- DL manuals

- QuickLabel Systems

- Label Maker

- pronto! 482

- User Manual

QuickLabel Systems pronto! 482 User Manual

4 8 6 • 4 8 2 • 8 6 3 • 6 8 2

QuickLabel.com

Part Number: 22834571-EN-E | Revision 2.0

Pronto! 486

•

Prints or laminates in

600 dpi at up to 4 ips

Pronto! 482

•

Prints or laminates in

200 dpi at up to 10 ips

Pronto! 863

•

Prints or laminates in

300 dpi at up to 6 ips

on labels up to 8.5” wide

Pronto! 682

•

Prints or laminates in

200 dpi at up to 8 ips

on labels up to 6.5” wide

Summary of pronto! 482

Page 3: User Guide

Quicklabel pronto! 482/486/682/863 user guide part number 22834571-en-e revision 2.0 12/13 specifications are subject to change without notice ___________________________________________ quicklabel systems® an astro-med, inc. Product group world headquarters 600 east greenwich ave., west warwick, ri...

Page 4: Trademarks

Copyright © 2013 astro-med ®, inc. This manual is copyrighted with all rights reserved. No part of this manual may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form by any means without written permission of quicklabel systems and astr...

Page 5: Obtaining Service

This warranty is void if the product has been damaged by accident, abuse, neglect or misapplication, or if the product has been improperly installed or maintained, or if the product has been used outside of its environmental specifications, or if the product has been modified without the express wri...

Page 6

Quicklabel canada #111 - 3555 isabelle, borssard, qc j4y 2r2 canada tel: (800) 565-2216 fax: (450) 619-9976 web site: www.Quicklabel.Ca sales e-mail: info@quicklabel.Ca technical support e-mail: support@quicklabel.Ca quicklabel deutschland astro-med gmbh, senefelderstraße 1/ t6 d-63110 rodgau tel. +...

Page 7: Ownership Information

Ownership information congratulations and thank you for your business. Your purchase of a quality quicklabel product is an investment in the finest of state-of-the-art printing and labeling technology. Please use the spaces below to list the model number and serial number of your product. If, for an...

Page 8: Rohs Compliance

Rohs compliance we declare that the pronto! 482/486/682/863 complies with the european rohs directives 2011/65/eu and 2002/95/eu (restriction of the use of certain hazardous substances in electrical and electronic equipment). This declaration is based on information provided by suppliers based on re...

Page 9

Declaration of conformity declaration de conformité ubereinstimmungserklärung dichiarazione di conformità id doc-22834571 manufacturer’s name and address nom et adresse du fabricant hersteller nome del costruttore astro-med, inc. 600 east greenwich avenue west warwick, ri 02893 usa model no. Modele ...

Page 10

Declaration of conformity declaration de conformité ubereinstimmungserklärung dichiarazione di conformità id doc-22834571-er4 manufacturer’s name and address nom et adresse du fabricant hersteller nome del costruttore astro-med, inc. 600 east greenwich avenue west warwick, ri 02893 usa model no. Mod...

Page 11

Declaration of conformity declaration de conformité ubereinstimmungserklärung dichiarazione di conformità id doc-22834571-cs4 manufacturer’s name and address nom et adresse du fabricant hersteller nome del costruttore astro-med, inc. 600 east greenwich avenue west warwick, ri 02893 usa model no. Mod...

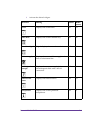

Page 13: Table Of Contents

Pronto! 482/486/682/863 1 table of contents chapter 1: introduction & installation ...................................................................... 1-1 safety and the environment ..................................................................................... 1-2 intended use ...............

Page 14

2 pronto! 482/486/682/863 chapter 5: configuration ............................................................................................ 5-1 configuration via the operating panel ................................................................... 5-2 local settings ..............................

Page 15

Pronto! 482/486/682/863 3 chapter 8: accessories ................................................................................................ 8-1 cutter ........................................................................................................................... 8-2 external keyboa...

Page 16

4 pronto! 482/486/682/863 mounting............................................................................................................... 8-39 printer configuration .......................................................................................... 8-40 operation ........................

Page 17

Pronto! 482/486/682/863 5 backfeed .................................................................................................................. 9-8 media loading ........................................................................................................... 9-8 operation .............

Page 18

6 pronto! 482/486/682/863 wifi status .............................................................................................................. 12-11 ascii dump mode ................................................................................................ 12-12 test grid ...................

Page 19

Pronto! 482/486/682/863 7 external rewinder (er4) ........................................................................................ 17-4 external unwinder (eu4) ....................................................................................... 17-5 appendix a: menu map .....................

Page 20

8 pronto! 482/486/682/863.

Page 21: Chapter 1:

Pronto! 482/486/682/863 1-1 chapter 1: introduction & installation this chapter contains the following sections: • safety and the environment - provides safety precautions and disposal information • unpacking the label printer - describes how to unpack and inspect the printer • setting up the label ...

Page 22: Safety and The Environment

1-2 introduction & installation safety and the environment read these operating instructions carefully before using the label printer for the first time. The operating instructions describe all of the functions of the label printer during operation. The available functions depend on the version used...

Page 23

Pronto! 482/486/682/863 1-3 • carry out only the actions described in these operating instructions. Other tasks may only be performed by trained personnel or service technicians. Environmentally-friendly disposal used devices contain valuable recyclable materials which should be utilized. Dispose of...

Page 24: Unpacking The Label Printer

1-4 introduction & installation unpacking the label printer 1 lift the label printer out of the box via the straps. 2 check label printer for damage which may have occurred during transport. 3 check delivery for completeness. • label printer • empty cardboard core, mounted on ribbon take-up hub • te...

Page 25: Setting Up The Label Printer

Pronto! 482/486/682/863 1-5 setting up the label printer caution: the device and the print media can be damaged by moisture and water. The label printer may only be set up in a dry place protected from sprayed water. • set up printer on a level surface. • open cover (1) of the label printer. • remov...

Page 26

1-6 introduction & installation connecting the label printer to power connecting to the power supply the printer is equipped with a versatile power supply unit. The device may be operated with a mains voltage of 230 v ac/ 50 hz or 115 v ac/60 hz without any adjustments or modifications. 1 insert pow...

Page 27

Pronto! 482/486/682/863 1-7 connecting the label printer to a computer choose from the following options for connecting a computer to the label printer: • direct connection to the serial rs-232 interface • direct connection to the ethernet interface • connection via a computer network to the etherne...

Page 28: Rs-232 Serial Interface

1-8 introduction & installation rs-232 serial interface the rs-232 interface is operated via an rs-232 cable. 1 connect computer and label printer with a suitable cable. 2 secure cable connections with the screws found at the plugs. 3 configure the rs-232 interface of the printer to match the settin...

Page 29

Pronto! 482/486/682/863 1-9 printer to the ethernet card of a local computer, you will need an appropriate crossover cable. 1 connect computer and label printer with a suitable cable. 2 press the menu button. Select setup > interfaces. Make basic settings for operation of the ethernet interface. 3 c...

Page 30: Usb Interface

1-10 introduction & installation during the installation of both print services, additional connections for print output are set up: • raw-ip: enter the same port address in the printer which you have selected during installation. • lpd: “lp” (line printer) must be entered as the name of the printer...

Page 31: Optional Interfaces

Pronto! 482/486/682/863 1-11 6 switch printer on. The windows installation wizard is started automatically. Follow the on-screen instructions. The source of the installation file is where d is the letter of the cd-rom drive used. After successful installation, an icon for the label printer appears i...

Page 32

1-12 introduction & installation • rs422/485 • wlan card switching the label printer on and off once all connections have been made: 1 switch printer on via the power switch (1). The printer runs through a system test and then indicates the system status ready in the display. If an error has occurre...

Page 33: Chapter 2:

Pronto! 482/486/682/863 2-1 chapter 2: operating panel this chapter contains the following sections: • about the operating panel - provides an overview of the operating panel • functions of the operating panel during printing - describes operating panel functions while printing.

Page 34: About The Operating Panel

2-2 operating panel about the operating panel the user can control the operation of the printer with the operating panel, for example: • pause, continue or cancel print jobs • set printing parameters, e.G. Heating energy of the printhead, print speed, configuration of the ports, language and time (s...

