- DL manuals

- Laplante

- Air Compressor

- V120103-RS11

- Operation Manual

Laplante V120103-RS11 Operation Manual

Summary of V120103-RS11

Page 1

Operation manual - 1 - operation manual model: v120103-rs11 rotary screw stationary air compressor 7502 mesa road houston, tx77028 telephone: (713) 635-6331 e-mail: service@lapante.Com web site: www.Laplantecompressor.Com.

Page 2: Laplante Warranty

Operation manual - 2 - general information: this compressor is for compressing atmospheric air and is not suitable for compressing any other gas. It is designed and manufactured to give optimum performance with long life and reliability. The manual gives the user all the information required to inst...

Page 3

Operation manual - 3 - contents 1.0 safety precautions 1.1safety precautions during installation 1.2 safety precautions during installation 1.3 safety precautions during maintenance and repair 1.4 symbols and warnings 2.0. Installation 2.1 compressor dimensions drawing 2.2 mounting & space requireme...

Page 4

Operation manual - 4 - 6.0: compressor system & funtional components 6.1 introduction 6.2 air end 6.3 air flow system 6.3.1 air filter and inlet valve 6.3.2 air/oil separator 6.3.3 minimum pressure check valve 6.4 oil system 6.4.1 oil cooler 6.4.2 oil filter 6.4.3 thermal mixing valve 6.5 electric s...

Page 5: 1.0: Safety Precautions

Operation manual - 5 - 1.0: safety precautions foreword this manual contains vital information for the safe use and efficient operation of this unit. It must be read carefully and understood before installing, operating or servicing. Otherwise, personnel are exposed to the risk of serious injury or ...

Page 6

Operation manual - 6 - of moisture at the inlet air. 3. Any blanking flanges, plugs, caps and desiccant bags must be removed before connecting the pipe. 4. Air hoses must be of correct size and suitable for the working pressure. Never use frayed, damaged or worn hose. Distribution pipes and connecti...

Page 7

Operation manual - 7 - 1.2 safety precautions during operation: general precautions: 1. The operator must employ safe working practices and observe all related local work safety requirements and regulations. 2. If any of the following statements does not comply with local legislation, the stricter o...

Page 8

Operation manual - 8 - workroom, take precautions against air pollution and possible contaminations of the breathing air. 9. Do not remove any of, or tamper with, the sound-damping material. 10. Never remove or tamper with the safety devices, guards or insulations fitted on the machine. Every pressu...

Page 9

Operation manual - 9 - to the starting equipment. 6. Persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one checking or working on the machine. To this end, a suitable notice shall be affixed to the remote start equipment. 7. Close the compre...

Page 10

Operation manual - 10 - equipment, hence some statements may not apply to your machine throughout the manual various safety concerns will be brought to your attention with boxes containing one of the following notations: danger is used to indicate the presence of a hazard, which will cause severe pe...

Page 11

Operation manual - 11 - rotation in direction of arrow emergency stop switch stop switch start-up switch.

Page 12: 2.0: Installation

Operation manual - 12 - 2.0: installation 2.1 compressor dimensions drawing: 2.2 mounting and space requirement: the lprs series is designed for indoor applications only. Allow at lease three (3) feet clearance on all sides of the compressor to facilitate maintenance as well as free circulation of a...

Page 13

Operation manual - 13 - the room should be of adequate size to provide full access to the machine for routine maintenance. It should have ventilation to keep the room as cool as possible. It is recommended that the air handling system be designed to permit no more than a 10 degree f rise in room tem...

Page 14

Operation manual - 14 - ft/s . Inlet containing reactive gases will cause the failure of the lubricant and compressor. Insure an air supply that is well clear of any reactive gas source. Air supply to compressor (cooling and compression): the cooling air discharge must be restriction free. Any louve...

Page 15

Operation manual - 15 - c. Check the fuses and the setting of the overload. D. Connect the power supply to the terminals the l1, l2, l3. E. Connect the earth conductor bolt. For choice the cable please reference table 3-2 of the electrical specification sheet. 2.3 guidelines for compressor air syste...

Page 16

Operation manual - 16 - immediately. It is best to send a confirming letter with the following information: a. Freight bill number. B. Date delivered - shipper's name & address. C. Description of item(s) damaged. D. Description of damage (a polaroid picture if possible). E. A copy of your invoice fo...

Page 17

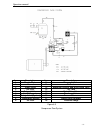

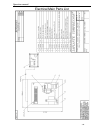

Operation manual - 17 - figure 2-2 installation drawings.

Page 18: 3.0: Specification

Operation manual - 18 - 3.0: specification – general 3.1 compressor specification sheet : table 3-1 compressor specification model item lprs11 cut-in pressure psig(bar) 135(9.3) cut-out pressure psig(bar) 150(10) volume flow cfm(m3/min) safety valve(system) setting psig 164 safety valve(network) set...

Page 19

Operation manual - 19 - if synthetic lubricants are not available contact your local lubricant supplier a lubricant that meets the specification in table 1 below. 3.3 electric specification sheet table 3-2 cable size, overload relay and fuses description voltage(v) amp (a) sf amp (a) frequency(hz) l...

