Summary of MONOMAG 180

Page 1

Monomag 180 user manual mig/mag welding machine www.Magmaweld.Com.

Page 2

1 monomag 180 safety rules 1. Technical informations 1.1 general explanations 1.2 components of monomag 180 1.3 data plate 1.4 technical specifications 1.5 accessories 2. Installation 2.1 upon receipt and claims 2.2 installing and working reccomendations 2.3 welding connections 2.3.1 earth clamp con...

Page 3

2 monomag 180 identifying safety information these symbols are being used to identify potential risks. When seen a safety symbol in the manual, it must be understood that there is an injury risk and following instructions must be read carefully to avoid potential risks. While welding, keep the third...

Page 4

3 monomag 180 safety rules breathing welding fumes can be hazardous to your health inhaling fumes and gases over a long period of time, generated during welding is dangerous and forbidden . Irritation of the eyes, nose and throat are symptoms of inadequate ventilation. Take immediate steps to improv...

Page 5

4 monomag 180 safety rules noise can damage hearing noise from certain industrial processes or equipments can damage hearing. Wear approved ear protection if noise level is high. Working in small and confined places can be dangerous while welding and cutting in small, confined places, always have a ...

Page 6

5 monomag 180 safety rules falling unit can cause injury wrong positioned power source or other equipment may cause serious injury to persons or damage to objects. While repositioning the power source always carry by using the lifting eye. Never pull cable, hose or torch. Always carry the gas cylind...

Page 7

1.2 components of monomag 180 monomag 180 is a single phase, step controlled, constant voltage, compact mig/mag welding equipment to be used especially for intensive thin metal repair applications. Any kind of metal can be welded with this machine, if proper welding wire and gas is used. For mild st...

Page 8

30 a / 16 v - 140 a / 21 v x 20 % 60 % 100 % 80 a 60 a 18 v 17 v cl.I. H u v 220 50 hz 1 s 1 ip 21 i a 13 1 i a 9,7 1 i a 28 1 2,9 kva 2,1 kva s t 32 a u v 14 - 29 0 i 2 u 2 monomag 180 seri no : organize sanayi bölgesi 5.Kısım manisa - tÜrkİye en 60974-1 en 60974-10 140 a 21 v 6,2 kva 1r magma meka...

Page 9

8 monomag 180 2. Installation installation 2.1 upon receipt and claims ú ú ú ú ú standard pallet contains: power source torch earth cable gas hose user manual 2.2 installation and working recommendations • use lifting eyes or fork-lift to carry the machine. Do not lift the machine together with the ...

Page 10

2.3 welding connections 9 monomag 180 2.3.1 connecting the earth cable to the workpiece topraklama pensesini, kaynak yapılacak bölgeye olabildiğince yakın yerden iş parçasına sıkıca bağlayın. After placing the gas cylinder on its platform, fasten it with the gas cylinder safety chain . To operate sa...

Page 11

While inserting the plug into the socket, pay attention that main switch is positioned to “0”. Before plugging your machine to the electrical line check with a voltmeter the correct voltages indicated at the plate of the machine and then insert the plug into the socket. 3.2 choosing and changing the...

Page 12

3.4 adjusting the gas flow for accurate gas flow rate adjustments, use the following table. A b c d e a: b: c: d: e: appropriate pressure on wire and appropriate roll size (canal depth) selection. Over pressure on wire may result in deformation of the shape of the wire. Over pressure on wire may res...

Page 13: Ø : 0,6 Mm

4. Welding 4.1 adjusting the stick out 4.2 welding parameters Ø : 0,6 mm Ø : 0, mm 8 Ø : mm 1,0 mm 0.5 2 3 35 19 1 3 5 60 20 2 4 8 70 21 mm a v 1 3 4 75 19 2 4 5.5 90 20 3 5 7 105 21 mm a v a v 2 4 3.5 100 20 3 5 5.5 125 21 5 6 7 140 25 co 2 1 2 5 55 17 2 3 7 70 20 3 5 13.5 115 22 0.5 1 4 45 16 2 4 ...

Page 14

13 monomag 180 open the covers of the machine and clean with dry air. Or 5. Maintenance and troubleshooting 5.1 e periodic maintenanc clean the labels on the m a c h i n e . R e p a i r o r replace the worn out labels. Repair or replace the worn out welding cables. Clean and tighten the weld termina...

Page 15

5.4 fuses fuse amperage feature protected circuit f1 f2 f3 0.8a 1a 10a t f f fan motor co heater 2 wire feeder 14 monomag 180 maintenance and troubleshooting 5.3 troubleshooting trouble reason remedy contact your authorized technical service. Machine does not work. Contact your authorized technical ...

Page 16

15 monomag 180 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 no material code designation spare parts list appendix 1 a253200001 a300101005 a300101015 a300102003 a300190001 a310310002 a310310004 a377100004 a410200003 a410801004 a229500002 a490300004 a314800102 k304400012...

Page 17

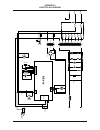

Electrical diagram appendix 2 r e 4 1 4 1 2 3 4 5 6 7 8 9 10 ja tel hizi 1k tetik th termik atik 5mm k›rm›z› led 1 2 jb m2 24vdc/90w 1 2 3 4 jc - + c1 22000uf/63v c2 22000uf/63v r 1 2 2 0 r /1 1 w + - l 1 8 6 0 m h r Ö l e 1 2 t r 1 0 1 2 3 4 5 6 7 7 6 5 4 3 2 1 1 1 4 4 4 6 1 0 1 4 1 2 1 6 1 8 8 4 4...

Page 18

Owm 09.06.2011 +90 236 226 27 00 +90 236 226 27 28 factory made in tÜrkİye organize sanayi bölgesi 5.Kısım 5503. Sokak no:1 manİsa www.Magmaweld.Com.