- DL manuals

- PALDU

- Log Splitter

- 1100-12

- Operating Instructions Manual

PALDU 1100-12 Operating Instructions Manual

Summary of 1100-12

Page 1

Operating instructions log splitter 1100-12 d1010396 - v001 *d1010396-v001* english copyright by posch gesellschaft m.B.H., made in austria.

Page 2

Manufacturer posch gesellschaft m.B.H. Paul-anton-keller-strasse 40 a-8430 leibnitz tel.: +43 (0) 3452/82954 fax: +43 (0) 3452/82954-53 e-mail: leibnitz@posch.Com http://www.Posch.Com © copyright by posch gesellschaft m.B.H., made in austria please be sure to fill this in before starting. Then you c...

Page 3

Contents 1 foreword 5 1.1 copyright notice 5 1.2 liability for defects 5 1.3 reservations 5 1.4 definitions 5 1.5 operating instructions 6 2 safety information 7 2.1 explanation of symbols 7 2.2 general safety information 8 2.3 safety instructions for log splitter 8 2.4 noise 9 2.5 remaining risks 9...

Page 4

8.3 electrical equipment 22 8.4 hydraulic lines 23 8.5 tool guide 23 8.6 oil level 23 8.7 two-hand controller 23 8.8 log retaining tip 23 9 maintenance 24 9.1 tool guide 24 9.2 oil changing 24 9.3 cleaning 26 10 additional equipment 27 10.1 splitting cross 27 10.2 splitting table 28 10.3 lifting uni...

Page 5

Foreword thank you for buying our product. This machine has been built in conformity with applicable european standards and regulations. These operating instructions explain how to operate the machine safely and efficiently and how to maintain it. Any person entrusted with the transport, installatio...

Page 6

The operating personnel (operators) are those entrusted by the operator to operate the machine. Technical personnel technical personnel are persons entrusted by the operator of the machine with special tasks such as installation, set-up, maintenance and troubleshooting. Electrician an electrician is...

Page 7

Safety information explanation of symbols the following symbols and instructions in this manual provide warnings about possible personal injury or property damage or give useful information about working with the machine. Danger warning about danger zones instruction regarding safe working, where no...

Page 8

Further information symbol for further information relating to a bought-in part. Information action-related information. General safety information the machine may only be operated by persons who are familiar with the machine’s operation and hazards and with the user manual. ▪ it is the operator’s r...

Page 9

Wear protective gloves. Never split angle-cut wood. Keep the work area free of chips and wood residues. Shut the drive down before removing any jammed pieces of wood. Max. Log length 15 - 110 cm always retract the splitting tool when the machine is being transported or is not in operation. The worki...

Page 10

General scope this user manual applies to the following machines: machine type article no. * designation - type drive m6602 log splitter 1100-12 - pzg pto m6604 log splitter 1100-12 - pzge5.5 pto/electric motor m6600 log splitter 1100-12 - ps tractor hydraulics *the article number is stamped on the ...

Page 11

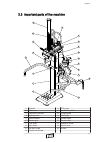

Important parts of the machine 16 1 2 3 4 5 6 7 8 9 10 11 13 12 15 17 18 19 14 1 cylinder 11 pto pump 2 guide rod 12 identification plate 3 two-hand controller 13 oil sight glass 4 splitting blade 14 switch/plug 5 guard bracket 15 grease nipple 6 retaining tip 16 electric motor 7 tool guide 17 venti...

Page 12

Stickers and their meaning 1 only one person may operate the machine at a time 2 only carry out repair, set-up, maintenance and cleaning work when the drive is switched off and the tool is stationary. 3 wear protective gloves 4 wear safety shoes 5 wear goggles and ear defenders 6 caution, moving too...

Page 13

Stickers on controls z2050870 using the splitter set-up ensure the machine is stable before starting it. Set up the machine on a level, firm and clear work surface. The machine must be placed directly on the ground. Do not place wooden boards, flat pieces of metal etc. Underneath it. The machine mus...

Page 14

Start-up before starting to operate the machine, please check that the protective and safety systems are working and also the hydraulic hoses and oil level. Before each start-up, the condition of the electrical cables must be checked. If a fault occurs during operation, the machine must be shut down...

Page 15

A tight plug connection can rip the cee plug out of the switch housing. ▪ this can be remedied using standard plugs and a silicone spray. Any such damage to the switch is not covered by the guarantee. Driven by tractor via cardan shaft (type z) ▪ assemble the machine on the three-point linkage of th...

Page 16: III

Operation at outdoor temperatures below 0°c, let the machine idle for approximately five minutes to allow the hydraulic system to reach the correct operating temperature (the hydraulic pipes will then be warm to the touch). Two-hand controller 0 i ii iii position "0" control levers in home position,...