Page 35

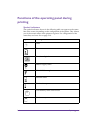

Pronto! 482/486/682/863 2-3 layout of the operating panel functions of the buttons • pause, cancel, menu, feed buttons: (see 'ready' mode on page 2-5) • arrows: up, down, left and right in the menu tree. • ↵ button: input of a parameter in the menu, calling up of help in case of an error the operati...

Page 36: Printing

2-4 operating panel functions of the operating panel during printing symbol indicators the symbol indicators shown in the following table can appear on the status line of the screen, depending on the configuration of the printer. They inform you of the current status of the printer at a glance. For ...

Page 37: Power-Save Mode

Pronto! 482/486/682/863 2-5 power-save mode if the printer is not used for some time, it switches to power-save mode automatically. The display shows the following graphic and button illumination is switched off. To exit power-save mode: • press any button on the navigator pad. 'ready' mode the prin...

Page 38: 'Printing Label' Mode

2-6 operating panel 'printing label' mode the printer is carrying out a print job. Data transfer for a new print job is possible in 'printing' mode. The new print job starts once the preceding job is completed. The display shows the text printing label and the number of the printed label within the ...

Page 39: 'Fault - Irrecoverable' Mode

Pronto! 482/486/682/863 2-7 the display shows the error type, the number of labels still to be printed, and the following symbol: 'fault - irrecoverable' mode an error which cannot be remedied without canceling the print job has occurred. The display shows the error type, the number of labels still ...

Page 40

2-8 operating panel • switch off printer via the power switch and switch it on again. Or • push the cancel button. If the error occurs repeatedly, notify support..

Page 41: Chapter 3:

Pronto! 482/486/682/863 3-1 chapter 3: offline menu this chapter contains the following sections: • offline menu - describes the structure and navigation of the offline menu.

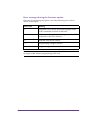

Page 42: Offline Menu

3-2 offline menu offline menu structure of the offline menu the offline menu contains setting options on several levels for configuring the label printer to meet your needs. In addition, the offline menu features test functions for supporting the configuration or checking the function of the label p...

Page 43

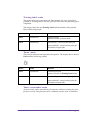

Pronto! 482/486/682/863 3-3 test status print font list device list wifi status only with wlan card installed ascii dump mode test grid label profile 1st menu level 2nd menu level access.

Page 44

3-4 offline menu setup local settings pin protection possible machine param. Print param. Interfaces status line security 1st menu level 2nd menu level access.

Page 45

Pronto! 482/486/682/863 3-5 service firmware upd. Pin protection possible firmw. Fr. Card only with memory medium inserted in the default card slot pin protection possible save settings only with memory medium inserted in the default card slot pin protection possible load settings only with memory m...

Page 46: Navigating The Offline Menu

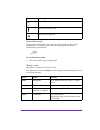

3-6 offline menu navigating the offline menu you can control all settings and functions in the offline menu with the navigator pad. Key menu parameter setting parameter choice numeric value ↑ return from a submenu - increase of the number at the cursor position ↓ jump into a submenu - decrease of th...

Page 47: Chapter 4:

Pronto! 482/486/682/863 4-1 chapter 4: device types this chapter contains the following sections: • standard device - describes the standard device version • peel-off device version - describes the peel-off device version with rewinder.

Page 48: Standard Device

4-2 device types standard device the standard device is used for printing labels or continuous media on rolls or fanfolded media. In tear-off mode, labels are removed by hand. The labels can be cut off automatically with the 'cutter' accessory. For details, see chapter 9: cu4 cutter accessory. The l...

Page 49: Peel-Off Device Version

Pronto! 482/486/682/863 4-3 peel-off device version the peel-off device version is capable of peel-off mode and thus has an internal rewinder and a pulling system comprised of a rewind assist roller and a locking system. Printing on labels or continuous media from rolls or fanfolded media is possibl...

Page 50

4-4 device types.

Page 51: Chapter 5:

Pronto! 482/486/682/863 5-1 chapter 5: configuration this chapter contains the following sections: • configuration via the operating panel - describes how to change printer settings using the operating panel • configuration via the printer website - describes how to change printer settings using the...

Page 52: Local Settings

5-2 configuration configuration via the operating panel a host of parameters for configuring the printer are found in the setup menu of the offline menu. Your printer is mainly configured via the operating panel during initial commissioning and when making major changes to the operational conditions...

Page 53: Device Settings

Pronto! 482/486/682/863 5-3 device settings 1 press the menu button. 2 select setup > machine param. Set time setting the system time in the hh:mm:ss format. When changing the time, ensure that the timezone, daylight saving and set date parameters are set correctly. The time can also be synchronized...

Page 54

5-4 configuration printhead pos. Y shifting of the entire print image in the direction of paper flow. With positive values, printing begins later in the direction of paper flow. Shifting of the print image in the direction of paper flow also influences the peel and cutting positions. • correct the p...

Page 55: Printing Parameters

Pronto! 482/486/682/863 5-5 printing parameters 1 press the menu button. 2 select setup > print param. Time powersave. Time between the last operation and the activation of powersave mode. 5 min. Debug mode operating mode which supports the firmware programmer when localizing errors. Off parameter m...

Page 56

5-6 configuration transfer print on for thermal transfer printing: sensor for monitoring the transfer ribbon is activated. Off for thermal direct printing: sensor for monitoring the transfer ribbon is not activated. You can overwrite the setting for each print job via software. On warn level ribbon ...

Page 57

Pronto! 482/486/682/863 5-7 backfeed method for backfeeding the label medium. Backfeeding is necessary in the cutting and peel-off modes since a label is pushed out passed the front edge of the next label above the print line when peeling off/cutting. Always: backfeeding occurs independently of labe...

Page 58: Interfaces

5-8 configuration interfaces 1 press the menu button. 2 select setup > interfaces. Width ascii dump width of the printing area in the “monitor mode” test function (see ascii dump mode on page 12-12). With the automatic setting, the printout of the control sequences arriving at the printer occurs ove...

Page 59

Pronto! 482/486/682/863 5-9 ieee 1284 configuration of the optional parallel interface. See the documentation of the parallel interface. If interface is not installed, this option is not available. Rs-422/485 configuration of the optional serial rs-422 or rs-485 interface. See documentation of the s...

Page 60: Status Line

5-10 configuration status line select the parameters (widgets) to be displayed in ready mode. The display has a width of 128 pixels. It is not possible to display all widgets simultaneously. When selecting widgets, only widgets that do not overfill the display will be available. It may be necessary ...

Page 61

Pronto! 482/486/682/863 5-11 3 activate the desired widgets. Parameter meaning default width (pixels) clock displays the current time. On 32 date sheet displays the current calendar day. On 20 date/time digital digital display of current date and time. Off 31 ribbon supply displays the current ribbo...

Page 62: Security

5-12 configuration security activating a pin by activating a pin, you can protect the setup menu, certain memory card functions and the firmware update from unauthorized access. The protected menu items are then marked with the lock symbol and are only accessible after the pin is entered. 1 press th...

Page 63

Pronto! 482/486/682/863 5-13 4 accept the setting with the ↵ button. Defining a pin 1 press the menu button. 2 select setup > security > pin menu. 3 select the digit of the pin to be changed with the left and right arrow buttons. 4 assign the selected digit a number with the up and down arrow button...

Page 64

5-14 configuration configuration via the printer website the parameters accessible via the operating panel can also be set via the website contained in the firmware of the printer. In addition, other parameters for the ethernet interface are accessible there. The printer website can be accessed with...

Page 65: Status Tab

Pronto! 482/486/682/863 5-15 status tab the following information is contained in the top section of the "status" tab: • printer type • firmware version • bootloader version • printhead temperature and temperature of cpu • heat voltage for the printhead. The heat voltage is only active during printi...

Page 66

5-16 configuration the "ready" event provides information on when the printer was switched on. The buttons on the bottom line of the "status" tab have the following functions: button function display opens a window which shows the current printer display. You can set the update interval on the scale...

Page 67: Setup Tab

Pronto! 482/486/682/863 5-17 setup tab on the “setup” tab, you can set all the configuration parameters which are also accessible via the operating panel in the setup menu. In addition, other parameters for the ethernet interface can be set (see below). The menus and parameters are arranged in a tre...

Page 68

5-18 configuration the printer can be given a name on the top line of the tree structure. This name does not have a functional meaning. Its sole purpose is to allow the operator to more easily differentiate between the printers on a network. The following parameters for the ethernet interface can on...

