.

Page 32

Page a - 30 a lw 225 e / lw 245 b version: 19.11.2015 o p e r a t i o n important operation instructions danger on petrol or diesel engines, operation unit must only be located outdoors, never indoors, not even in partially closed rooms however large they may be. ! Note ensure that all persons handl...

Page 33

Page a - 31 a lw 225 e / lw 245 b version: 19.11.2015 prior to first commissioning, observe the following: • ensure that cooling air can flow freely. • check compressor oil level (see "service and maintenance"). • check all connections and retighten if necessary. • check if the filter cartridge is i...

Page 34

Page a - 32 a lw 225 e / lw 245 b version: 19.11.2015 check turning direction - lw 225 e before starting the compressor for the first time, check rotation direction (see the rotary direction arrow on the compressor block). If the direction of rotation is wrong, the guide pistons of the 2nd and 3rd s...

Page 35

Page a - 33 a lw 225 e / lw 245 b version: 19.11.2015 prior to first commissioning, observe the following: • ensure that cooling air can flow freely. • position compressor in direction of wind so that exhaust fumes are blown away from the unit. • take protection measures to avoid damages or injury b...

Page 36

Page a - 34 a lw 225 e / lw 245 b version: 19.11.2015 prior to daily operation observe the following: lw 225 e • ensure cooling air can flow freely. • check the compressor oil level. • check if filter cartridge is in place / observe filter cartridge life! • ensure toxic-free, pure intake air. Lw 245...

Page 37

Page a - 35 a lw 225 e / lw 245 b version: 19.11.2015 o p e r a t i o n filling procedure 1. Close all filling valves. 2. Connect the closed compressed air cylinders. 3. Open cylinder valves. 4. Start the compressor 5. When filling pressure gauge increases, open filling valves slowly. 6. Fill the co...

Page 38

Page a - 36 a lw 225 e / lw 245 b version: 19.11.2015 o p e r a t i o n switch off the compressor the compressor unit is not equipped as standard with an auto shut down. The unit must always be stopped manually when final pressure is reached. During filling process, the system can be shut down at an...

Page 39

A r e m e d y i n g f a u l t s.

Page 40

Page a - 38 a lw 225 e / lw 245 b version: 19.11.2015 r e m e d y i n g f a u l t s final pressure can not be reached strong compressor vibration cause of fault remedy v-belt tension too loose tension v-belt drive motor / compressor unit loosely retighten mounting screws anti vibration mounts used u...

Page 41

Page a - 39 a lw 225 e / lw 245 b version: 19.11.2015 r e m e d y i n g f a u l t s compressor overheated cause of fault remedy inlet filter cartridge contaminated replace ambient temperature too high improve room ventilation / reduce operation times cooling air inlet and outlet insufficient observe...

Page 42

Page a - 40 a lw 225 e / lw 245 b version: 19.11.2015 r e m e d y i n g f a u l t s automatic condensate drain defective only valid with the option - automatic condensate drain cause of fault remedy solenoid coils defective replace cable / supply cable defective repair, replace if necessary timer / ...

Page 43

Page a - 41 a lw 225 e / lw 245 b version: 19.11.2015 r e m e d y i n g f a u l t s filter life not sufficient cause of fault remedy pressure maintaining valve settings not correct adjust as prescribed filter cartridge unsuitable replace by a prescribed filter cartridge type filter cartridge too old...

Page 44

A m a i n t e n a n c e a n d s e r v i c e.

Page 45

Page a - 43 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e a n d s e r v i c e service, repair and maintenance carry out service and maintenance work exclusively when the compressor is stopped and depressurised. The unit should be leak-checked regularly. Leaks can be preferably loca...

Page 46

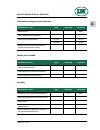

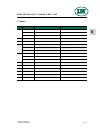

Page a - 44 a lw 225 e / lw 245 b version: 19.11.2015 daily before taking unit into operation maintenance work type quantity order no. Check oil level - - 000001 check condition of all filling hoses - - - lw 225 e 1 001374 lw 245 b 1 001464 operate unit to final pressure and check function of final ...

