- DL manuals

- Rand-Kar

- Aircrafts

- X-AIR HANUMAN 602T AP

- User Manual

Rand-Kar X-AIR HANUMAN 602T AP User Manual

2008, october, 17

-User’s Manual

Section 1 to 7

-Maintenance Manual

Section 8

-Engine Manual

Annex

X-AIR

« HANUMAN »

X-AIR HANUMAN 602T AP

(with Rotax 582 and parachute)

X-AIR HANUMAN 602T SP

(with Rotax 582 without parachute)

X-AIR HANUMAN JABIRU AP

(with Jabiru 2200 and parachute)

X-AIR HANUMAN JABIRU SP

(with Jabiru 2200 without parachute)

X-AIR HANUMAN 912 AP

(with Rotax 912 and parachute)

X-AIR HANUMAN 912 SP

(with Rotax 912 without parachute)

X-AIR HANUMAN 912S AP

(with Rotax 912S and parachute)

X-AIR HANUMAN 912S SP

(with Rotax 912S without parachute)

RAND-KAR sa Canal de la Martinière 44320 Frossay - France Tél.:+33 (0) 240 642 166 Fax : +33 (0) 240 641 522

Société au capital de 46 000 € siret : 384.220.695.00017 RM 44 APE 353 B FR 39.384.220.695

http///www.randkar.fr

E-mail :

contact@randkar.fr

support technique

xair-info@randkar.fr

Summary of X-AIR HANUMAN 602T AP

Page 1

2008, october, 17 -user’s manual section 1 to 7 -maintenance manual section 8 -engine manual annex x-air « hanuman » x-air hanuman 602t ap (with rotax 582 and parachute) x-air hanuman 602t sp (with rotax 582 without parachute) x-air hanuman jabiru ap (with jabiru 2200 and parachute) x-air hanuman ja...

Page 2

2008, october, 17 summary introduction (pages 5 to 9) section 1 : general points (pages 11 to 15) 1-1 on-board documents 1-2 3 views drawings 1-3 design features 1-3.1 dimensions 1-3.2 landing gear 1-3.3 travel of control surfaces 1-3.4 fuel tank 1-3.5 wings 1-3.6 fuselage 1-3.7 empennage 1-3.8 elev...

Page 3

2008, october, 17 section 4 : performances (pages 25 to 27) 4-1 x-air hanuman jabiru 4-1.1 service ceiling 4-1.2 take off distance 4-1.3 climb 4-1.4 speeds 4-1.5 engine off 4-1.6 landing 4-2 x-air hanuman 602t (rotax 582) 4-2.1 service ceiling 4-2.2 take off distance 4-2.3 climb 4-2.4 speeds 4-2.5 e...

Page 4

2008, october, 17 section 6 : emergency procedures (pages 37 to 40) 6-1 engine failure, emergency landing 6-1.1 before take-off 6-1.2 on take-off 6-1.3 in flight 6-2 fire 6-2.1 engine fire 6-2.2 cabin fire 6-2.3 electric cables fire 6-3 regulator failure 6-4 landing without elevator 6-5 emergency la...

Page 5

2008, october, 17 introduction dear fellow pilot, our congratulations and our thanks, for choosing our new x-air hanuman ultralight. We wish you many pleasant hours of flight. This maintenance and flight manual will help you achieve safe flying conditions. Please read it attentively and follow all t...

Page 6

2008, october, 17 warning even in the best of conditions, ultralight flying may be hazardous. The user of this ultralight acknowledges the existence of such hazards. Before his first flight, the user must pledge to read this manual. He shall follow exactly the instructions given. He should be advise...

Page 7

2008, october, 17 to make warranty efficient, this form have to be returned to rand kar sa canal de la martinière f - 44320 frossay - france warning even in the best of conditions, ultralight flying may be hazardous. The user of this ultralight acknowledges the existence of such hazards. Before his ...

Page 8

2008, october, 17 c.Of g calculation method.: aircraft must be horizontal weighing operation must be done with 3 similar weighing machines located each under every wheel of the aircraft. Acceptable limit of c g = from 22 to 40,5 (cm) weight ( kg ) front wheel a main gear : left wheel b main gear : r...

Page 9

2008, october, 17 owner n°1 name and adress : ........................................................................................................ ........................................................................................................................................................

Page 10

2008, october, 17.

Page 11

2008, october, 17 section 1 : general points 1-1 board documents - the pilot will check before each flight the presence on board of all the necessary documentation according the local regulations..

