© panasonic ha air-conditioning (m) sdn. Bhd. 2008. Unauthorized copying and distribution is a violation of law. Order no. Phaam0810074c2 air conditioner indoor unit outdoor unit cs-pc36jkv cu-pc36jkv table of contents page page 1 safety precautions----------------------------------------------- 3 2...

2 12.2. Soft dry operation --------------------------------------- 29 12.3. Auto operation-------------------------------------------- 29 12.4. Thermostat control -------------------------------------- 30 12.5. Indoor fan control --------------------------------------- 30 12.6. Outdoor fan operation...

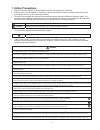

3 caution warning warning 1. Safety precautions • read the following “safety precautions” carefully before perform any servicing. • electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. •...

4 caution warning 20. After completion of installation or service, confirm there is no leakage or refrigerant gas. It may generate toxic gas when the refrigerant contacts with fire. 21. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when refrigerant contacts w...

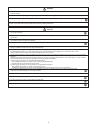

5 2 specifications model indoor cs-pc36jkv outdoor cu-pc36jkv performance test condition new jis power supply phase, hz single, 60 v 220 c o o l i n g capacity kw 10.55 btu/h 36000 kj/h 37980 running current a 17.5 input power w 3600 eer w/w 2.93 btu/hw 10.00 power factor % 94 indoor noise (h / l ) ...

6 1. Cooling capacities are based on indoor temperature of 27 c dry bulb (80.6f dry bulb), 19.0c wet bulb (66.2f wet bulb) and outdoor air temperature of 35 c dry bulb (95f dry bulb), 24c wet bulb (75.2f wet bulb) 2. Specifications are subjected to change without prior notice for further improvement...

7 3 features • long installation piping - long piping up to 30 meter. • easy to use remote control • quality improvement - random auto restart after power failure for safety restart operation. - gas leakage detection. - prevent compressor reverse cycle. - inner protector to protect compressor. - noi...

8 4 location of controls and components 4.1. Indoor unit 4.2. Outdoor unit • outdoor unit shown is cu-pc36jk. 4.3. Remote control.

9 5 dimensions 5.1. Indoor unit & remote control.

10 5.2. Outdoor unit.

11 6 refrigeration cycle diagram.

12 7 block diagram.

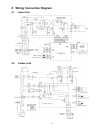

13 8 wiring connection diagram 8.1. Indoor unit 8.2. Outdoor unit.

14 9 electronic circuit diagram 9.1. Indoor unit.

15 9.2. Outdoor unit.

16 10 printed circuit board 10.1. Indoor unit 10.1.1. Main printed circuit board.

17 10.1.2. Power printed circuit board 10.1.3. Indicator printed circuit board.

18 10.2. Outdoor unit 10.2.1. Main printed circuit board.

19 11 installation instruction 11.1. Select the best location 11.1.1. Indoor unit • do not install the unit in excessive oil fume area such as kitchen, workshop and etc. • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • ...

20 11.3. Indoor unit 11.3.1. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The centre of installation plate should be at more than 680 mm at right and 570mm at left of the wall. The distance from installation plate edge to ceiling should...

21 11.3.3.3. For the embedded piping install accessory of tube ass’y 1. Remove chassis back particular piece..

22 2. Connect tube ass’y to gas side piping. Liquid side piping need to pull out to joint tube ass’y. 3. Set the piping direction. (for bottom piping, need to perform cutting and flaring process.) 4. Use 2 spanner to tighten the nut. (tighten torque 65 n lm) 5. Check gas leak at joint area using tub...

23 11.3.4. Connect the cable to the indoor unit 1. The indoor and outdoor connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 2.5 mm 2 flexible cord, type designation 245 iec 57 or ...

24 11.4. Outdoor unit 11.4.1. Install the outdoor unit • after selecting the best location, start installation according to indoor/outdoor unit installation diagram. 1. If installing the unit to a concrete base or other solid base, use m10 or w3/8 bolts and nuts to secure the unit, and ensure that t...

25 11.4.2.2. Connecting the piping to outdoor unit decide piping length and then cut by using pipe cutter. Remove burrs from cut edge. Make flare after inserting the flare nut (locate at valve) onto the copper pipe. Align center of piping to valves and then tighten with torque wrench to the specifie...

26 11.4.3. Air purging of the pipings and indoor unit 1) checking a gas leakage 1. Remove the service port cap from 3-way valves. 2. Connect the manifold gauge set to the service port of liquid side 3-way valve. 3. Connect the charging cylinder to the manifold gauge set and open the valve of the cyl...