Page 47

Page a - 45 a lw 225 e / lw 245 b version: 19.11.2015 every 250 operating hours maintenance work type quantity order no. Oil change - 0.8 000001 clean oil/water separators - - - every 500 operating hours maintenance work type quantity order no. Replace v-belt lw 225 e (50hz) 2 000123 lw 225 e (60hz)...

Page 48

Page a - 46 a lw 225 e / lw 245 b version: 19.11.2015 maintenance work type quantity order no. Replace o-rings and gaskets of 1st, 2nd and 3rd stage gasket (1st stage) 1 003651 o-ring valve (2nd stage) 1 000035 o-ring valve (3rd stage) 1 000034 replace all inlet and outlet valves incl. Gaskets 1st s...

Page 49

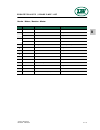

Page a - 47 a lw 225 e / lw 245 b version: 19.11.2015 service kits lw 225 e the service kits contain parts for maintenance according to the factory requirements. The use of the service kits ensures that all required parts are ordered and replaced and gives assurance that all parts are included in th...

Page 50

Page a - 48 a lw 225 e / lw 245 b version: 19.11.2015 service kits lw 245 b the service kits contain parts for maintenance according to the factory requirements. The use of the service kits ensures that all required parts are ordered and replaced and gives assurance that all parts are included in th...

Page 51

Page a - 49 a lw 225 e / lw 245 b version: 19.11.2015 check v-belt tension the compressors of lw 225 e and lw 245 b are driven by v-belts. Check correct v-belt tension regularly, adjust if necessary. The v- belt could lose tension during transportation. Please check the v- belt tension before starti...

Page 52

Page a - 50 a lw 225 e / lw 245 b version: 19.11.2015 compressor lubrication pistons, cylinders, crankshaft and connecting rods are provided with oil by splash lubrication. Check oil level check the oil level before each operation of the unit. Oil level check as follows: • screw out oil dipstick • w...

Page 53

Page a - 51 a lw 225 e / lw 245 b version: 19.11.2015 oil change oil change as follows: • run compressor warm for about 2 minutes. • switch off and vent compressor. • tilt the compressor aside. • place a suitable oil drain tray under the drain plug (red marked hexagon bolt). • screw off red oil drai...

Page 54

Page a - 52 a lw 225 e / lw 245 b version: 19.11.2015 manual condensation dump system oil- / water separators the compressor comes as standard with a manual condensation dump system. Drain condensate separators every 15 to 30 minutes, depending to air moisture. Option automatic condensate drain: to ...

Page 55

Page a - 53 a lw 225 e / lw 245 b version: 19.11.2015 oil- / water separator 2nd stage - maintenance maintenance / cleaning of oil / water separators 2nd stage as follows: • loosen mounting screws of the cooler bracket (fig. 1) and pipe connections (fig. 2+3), extract cooler afterwards. • open lock ...

Page 56

Page a - 54 a lw 225 e / lw 245 b version: 19.11.2015 filter housing the mole carbon filter housing is installed on the right hand side of the compressor housing. Inside the filter housing a jet blows air on to the housing wall. Condensation water and oil are led by centrifugal force to the bottom o...

Page 57

Page a - 55 a lw 225 e / lw 245 b version: 19.11.2015 filter cartridge change filter cartridge change as follows: • stop the compressor and open carefully the drain valves. Please wait till the filter housing is completely vented; this procedure takes approx. 1 - 2 minutes. • when no air discharges ...

Page 58

Page a - 56 a lw 225 e / lw 245 b version: 19.11.2015 filter housing - maintenance filter housing maintenance as follows: • open filter cover with the filter key, extract it (fig. 1) and pull out spring and filter cartridge (fig. 2). • change o-ring and turn off the filter housing with the filter ke...

Page 59

Page a - 57 a lw 225 e / lw 245 b version: 19.11.2015 inlet filter a paper dry filter is used for the inlet filter. Check air inlet filter regularly or replace it. Depending on the degree of contamination, the filter inlet can be cleaned by compressed air. Defective air inlet filters should be immed...

