- DL manuals

- Paice Setter

- Brush Cutter

- PS260S

- Operator's Manual

Paice Setter PS260S Operator's Manual

Operator’s

manual

READ THESE INSTRUCTIONS

CAREFULLY BEFORE USE

Please also refer to engine manufacturer’s instructions.

Contact your dealer or manufacturer if you have a

question that is not answered in this manual.

OBSERVE SAFETY REGULATIONS

Keep this manual safe for future reference.

Brushcutter

PS260S

PS260W

PSX260S

PSX280W

PaiceSetter

TM

Summary of PS260S

Page 1

Operator’s manual read these instructions carefully before use please also refer to engine manufacturer’s instructions. Contact your dealer or manufacturer if you have a question that is not answered in this manual. Observe safety regulations keep this manual safe for future reference. Brushcutter p...

Page 2

E.E.C. Declaration of conformity the undersigned, brian m. Child, authorized by meetens industrial engines limited. Of 261-269, coombe lane, wimbledon, london, sw20 0rh declare that the following: ‘paice setter’ petrol powered brushcutters / grass trimmers model: ps260s / ps260w serial no.: 3002001 ...

Page 3: Safety Alert Symbol

Safety alert symbol this is the safety alert symbol. When you see this symbol in this manual, be alert to the potential of personal injury. When accompanied by the words ‘caution’ and ‘warning’, it calls your attention to items or operations which can lead to serious injury. Understand signal words ...

Page 4: Safety Rules and Precautions

Safety rules and precautions read the operator’s manual carefully. Be familiar with the controls and the proper use of the unit. Know how to shut the unit off and how to unhook a harnessed unit quickly. Dress warning: to avoid serious injury there is a risk of eye damage from thrown objects. Always ...

Page 5: Safety Rules and Precautions

Safety rules and precautions strictly no fire warning: to avoid serious injury handle petrol with care. It is highly flammable. Move at least 3 metres away from the fuelling point before starting engine. Do not move the fuel tank cap when the engine is still warm or running. Eliminate all sources of...

Page 6: Cautions During Operation

Never operate the unit without proper guards, shields or other safety protective devices in place and properly connected. Inspect to determine that these safety devices are installed properly, are in good condition and operate properly. If the condition or operation of these devices are abnormal, th...

Page 7: Warning:

Warning: to avoid serious injury blade thrust may occur when the spinning blade contacts a solid object in the critical area. A dangerous reaction may occur causing the entire unit and operator to be thrust violently. This reaction is called blade thrust. As a result, the operator may lose control o...

Page 8: Caution:

Caution: to avoid serious injury carefully follow the instructions in this manual to avoid any mistakes. We shall not be held responsible for any accident due to any operational error resulting from negligence in following the instructions, nor for any accident due to repair, remodelling, overhaul e...

Page 9: Section 1

9 section 1 operation 1.

Page 10: Preparing For Operation

Preparing for operation fuel and oil mixture (2-stroke engines) inspect the fuel tank and fill with clean, fresh fuel of the proper mixture to ensure long life of the machine. Use the following fuel mixture: 1. For the first 20 hours: petrol : 2 cycle engine oil = 15 - 20 : 1 2. After 20 hours: petr...

Page 11: Note

Starting & stopping the engine note the follow information is only a guide. For definitive instructions regarding the engine, always refer to the engine manufacturer’s instructions. Starting (before starting, see safety rules on page 4) caution release the lock lever before operating the half thrott...

Page 12: Stopping

Stopping release the throttle lever. Shift the main switch from the [i] position to the [o] position. If no more work is to be carried out, evacuate the fuel from the fuel tank, restart the engine and continue to operate until it stops. The fuel remaining in the float chamber of the carburettor will...

Page 13: Carburettor Adjustment

Carburettor adjustment for details of carburettor adjustment, please refer to the engine manufacturer’s instructions supplied with your paicesetter main pipe assembly. Caution adjustment of the carburettor is not usually necessary, since it is adjusted to the optimum position when delivered from the...

Page 14: Correct Handling of Machine

14 correct handling of machine attaching the shoulder harness put on the shoulder harness and connect the buckle, ensuring that it is properly fastened. Attach the brushcutter to the harness and adjust the strap length so that the cutter blade or the nylon cutting head will be kept parallel to the g...

Page 15: Working Methods

Working methods warning: to avoid serious injury always wear safety goggles, safety shoes, gloves and helmet whenever operating the machine. Nylon cutter pull out the cord of the nylon cutter by 12-15cm. Blade blades can be sharpest from the edge to one third up the shaft. When mowing grass, use two...

Page 16: Working Methods (Continued)

16 working methods (continued) kickback warning: risk of serious injury when operating the brushcutter, uncontrolled kickback may occur. Kickback can occur particularly when attempting to cut within a blade segment between 12 and 2 o’clock. Never apply the brushcutter within a segment between 12 and...