27 11.4.4. Connect the cable to the outdoor unit (for detail refer to wiring diagram at unit) 1. Remove the control board cover from the unit by loosening the screw. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 x 2.5 mm 2 flexible cord, type d...

28 11.4.6. Precautions with regard to test operation • use only insulation tool to switch on the microswitch on the electric circuit board (do not use finger or metallic tool). • do not switch on power before all installation is completed. • after power on, make sure the voltage is 90% ~ 110% of the...

29 12 operation control 12.1. Cooling operation • cooling operation can be set using remote control. • this operation is applied to cool down the room temperature reaches the setting temperature set on the remote control. • cooling operation time diagram. 12.2. Soft dry operation • soft dry operatio...

30 12.4. Thermostat control • depending on differences between room temperature and setting temperature, compressor operation is decided and starts operation. • if temperature difference matches values shown below, thermostat switches off. 12.5. Indoor fan control 12.5.1. Manual fan speed • fan oper...

31 12.7. Odour cut control • odour cut operation removes the odour generated at indoor heat exchanger by using drain water come out from indoor heat exchanger. • press “odour” button at remote control to enable odour cut operation. • odour cut operation starts when compressor or thermostat is on. 12...

32 13 protection control 13.1. Restart control (time delay safety control) • when the thermo-off temperature (temperature which compressor stops to operate) is reached, the compressor stops for 3 minutes (minimum) before resume operation. • if the operation is stopped by the remote control, the comp...

33 • dew prevention control will be cancel when: - any one of the condition above does not comply. 13.4. Outdoor fan residual heat removal control • when the compressor stops to operate, the outdoor fan motor continue to operate for 60 seconds before stops operation. • this phenomenon is to extract ...

34 14 servicing mode 14.1. Auto off/on button 1. Auto operation mode the auto operation will be activated immediately once the auto off/on button is pressed. This operation can be used to operate air conditioner with limited function if remote control is misplaced or malfunction. 2. Test run operati...

35 after auto off/on button is pressed, the 20 seconds counter for remote control receiving sound off/on mode is restarted. 14.2. Remote control button 14.2.1. Set • to change the type of remote control transmission signal (there are totally four types of transmission codes). - modify the jumper (ba...

36 15 troubleshooting guide 15.1. Refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a f...

37 15.2. Relationship between the condition of the air conditioner and pressure and electric current • carry out the measurements of pressure, electric current, and temperature fifteen minutes after an operation is started. 15.3. Diagnosis methods of a malfunction of a compressor cooling mode condit...

38 15.4. Error code table 15.4.1. Self-diagnosis function 1. The self-diagnosis leds (red) on the outdoor unit printed circuit board can be used to indicate where the location of a problem is. Refer to the table below to remove the cause of the problem and then re-start the air conditioner system. 2...

39 15.5. Test run (forced cooling control) • test run can be enable using the switch at the outdoor unit's pcb according to procedure below: - set the ds1 to (cooling test run) mode - press sw1 for 1 second to test run. - be sure to select cooling mode first, and run the unit in this mode for 5 minu...

40 16 disassembly and assembly instructions 16.1. Indoor electronic controllers, cross flow fan and indoor fan motor removal procedures 16.1.1. To remove front grille 16.1.2. To remove electronic controller warning high voltage are generated in the electrical parts area by the capacitor. Ensure that...

41 16.1.3. To remove discharge grille.

42 16.1.4. To remove control board 16.1.5. To remove cross flow fan and indoor fan motor.

43.

44 17 technical data 17.1. Thermostat characteristics cooling soft dry.

45 17.2. Operation characteristics.

46.

47 18 exploded view and replacement parts list 18.1. Indoor unit note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

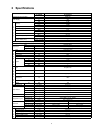

48 (note) • all parts are supplied from phaam, malaysia (vendor code: 00029488). • “o” marked parts are recommended to be kept in stock. Ref. No. Part name & description qty. Cs-pc36jkv remarks 1 chassy complete 1 cwd50c1477 2 fan motor dc 60w 3ph 1 arw42a8p60ac o 3 cross flow fan complete 1 cwh02c1...

49 18.2. Outdoor unit.

50

51 note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

52 (note) • all parts are supplied from phaam, malaysia (vendor code: 00029488). • “o” marked parts are recommended to be kept in stock. [phaam] printed in malaysia sssc0906 - 01 ref. No. Part name & description qty. Cu-pc36jkv remarks 1 base pan ass’y 1 cwd52k1157 2 compressor 1 zr40k3-pfv-512 o 3 ...