Page 60

Page a - 58 a lw 225 e / lw 245 b version: 19.11.2015 check or change filter inlet to properly change the filter inlet, proceed as follows: • disconnect spring wire clamp at the ventilation hose (fig. 1). • remove mounting screw and pull out filter housing carefully (fig. 2). • clean filter housing ...

Page 61

Page a - 59 a lw 225 e / lw 245 b version: 19.11.2015 valve heads and valves inlet and outlet valves of the specific compressor stages are located between valve head and cylinder. Inlet valves open while piston downstroke; outlet valves open while upstroke or compression stroke. Valves are subject t...

Page 62

Page a - 60 a lw 225 e / lw 245 b version: 19.11.2015 fan protection cover dismantling dismantle the fan protection cover as follows: • remove top mounting screw (fig. 1). • remove protection plate (fig. 2). • tilt the compressor aside. • loosen both bottom mounting screws (fig. 3). • remove fan pro...

Page 63

Page a - 61 a lw 225 e / lw 245 b version: 19.11.2015 replace in- & outlet valve 1st stage replace the inlet and outlet valve 1st stage as follows: • disconnect spring wire clamp at the ventilation hose (fig. 1). • loosen pipe connections (fig. 2). • remove valve head screws (fig.3). • check valve h...

Page 64

Page a - 62 a lw 225 e / lw 245 b version: 19.11.2015 replace in- & outlet valve 1st stage replace the inlet and outlet valve 1st stage as follows: • insert lower valve gasket (fig.1). • insert upper valve gasket (fig.2). • insert in– and outlet valve. Caution: observe correct position between valve...

Page 65

Page a - 63 a lw 225 e / lw 245 b version: 19.11.2015 replace inlet and outlet valve 2nd stage replace the inlet and outlet valve 2nd stage as follows: • loosen pipe connections (fig. 1). • loosen valve head screws (fig. 2). • remove valve head (fig. 3) observe that the lower valve gasket is also pu...

Page 66

Page a - 64 a lw 225 e / lw 245 b version: 19.11.2015 replace inlet and outlet valve 3rd stage replace the inlet and outlet valve 3rd stage as follows: • loosen pipe connections of the water separator 2nd stage and the filter housing (fig. 1+2). • remove mounting screws from the cooling pipe bracket...

Page 67

Page a - 65 a lw 225 e / lw 245 b version: 19.11.2015 safety valves every pressure stage is equipped with a separate over pressure safety valve. Safety valves avoid a non permissible high pressure at the specific pressure stages and limit maximum operation pressure of the compressor. Safety valves a...

Page 68

Page a - 66 a lw 225 e / lw 245 b version: 19.11.2015 pressure maintaining / non return valve the pressure maintaining / non return valve combination is placed in the flow direction after the final filter housing. Pressure maintaining valve the pressure maintaining valve drains a large part of the w...

Page 69

Page a - 67 a lw 225 e / lw 245 b version: 19.11.2015 adjust pressure maintaining valve • vent filling valve and close afterwards (filling pressure gauge 0 bar) • start the compressor • observe filling pressure gauge • when the opening pressure of the pressure maintaining valve is reached, the indic...

Page 70

Page a - 68 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e a n d s e r v i c e o-rings - filling valve and filling hose check o-rings from filling valve and filling hose regularly and change if necessary. O-ring at the filling valve • change o-ring, previously grease new o-ring (fig...

Page 71

Page a - 69 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e a n d s e r v i c e motor change the drive motors of the lw 225 and lw 245 are generally interchangeable. Motor change as follows: • switch off the compressor unit, pull the plug if necessary • remove v-belt cover • remove m...

Page 72

Page a - 70 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e a n d s e r v i c e test of pressure equipment according to the pressure equipment directive (ped 97/23/ec) and tÜv darmstadt (german supervising authorities). State: 10th of december, 2005 subject pressure equipment with a ...

Page 73

A m a i n t e n a n c e r e c o r d s.