Page 69: System Messages Tab

Pronto! 482/486/682/863 5-19 system messages tab status and error messages can be sent automatically to the snmp manager or via e-mail to the selected addresses immediately after they occur via the snmp data exchange between printer and management station via snmp (simple network management protocol...

Page 70

5-20 configuration ethernet interface. You can select the messages to be sent and the destination addresses on the “system messages” tab. Column meaning description status and error messages that can be sent. • expand tree structure by clicking the circular symbol once or double-clicking the descrip...

Page 71: Printer Status Line Tab

Pronto! 482/486/682/863 5-21 printer status line tab on the “printer status line” tab, you can select the status parameters (widgets) which are to be displayed on the printer status line. Adding a status parameter: 1 select widget in pull-down menu. Note the text color: • pale green: widget may be a...

Page 72: Fonts Tab

5-22 configuration 2 click set. The symbol, the parameter designation and the width of the symbol in the display (in pixels) are displayed in the top section of the tab. The entire width of all symbols in the display (e.G. 92 pixels) and the maximum width of the display (e.G. 128 pixels) are display...

Page 73: Devices Tab

Pronto! 482/486/682/863 5-23 devices tab the "devices" tab provides an overview of the most important hardware components installed in the printer and the optional devices connected. The contents of the display correspond with those of the device list and are described in device list on page 12-9..

Page 74

5-24 configuration.

Page 75: Chapter 6:

Pronto! 482/486/682/863 6-1 chapter 6: loading media this chapter contains the following sections: • opening and closing the support bracket pronto! 863 - describes how to open/close the support bracket on the pronto! 863 printer • loading labels from a roll - describes how to load label rolls • rem...

Page 76: Pronto! 863

6-2 loading media opening and closing the support bracket pronto! 863 for additional bearing of the roller and printhead assemblies and the ribbon hubs the pronto! 863 is equipped with a support bracket (1). Opening the support bracket 1 open cover. 2 turn lever (2) counterclockwise to lift the prin...

Page 77: Loading Labels From A Roll

Pronto! 482/486/682/863 6-3 loading labels from a roll positioning the label roll on the roll retainer 1 open cover (9). 2 turn ring (2) at the margin stop (1) counterclockwise, so that the arrow points to the symbol, and thus release the margin stop. 3 remove the margin stop (1) from the roll retai...

Page 78: Setting The Label Sensor

6-4 loading media inserting a label strip into the printhead 1 turn lever (8) counterclockwise to lift the printhead. 2 push guide ring on axis (6) all the way out. 3 guide label strip to the print unit above the internal rewinder (5). 4 guide label strips below the axis (6) and through the label se...

Page 79

Pronto! 482/486/682/863 6-5 • for use in tear-off mode only: turn lever clockwise to lock the printhead. The label roll is loaded for use in tear-off mode. Winding up the label strip in rewind mode in rewind mode, the labels are wound up internally after printing for later use. 1 remove the locking ...

Page 80

6-6 loading media 3 hold rewinder (2) firmly and turn knob (3) clockwise until it stops. 4 push label strip under a bracket (1) of the rewinder and turn knob (3) counterclockwise until it stops. The rewinder is fully spread, thus gripping the label strip firmly. 5 turn rewinder (2) counterclockwise ...

Page 81

Pronto! 482/486/682/863 6-7 the rewinder is fully spread, thus gripping the liner firmly. 6 turn rewinder (2) counterclockwise to tighten the liner. 7 slightly loosen top fixing screw at the locking system with hexagonal wrench and position the pinch roller (4) centrally to the liner (see removing a...

Page 82: Removing The Wound Roll

6-8 loading media removing the wound roll 1 turn lever (1) counterclockwise to lift the printhead. 2 cut label strip and wind it fully around the rewinder (3). 3 hold rewinder (3) firmly and turn knob (2) clockwise. The rewinder spindle relaxes and the wound roll (4) is released. 4 remove wound (4) ...

Page 83: Loading Fanfold Labels

Pronto! 482/486/682/863 6-9 loading fanfold labels 1 turn ring (2) counterclockwise, so that the arrow points to the unlocked symbol, and thus release the margin stop (1). 2 move the margin stop (1) outwards as far as possible. 3 position label stack (4) behind the printer. Ensure that the labels on...

Page 84: Loading Transfer Ribbon

6-10 loading media loading transfer ribbon 1 clean printhead before loading the transfer ribbon (see cleaning the printhead on page 11-5). 2 turn lever (5) counterclockwise to lift the printhead. 3 slide transfer ribbon roll (3) onto the ribbon supply hub (4) until it stops and so that the color coa...

Page 85

Pronto! 482/486/682/863 6-11 setting the feed path of the transfer ribbon transfer ribbon wrinkling can lead to print image errors. Transfer ribbon deflection can be adjusted so as to prevent wrinkles. See also setting the head locking system on page 6-7. The adjustment is best carried out during pr...

Page 86

6-12 loading media removing and installing the rewind guide plate, dispense plate or tear-off plate to convert the printer for use in another operating mode, a rewind guide plate, a dispense plate or a tear-off plate may need to be installed. Note: for printer versions with a locking system on the r...

Page 87

Pronto! 482/486/682/863 6-13 removing and installing the locking system removing the locking system 1 position printer at edge of table so that the oblong hole is accessible from below. 2 screw out screws (1) (2) and remove them. 3 remove the pinch roller (4) and bottom plate (3). Installing the loc...

Page 88

6-14 loading media.

Page 89: Chapter 7:

Pronto! 482/486/682/863 7-1 chapter 7: printing • synchronization - describes how to synchronize the printer and automatically set label advancement • tear-off mode - describes tear-off mode • peel-off mode - describes peel-off mode • internal rewinding - describes rewinding labels caution: the prin...

Page 90: Synchronization

7-2 printing synchronization after the label stock has been inserted, for peel-off or cutting mode a synchronization of the paper feed is required. That way the first label, which is detected by the label sensor, will be transported to the print position and all labels in front will be fed out of th...

Page 91: Chapter 8:

Pronto! 482/486/682/863 8-1 chapter 8: accessories this chapter contains the following sections: • cutter - references information about the cutter accessory • external keyboard - describes how to use the external keyboard • external rewinder (er1) - describes how to use the er1 external rewinder • ...

Page 92: Cutter

8-2 accessories cutter the cutter accessory is described in cu4 cutter accessory on page 9-1. External keyboard you can connect an external keyboard or compatible input device (e.G. Barcode scanner) directly to the printer. Using an external keyboard facilitates the entry of variable data while proc...

Page 93

Pronto! 482/486/682/863 8-3 in the offline menu and for entry of variable data: key assignment and special characters the printer features a specific keyboard assignment table for each setting of the country configuration parameter. These tables generally match the dos keyboard assignments (see inte...

Page 95

Pronto! 482/486/682/863 8-5 other special characters: example: entering the character: ñ 1st entry: [~] 2. Entry: [alt] + [n] zz z1 z2 À ` a Á ´ a ^ a à ~ a Ä ¨ a Å ° a Æ a e Ç , c Č ˇ c d' ' d È ` e É ´ e Ê ^ e Ë ¨ e Ì ` i Í ´ i Î ^ i Ï ¨ i IJ i j £ - l Ñ ~ n zz z1 z2 Ò ` o Ó ´ o Ô ^ o Õ ~ o Ö ¨ o Ø...

Page 96: External Rewinder (Er1)

8-6 accessories external rewinder (er1) to handle large print jobs, the external rewinder is available which allows you to rewind complete rolls of label material. The rewinder is powered and controlled directly by the peripheral port of the printer. The rewinder operates only when the printer is fe...

Page 97

Pronto! 482/486/682/863 8-7 2 flange 3 clamp 4 rewind axle adapters (2).

Page 98

8-8 accessories mounting the external rewinder the printer is normally shipped with the front cover (6) mounted. In order to install the rewinder the front cover has to be removed. 1 loosen the screw (7). 2 remove the front cover (6). The external rewinder is mounted on the printer so it is not nece...

Page 99

Pronto! 482/486/682/863 8-9 3 insert the pin (10) of the rewinder into the hole (12) of the printer. Press the rewinder against the printer. That way the plug (9) of the rewinder will be connected to the peripheral port (13) of the printer. 4 secure the rewinder by tightening the spindle (8). Select...

Page 100

8-10 accessories rewinding directly onto the rewind axle.

