- DL manuals

- Maga

- Boiler

- MA 15

- Operation And Maintenance Manual

Maga MA 15 Operation And Maintenance Manual

WOOD - FIRED HOT WATER GASIFYING BOILER

MA 15, MA 20, MA 25

MA 31, MA 40, MA 49, MA 80

With an exhaust fan and CONTROL UNIT ST 81 zPID

BOILER OPERATION AND MAINTENANCE MANUAL

MAGA s.r.o., S. Kollára 86

979 01 Čerenčany – Rimavská Sobota

Slovakia

Tel / fax:

+421 47 56 34 798

E-mail:

sales@magasro.sk

Web:

http://www.magasro.sk

Thank you for buying our product!

1

Summary of MA 15

Page 1

Wood - fired hot water gasifying boiler ma 15, ma 20, ma 25 ma 31, ma 40, ma 49, ma 80 with an exhaust fan and control unit st 81 zpid boiler operation and maintenance manual maga s.R.O., s. Kollára 86 979 01 Čerenčany – rimavská sobota slovakia tel / fax: +421 47 56 34 798 e-mail: sales@magasro.Sk ...

Page 2

So that you remain satisfied with our product, we recommend that you follow these fundamental principles for long lifespan and sustainable proper operation of the boiler 1. Use only dry wood fuel with max. 20 percent moisture content – (2 years old wood). 2. During the process of gasification of sol...

Page 3

1. Purpose of use the ma hot-water boiler is intended for heating homes and other types of buildings. The boiler is designed exclusively to work on burning wood. Any dry wood such as chopped logs or wood chips with maximum length of 500 mm (ma 15 – 350 mm, ma 80 – 650 mm) can be used as fuel for thi...

Page 4

3. Technical description the boiler is designed to work on burning wood. The combustion process (which is based upon power generating gasification) is obtained by passing ambient air into the firebox (furnace) with the use of an exhaust fan. The boiler shell is made from steel plates as a welded ass...

Page 5

Output capacity regulation the regulation of output capacity is performed automatically through turning on and off the fan or by adjusting the fan speed in the control unit. Refueling refueling should be carried out in the following manner: - by pressing the option button the “ fan 100 % ” symbol ap...

Page 6

8. Accessories scraper for sweeping pipes 1 pc inlet valve 1 pc sweeping scraper 1 pc operation and maintenance manual 1 pc warranty certificate 1 pc female socket for pump 1 pc 9. Electrical connection of the boiler to the power supply the boiler is connected to the electric power supply by a three...

Page 7

Combustibility class of building materials and products building materials and products falling within the combustibility class a – incombustible granite, sandstone, concrete, bricks, ceramic tiles, mortar, fire retardant plasters etc. B – not easily combustible wood-wool slabs, isomin, lignostone, ...

Page 8

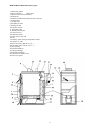

Boiler basic drawing(more types): 1 boiler body (shell) 2 door to add fuel (upper door) 3 door to remove ash (lower door) 4 exhaust fan 5 bottom of combustion space(refractory concrete) 6 control panel 7 air flap valve 8 secondary air inlet 9 primary air inlet 10 ceramics nozzle 11 firing flap valve...

Page 9

16. Boiler installation boilers are typically supplied to customers equipped with basic boiler regulation. The regulation ensures the required heating water output temperature of 75 to 90° c. It does not cover the control of mixing valves and pumps. Each of the pumps within the system must be operat...

Page 10

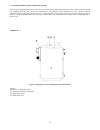

Boiler installation/connection with a thermoregulating valve boiler installation/connection with a heat storage tank 10

Page 11

Boiler installation/connection with a 4-way valve operation of the system with heat storage units (tanks) after the boiler is fired up and is operated at full capacity, it will heat the water in the storage tank to a temperature of about 80-90 °c (which may take from 2 to 4 fuel loads). Then the boi...

Page 12

17. Protecting the boiler against accidental overheating there are several methods that can be used to secure your boiler against unwanted overheating. You can either connect a cooling heat exchanger protecting the system from overheating by using danfoss bvts, honeywell ts 130 or watts sts 20 conne...

Page 13

Version nr. 2: figure: cooling pipes, valves and fittings connection scheme 1) safety relief valve 2) reservoir + temperature sensor 3) cooling heat exchanger in the boiler 4) cooling water output 5) boiler 6) cooling water input a - cooling water inlet, 2 - 6 bar, temperature of 10-15 °c b - drain ...

Page 14

18. Control unit st 81 zpid service manual for control unit st 81 zpid for maga wood-fired gasifying boiler the control unit st 81 zpid is intelligent system, that operates the maximum capacity output of the boiler regarding the information received from the chimney sensor. The control unit controls...

Page 15

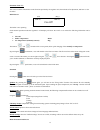

Functions of the cu: this section contains information on the functions provided by the regulator unit, the methods of its adjustment, and how to view the menu. Initial screen (ch) (reg.) the boiler is not operating. Under normal operation mode the regulator’s lcd display will show the initial scree...

Page 16

In order to ensure the safest possible and failure-free operation, the regulator is equipped with a variety of protective elements. In the event of malfunction you will hear a warning sound (alarm – if not silenced) and the display will show the applicable error information. Alarm sound could be sil...

Page 17

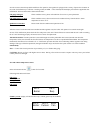

How to connect the cu: fuse: 3.15 amp power: 230 volts / 50hz fan: 230 volt / 1 amp max. Ch pump: circulating pump 230 volt / 1 amp max. Termik: safety thermostat fumes sensor: chimney temperature sensor ch sensor: boiler temperature sensor indication for power, fan, ch pump: l power (brown) pe prot...

Page 18

Letter of guarantee of the wood-fired hot water gasifying boiler this letter of guarantee substitutes certificate of quality and integrity of the product. Producer confirms that the boiler meets requirements of demanded quality, is complete in an extent specified by documentation and is in accordanc...

Page 19

Instructions for purchaser - conditions for guarantee and complaints: 1) complaints of completeness of the delivery can be exercised in accordance with the commercial code and civil code at the supplier. 2) producer gives a guarantee on the product for the period of 24 months starting on a day of sa...

Page 20

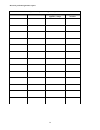

Record of performed guarantee repairs record of performed repairs within guarantee period and after date of the record performed activity organization (signature, stamp) signature of the customer 20

Page 21

Conformity declaration issued according to § 12 section 3 letter a) of the law number 264/1999 of the code a 97 / 23 ec we maga ltd. S. KollÁra 86 ČerenČany 979 01 rimavskÁ sobota slovakia iČ dph: sk 2020075904 declare to our full responsibility that the mentioned products meet the requirements of t...