Page 74

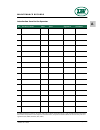

Page a - 72 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e r e c o r d s introduction form for the operator no. Surname, name date place signature instructor by adding themselves to this list, the person that signs it confirms having been given a yearly introduction/instruction abou...

Page 75

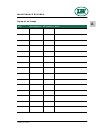

Page a - 73 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e r e c o r d s top up oil, oil change date operating hours oil quantity [l] name.

Page 76

Page a - 74 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e r e c o r d s cartridge change date operating hours difference name.

Page 77

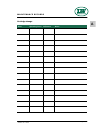

Page a - 75 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e r e c o r d s maintenance work description date, signature.

Page 78

Page a - 76 a lw 225 e / lw 245 b version: 19.11.2015 m a i n t e n a n c e r e c o r d s replaced parts designation part number date, signature.

Page 79

Page a - 77 a lw 225 e / lw 245 b version: 19.11.2015 s t o r a g e note please check the specific handbook of the petrol engine regarding conservation / storage, de-conservation and commissioning of the lw 100 b compressors. I conservation / storage of the compressor if the compressor unit is not t...

Page 80

Page a - 78 a lw 225 e / lw 245 b version: 19.11.2015 s t o r a g e note please check the specific handbook of the petrol engine regarding conservation / storage, de-conservation and commissioning of the lw 100 b compressors. I de-conservation, commissioning after the compressor has been stored, the...

Page 81

Page a - 79 a lw 225 e / lw 245 b version: 19.11.2015 s t o r a g e transportation instructions • parts which need to be dismantled for transport purposes must be carefully replaced and secured before taking into operation. • the transport may only be carried out by trained personnel. • for transpor...

Page 82

B e r s a t z t e i l l i s t e n / s pa r e pa r t s l i s t s d e t a i l a n s i c h t e n / d e t a i l e d v i e w s.

Page 83

I n hal t sve r zei ch nis - ta ble o f co n te nt s c kurbelgehäuse - crankcase ......................................................................................................... 2 kurbeltrieb - crank drive ........................................................................................

Page 84

B version: 11.02.2014 kurbelgehäuse / crankcase e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 1 004121 kurbelgehäuse crankcase 2 006676 lagerflansch, aluminium main bearing flange, alloy 3 008163 gehäusedeckel housing cover 4 000132 staender fü...

Page 85

B version: 11.02.2014 d e t a i l a n s i c h t / d e t a i l e d v i e w kurbelgehäuse / crankcase b - 3 lw 225 e - lw 245 b.

Page 86

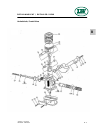

B version: 11.02.2014 kurbeltrieb / crank drive e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 35 000097 kreuzkopf und kulisse slider & plunger assembly 36 000095 gleitbrücke sliding bridge 37 000062 kurbelwelle crankshaft 39 000045 kolben 3. St...

Page 87

B version: 11.02.2014 d e t a i l a n s i c h t / d e t a i l e d v i e w (+47) (+35) (+38) kurbeltrieb / crank drive b - 5 lw 225 e - lw 245 b.

Page 88

B version: 18.11.2015 e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 72 000031 saug-druckventil 2. Stufe inkl. Dichtung und o-ring in-& outlet valve 2nd stage icl. Gasket and o-ring 73 000032 saug-druckventil 3. Stufe inkl. Dichtung und o-ring i...

Page 89

B version: 18.11.2015 d e t a i l a n s i c h t / d e t a i l e d v i e w zylinder & ventilköpfe / cylinders & valve heads (+ 9 8 ) (+ 9 1 ) 1 1 1 1 1 0 b b - 7 lw 225 e - lw 245 b.

Page 90

B version: 07.02.2014 tragrahmen / carrying frame e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 1 004085 tragrahmen carrying frame 2 004086 befestigungsrahmen kompressor frame compressor 3 000120 motorplatte komplett lw 160 e motor mounting pla...

Page 91

B version: 07.02.2014 d e t a i l a n s i c h t / d e t a i l e d v i e w tragrahmen / carrying frame b - 9 lw 225 e - lw 245 b.