Page 101

Pronto! 482/486/682/863 8-11 1 to rewind directly onto the rewind axle the spring (21) must be removed. Loosen the screws (20) and remove the spring (21). 2 feed the label strip over the guide bar (16) and under the roller (18) to the rewind axle (15). Ensure that the label strip is even with the di...

Page 102

8-12 accessories rewinding onto 3 in (76 mm) cardboard core.

Page 103

Pronto! 482/486/682/863 8-13 1 for this operation mode, the spring must be removed from the rewind axle as described in the previous chapter. Loosen the screws and remove the spring. 2 use a cardboard core (20) which is about .04 in (1 mm) wider than the label strip. 3 put the first axle adapter (4)...

Page 104

8-14 accessories rewinding onto 1.56 in (40 mm) cardboard core note: for rewind mode the spring on the rewind axle must be mounted..

Page 105

Pronto! 482/486/682/863 8-15 1 use a cardboard core (20) which is about .04 in (1 mm) wider than the label strip 2 put the cardboard core (20) onto the rewind axle (15). 3 feed the label strip over the guide bar (16) and under the roller (18) up to the cardboard core (20). Ensure that the label stri...

Page 106: External Rewinder (Er4)

8-16 accessories external rewinder (er4) intended use • the device is manufactured in accordance with the current technological status and the recognized safety rules. However, danger to the life and limb of the user or third parties and/or damage to the device and other tangible assets can arise du...

Page 107: Environment

Pronto! 482/486/682/863 8-17 environment obsolete devices contain valuable recyclable materials that should be sent for recycling. • send to suitable collection points, separately from residual waste. • send the parts for recycling. Function the external rewinders are peripheral devices for transfer...

Page 108: Device Overview

8-18 accessories device overview er4 1 switch rotating direction 2 rewind axle 3 roll 4 guide axle 5 rewind adapter 6 flange 7 clamp 8 power switch 9 power input module.

Page 109: Contents of Delivery

Pronto! 482/486/682/863 8-19 contents of delivery check the external rewinder for damage in transit and totality. Contents of delivery: • external rewinder • rewind adapter 2x • flange for er4 • power cable connecting to power supply the rewinder is equipped with a wide range power unit (100-240v~),...

Page 110

8-20 accessories selection of the rewind direction the selection of the rewind direction is depend of using an inside or outside wound label. Turn off the rewinder and set the switch (1) to the required direction of rewinding: rewinding with labels inside rewinding with labels outside.

Page 111: Aligning The Guide Axle

Pronto! 482/486/682/863 8-21 aligning the guide axle depend of the used printer the guide axle should be aligned so, that the label strip is led horizontally from the printer to the rewinder. 1 loosen the guide axle (1) by turning it counterclockwise. 2 move it in the guide plate (2) up to the desir...

Page 112

8-22 accessories rewinding directly onto the rewind axle 1 loosen the screws (1) and remove the spring (2). Note: first remove the spring (2) from the rewind axle! Warning! Risk of injury by rotating engine parts. When switching on the rewinder starts immediately and winds to the material is tighten...

Page 113

Pronto! 482/486/682/863 8-23 2 feed the label strip over the guide axle (9) and under the roller (8) to the rewind axle (7). 3 attach the label strip appropriately to the rewind axle by sliding the clamp (5) over the label strip with the clamp set in the groove of the rewind axle (7). 4 slide the cl...

Page 114

8-24 accessories rewinding onto 40 mm (1.6 in) cardboard core note: make sure that the spring (1) is mounted on the rewind axle (2)! Consider that the cardboard core (3) should be about 1 mm (0.04 in) broader than the label strip. Warning! Risk of injury by rotating engine parts. When switching on t...

Page 115

Pronto! 482/486/682/863 8-25 1 put the cardboard core (3) on the rewind axle (2). 2 feed the label strip over the guide axle (8) and under the roller (7) up to the cardboard core (3). 3 affix the end of the label strip with consideration of the selected rewinding direction to the cardboard core usin...

Page 116

8-26 accessories rewinding onto 76 mm (3 in) cardboard core note: first remove the spring from the rewind axle! Consider that the cardboard core (3) should be about 1 mm (0.04 in) broader than the label strip. Warning! Risk of injury by rotating engine parts. When switching on the rewinder starts im...

Page 117

Pronto! 482/486/682/863 8-27 1 put the first rewind adapter (3) onto the rewind axle (4) and slide it up to the disc (1) until it stops. Make sure that the knurled screw (2) of the rewind adapter is led in the groove of the rewind axle.Tighten the knurled screw (2). 2 put the second rewind adapter (...

Page 118: External Unwinder (Eu4)

8-28 accessories external unwinder (eu4) the external unwinder is used if the label roll outside diameter is greater than 8 inches and/or the roll is heavy. It allows you to unwind complete rolls of label material. Safety instructions delivery contents 1 unwinder 2 winding axle note: this accessory ...

Page 119: Placing The Unwinder

Pronto! 482/486/682/863 8-29 3 flanges (2) 4 winding adapters (2) 5 screws (8) placing the unwinder when you switch between outside and inside wound materials you have to turn the unwinder 180 degrees. Compare the position of the swing arm (7) in the two following figures. Placing the unwinder for o...

Page 120: Media Loading

8-30 accessories placing the unwinder for inside wound labels media loading the mounting steps depend on the cardboard core of the chosen material roll. Possible cardboard cores are 1.56 in (40 mm) and 3 in (76 mm). At first you have to prepare the flanges and the winding axle in dependence to the c...

Page 121: Winding Axle

Pronto! 482/486/682/863 8-31 the roll. Fix the winding adapters (4) on the flanges (3) by using the screws (5) included in the delivery content. Preparing the flanges retaining rolls with 1.56 in (40 mm) cardboard core on the winding axle mounting the winding axle note: before mounting the winding a...

Page 122

8-32 accessories • slide the flange (3a) on the winding axle (2) so that the attachment of the flange points to the outside. • align the flange (3a) so that the screw (10) grasps into the groove (11) of the winding axle (2). Tighten the screw (10) in the flange. • slide the material roll (12) onto t...

Page 123: Winding Axle

Pronto! 482/486/682/863 8-33 retaining rolls with 3 in (76 mm) cardboard core on the winding axle mounting the winding axle • slide the flange (3a) on the winding axle (2) so that the attachment of the flange points to the outside. • align the flange (3a) so that the screw (10) grasps into the groov...

Page 124

8-34 accessories insertion of the prepared winding axle unwinding from a roll with outside wound labels unwinding from a roll with inside wound labels • hang up the axle with material in the unwinder. When hanging up, the flange with the knurled screw has to be in front. • feed the label strip (14) ...

Page 125: Adjusting The Unwinder

Pronto! 482/486/682/863 8-35 • insert the material according to the instructions of the printers operator`s manual. • align the unwinder to the printer (see adjusting the unwinder on page 8- 35). Adjusting the unwinder to avoid crinkling in the material the unwinder has to be aligned exactly to the ...

Page 126: Label Present Sensor (Ps6)

8-36 accessories label present sensor (ps6) product description the present sensor ps6 is optional for p-version-printers. These printers are equipped with an internal rewinder and a dispense edge for operation in peel-off mode. In peel-off mode, labels are removed from the liner immediately after p...

Page 127: Operation Modes

Pronto! 482/486/682/863 8-37 operation modes to position the jumper correctly, pull the jumper (4) carefully from the pins on the circuit board (2) and reposition it on the jumper position jp4 (3). The present sensor ps6 can be used in several operation modes. The operation mode depends on the perip...

Page 128

8-38 accessories the print of a label is executed if: • a print job is available • there is no label waiting to be removed from peel position • the trigger switch sends the xstart signal this operation mode requires that there is a contact between pin13 (sta) and pin12 (gnd). Print on demand with re...

Page 129: Safety Instructions

Pronto! 482/486/682/863 8-39 safety instructions mounting 1 switch off the printer. 2 2. Slide the guiding pins (2) of the module (3) according to arrow a under the control panel cover (1). 3 swing the lower edge of the module according to arrow b against the printer. Make sure the plug-in connector...

Page 130: Printer Configuration

8-40 accessories 4 secure the module (3) by tightening the screw (4). Printer configuration once the module is connected to the printer it will be recognized by the printer automatically. The printer can be configured to suit the individual requirements of peel-off mode in the setup. When the module...

