Summary of G300

Page 1

V.12.15.00 g300 operations manual.

Page 2

Page 1 introduction page 2 warning page 3 technical specifications page 4 operating procedure page 7 remote and external control features page 7 analog 0 - 10v control page 8 link switch setting options page 8 g300 / haze - mode changing. Page 8 machine to machine linking page 10 maintenance page 10...

Page 3: Introduction

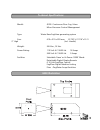

The g300 is a microprocessor controlled, water base fog and haze generating system. The microprocessor is responsible for the following control elements - monitoring the heat exchanger temperature. Driving the heater within the heat-exchanger in a proportional power mode. Driving the fluid pump unit...

Page 4

M.S.D.S. Available by request or at www.Lemaitrefx.Com warning read these important safety instructions do not remove the outer case until power has been disconnected from the machine read these important safety instructions persons suffering from asthma or allergenic sensitivity may experience irri...

Page 5

Model: g300 continuous flow fog / haze micro-processor control management type: water base fog/haze generating system size: 610 x 210 x 295 mm. 23 7/8”x11 7/16”x10 1/ 2” high (incl. Handle) weight: 24 kilos , 52 lbs. Power rating: 110 volt a.C.50/60 hz 18 amps 240 volt a.C.50/60 hz 9 amps facilities...

Page 6: Operating Procedure

1) the g300 must only be connected to a mains supply capable of sustaining at least 18 amps, and be adequately grounded. The supply should be ‘clean’ and free of interference. 2) the power to the g300 should be controlled by the illuminated mains power switch located on the rear panel. 3) shortly af...

Page 7

5) the remote display will now enter its standard phase. This indicates the ‘heating’ power, the ‘flow’ rate setting, and the ‘ready’ status. At this stage the flow rate may be adjusted freely between minimum and maximum settings. (upon entering a ‘ready to operate’ phase the maximum allowable flow ...

Page 8

At this time, or shortly afterwards, the ‘heat flash’ indicator bars on the remote handset will reduce from 3 bars to 2, and then 1 and finally no bars, as the heater switches off. When settled, the ‘heat flash’ indicator will indicate the power being used in maintaining the working temperature. Sin...

Page 9

The standard remote handset may be removed from the machine, and operated effectively away from the issue site. The maximum recommended cable length is 30 me- tres.(100 feet). It is not recommended to plug/unplug the handset while the machine is still pow- ered up. If this should occur, there is a p...

Page 10

If it is required for a machine to accept ‘flow rate’ data from an ‘upstream’ unit, then the ‘flow accept’ switch on this machine must be active. If it is required for a machine to accept the ‘smoke on’ switch data from an ‘up- stream’ unit, then the ‘smoke accept’ switch on this machine must be act...

Page 11

It is important to note that the ‘user’ will be responsible for ensuring that the ma- chine is in the correct mode for the prevailing fluid type. All that is required is a brief machine switch ‘off’ then back ‘on’ again. In the example given i.E. From hi-power g300 mode to haze mode, a re- adjustmen...

Page 12

Maintenance the casing of the g300 is steel with a powder paint coating. To clean simply wash with mild soap and warm water. Periodically check to ensure that the fluid pick up filter screen is in place and clean from debris. Using high quality le maitre fluid should result in a long heat exchanger ...

Page 13

It is very similar to the "quick dissipating" but dissipates at about twice the rate of the "quick dissipating". The "molecular fluid" was originally designed for use in the lsx, however, many other applications were found very quickly. It is a clean, white, thick fog, practically odour- less and di...

Page 14

Warranty: all warranty is one year parts and labour unless specified and is on manufacturer defect only. Overuse or poor maintenance is not accepted. Le maitre fluids must always be used. Any trace of other fluids will automatically void all warranties. Accept no substitutions as there are no except...

Page 15

1. Ensure that operation of the machine is supervised by suitably trained and authorised personnel. 2. Do not modify the machine or use a machine which has been damaged in any way. 3. Allow sufficient air circulation around the machine at all times. 4. Protect the g300 from direct weather effects an...

Page 16

G300 industrial 20 l. Pail option 1. Follow these steps for easy setup. A) remove cap from 20l pail (this will not be used, so you may want to put it in a safe place for use later on.), and remove inner cap if equipped. B) examine the end of the hose from your machine and make sure the filter is in ...

Page 17

A- air pressure gauge: this is used as a visual aid to help in setting the air pressure used in the steam simulation/ air purge effect. B- air pressure control: this is used to control the velocity of the steam/ air purge effect, with the setting being displayed on the air pressure gauge in p.S.I (p...

Page 18

1.) place the g300 directly against the foam ring input of the lsg. Proper alignment can be observed by shining a flashlight into the 12" exit of the lsg and noting the g300 output nozzle is centered in the lsg input. 2.) connect the blue twist lock connector into custom port on the rear panel of th...

Page 19

7.) the second connection to be made is the co2 supply hose. This is connected to the liquid port of the co2 supply. A washer is necessary to prevent leaks and are available from your gas supplier. 8.) a lsg low requires a 350 lb. Low pressure dewar. You must connect the supply hose to the liquid ou...

Page 20

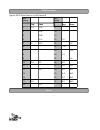

Notes 18 g300 flow rates typical g300 flow rates in cc (ml.)/second flow setting flow setting fog haze fog haze 1 0.3 0.05 17 2 0.06 18 3 0.08 19 4 0.12 20 1.0 5 .5 0.25 21 1.0 6 22 1.25 7 23 1.25 8 24 1.5 9 25 1.5 10 0.6 0.5 26 2.0 11 27 2.5 2.0 12 0.6 28 3.0 n/a 13 29 4.0 n/a 14 30 5.0 n/a 15 0.8 ...