Page 92

B version: 14.02.2014 kühlrohre / cooling pipes e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 1 000010 filtergehäuse kühlrohr 3. Stufe final cooling pipe 3rd stage 2 000009 kühlrohr komplett 3. Stufe cooling pipe 3rd stage 3 000011 kühlrohr 2. ...

Page 93

B version: 14.02.2014 d e t a i l a n s i c h t / d e t a i l e d v i e w kühlrohre / cooling pipes 2 0 b - 11 lw 225 e - lw 245 b.

Page 94

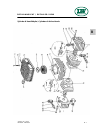

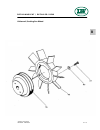

B version: 07.02.2014 lüfterrad / cooling fan wheel e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 115 000025 lüfterrad cooling fan wheel 116 002801 keilriemenscheibe v-belt pulley 117 001082 sechskantschraube hexagon screw 118 004096 unterlegsc...

Page 95

B version: 07.02.2014 lüfterrad / cooling fan wheel d e t a i l a n s i c h t / d e t a i l e d v i e w b - 13 lw 225 e - lw 245 b.

Page 96

B version: 08.08.2014 e - motor e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 1 002239 motor lw225 (400v – 50/60hz – 3~) motor lw225 (400v—50/60hz—3~) 005009 motor lw225 (230v – 50/60hz – 3~) motor lw225 (230v – 50/60hz – 3~) 005032 motor lw225...

Page 97

B version: 08.08.2014 d e t a i l a n s i c h t / d e t a i l e d v i e w e - motor b - 15 lw 225 e - lw 245 b.

Page 98

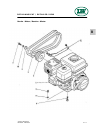

B version: 08.06.2015 benzin - motor / bencine - motor e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 1 002238 motor lw 190 b / lw 245 b motor lw 190 b / lw 245 b 2 000159 riemenscheibe lw 190 b pulley lw 190 b 000160 riemenscheibe lw 245 b pull...

Page 99

B version: 08.06.2015 d e t a i l a n s i c h t / d e t a i l e d v i e w benzin - motor / bencine - motor b - 17 lw 225 e - lw 245 b.

Page 100

B version: 07.02.2014 Öl-wasserabscheider 2. Stufe / oil-water separator 2nd stage e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 1 000288 Öl-wasserabscheider komplett complete oil-water separator 5 000786 verschraubung connection 6 000040 entwä...

Page 101

B version: 07.02.2014 Öl-wasserabscheider 2. Stufe / oil-water separator 2nd stage d e t a i l a n s i c h t / d e t a i l e d v i e w Öl-wasserabscheider komplett / complete oil-water separator 000288 1 b - 19 lw 225 e - lw 245 b.

Page 102

B version: 27.05.2014 filtergehäuse / filter housing e r s a t z t e i l l i s t e / s p a r e p a r t l i s t pos. Best.-nr. / p/n. Benennung description 1 000162 filtergehäuse komplett filter housing complete 4 000072 stutzen inkl. O-ring filtergehäuse inner manifold & o-ring 5 001374 filterpatron...

Page 103

B version: 27.05.2014 d e t a i l a n s i c h t / d e t a i l e d v i e w filtergehäuse / filter housing Öl-wasserabscheider komplett / complete oil-water separator 000162 1 37 b - 21 lw 225 e - lw 245 b.

Page 104

C version: 13.02.2014 e r s a t z t e i l l i s t e / s p a r e p a r t l i s t sicherheitsventil / safety valve best.-nr. / order no. Benennung description 000234 sockel für sicherheitsventil mit tÜv/ce base f. Safety valve tÜv 000553 sicherheitsventil - bauteilgeprüft safety valve tÜv 225 bar 0005...

Page 105

C version: 13.02.2014 sicherheitsventil / safety valve d e t a i l a n s i c h t / d e t a i l e d v i e w b - 23 lw 225 e - lw 245 b.