Page 131: Operation

Pronto! 482/486/682/863 8-41 initial offset value of “0“causes the printed label to be peeled off from the liner leaving approximately a .1“(2mm) wide strip of the label still adhering to the liner. The amount of label left adhering to the liner can be altered with this parameter. Positive offset va...

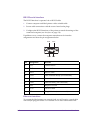

Page 132: Overview Signals

8-42 accessories overview signals for use in a network environment or with a switch, the present sensor ps6 is equipped with a peripheral interface to allow control of the dispensing process. The interface has a 15 pin sub-d connector (1). Pin signal direction system function user function 1 xstart ...

Page 133: Explanation of The Signals

Pronto! 482/486/682/863 8-43 explanation of the signals • pin1 - xstart - start the activation of the signal xstart triggers the start of printing a label. This signal is checked if there is a connection between signal sta and ground gnd. The signal xstart is active when current flows between pin1 a...

Page 134

8-44 accessories in this state the contact between pin5 and pin14 is opened. • pin6 - xdnb - printer is not ready an error has occurred on the printer. The label print is stopped and the details and type of error can be read from the printer’s display ('ribbon out'; 'paper out'; 'no label'; 'externa...

Page 135: Circuit Diagram of Inputs

Pronto! 482/486/682/863 8-45 in operation mode 2 and 3 “print on demand”, connect the signal sta (pin13) with gnd (pin12) • pin14 - ruel - reverse line (for all output signals) • pin15 - 24p - operating voltage +24v, si t 100ma the printer provides an operating voltage of 24v at pin15. Circuit diagr...

Page 136

8-46 accessories the switch function of the outputs is to open or close the contact between the joint line rÜl and the respective output. Examples external circuits to operate present sensor ps6 the external control device (trigger switch, external control, optical sensor) must be equipped with a 15...

Page 137

Pronto! 482/486/682/863 8-47.

Page 138: Pause Adapter Ps7

8-48 accessories pause adapter ps7 product description the pause adapter allows an external control of the pronto! 482/486/682/863. This external control can pause printing the labels by sending a pause signal. The printer finishes the current printed label and pauses the print job until the pause s...

Page 139: Mounting The Pause Adapter

Pronto! 482/486/682/863 8-49 mounting the pause adapter when operating with the pause adapter, solely the front cover (1) has to be replaced by the pause adapter ps7. 1 loosen the screw (2). 2 remove the front cover (1). Caution: • the printer must be powered off before attaching the pause adapter! ...

Page 140: Modes of Operation

8-50 accessories 3 angle the pause adapter (3) slightly and slide it according to arrow a inserting the guiding pins (5) under the control panel cover (6). 4 swing the lower edge of the pause adapter according to arrow b against the printer. Make sure that the plug-in connector of the present sensor...

Page 141

Pronto! 482/486/682/863 8-51 when the pause signal (xpse) is getting active during a print job, the printer finishes the current printed label. Then the printer pauses the print job. By inactivation of the pause signal (xpse) the printer continues its regular print job. If you turn on the printer an...

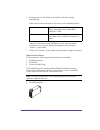

Page 142: Explanation Of The Signals

8-52 accessories explanation of the signals • xpse - pause if the pause signal xpse becomes active the printer will finish the current printed label. Then the printer will pause the print job as long as the pin signal direction system function 1 xpse input pause signal 2 xfeh input external error 3 ...

Page 143

Pronto! 482/486/682/863 8-53 signal is active. On inactive pause signal the printer continues the print job at the pause position. Xpse is active when current flows between pin1 and pin9. • xfeh - external error an error has occurred on the external device. The label print is stopped and the display...

Page 144: Circuit Diagram of Inputs

8-54 accessories • rxfeh - reverse line of the signal xfeh • ruel - reverse line (for all output signals) • 24p - operating voltage +24v, si t 100ma the printer provides an operating voltage of 24v at pin15. Using that voltage a trigger switch or an optical sensor can be connected to control the pee...

Page 145: Circuit Diagram of Outputs

Pronto! 482/486/682/863 8-55 minimum external circuit for operation with pause adapter ps7 circuit diagram of outputs all outputs are recognized through solid state relays. Their outputs are connected to one another on one-side. The joint line is lead to the plug connector as a rÜl signal. The switc...

Page 146: Wlan-Card

8-56 accessories wlan-card function the wlan-card 802.11 b/g allows to link a printer to a wireless network which contains a wireless access point. The ad-hoc mode for direct connection between several end devices is not supported. Mounting slide the wlan-card (1) considering the correct orientation...

Page 147: Setup

Pronto! 482/486/682/863 8-57 setup set the following parameters of the menu setup > interfaces > wireless lan 802.11 matching to the configuration of the access point: set the remaining parameters of the menu (dhcp, ip, mask, gateway, network error). Those parameters conform to the parameters of the...

Page 148: External Operating Panel

8-58 accessories external operating panel delivery contents • external operating panel • cable sub-d-9 socket - usb a • 2 screws din7984-m4x10 function the external operating panel is designed as a build-in module and has the same functionality as the printer integrated operating panel. Additionally...

Page 149: Mounting

Pronto! 482/486/682/863 8-59 mounting • prepare the installation point for the external operating panel as shown in the drilling template. Dimensions are in millimeters. • fix the external operating panel with 2 screws (din7984-m4x10). Dimensions are in millimeters. • connect the delivered cable at ...

Page 150: Antistatic Brush

8-60 accessories antistatic brush delivery contents • antistatic brush • 2 screws din7984-m4x6 • washer din125-a4.3 function the antistatic brush is made to reduce electrostatic charges around the printhead unit. Mounting 1 remove the rear cover. 2 insert the screw (3) incl. Washer (2) from the rear...

Page 151: Adjustment

Pronto! 482/486/682/863 8-61 3 tighten the screw (3). 4 mount the rear cover. 5 put the antistatic brush (5) with the lower elongated hole onto the thread of screw (3) 6 fix the antistatic brush in the upper elongated hole with the screw (6) at the drilling (4). Adjustment 1 load label material. 2 l...

Page 152

8-62 accessories.

Page 153: Chapter 9:

Pronto! 482/486/682/863 9-1 chapter 9: cu4 cutter accessory this chapter contains the following sections: • cutter - describes available cutter types • safety instructions - describes safety precautions • mounting the tear-off plate / dispense plate - describes how to install • mounting the cutter t...

Page 154: Cutter

9-2 cu4 cutter accessory cutter cutter the cutter is an optional peripheral device. With the cutter unit installed, labels or continuous material may be cut when desired. Cutter options include a choice of: cut after each label, cut after a specific quantity of labels, or cut at the end of a print j...

Page 155: Safety Instructions

Pronto! 482/486/682/863 9-3 safety instructions caution! • switch off the before attaching the cutter! • risk of injury, particularly during maintenance, the cutter blades are sharp! • the cutter may only be used when it is mounted on the printer! • do not try to cut any materials which exceed the m...

Page 156

9-4 cu4 cutter accessory mounting the tear-off plate / dispense plate for cutter operation there has to be mounted a tear-off plate or a dispense plate on the printer, to lead the material through the blades of the cutter. The printers have such a plate mounted when delivered. 1 to dismount the rewi...

Page 157: Mounting The Cutter Tray

Pronto! 482/486/682/863 9-5 mounting the cutter tray 1 loosen the screws (1). 2 place the cutter tray (2) on the screws (1) in front of the tear-off plate or the dispense plate and slide it to the left until it stops. 3 tighten the screws (1). 4 the length of the cutter tray (2) may be modified by m...

Page 158: Mounting The Cutter

9-6 cu4 cutter accessory mounting the cutter in order to install the cutter, the front cover is to be removed. 1 turn the printer off. Open the media cover. 2 loosen the screw (2). 3 remove the front cover (1). 4 insert the pins (3) of the cutter (7) into the holes (4) of the printer. 5 press the cu...

Page 159: Printer Configuration

Pronto! 482/486/682/863 9-7 printer configuration once the cutter is connected to the printer, the printer will automatically recognize it on turn on. Once the cutter is recognized, the printer can be operated in cut mode. The printer can be configured to suit the individual requirements of cut mode...

Page 160: Backfeed

9-8 cu4 cutter accessory backfeed in cut mode, the media will be stopped in a position where the leading edge of the following label has already been moved beyond the printhead. The printer can backfeed the label material from its cut position to the printhead. Therefore, the next label can be print...

