- DL manuals

- Ochsner

- Heat Pump

- GMLW

- Installation And Operating Instructions Manual

Ochsner GMLW Installation And Operating Instructions Manual

Summary of GMLW

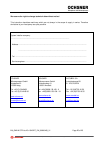

Page 1

Installation and operating instructions gmlw heat pump heating/cooling/hot water.

Page 2

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 2 of 25 contents: installation and operating instructions heat pump ................................................................... 2 1 notes on the documentation .................. 4 2 safety instructions ................................. 4 2.1 ce ...

Page 3

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 3 of 25.

Page 4: 2 Safety

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 4 of 25 1 notes on the documentation the following pointers are valid for the whole of the documentation. Storage: this instruction manual must be kept within easy access close to the heat pump. Symbols: the precautionary pointers below will be used in ...

Page 5: 3 Appliance

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 5 of 25 safety functions for the heat pump may be activated with the control. As the control is, however, not certi- fied as a safety appliance, safety mechanisms against failure of, or damage to the heat pump must ad- here to local safety regulations (...

Page 6: 4 Installation

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 6 of 25 the heat pump is to be commis- sioned by ochsner factory cus- tomer service engineers. The cor- rect construction and function of the heating system, the heat source and the electrical installa- tion is the be ensured by the in- staller. Otherwi...

Page 7

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 7 of 25 4.2 transport the heat pump is to be transported and stored in a packaged condition. Careful transport at an angle of 45° is allowed over short distances. Ambient temperatures of –20°c to +45°c are allowed both for transport and storage. The sta...

Page 8

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 8 of 25 • avoid installing the evaporator alongside bedrooms • plants and vegetated surfaces can reduce the noise level • in closed rooms, the noise level is depend- ent on the volume of the room and its re- verberation time. • a frost-protected drainag...

Page 9

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 9 of 25 4.4.1 cooling operation for cooling operation, all system components (pipework, fittings) must be insulated against condensate forming by means od suitable insu- lating materials. This holds especially for the flow pipework from the heat pump to...

Page 10

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 10 of 25 4.6 electrical connection the regulations of the energy util- ity and the relevant en-standards are to be adhered to without fail. The values indicated in the appendix for fuse- protection are given solely as reference values. The implementatio...

Page 11

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 11 of 25 due to the fact that the scroll-compressors are 3-phase models, they will run in one or the other direction, depending upon how the termi- nal l1, l2 and l3 are connected. To check for correct connection, test whether, when switch- ing on, the ...

Page 12

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 12 of 25 4.6.4 sensor wiring de-icing sensors: 2 de-icing sensors (tqa, tqe) are to be in- stalled in the fin-packet of the evaporator. (see the wiring diagram for the exact positioning of the sensors) for this, a 4-pole cable is to be run from the indo...

Page 13: 5 Commissioning

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 13 of 25 4.7.1 switch off via tariff relay: for switching by means of a tariff relay (sealed by the utility on site) the 3-phase power supply to the heat pump is switched off. The heat pump signal contact must be executed via the auxiliary contact on th...

Page 14: 6 Operating The System

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 14 of 25 5.2 check list for commissioning adhere to the following sequence: 1) check heating system circuit: system- pressure, expansion vessel function, bleeding valves, quantity adjustment 2) check whether all non-return valves are open 3) check power...

Page 15: 7 Maintenance

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 15 of 25 an increase of the room temperature by 1°c means a 5-7% increase in energy consumption. Generally, higher operation costs can be ex- pected in the first heating season, depending upon the residual moisture (up to 50%) in the building materials ...

Page 16

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 16 of 25 7.3 trouble shooting should a defect or problem arise, despite the selection of parts of highest quality and the painstaking care put into production, please notify your contracting partner or the ochsner customer service de- partment with the ...

Page 17

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 17 of 25 error / warning possible cause recommended action 2. Energy provider error - high pressure (er 36) energy dispersion not guaranteed / heating loop over-regulated open barriers to flow (valves) one or more circulation pumps not functioning reset...

Page 18: Annex

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 18 of 25 trouble shooting, continued 8. Hot water temperature not reached heat exchanger (hot water) too small enlarge surface area heat exchanger (hot water) chalked contact installer, clean, decalcify wrong sensor positioning position correctly pipewo...

Page 19

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 19 of 25 technical data gmlw performance data normal mode gmlw 9 gmlw 14 gmlw 19 gmlw 25 heating capacity l7/w35 9,9 15,1 20,2 27,0 kw power consumption l7/w35 2,2 3,4 4,6 6,3 kw coefficient of perfomance l7/w35 4,5 4,4 4,4 4,3 drawn current l7/w35 4,7 ...

Page 20

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 20 of 25 technical data gmlw plus performance data normal mode gmlw 9 plus gmlw 14 plus gmlw 19 plus gmlw 25 plus gmlw 35 plus heating capacity l7/w35 10,0 14,1 19,8 26 34,8 kw refrigerating capacity l7/w35 7,8 11,1 15,4 20,4 27,7 kw power consumption c...

Page 21

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 21 of 25 evaporator connection pipework anzahl artikel nr. Wp-type bögen 90° flüssigl. Saugg.L flüssigl. Saugg.L flüssigl. Saugg.L flüssigl. Saugg.L 284050 gmlw 9 2 bis 8 12 18 12 18 12 22 12 22 284060 gmlw 9 plus 2 bis 8 12 18 12 18 12 22 12 22 284100 ...

Page 22

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 22 of 25 dimensions sheet gmlw 9 – gmlw 19 gmlw 9 plus – gmlw 19 plus rlq vlq oc hsner 115 0 600 650 92 0 85 385 15 5 62 1 vlh ea rlh elektroanschluss/electrical connection rücklauf quellenergie/heat source return vorlauf quellenergie/heat source supply...

Page 23

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 23 of 25 operation data mllenium evaporator msv 14: msv 19-35: operating data: heat pump type gmlw 9 plus gmlw 19 plus gmlw 25 plus gmlw 35 plus evaporator type msv 14 msv 19 msv 25 msv 35 flow rate [m3/h] 4000 8000 8000 9800 number of fans 1 2 2 2 powe...

Page 24

Ba_gmlw ote bis v3.4 short_en_20090408_v1 page 24 of 25 declaration of conformity european community – manufacturer disclosure the signatory ochsner wärmepumpen gmbh werk: a 3350 haag ochsnerstrasse 1 certifies that the following indicated device(s) introduced into the market by ochsner fulfill the ...

Page 25

5 2 f o 5 2 e g a p 1 v _ 8 0 4 0 9 0 0 2 _ n e _ t r o h s 4 . 3 v s i b e t o w l m g _ a b we reserve the right to change technical data without notice! This instruction describes machines, which are not always in the scope of supply in series. Therefore deviations to your heat pump are quite pos...