- DL manuals

- Rayburn

- Boiler

- Heatranger 368K

- Installation And Servicing Instructions

Rayburn Heatranger 368K Installation And Servicing Instructions

Summary of Heatranger 368K

Page 1

Warning this information is a copy of an original archive, therefore aga cannot be held responsible for its continued accuracy..

Page 2: Installation

The rayburn heatranger 368k is a combined cooker/boiler appliance, providing central heating, domestic hot water and cooking facilities. It is available with a vertical flue outlet only. The cooker burner operates on natural draught. The boiler burner is fan assisted in conjunction with full sequent...

Page 3

The installation of the appliance must be in accordance with the relevant requirements of the current building regulations, current i.E.E. Wiring regulations and the bylaws of the local water authority. It should be in accordance with any relevant requirements of the local authority and the relevant...

Page 4

Detailed recommendations for fluing are given in the current building regulations j/1/2/3. The following notes are intended to give general guidance. The cross sectional area of the flue serving the appliance must not be less than the area of the flue outlet of the appliance and be at least 4.5m hig...

Page 5

Detailed recommendations for the water circulation system are given in bs. 5449: part 1 (for smallbore and microbore central heating systems) and bs. 6700. Draining taps must be located in accessible positions which permit the draining of the whole system, including the appliance and hot water stora...

Page 6

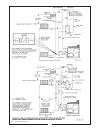

Typical dhw gravity system fig. 4 - typical pumped system 5.

Page 7

Wiring external to the appliance must be installed in accordance with current national wiring regulations and any local regulations which apply. The appliance is supplied for 220/240 volt ~ 50hz and a fuse rating of 5 amps. The method of connection to the mains supply should facilitate complete elec...

Page 8

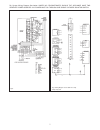

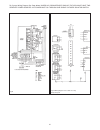

For system wiring diagram see below. Under no circumstances should the appliance have two separate power sources. All power must go through one single 5a fused isolator switch. Fig.6 fig.7 wiring diagram for the 368k on a fully pumped system 7.

Page 9

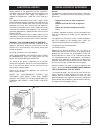

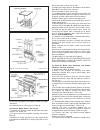

1. Fit and lightly secure oil control valve support bracket to cooker lh side panel. See fig. 8. Using a spirit level, check that the horizontal face of the support bracket is level in all directions, then tighten and secure bracket fixing screws. 2. Fit and align boiler burner feed, minus the solen...

Page 10

(x) connect oil supply pipe from tank to inlet of oil control valve - open all oil valves to allow oil into the control valve. (xi) depress trip lever d on the front of the oil control valve p (see fig. 13). (xii) connect main burner solenoid to 13a plug and extension lead - switch on power to solen...

Page 11

Fig.12 fig.10 fig.11 desn 510388 10 desn 511324.

Page 12

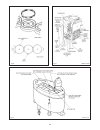

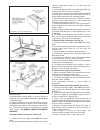

9. Fit the burner shells on to the burner base and locate check that the joint between the oil burner base and shells, is near airtight, otherwise, unacceptable air gaps may cause “burner light-back”, with ignited fuel occurring below the oil burner base. Remove the shells, place wicks in oil burner...

Page 13

Cooker burner see fig. 12 after checking the burner is level and that the oil is the correct depth in the burner disconnect the oil feed pipe to the burner and attach adaptor for measuring oil rates by the drip feed method. To make adjustments to the control it is necessary to remove the electric to...

Page 14

1. Connect pressure gauge to nipple n . Initial cold start should indicate a cold pressure reading of 3.1mm w.G. (0.125in w.G.) which on hot cycling, should rise to a stable 4.1mm w.G. (0.165in w.G.). 2. Adjust excess air pressure via air pressure adjustment flap on top of air duct at the l.H. Side ...

Page 15

Replace cooker burner door f and outer door e . 6. The cooker burner will gradually increase its oil rate, yet under the control of the oven thermostat, taking 2 1 / 2 hours to attain 220°c (400°f) from cold. Appliance and flue pipe draught (i) flue pipe draught the draught must be measured in the f...

Page 16

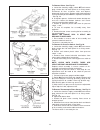

B. Ensure that the oil line isolating valve, near to the appliance is turned off and the trip lever on the appliance d is lifted up. C. Set boiler and cooker oil control valve knob c to off . D. To remove cooker burner (i) break the cooker oil feed pipe at inlet joint (fig. 19) taking care to collec...

Page 17

Re-connect the cooker oil feed pipe to carbon leg elbow and tighten. The cooker burner is now ready for re-lighting. To clean the boiler burner - see fig. 20 (i) remove the top burner baffle a and brush clean both surfaces free of soot, etc. (ii) lift and remove front and back interstage end sealing...

Page 18

With fallen debris. (ix)replace boiler flueway bricks in reverse manner of withdrawal, then locate boiler combustion separator baffle in original position. (x) replace hotplate ensuring the underside ribs lie over the combustion chamber, and that it seals to the top plate. (xi)replace both oil burne...

Page 19

To remove airfan - see fig. 26 a. Isolate the electricity supply (switch off and remove plug), remove the side cover panel via its fixing screws. Disconnect oil lines at burner inlets and depress downwards for fan access. Remove cable lead connected to terminal block position ‘ fan ’ on sequential c...

Page 20

To remove ignition transformer - see fig. 26. A. Isolate electrical supply (switch off and remove plug), remove the side cover panel via its fixing screws. B. Open outer burner door. C. Remove glo-coil cable locking nut and detach both cable leads from go-coil termination spindle. D. Detach transfor...

Page 21

1. To start the boiler sequence cycle, set the boiler thermostat knob to 80°c. The glo-coil ignition and airfan become energised with switch-on. 2. After 1 minute of energisation, the pilot solenoid valve opens, and admits a pilot supply of oil into the pilot reservoir at the front of the boiler bur...

Page 22

For system wiring diagram see page below. Under no circumstances should the appliance have two separate power sources. All power must go through one single 5a fused isolator switch. Fig.29 wiring diagram for the 368k on a fully pumped system 21 fig.28.

Page 23: Fault Finding

Fault finding boiler burner symptoms cause remedy switch on - nothing happens. No power to unit. Check mains supply, time clock, external thermostat. No output from pcb fuse (f2) failure. Check for wiring failure to pcb, replace fuse, if fuse fails replace pcb. Boiler thermostat off. Switch on. Faul...

Page 24: Fault Finding

Symptoms cause remedy cooker burner fault finding burner will not light. Check wicks in position. Fit wicks. Lack of oil to burner. Check oil valve switched on. Check oil valve trip is down. Check oil feed pipe gradient ensure steady rise. No high fire. Control valve setting wrong. Check control val...

Page 25

24 for further advice or information contact your local distributor/stockist with aga’s policy of continuous product improvement, the company reserves the right to change specifications and make modifications to the appliance described at any time. Manufactured by aga station road ketley telford shr...