R . O . Drinking water system model t.F.C.-300 installation, operation & service manual important notices: this reverse osmosis system contains replaceable treatment components critical for effective performance. It is the user's responsibility to, and the manufacturer strongly recommends that the u...

Table of contents page section i. Introduction ........................................................................................... 3 section ii. Specifications .......................................................................................... 5 section iii. Installation steps ..........

3 section i. Introduction your new reverse osmosis (r.O.) drinking water system uses a combination of filtration technologies to reduce unwanted contaminants in a water supply. The following steps combine to give you the best in clear sparkling drinking water: mechanical filtration/activated carbon–t...

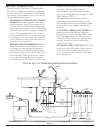

4 optional t.F.C.–300 basement installation diagram ...

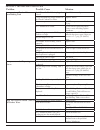

5 section ii. Specifications table a – qualified system performance because the performance of an r.O. Membrane is highly dependent upon pressure, temperature, ph and tds, the following should be used for comparison purposes only. U.S. Metric membrane production 1 40-60 gpd 151-227 lpd membrane tds ...

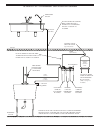

6 section iii. Installation steps all plumbing should be done in accordance with state and local plumbing codes. Note: some codes may require installation by a licensed plumber; check with the local plumbing authority prior to installation. In restricted under–sink areas, it may be easier to install...

7 •rotate the spout and body into position. Align the split washer and the spacer to allow access to the hose barbs, and tighten the hex nut while holding the faucet in alignment with a padded crescent wrench. Do not over tighten. B. Feed water saddle valve installation decide on location. Do not co...

8 firmly press one end of the tubing over the 3 / 8 " drain outlet hose barb on the air gap faucet. Allow the tubing to relax, then press firmly again to insure proper seating. No connectors are required when attaching hose to hose barbs. Route the tubing to the drain clamp and trim to length. •refer...

9 the black plug from the fitting labelled “drain” on the manifold and insert the tubing. The end of the black drain tubing that should be inserted into the “drain” port will have a green drain restrictor in it. Run the tubing along its course to the ¼" hose barb on the dispensing faucet, trim to len...

10 •insert the membrane up into the manifold. (the o–rings should be up toward the manifold.) check the housing o–ring for proper position in its groove, engage and firmly tighten the housing hand tight only. 3. Rinsing the system: •slowly open the feed water saddle valve fully counter clockwise. •th...

11 •use a good quality unscented 5¼% liquid chlorine household bleach. •add one capful of bleach (this is 2 tsp. Or 10 ml) to the sediment/carbon filter housing and temporarily install the housing without the sediment/carbon prefilter. Check the housing o–ring for proper position in its groove, engag...

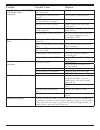

12 section v. Trouble shooting guide problem possible cause solution low quantity of product water from holding tank feed water saddle valve is plugged or closed. Open valve or unclog. Clogged sediment/carbon prefilter or activated carbon post filter. Replace filters. Low water pressure feed water pre...

13 problem possible cause solution high total dissolved solids (tds) in the product water (continued) the product water and drain water lines are reversed. Correct plumbing. No drain flow, drain restrictor is clogged. Clear or replace drain restrictor. No drain flow, the drain orifice in the air gap fa...

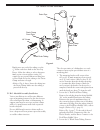

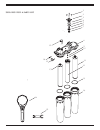

14 made in usa 1 2 3 4 5 6 7 8 9 10 11 12 13 14 17 19 18 exploded view & parts list 16 15 15.

15 drawing no. Part no. Description 1...................... S2009 ..................................... Self tapping screw 2...................... S2005pp ................................. Aso cap 3...................... S2013 ..................................... Aso cap o–ring 4......................

Form no. S1462-03 04/05 r.O. Drinking water system five/one year limited warranty what does this warranty cover? This warranty covers any defects in materials and workmanship of the r.O. Drinking water system when installed and operated within recommended parameters, with the exceptions stated below...