Page 106

B version: 05.07.2013 baugruppe: ansaugfilter / assembly: intake filter e r s a t z t e i l l i s t e / s p a r e p a r t l i s t best.-nr. / order no. Benennung description 001707 ansaugfiltergehäuse air intake filter housing 001708 ansaugfilterpatrone air intake filter cartridge 001772 flügelmutte...

Page 107

B version: 05.07.2013 baugruppe: ansaugfilter / assembly: intake filter d e t a i l a n s i c h t / d e t a i l e d v i e w b - 25 lw 225 e - lw 245 b.

Page 108

C version: 06.11.2014 e r s a t z t e i l l i s t e / s p a r e p a r t l i s t best.-nr. / order no. Benennung description 002811 hochdruckschlauch 10l, hp-hose 10l füllschlauch / filling hose 002811 b - 26 lw 225 e - lw 245 b.

Page 109

C version: 09.05.2014 e r s a t z t e i l l i s t e / s p a r e p a r t l i s t best.-nr. / order no. Benennung description 000213 handrad, schwarz din 200bar hand wheel din 200 bar, black 000215 handrad rot din 300bar hand wheel din 300 bar, red 000386 gleitscheibe, kreuzventil slide washer 000387 ...

Page 110

C v e rs io n : 0 9 .0 5 .2 0 1 4 d e t a i l a n s i c h t / d e t a i l e d v i e w b a u g ru p p e : k re u z v e n ti l / a s s e m b ly: c ro s s d e s ig n v a lv e andere verfügbare füllanschlüsse (other available filling connectors) benennung (description) best.-nr. (order no.) cga 346 - 20...

Page 111

C o p t i o n s version: 11/12-d.

Page 112

T able o f c on te nts c auto shut down .......................................................................................................................... 2 automatic condensation drain ................................................................................................... 5 swit...

Page 113

C a u t o s h u t d o w n d - 2 lw 225 e - 245 b.

Page 114

C version: 14.02.2014 a u t o s h u t d o w n operation: the compressor has a control box with an integrated hour counter. Before starting the compressor, press the blue condensate button for 5 seconds. This needs to be done to vent the residual pressure and the condensate. There´s none blue condens...

Page 115

C version: 14.02.2014 a u t o s h u t d o w n best.-nr. / order no. Benennung description 000203 druckschalter 50-350 bar pressure switch 50-350 bar 000712 verschraubung connection 000722 winkelverschraubung elbow connection druckschalter / pressure switch d - 4 lw 225 e - 245 b.

Page 116

C a u t o m a t i c c o n d e n s a t i o n d r a i n d - 5 lw 225 e - 245 b.

Page 117

C version: 14.02.2014 a u t o m a t i c c o n d e n s a t i o n d r a i n automatic condensation dump system the lw 100 compressor can be optional equipped with an automatic condensation dump system. A solenoid valve drains the 2nd and 3rd condensate separators every 20 minutes. To test the system, ...

Page 118

C s w i t c h o v e r d e v i c e 2 0 0 / 3 0 0 b a r d - 7 lw 225 e - 245 b.

Page 119

C version: 14.02.2014 s w i t c h o v e r d e v i c e 2 0 0 / 3 0 0 b a r 200 bar / 300 bar this option allows the filling of 200 bar or 300 bar. In this case, the compressor is equipped with a ball valve and a second final pressure safety valve and a second filling pressure gauge. When opening the ...

Page 120

C version: 14.02.2014 operation: 300 bar the ball valve should be fully closed to ensure the final pressure will be 300bar. 200 bar the ball valve should be completely opened to reduce the pressure to 200 bar. The opened ball valve ensures an air flow to the 200 bar fill connector. S w i t c h o v e...

Page 121

C a d d i t i o n a l f i l l i n g h o s e d - 10 lw 225 e - 245 b.

Page 122

C version: 09.07.2013 a d d i t i o n a l f i l l i n g h o s e best.-nr. / order no. Benennung description 000126 y-verteiler y-connector 000783 verschraubung connection 000799 verschraubung mit fester mutter connection with fixed nut 000783 000799 000783 000126 the additional hose with filling val...

Page 123

D a t t a c h m e n t version: 11/12-e.