Page 17

1 hexagon nut the machine is supplied with the cylinder in the retracted position. Before starting work, the cylinder must be extended and fixed. When extending and retracting the cylinder, make sure the hydraulic hoses are not trapped! ▪ press the control levers downwards. – the cylinder rises unti...

Page 18

If the wood presses against the guard bracket during the splitting process, the guard bracket jumps out of the detent position and swings downwards. This means that the guard bracket is not damaged. Before starting a new splitting process, the guard bracket must be pressed back up again into the wor...

Page 19

Put out of operation before switching off the machine, depressurise all hydraulic functions by placing all control levers in the neutral position. Switching off the machine driven by electric motor (type e) type e5.5 ▪ move the switch to the 0 position. Driven by tractor via universal joint shaft (t...

Page 20

Transport before transport, it is vital to switch off the drive and secure it so it cannot be switched on accidentally or started-up by unauthorised persons. Disconnect the machine from the mains. ▪ in addition, pull out the plug of the device. ▪ disengage the universal joint shaft on the tractor. –...

Page 21

I f i r t e t f t r i f,min = i r ( x ( c + d )) - ( ) t f x b ( 0,2 x ) + t e x b a + b t e (kg) empty weight of the tractor * t f (kg) front axle load of the empty tractor * t r (kg) rear axle load of the empty tractor * i r (kg) total weight of the machine ** i f (kg) total weight of the front lo...

Page 22

Checks before control work on the machine, it is vital to switch off the drive and secure it so it cannot be switched on accidentally or started-up by unauthorised persons. Disconnect the machine from the mains. ▪ in addition, pull out the plug of the device. ▪ disengage the universal joint shaft on...

Page 23

Hydraulic lines after the first hour of operation, check that all hydraulic connections are secure and are not leaking. Check that all hydraulic connections are secure and are not leaking after every further 100 hours of operation. ▪ damaged hydraulic lines must be replaced immediately. Tool guide t...

Page 24

Maintenance before maintenance work on the machine, it is vital to switch off the drive and secure it so it cannot be switched on accidentally or started-up by unauthorised persons. Disconnect the machine from the mains. ▪ in addition, pull out the plug of the device. ▪ disengage the universal joint...

Page 25

▪ open the oil drain screw. The oil drain screw is located at the rear of the base of the column. ▪ drain the old hydraulic oil into a container. ▪ screw the oil drain screw back into the tank and fill with new hydraulic oil through the ventilation screw opening. ▪ screw the ventilation screw into t...

Page 26

Cleaning before cleaning work on the machine, it is vital to switch off the drive and secure it so it cannot be switched on accidentally or started-up by unauthorised persons. Disconnect the machine from the mains. ▪ in addition, pull out the plug of the device. ▪ disengage the universal joint shaft...

Page 27

Additional equipment splitting cross 3 1 2 1 splitting cross 3 splitting blade 2 locking clip during the splitting process the log is split into four billets. For uniform billets with maximum log diameter of 30-35 cm. Not suitable for knotty or deformed wood (danger of jamming). Fitting: 1. Extend t...

Page 28

Splitting table 1 2 1 splitting table 2 fixing lever the splitting table is for splitting short logs up to 55 cm in length. Fitting: place the splitting table on the base plate. When fitting the splitting table, be careful not to put your head under the splitting blade or injure your head on the spl...

Page 29

The logs which are to be split are lifted into the splitting position by means of the lifting device. The lifting device must only be used when the machine is attached to the three-point linkage. Mounting: ▪ remove the right-hand guard bracket ▪ screw the mounting plate (frame) onto the guard bracke...

Page 30

Troubleshooting before rectifying faults on the machine, it is vital to switch off the drive and secure it so it cannot be switched on accidentally or started-up by unauthorised persons. Disconnect the machine from the mains. ▪ in addition, pull out the plug of the device. ▪ disengage the universal ...

Page 31

Control lever does not stay in return position latch seat in control valve is worn turn the latch seat latch seat is worn replace latch seat disposal disposal must be carried out in accordance with the relevant national applicable regulations and/or guidelines. Dispose of recyclable materials separa...

Page 32

Technical data type pzg pzge5.5 ps drive drive type pto pto/electric motor tractor hydraulics output kw 7 7 / 5.5 s6 ** 5 voltage v - 400 - fusing a - 16 - motor speed rpm - 1500 - pto shaft speed rpm 380 380 - splitting system splitting force t 12 12 12 cylinder stroke cm 100 100 100 max. Pressure ...

Page 33

Service paldu- product to order spare parts for your machine please contact your local dealer directly. If you require a replacement parts list for your machine, you can download this at any time by entering the serial number at the following link: www.Posch.Com/download 13 service 33.

Page 34

Ec declaration of conformity we hereby declare that the following machine, its design and manufacture, comply with the health and safety requirements of the ec machinery directive 2006/42/ec. The machine furthermore complies with the ec low voltage directive 2006/95/ec and the ec electromagnetic com...

Page 36

Your paldu-dealer.