Page 17: Regular Maintenance Chart

17 regular maintenance chart complete unit visual inspection 1 ★ clean ★ cutting tool* inspect cutters 1 ★ check tightness 1 ★ ★ throttle check operation of trigger, ignition switch & throttle lock 1 ★ bolts inspect & re-tighten 1 ★ shaft tube visual inspection 1 ★ ★ safety guard visual inspection 1...

Page 18: Regular Maintenance Notes

18 regular maintenance notes for engine maintenance details, please refer to the engine manufacturer’s instructions. 1. Before operation check the machine for loose screws or missing parts. Pay particular attention to the tightness of the cutter blade. (see page 23 - ‘installation of cutter’.) alway...

Page 19: 6. Checking The Spark Plug

19 6. Checking the spark plug the spark plug may gather carbon deposits on its firing end with reasonable use. Remove and inspect the spark plug every 25 hours and clean the electrodes as necessary with a wire brush. For the correct spark plug gap, please refer to the engine manufacturer’s recommend...

Page 20: Troubleshooting

20 troubleshooting 1. Machine does not start: a) check that water, etc. Is not mixed in with the fuel. B) check that the intake of fuel is not excessive. 2. Rotating speed does not increase after starting: a) check if the choke is fully open. B) check that the mixing ratio of fuel is correct. C) che...

Page 21: Section 2

Section 2 installation 21 2.

Page 22: Assembly Of The Machine

Assembly of the machine installation of engine 1. Attach the clutch case to the engine with the 4 allen screws (in tool bag). 2. Remove cable adjuster and nut from carburettor adjuster bracket and replace with the cable adjuster fitted to paice setter throttle cable. The procedure may be easier if t...

Page 23: Attaching The Handle

23 when a bessertrim™ head is fitted to the brushcutter, please move the guard to the bessertrim™ mark on the shaft for the required clearance. Bessert rim option: attaching the handle position the handle for comfortable operation and securely fasten it using the fixings supplied. Attaching the safe...

Page 24: Installation of Cutter

24 installation of cutter caution: to avoid serious injury blade is sharp. Please handle carefully to avoid injury. Blade 1. Assemble parts in the following order: holder a, blade, holder b, guard, fastening nut. 2. In order to lock the rotation of the spline shaft, align the holes (x) of gear case ...

Page 25: Section 3

25 section 3 parts specifications 3.

Page 26: Ps-260 S

26 ps-260 s guard grease points (see p.17).

Page 27: Psx-260 S

Psx-260 s guard grease points (see p.17) 27.

Page 28: Parts Diagram

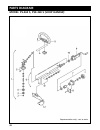

28 parts diagram model: ps-260 s, psx-260 s (loop handle) representation only - not to scale.

Page 29: Parts List

29 no. Part no. Part description 1 ps26-01 gearbox assembly 2 ps10-02 flange nut 10mm l/h 3 ps26-03 flange clamping washer (top) 4 ps26-04 flange clamping washer (bottom) 5 ps26-05 grass cover (includes fixing screws) 6 ps26-06 main pipe assembly 7 pss-07 anti-vibe clutch housing assembly (includes ...

Page 30: Ps-260 W

Ps-260 w 30 half throttle control throttle trigger (see inset for det ail) throttle control det ail guard grease points (see p.17) blade throttle trigger (c) safety lever (b) half throttle button (d) ignition cut-of f switch (a) throttle trigger (c) half throttle button (d).

Page 31: Psx-280 W

Psx-280 w 31 half throttle control throttle trigger (see inset for det ail) throttle control det ail guard grease points (see p.17) blade throttle trigger (c) safety lever (b) half throttle button (d) ignition cut-of f switch (a) throttle trigger (c) half throttle button (d).

Page 32: Parts Diagram

32 parts diagram model: ps-260 w, psx-280 w (cowhorn handle) representation only - not to scale.

Page 33: Parts List

33 no. Part no. Part description 1 ps26-01 gearbox assembly 2 ps10-02 flange nut 10mm l/h 3 ps26-03 flange clamping washer (top) 4 ps26-04 flange clamping washer (bottom) 5 ps26-05 grass cover (includes fixing screws) 6 ps26-06 main pipe assembly 7 pss-07 anti-vibe clutch housing assembly (includes ...

Page 34: Notes

34 notes.

Page 35: Limited Warranty

Limited warranty should any failure occur with the product under normal operating conditions within the applicable warranty period, the failed part will be replaced or repaired free of charge by your paicesetter authorised dealer. Warranty period: paicesetter main pipe assembly: 2 years from the dat...

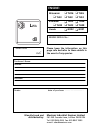

Page 36: Tu26

Meetens industrial engines limited 261-269 coombe lane, london sw20 0rh tel: 020 8946 4244 fax: 020 8947 2595 e-mail: sales@meetens.Com manufactured and distributed by: mitsubishi ❑ tu26 ❑ tl26 ❑ tl33 ❑ tl43 ❑ tl52 kawasaki ❑ th23 ❑ th26 ❑ th34 ❑ th43 ❑ th48 honda ❑ gx22 ❑ gx31 engine: engine serial...