Page 12

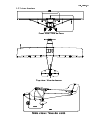

2008, october, 17 1-2 3 views drawings front view / vue de face 1740 2500 2 2 8 0 10050 2 ° top view / vue de dessus side view / vue de coté 1500 6100

Page 13

2008, october, 17 1-3 design features 1-3.1 dimensions : wing span 10.05 m length 6.09 m heigth 2.40 m surface 13.92 m² 1-3.2 landing gear tricycle, brakes on main gear. Wheel track width: 1.74 m wheel base : 1.50 m shock absorbers : bungee alloyed aluminium wheels tyres 4 plys 3.50 x 8 1-3.3 travel...

Page 14

2008, october, 17 flaps material leading edge aluminium tube 38 x 1,6 mm trailing edge aluminium tube 12,7 x 1,2 mm 1-3.6 fuselage cone rectangular section material main upper and lower tubes aluminium tube 28,6 x 2 mm stiffeners aluminium tube 18,6 x 1,1 mm aluminium tube 12,7 x 1,2 mm 1-3.7 empenn...

Page 15

2008, october, 17 1-4 : settings the following elements can be subject to adjustment. Elevator to adjust the position of the stick relative to the pilot, the elevator control tube has three holes drilled to allow length adjustment . Choose the suitable hole and insert the bolt. Add loctite. Tighten ...

Page 16

2008, october, 17.

Page 17

2008, october, 17 section 2 : limitations 2-1 certification x-air hanuman comes under class 3 of the ultralight aircraft certification of november, the 1rst, 1998, regulating flight authorization of ultralights. Certificates stipulated in sections r133-1 and following of the code de l'aviation civil...

Page 18

2008, october, 17 2-5 weight and balance 2-5.1 empty weight basic empty weight (kg) max. Empty weight (kg) x-air hanuman jabiru sp 276 284 x-air hanuman jabiru ap 289 306,5 x-air hanuman 602t sp 263 281 x-air hanuman 602t ap 276 303,5 x-air hanuman 912 ap 296 306,5 x-air hanuman 912 sp 280 284 x-air...

Page 19

2008, october, 17 2-5.4 changes made to the aircraft each owner is required to inform his local authority of any changes made to the aircraft's characteristics as recorded in its type certificate (engine, propeller or any other part) according to the local regulations added weight for options option...

Page 20

2008, october, 17.

Page 21

2008, october, 17 section 3 : powerplant 3-1 jabiru 2200 3-1.1 manufacturer jabiru aircraft pty. Ltd. P.O. Box 5168 bundaberg west qld 4670 australia 3-1.2 technical datas 4 cylinders, 4 stroke 2209 cc 80 hp (58kw) at 3300tr/mn double ignition air cooled direct drive 63 kg service life 1000 hours fu...

Page 22

2008, october, 17 3-2 rotax 582 3-2.1 manufacturer rotax gesmbh & co kg motorenfabrik, welser str 32 4623 guunskirchen / austria 3-2.2 technical datas 2 cylinders 2 stroke water cooled 580,7 cc gearbox b :1/2,58 gearbox c :1/3,47 double ignition fuel : mixture unleaded 95 octane + 2 stroke engine oi...

Page 23

2008, october, 17 3-3 rotax 912 3-3.1 manufacturer rotax gesmbh & co kg motorenfabrik, welser str 32 4623 guunskirchen / austria 3-3.2 technical datas 4 cylinders 4 stroke air/water/oil cooled 1211 cc 79 hp (58 kw) at 5800 tr/mn gearbox 1 :2,273 double ignition fuel : mixture unleaded 95 octane oil ...

Page 24

2008, october, 17 3-4 rotax 912 s 3-4.1 manufacturer rotax gesmbh & co kg motorenfabrik, welser str 32 4623 guunskirchen / austria 3-4.2 technical datas 4 cylinders 4 stroke air/water/oil cooled 1211 cc 79 hp (58 kw) at 5800 tr/mn gearbox 1 :2,273 double ignition fuel : mixture unleaded 95 octane oi...

Page 25

2008, october, 17 section 4 : performances 4-1 x-air hanuman jabiru 4-1.1 service ceiling 4500 m ( 14700 ft) (take care of oxygen lack) 4-1.2 take-off distance with flaps position 2 -run : 80 m (262 ft) -df15 : 190 m (623 ft) 4-1.3 climb -best ratio : 4,2 m/s (826 ft/mn) at 95 km/h (51 kts) (flaps p...