Page 20: 4.0: Controller

Operation manual - 20 - 4.0: controller 4.1 introduction: in general, the controller has following functions: l controlling the compressor l protecting the compressor l monitoring components subject to service l automatic restart after voltage failure automatic control of the compressor the controll...

Page 21

Operation manual - 21 - figure 4-1 the controller surface 4.2.2 keys: table 4-1 the figure name and function figure name function emergency stop push button to stop the compressor immediately in the event of an emergency. After remedying the trouble , unlock the button by twist it out and press rese...

Page 22

Operation manual - 22 - 4: user menu item display units: bar, psi, , ℃ ℉, hr, lhr 5: status symbols started, running, loaded 6: service/fault symbols service, fault: alarm/warning/trip symbol meaning main display value; pressure (bar/psig menu selectable) default user menu item; temperature (℃/℉ men...

Page 23

Operation manual - 23 - fault conditions: if a fault condition occurs the fault triangle symbol will switch on steady (alarm/warning) or flash (trip/shutdown) the user menu display item will show a ‘fault code’ dependant on the fault. Fault codes service due countdown timer: if the service due count...

Page 24

Operation manual - 24 - are must been inspected . Stop manual stop press the stop button , the compressor will stop after 10 seconds, display as figure 4- 6. After the machine stop, the controller display will show back to start display (figure 4-3). Figure 4-6 stopping display un-loading stop if th...

Page 25

Operation manual - 25 - figure 4-8 trouble display.

Page 26

Operation manual - 26 - table 4-2 err code err code malfunction cause solution e:0010 emergency stop the emergency button be pressed deal with the emergency cause, loose the emergency button, press the reset button back to start state. E:0020 main motor overload relay protection the main motor curre...

Page 27

Operation manual - 27 - figure 4-9 alarming display figure 4-10 parameter display.

Page 28

Operation manual - 28 - table 4-3 alarming code alarm code alarm name cause action a:2050 oil separator pressure different alarm the oil separator pressure different value is bigger than set-point replace fine separator, press the controller ’s reset button, the controller will back to initial state...

Page 29

Operation manual - 29 - a:4804 service due service interval hours counter has reduced to zero. Reset the service interval time. Calling up the display the controller can display the parameter what show the compressor state when the machine is running, but this parameter cannot be edit. The view as f...

Page 30

Operation manual - 30 - temperature display units 1.T- o f - o f - - auto restart time 1.At sec 0 0 120 - the access code is 0121 for setting configuration menu: table 4-5 parameters description code units set minimum setting factory setting maximum setting default load delay time (star-delta) 2.Sd ...

Page 31

Operation manual - 31 - compressor parameter outlet the controller does not accept illogical setting, e.G. If the warning level is programmed at 203℉, the minimum limit for the shut-down level changes to 204℉. The recommended different between the warning level and shut-down level is 10℉ . Pressure ...

Page 32: 5.0: Operation

Operation manual - 32 - 5.0: operation 5.1 before initial start-up the operator must apply all relevant safety precautions, including those mentioned in this book. The operator must have a formally training for authority operation this machine. Be alarm! A careful operation is the best insurance aga...

Page 33

Operation manual - 33 - rotation of the air end is correct when the input drive shaft turns counter clockwise when facing the air end from the driveshaft end. If rotation is incorrect, open the line disconnect switch and rewire the power feed line at the compressor to obtain correct direction of rot...

Page 34

Operation manual - 34 - 5.7.4 unscrew the oil filler plug one turn to permit any pressure in the system to escape. 5.7.5 shut off and depressurize the part of the air net which is connected to the discharge valve. Disconnect the compressor air discharge pipe from the air net. 5.7.6 drain oil. Air es...

Page 35: 6.0:

Operation manual - 35 - 6.0: description 6.1 introduction the lprs11 compressor is an electric, belt driven, single stage, oil flooded rotary screw compressor complete with accessories, piped, wired and base mounted. It is available as a total self contained air compressor package fully enclosed wit...

Page 36

Operation manual - 36 - compressor (c) and is sent to the oil separator. During the compressor cycle, oil is injected into the compressor for the purpose of dissipating the heat of compressor and to seal the internal clearances. The compressed air laden with oil gas leaves the compressor through the...

Page 37

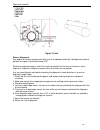

Operation manual - 37 - item description item description 1 electric motor 10 thermostat valve 2 air end 11 oil cooler 3 intake valve 12 minimum pressure and non return valve 4 air filter 13 air tank 5 solenoid valve 14 drain water valve 6 air/ oil separator 15 discharge valve 7 safety valve (system...

Page 38

Operation manual - 38 - 6.3.1 air filter and inlet valve the air filter is the primary protection of compressor from harmful dirt being ingested into the oil system. It needs to be looked at weekly for clogging or holes. The period for these inspections is dependent on the environment the machine is...

Page 39

Operation manual - 39 - figure 6-4 oil filter 6.4.3 thermal mixing valve: during start-up this valve provides for a bypassing of the heat exchanger so that oil flow is quickly established to the airend. The bypass stays start closed from 174 degree s f and will tightly closed bypass at 201 degrees f...