Page 161: Operation

Pronto! 482/486/682/863 9-9 operation standard operation the printer is ready for operation when all connections have been made and all materials are loaded correctly. After loading the media it is necessary to locate top of form by pressing the feed key. The media will be moved forward and then cut...

Page 162: Lubrication

9-10 cu4 cutter accessory lubrication to guarantee of a normal function of the cutter the cylindrical area (1) of the circular blade (2) must be greased regularly. We recommend for lubrication an all round-high quality grease. • hold a greased brush on the cylindrical area and turn the axle (3) with...

Page 163: Cleaning

Pronto! 482/486/682/863 9-11 cleaning during the normal operation of the cutter, particles of dust and paper can accumulate inside the cutter. Remove these particles with a soft brush or a vacuum. When cutting through the label material instead of the label gap remains of adhesive may accumulate on ...

Page 164: Changing The Blades

9-12 cu4 cutter accessory 2 grease the circular blade according to lubrication on page 9-10. Changing the blades 1 turn the printer off and dismount the cutter from the printer. 2 turn the axle (3) of the circular blade (2) with a screwdriver for slotted head screws (slot width 7 mm) so that the ins...

Page 165

Pronto! 482/486/682/863 9-13 if you don`t want to change the linear blade you can skip to step 9. 6 take the spring (6) and the linear blade (11) from the mounting plate (9). 7 insert the axle of the (new) linear blade withe the washer (b) in the bearing (10) of the mounting plate. (the inscription ...

Page 166: Wheel

9-14 cu4 cutter accessory 1 tighten the bearing plate (15) with the screws (8) at the profile (7). Keep the bearing plate in position and push it slightly to the profile (7) during tightening. 2 tighten the screw set (4) of the gear-wheel circular blade at the rear of the printer. 3 grease the circu...

Page 167

Pronto! 482/486/682/863 9-15 4 tighten the screw (8) for arresting the circular blade. Caution: if you tight screw (8) too strong, you could damage the screw thread..

Page 168

9-16 cu4 cutter accessory.

Page 169: Chapter 10:

Pronto! 482/486/682/863 10-1 chapter 10: cs4 cutter/stacker accessory this chapter contains the following sections: • cs4 cutter/stacker - describes the cs4 cutter/stacker • safety instructions - provides important safety information • installation - describes how to install the cs4 cutter/stacker •...

Page 170: Cs4 Cutter/stacker

10-2 cs4 cutter/stacker accessory cs4 cutter/stacker 1 cover 2 knurled screw 3 table 4 handle for height displacement of the table 5 upper blade 6 lower blade 7 safety cover 8 scale 9 side plate (movable) 10 side plate (fixed).

Page 171: Safety Instructions

Pronto! 482/486/682/863 10-3 safety instructions • disconnect the printer from the electrical outlet before mounting or removing the stacker (2). • the stacker protrudes the base plate of the printer. Therefore the system must be positioned at the edge of the platform or on a mounting unit. Position...

Page 172

10-4 cs4 cutter/stacker accessory • the device may only be used in a dry environment, do not expose it to moisture (sprays of water, mists, etc.). • do not use the device in an explosive atmosphere. • do not use the device close to high-voltage power lines. • perform only those actions described in ...

Page 173: Installation

Pronto! 482/486/682/863 10-5 installation preparing the printer removing tear-off plate, dispense plate or rewind guide plate 1 loosen screws (2) several turns. 2 slide plate (1) to the right and remove it. Removing cover or present sensor 1 loosen screw (4). 2 remove cover (3) or present sensor. Re...

Page 174

10-6 cs4 cutter/stacker accessory mounting the stacker to the printer to mount the stacker to the printer: 1 insert the pins (4) of the stacker into the holes (1) of the printer. 2 press the stacker against the printer. That way the plug (5) of the stacker will be connected to the peripheral port (2...

Page 175

Pronto! 482/486/682/863 10-7 adapting the stacker to the media size adjusting the side plates 1 loosen screws (2). 2 adjust the side plates (4) to the media width using the scale (1). Use the edges (3) of the side plates as pointers. 3 tighten screws (2). Warning: equip the stacker only with a table...

Page 176

10-8 cs4 cutter/stacker accessory mounting the table 1 loosely screw the knurled nuts (3) contained in the delivery contents of the table onto the threaded pins (2). 2 insert the threaded pins of the table (1) into the holes of the retainer (4) and move the table to the printer until it stops. 3 tig...

Page 177

Pronto! 482/486/682/863 10-9 1 open cover (1). 2 loosen two screws (3) in the side plates (4,6) several turns. 3 place the safety cover (2) onto the screws (3) and slide the cover to the printer. 4 tighten the screws (3). 5 close cover (1)..

Page 178: Printer Configuration

10-10 cs4 cutter/stacker accessory printer configuration once the stacker is connected to the printer, the printer will automatically recognize it on turn on. The printer can be configured to suit the individual requirements of cut mode in the “setup” menu. When the stacker is installed, the “cutter...

Page 179

Pronto! 482/486/682/863 10-11 under setup> print parameters the method for recognizing the material and the method of backfeed when using cut mode can be selected. Parameter meaning default label sensor method for detecting the starting end of the label. Gap sensor: detection using changes in the tr...

Page 180: Loading Material

10-12 cs4 cutter/stacker accessory loading material • load transfer ribbon and endless material as described in loading media on page 6-1. • use the tear-off mode information for loading endless material for cut mode. Place the media strip between the printhead and the drive roller, so that the fron...

Page 181

Pronto! 482/486/682/863 10-13 • press the feed key. For synchronization the media will be moved forward and cut off. Synchronization is not necessary when the printhead was not opened between print jobs, even if the printer was powered off between print jobs. • remove the cuts from the table. • acti...

Page 182: Maintenance

10-14 cs4 cutter/stacker accessory maintenance the maintenance is limited to monthly cleaning of the device. The most important is the cleaning of the cutter blades. 1 open cover (1). 2 move table (6) downwards. 3 remove safety covers (mounting the safety cover on page 10-8) and shift the movable si...

Page 183

Pronto! 482/486/682/863 10-15 8 move the table upwards until it stops. 9 close cover..

Page 184: Error Messages

10-16 cs4 cutter/stacker accessory error messages specific error messages concerning the stacker with cutter error message cause remedy cutter jammed motor current increases too much, cutter returns in the home position without completion of the cut. Material too thick change material bracket on the...

Page 185: Chapter 11:

Pronto! 482/486/682/863 11-1 chapter 11: cleaning and basic maintenance • maintenance plan - describes how often maintenance tasks should be performed • tools and cleaning agents - describes the tools needed for maintenance • general cleaning - describes general cleaning • cleaning the print roller ...

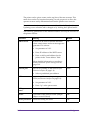

Page 186: Maintenance Plan

11-2 cleaning and basic maintenance maintenance plan maintenance task when general cleaning (see general cleaning on page 11-3) as necessary clean print roller (see cleaning the print roller on page 11-4) each time the label roll is changed or when the print image and label transport are adversely a...

Page 187: Tools and Cleaning Agents

Pronto! 482/486/682/863 11-3 tools and cleaning agents cleaning agents • soft brush • roller cleaner • soft cloth • cotton swabs • pure alcohol • special cleaning pen general cleaning • remove dust and paper fuzz in the printing area with a soft brush or vacuum cleaner. • clean outer surfaces with a...

Page 188: Cleaning The Print Roller

11-4 cleaning and basic maintenance cleaning the print roller 1 turn lever counterclockwise to lift the printhead. 2 remove labels and transfer ribbon from the printer. 3 remove deposits with roller cleaner and a soft cloth. 4 if the roller appears damaged, replace it (see replacing the print roller...

Page 189: Cleaning The Printhead

Pronto! 482/486/682/863 11-5 cleaning the printhead substances may accumulate on the printhead during printing and adversely affect printing, e.G. Differences in contrast or vertical stripes. 1 turn lever counterclockwise to lift the printhead. 2 remove labels and transfer ribbon from the printer. 3...

Page 190: Cleaning The Label Sensor

11-6 cleaning and basic maintenance cleaning the label sensor the label sensor can become dirtied with paper dust. This can adversely affect label detection. Caution: the cleaning method described here cannot be used for the pronto! 682 and pronto! 863 label printers. There is a risk that the label ...

Page 191: Models

Pronto! 482/486/682/863 11-7 replacing the printhead on pronto! 482/486 models replacing the printhead the printhead of the label printer can be replaced without the need for fine adjustment. The printhead must be replaced if worn or when switching to a printhead with higher or lower resolution. For...