Page 26

2008, october, 17 4-2.4 speeds vd 210 km/h (113 kts) vne 187 km/h (100 kts) vno 170 km/h (92 kts) vc 130 km/h (70 kts) at 6200 rpm vc eco 110 km/h (59 kts) at 5500 rpm vs 77 km/h (41 kts) no flaps 72 km/h (39 kts) flaps position1 70 km/h (38 kts) flaps position2 63 km/h (34 kts) flaps position3 4-2....

Page 27

2008, october, 17 4-4 x-air hanuman 912 s 4-4.1 service ceiling 4500 m ( 14700 ft) (take care of oxygen lack) 4-4.2 take-off distance with flaps position 2 -run : 80 m (262 ft) -df15 : 190 m (623 ft) 4-4.3 climb -best ratio : 4,8 m/s (826 ft/mn) at 87 km/h (48 kts) (flaps position3) -best climb : 19...

Page 28

2008, october, 17.

Page 29

2008, october, 17 section 5 : standard procedures 5-1 pre-flight inspection this is where a safe flight begins. A preflight inspection should be carried out before every take off. 5-1.1 cabin -ignition switches off -harness opened -seats fitted, cushions in place -free movement of controls -throttle...

Page 30

2008, october, 17 walk back along the fuselage and check: - linkage on elevator bellcrank - fastenings of stab fitting cables - clevises on pushtubes to elevator bellcranks - elevator attach fittings - hinges of elevator and rudder - condition of fabric on tail surfaces - shackles on rudder cables -...

Page 31

2008, october, 17 5-2 installation on board and starting engine when sit in the cockpit, it’s imperative to make all the following controls: - stick back => elevator up - stick forward => elevator down - stick left => left aileron up and right aileron down - stick right => right aileron up and left ...

Page 32

2008, october, 17 5. 3 : before take-off check: - altimeter set - check controls move freely and to the stops - trim tab : centered - both seat belts fastened - parachute: control box plugged and tested (optional) - enough fuel in tank: never take off with less than 10 liters (2,64 us gals, 2,2 imp....

Page 33

2008, october, 17 5. 7 : flight in turbulences at first, fly only in calm air or light winds. Flying in turbulence is advised only after a certain degree of experience has been achieved. Keep your airspeed reasonable: 100 to 110 km/h (54 to 59 kts) is the recommended speed for comfortable flying in ...

Page 34

2008, october, 17 5-10 : descent-landing to descend, reduce power for 90km/h (49 kts) at full load. To use the flaps on landing allows: -on first position, reduction of minimum speed of 5 km/h (2,7 kts) (do not exceed 120 km/h (65 kts) with flaps on first position) -on second position, a reduction o...

Page 35

2008, october, 17 important notice: always keep in mind that any aircraft may experience unexpected engine failure. Hence, make sure you always have enough altitude to be able to pick as safe an emergency field as possible. Never overfly built up or hostile areas such as forests, swamps, etc... With...

Page 36

2008, october, 17.

Page 37

2008, october, 17 section 6 : emergency procedures 6-1 engine failure - emergency landing 6-1.1 : before take-off, when taxiing - throttle down - brake - cut off engine ignition 6-1.2 : during take-off -set airspeed at 100 km/h - land straight ahead; only minor course changes should be made, to avoi...

Page 38

2008, october, 17 6-2.2 : fire in cockpit - close heating and ventilation - cut off auxiliary electric supply - if necessary, cut off engine ignition and shut off the fuel line - land as soon as possible 6-2.3 : electric fire - close heating and ventilation - cut off auxiliary electric supply - if n...

Page 39

2008, october, 17 6-7 : emergency landing on trees prefer one or several low, bushy trees. Belts and helmets tight. Keep some speed on in final, as the air is often turbulent next to the trees. Pull up sharply to break your speed as soon as you hear contact with the branches. Good luck! 6-8 : flight...

Page 40

2008, october, 17 note concerning ballistic parachutes speed at opening exerts extremely high strains on the parachute. The user should inquire from the parachute manufacturer if the characteristics of parachute(s) are compatible with the performances of the airplane maintenance : follow instruction...

Page 41

2008, october, 17 section 7 : accessories and options note : since rand kar is constantly developing new accessories, we reserve the right to alter the design and specification of our products. We also reserve the right to substitute or withdraw any kind of equipment presented in this document witho...