Page 40

Operation manual - 40 - loading status again. Shut down and blow off when the “stop” button pressed, the compressor stops. The solenoid valve closes and control air flows into inlet valve to close it. The blowing off valve opens at the same time to release the pressure in the package. 6.7 safety sys...

Page 41

Operation manual - 41 -.

Page 42

Operation manual - 42 - figure 6-5-a the electrical drawing 230 voltage.

Page 43

Operation manual - 43 -.

Page 44

Operation manual - 44 - figure 6-5-b the electrical drawing 575 voltage.

Page 45

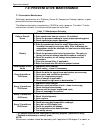

Operation manual - 45 - 7.0: preventative maintenance 7.1 preventative maintenance satisfactory performance of a stationary screw air compressor package requires a good preventative maintenance program. The following information is provided as a guide for such a program. The table 7-1 for the mainte...

Page 46

Operation manual - 46 - in dirty ambient environment, or with frequent cold starts. 7.2 oil testing : regular testing of the compressor oil as specified in the following maintenance guide is intended to assist in establishing oil and oil filter change intervals. It is possible, however, to obtain in...

Page 47

Operation manual - 47 - use the same brand oil. Collect the waste oil, do not allow it to seep into the ground! Disposal in accordance with the regulations! Do not spill oil! Check for leakage. With these compressor, the oil change intervals strongly depend on the degree of contamination of the circ...

Page 48

Operation manual - 48 - if the controller display need change the oil cartridge, change the oil filter cartridge as following 1. Make sure that the screw compressor unit is depressurized. 2. Unscrew the oil filter cartridge using an appropriate tool 3. Dispose of the oil filter cartridge according t...

Page 49

Operation manual - 49 - 4. Loosen the latch that secures the element and remove the element 5. Place a bright light inside the element to inspect for damage or leak holes. Discard any element that shows the slightest hole. 6. Clean the housing with a damp cloth. Do not attempt to blow out dirt with ...

Page 50

Operation manual - 50 - figure 7-5 belt sheave alignment: any degree of sheave misalignment will result in a reduction of belt life. Misalignment whether parallel or angular should not exceed 1/16 ” parallel misalignment occurs when the shaft are parallel, but the face of sheaves is not in alignment...

Page 51

Operation manual - 51 - only perform checks and carry out work when the screw compressor unit is out of operation and depressurized, electrically isolated and locked off. Any safety equipment which had to be removed for the replacement of the v-belt set must be remounted after completion of this wor...

Page 52

Operation manual - 52 - 1. Remove the service control piping from the minimum pressure/check valve. 2. Remove the valve from the air/oil receiver cover. 3. Clamp the valve securely in a vertical position (cap end up) in a suitable fixture or bench vice. 4. With a suitable wrench remove the valve cap...

Page 53

Operation manual - 53 - 2. Piston 3. Cap 4. Shim 5. Large spring 6. Small spring 7. Seal 8. Check valve assembly 8.0 oil cooler: cleaning: keep the cooler clean to maintain efficiency. 1) stop the compressor, close the air outlet valve and switch off the voltage. 2) cover all parts under the coolers...

Page 54

Operation manual - 54 - compressors, which are exposed to hot compressed air, according to the operating instructions. Blow off the screw compressor unit with compressed air at the specified intervals (never aim compressed air at persons) paying particular attention to: • regulating elements • fitti...

Page 55: 8.0: Troubleshooting Table

Operation manual - 55 - 8.0: troubleshooting table there are a lot of reasons result fault. Information collection is important for operator to find out the causations. Do analysis carefully before repair or change parts. Please inspect the machine following this way. A. Check cable connection, b. I...

Page 56

Operation manual - 56 - compressor fails to provide sufficient air for demands 1. Clogged or restricted air filter element 2. Excessive distribution system leakage 3. Air demand exceeds compressor capacity 4. Motor not running up to speed. 5. Drive belts loose and slipping. 6. Damaged or excessively...

Page 57

Operation manual - 57 - unit shut down caused by air end discharge or separator out high temperature 1. Air end discharge temperature too high due to: a. Insufficient oil in oil reservoir b. Compressor operating above maximum recommended pressure c. Dirty or clogged oil cooler inside or out 2. Fault...

Page 58: 9.0 Parts List

Operation manual - 58 - 9.0 parts list 9.1 lprs11-230v, the p/n of laplante is 001117: 001117 exploded drawing 001117 parts list.

Page 59

Operation manual - 59 -.

Page 60

Operation manual - 60 - electrical main parts list.

Page 61

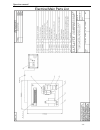

Operation manual - 61 - 9.2 lprs11-575v, the p/n of laplante is 001118: 001118 exploded drawing.

Page 62

Operation manual - 62 - 001118 parts list.

Page 63

Operation manual - 63 - electrical main parts list.

Page 64

Operation manual - 64 - 10.0 main wearable parts list item lp p/n description qty 36 420055 belt xpz1312lp 2 54 280001 element of air filter 1 59 071000 gasket, intake valve 1 61 900002 oil/air separator 1 62 900003 oil filter 1.