Page 192

11-8 cleaning and basic maintenance removing the printhead 1 turn lever (10) counterclockwise to lift the printhead. 2 remove labels and transfer ribbon from the printer. 3 remove hexagonal wrench (11) from its retainer. 4 lightly keep printhead mounting bracket (9) on the print roller with one fing...

Page 193: Replacing The Printhead

Pronto! 482/486/682/863 11-9 replacing the printhead on pronto! 682/863 replacing the printhead the printhead of the label printer can be replaced without the need for fine adjustment. The printhead must be replaced if worn or when switching to a printhead with higher or lower resolution. For better...

Page 194

11-10 cleaning and basic maintenance removing the printhead 1 turn lever (8) counterclockwise to lift the printhead. 2 remove labels and transfer ribbon from the printer. 3 remove hexagonal wrench (9) from its retainer. 4 lightly keep printhead mounting bracket (7) on the print roller with one finge...

Page 195

Pronto! 482/486/682/863 11-11 installing the printhead 1 attach plug connections (2, 3). 2 swing the adjustment elements (11) sidewards to uncover the slots (10) in the printhead carriage. 3 put in the printhead into the printhead carriage and swing down the printhead assembly by hand and hold it. 4...

Page 196: Roller

11-12 cleaning and basic maintenance replacing the print roller and rewind assist roller removing the side plate 1 turn lever (1) counterclockwise to lift the printhead. 2 lift the pinch roller (5) off the rewind assist roller. 3 remove labels and transfer ribbon from the printer. 4 loosen screws (4...

Page 197: Chapter 12:

Pronto! 482/486/682/863 12-1 chapter 12: test functions this chapter contains the following sections: • overview - provides an overview of test functions • short status - describes the short status menu • status print - describes the status print function • font list - describes the font list functi...

Page 198: Overview

12-2 test functions overview the printer is equipped with different test functions providing information on: • the most important configuration parameters • the fonts available in the printer • important hardware components and connected peripheral devices • the print image quality and state of the ...

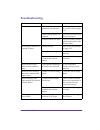

Page 199: Short Status

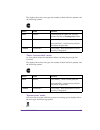

Pronto! 482/486/682/863 12-3 short status 1 press the menu button. 2 select short status menu. 3 scroll through the individual lines with the up and down arrow buttons. You can exit the short status menu with the ↵ button. The following configuration parameters are displayed in the short status menu...

Page 200

12-4 test functions 12 mac address of the network adapter on the cpu pcb mac 0002e70228f4 13 type and size of the installed memory medium cf 30mb 14 size of the internal flash-file-systems see the “quicklabel pronto 482/486/682/863 programmer's guide” iffs 8mb 15 resolution of the installed thermal ...

Page 201: Status Print

Pronto! 482/486/682/863 12-5 status print 1 insert printable medium (labels, endless paper) which extends across the entire printing width. 2 if the printout is to occur using thermal transfer printing, insert transfer ribbon with the maximum width. 3 press the menu button. 4 select test > status pr...

Page 202

12-6 test functions the status print contains the following information: symbol information • device type • version and creation date of the firmware • version and creation date of the system loader (bootloader) current values of selected local settings (see local settings on page 5-2). Current valu...

Page 203: Font List

Pronto! 482/486/682/863 12-7 font list 1 insert printable medium (labels, endless paper) which extends across the entire printing width. 2 if the printout is to occur using thermal transfer printing, insert transfer ribbon with the maximum width. 3 press the menu button. 4 select test > font list me...

Page 204

12-8 test functions type type of font generation. It provides information on the variability of the font and is important when programming (command t). Description explanations of the font: size, font family. The printout occurs in the appropriate font. Column meaning.

Page 205: Device List

Pronto! 482/486/682/863 12-9 device list 1 insert printable medium (labels, endless paper) which extends across the entire printing width. 2 if the printout is to occur using thermal transfer printing, insert transfer ribbon with the maximum width. 3 press the menu button. 4 select test > device lis...

Page 206

12-10 test functions name information cpu • type and serial number of the cpu pcb • revision of cpu pcb and fpga tph resolution and heating point number of the installed thermal printhead. I/f [x] type of interfaces installed x: number of interface iffs size of the internal flash file system. Cf / c...

Page 207: Wifi Status

Pronto! 482/486/682/863 12-11 wifi status 1 insert printable medium (labels, endless paper) which extends across the entire printing width. 2 if the printout is to occur using thermal transfer printing, insert transfer ribbon with the maximum width. 3 press the menu button. 4 select test > wifi stat...

Page 208: Ascii Dump Mode

12-12 test functions ascii dump mode 1 load printable medium (labels, endless paper). 2 if the printout is to occur using thermal transfer printing, insert transfer ribbon. 3 if the printable medium and/or the transfer ribbon does not cover the entire printing width, reduce the width of the printout...

Page 209

Pronto! 482/486/682/863 12-13 the control characters (ascii code 00 to 31) are presented in the following form: example: in the following two figures, the printout in monitor mode is contrasted with the “normal” printout of a label..

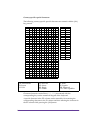

Page 210: Test Grid

12-14 test functions test grid 1 insert printable medium (labels, endless paper) which extends across the entire printing width. 2 if the printout is to occur using thermal transfer printing, insert transfer ribbon with the maximum width. 3 press the menu button. 4 select test > test grid menu. 5 st...

Page 211: Label Profile

Pronto! 482/486/682/863 12-15 label profile 1 select the label sensor to be tested in the menu setup > print param. (see printing parameters on page 5-5). 2 load the label medium to be tested into the printer. 3 press the menu button. 4 select test > label profile menu. 5 start the function with the...

Page 212

12-16 test functions located at the point where the rise of the gradient exhibits a minimum (see vertical dotted line). 1 coordinate in the direction of paper flow at which the label start was detected 2 type of peripheral device connected 3 information for the firmware developer 4 width of the nega...

Page 213: Chapter 13:

Pronto! 482/486/682/863 13-1 chapter 13: service functions this chapter contains the following sections: • performing firmware update - describes how to update the printer firmware • save settings - describes how to save printer configurations to a file • load settings - describes how to load printe...

Page 214: Performing Firmware Update

13-2 service functions performing firmware update the firmware of the printer is saved in a flash eprom. You can update the firmware using the following functions: • firmware upd.: copy a firmware file from a computer connected to one of the interfaces of a label printer (see copying new firmware vi...

Page 215

Pronto! 482/486/682/863 13-3 copying new firmware from memory medium 1 select in the menu setup > interfaces > default card slot depending on the used memory medium compactflash or usb memory. 2 format compactflash memory card or usb flash drive in the printer (see format card on page 15-7). The dir...

Page 216

13-4 service functions error messages during the firmware update if an error occurs during the update, one of the following error codes is shown in the display: error code meaning c checksum error. /b may have been forgotten in the copy command or the file is defective. H header error. /b may have b...

Page 217: Save Settings

Pronto! 482/486/682/863 13-5 save settings you can save the printer configuration to a memory medium (memory card, usb flash drive, internal flash file system) in the default card slot. The configuration will be saved as xml file in the folder \misc of the cf card. The current date is used as file n...

Page 218: Load Settings

13-6 service functions load settings you can load a printer configuration previously saved to a memory medium (memory card, usb flash drive, internal flash file system) into the printer with the load settings function. 1 insert memory medium. 2 press the menu button. 3 select service > load settings...

Page 219: Cleaning Interval

Pronto! 482/486/682/863 13-7 cleaning interval the cleaning interval function is used for additional printhead maintenance control. The length of medium which passes the printhead can be selected in increments of 100 m after which the printhead is to be cleaned. 1 press the menu button. 2 select ser...

Page 220

13-8 service functions.

Page 221: Chapter 14:

Pronto! 482/486/682/863 14-1 chapter 14: ftp printer management this chapter contains the following sections: • ftp logon - describes how to establish an ftp connection • directory structure of the ftp server - describes the folder structure of the ftp server • ftp firmware update - describes how to...

Page 222: Ftp Logon

14-2 ftp printer management ftp logon to establish an ftp connection, the client must be logged on to the server. The logon type depends on the client. The following information must be specified in any case, however: • ip address of the label printer • user name and password access to the printer m...