Page 42

2008, october, 17 after the flare off, skim the water, with the same attitude as you had for take off, always keep some power on and let the aircraft settle slowly rather than bringing it to the stall. As soon as the hull touches down, reduce power to idle and try to maintain the same attitude until...

Page 43

2008, october, 17 7-1.3 banner towing make sure the tow hook is properly secured on the centerline. Two technics are possible for towing: - direct pick up of the banner at take off, with a minimum rope length of 70m (230 ft) the banner is stretched in front of you along the center of the runway. As ...

Page 44

2008, october, 17 7- 2 : effects of the equipment mentioned above on flight parameters and performances of the aircraft 7-2.1 snow skis top speed is approximately 10km/h lower (6mph). 7-2.2 floats or hull ( only with engines of more than 60 hp) top speed at maximum load in decreased by approximately...

Page 45

2008, october, 17 section 8 : maintenance 8-1 taking down and transport preparing the aircraft for transport on a trailer or for off airport storage is a simple operation that needs two people and about 1/2 an hour. It’s recommended to proceed as follows: to avoid losing the parts removed, re-fit im...

Page 46

2008, october, 17 8-2 airframe maintenance ( to be carried out periodically as per table below) the following maintenance tables never can replace the pre- flight check, obligatory before every take-off. Nota: these maintenance periods concern only the aircrafts flying under a continental climate an...

Page 47

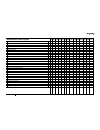

2008, october, 17 maintenance every 50 hours or 1 month périodicity 1 month 50 h date control date control date control date control wings, control surfaces and empennage fabrics fork and landing gear tyres pressure (1.8) v tyres wear v brakes wear v front fork and main gear shok absorbers v windsre...

Page 48

2008, october, 17 maintenance every 150 hours or 6 month périodicity 6 month 150 h date control date control date control date control wings, control surfaces and empennage fabrics fork and landing gear tyres pressure (1.8) v tyres wear v brakes wear v front fork and main gear shok absorbers v winds...

Page 49

2008, october, 17 maintenance every 300 h or 1 year périodicity 1 year 300 h date control date control date control date control wings, control surfaces and empennage fabrics v fork and landing gear tyres pressure (1.8) v tyres wear v brakes wear v front fork and main gear shok absorbers v windsreen...

Page 50

2008, october, 17 maintenance every 600 h or 2years périodicity 2 years 600 h date control date control date control date control wings, control surfaces and empennage fabrics v fork and landing gear tyres pressure (1.8) v tyres wear v brakes wear v front fork and main gear shok absorbers v windsree...

Page 51

2008, october, 17 maintenance every 900 h or 5 years périodicity 5 years 900 h date control date control date control date control wings, control surfaces and empennage fabrics c fork and landing gear tyres pressure (1.8) v tyres wear v brakes wear v front fork and main gear shok absorbers v windsre...

Page 52

2008, october, 17 8-4 powerplant see maintenance instructions in the engine manufacturer’s manual 8-4.1 maintenance jabiru 2200 25h 50h 100h 200h or 1 year if necessary 1- oil r 2- fuel filter v r 3- air filter v r 4- oil filter r 5- oil leaks v 6- hoses v r 7- intake - exhaust v clamps 8- electric ...

Page 53

2008, october, 17 8-4.2 maintenance rotax 912 25h 50h 100h ou 1 an 200h 600h oil r r fuel filter v r air filter v r oil filter r lubrication line v r cooling line v r intake-exhaust v electrics and ignition v spark plugs v r compressions v throttle drive v carburettors-fuel line v engine silent-bloc...

Page 54

2008, october, 17 air hanuman – use and maintenance manual 54 /55 maintenance rotax engines 2h 10h 12,5h 25h 50h 75h 100h 125h 150h 175h 200h 225h 250h 275h tighten up the cylinder head nuts 1 x tighten up the exhaust pipe screws 1 x check the handlestarter rope x check the crown wheel of electric s...

Page 55

2008, october, 17 air hanuman – use and maintenance manual 55 /55 2h 10h 12,5h 25h 50h 75h 100h 125h 150h 175h 200h 225h 250h 275h 9 change the lubricating oil of water pump x x 0 check cylinder heads and pistons 5 x x x x x 1 check the gap of piston rings 6 x x x x x 2 check pistons diameter 8 x 7 ...