Page 223

Pronto! 482/486/682/863 14-3 directory structure of the ftp server the files accessible via ftp are found in several folders: folder name contents execute printing of label files stored in this folder is started immediately. The files must be of the type .Lbl. The corresponding file is deleted once ...

Page 224: Ftp Firmware Update

14-4 ftp printer management ftp firmware update to carry out a firmware update, you must be logged on with the username “root” (see ftp logon on page 14-2). 1 ensure that the label printer is in “ready” mode. See status tab on page 5- 15. 2 set the "binary" transfer mode in the ftp client. 3 open th...

Page 225: Chapter 15:

Pronto! 482/486/682/863 15-1 chapter 15: memory media this chapter contains the following sections: • suitable memory media - describes compatible media types • installation - describes how to install external memory media • formatting - describes how to format a memory card • directory structure - ...

Page 226: Suitable Memory Media

15-2 memory media suitable memory media external media • type 1 compactflash card up to a maximum size of 2 gb in the corresponding card slot of the printer or in the external operating panel • pc card (pcmcia) in the corresponding card slot of the printer • usb flash drive up to a maximum size of 2...

Page 227: Formatting

Pronto! 482/486/682/863 15-3 formatting if the memory medium has not been pre-formatted in a suitable way, it can be formatted it in the following manners: • formatting in the printer via the format card (see formatting on page 15- 3) menu item. • formatting in the printer via the interface with the...

Page 228: Writing

15-4 memory media writing the memory medium can be written to in several ways. The most functionally secure way is writing to the card in the printer via a data interface. Example: with direct programming, the command sequence for saving a label (file abc) has the following form: ms lbl; abc command...

Page 229: Label From Card

Pronto! 482/486/682/863 15-5 memory media functions in the offline menu accessing the memory card menu is only possible if a memory medium is installed in the default card slot. Only the medium in the default slot can be operated via the operating panel (see interfaces on page 5-8). When operating v...

Page 230: Print Directory

15-6 memory media canceling input: you can cancel the selection of the label and the label quantity at any time by pressing and holding the ↵ button (at least 2 seconds). Print directory you can print out the index of the installed memory card with the print directory function. 1 insert printable me...

Page 231: Format Card

Pronto! 482/486/682/863 15-7 1 insert original medium. 2 press the menu button. 3 select memory card > copy memory card with the right and left arrow buttons. 4 press the ↵ button. A selection field with the selection no appears in the display. 5 use the up and down arrow buttons to select yes. 6 pr...

Page 232: Printing File Contents

15-8 memory media you can prevent unauthorized deleting of memory cards by using a pin (see security on page 5-12). 1 insert original medium. 2 press the menu button. 3 select memory card > format card with the right and left arrow buttons. 4 press the ↵ button. A selection field with the selection ...

Page 233

Pronto! 482/486/682/863 15-9 7 select the desired label file in the index of the medium with the up and down buttons. 8 start printout with the ↵ button. The data printout is started after four lines are received. For this reason, it is often necessary to call up the last few lines of a label descri...

Page 234

15-10 memory media.

Page 235: Chapter 16:

Pronto! 482/486/682/863 16-1 chapter 16: error treatment this chapter contains the following sections: • error types - describes error types • troubleshooting - describes troubleshooting issues and solutions • error messages and recovery - describes error messages and solutions.

Page 236: Error Types

16-2 error treatment error types when an error occurs, the diagnostic system displays the error on the screen and switches the printer into one of the three possible error modes, depending on the error type: symbol navigator pad error type pause flashes cancel illuminates fault - correctable (see 'f...

Page 237: Troubleshooting

Pronto! 482/486/682/863 16-3 troubleshooting problem cause solution transfer ribbon wrinkles transfer ribbon deflection not adjusted see setting the feed path of the transfer ribbon on page 6-11 head locking system not adjusted see setting the head locking system on page 6-7 transfer ribbon too wide...

Page 238

16-4 error treatment vertical white lines in print image printhead dirty see cleaning the printhead on page 11-5 printhead defective (failure of dots) see replacing the printhead on pronto! 482/486 models on page 11-7 horizontal white lines in print image printer is being operated in cutting mode or...

Page 239: Error Messages and Recovery

Pronto! 482/486/682/863 16-5 error messages and recovery error message cause error recovery adc malfunction hardware error switch printer off and on again. If it occurs again → service. Barcode error invalid barcode contents, e.G. Alphanumeric characters in numerical barcode correct barcode contents...

Page 240

16-6 error treatment file not found requested file is not on the card check the contents of the card. Font not found error with the selected download font cancel current print job, change font. Fpga malfunction hardware error switch printer off and on again. If it occurs again → service. Head error ...

Page 241

Pronto! 482/486/682/863 16-7 no label found several labels are missing from the label strip press the pause button several times until the next label on the strip is detected by the printer. The label format specified in the software does not match the actual format used cancel print job. Change lab...

Page 242

16-8 error treatment out of paper label roll used up load a label roll (see loading labels from a roll on page 6-3) or load fanfold labels (see loading fanfold labels on page 6-9). Error in paper course check paper course. Out of ribbon transfer ribbon used up load new transfer ribbon transfer ribbo...

Page 243

Pronto! 482/486/682/863 16-9 remove ribbon transfer ribbon is loaded although the printer is set to direct thermal printing for direct thermal printing remove ribbon for thermal transfer printing set the printer in the configuration or in the software to transfer printing structural err. Error in di...

Page 244

16-10 error treatment.

Page 245: Chapter 17:

Pronto! 482/486/682/863 17-1 chapter 17: specifications this chapter contains the following sections: • cutter - provides specification for the cutter • external rewinder (er1) - provides specifications for the external rewinder (er1) • external rewinder (er4) - provides specifications for the exter...

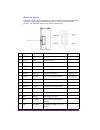

Page 246: Cutter

17-2 specifications cutter the cutters have a durability of more than one million cuts. The blades are self-sharpening. Depending on the type of material cut the blades could wear earlier and have to be replaced. Used blades are not designed to be sharpened again. Material width up to (in/mm) 4.7 / ...

Page 247: External Rewinder (Er1)

Pronto! 482/486/682/863 17-3 external rewinder (er1) label width er1: up to 4.7 in (120 mm) rewind diameter max. 8.19 in (210 mm) core diameter 1.56 in (40 mm) on rewind axle 1.56 in (40 mm) on cardboard core with adapter 3 in (76 mm) on cardboard core rewind speed 2 - 12 ips (50 - 300 mm/s) label r...

Page 248: External Rewinder (Er4)

17-4 specifications external rewinder (er4) max. Material width 120 mm (4.7 in) max. Rewind diameter 210 mm (8.3 in) core diameter 40 mm (1.6 in) on rewind axle 40 mm (1.6 in) on cardboard core 76 mm (3 in) on cardboard core with adapter rewind speed max 300 mm/s (12 in/s) label rewinding labels in-...

Page 249: External Unwinder (Eu4)

Pronto! 482/486/682/863 17-5 external unwinder (eu4) label width up to 4.7 in (120 mm) unwind diameter max. 11.7 in (300 mm) core diameter 1.56 in (40 mm) on cardboard core 3 in (76 mm) on cardboard core with adapter label rewinding labels inside or outside dimensions of the unwinder height 17.5 in ...

Page 250

17-6 specifications.

Page 251: Appendix A:

Pronto! 482/486/682/863 a-1 appendix a: menu map.

Page 252

A-2 pronto 482/486 menus memory car d shor t sta tus test setup ser vice la bel f rom car d print dir ectory ascii dump car d sta tus print f ont list de vice list ascii dump mode t est grid la bel pr of ile f irmw . Fr car d f irmw a re upda te sa v e settings load settings cleaning inter v a l cou...

Page 253: Index

Pronto! 482/486/682/863 index index symbols 'fault - correctable' mode .................... 2-6 'fault - irrecoverable' mode ................ 2-7 'pause' mode ......................................... 2-6 'system error' mode ............................. 2-7 > dhcp .....................................

Page 254

Index pronto! 482/486/682/863 inserting a label strip into the printhead 6-4 installation .............................................1-1 interfaces ...............................................5-8 k keyboard .............................................5-10 keyboard, external ......................

Page 255

Pronto! 482/486/682/863 index short status .......................................... 12-3 standard device .................................... 4-2 status line ............................................ 5-10 status print .......................................... 12-5 switching off ..................

Page 256

Index pronto! 482/486/682/863.