- DL manuals

- TallyGenicom

- Other

- 2900 -

- Operator's Manual

TallyGenicom 2900 - Operator's Manual

Summary of 2900 -

Page 1

Operator manual 1 2900 operator manual serial - parallel - lan.

Page 2

2 operator manual this manual is published by tallygenicom for use with the computer printer described herein. Translations, reprinting or copying by any means of this manual, complete or in part, in any different form requires our explicit approval. Tallygenicom reserves the right to revise this ma...

Page 3

Operator manual 3 contents preface ......................................................................................................... 3–9 introduction ............................................................................................................................... 3–9 about this...

Page 4

4 operator manual chapter 2 .................................................................................................... 3–21 introduction ............................................................................................................................. 3–21 loading paper for stan...

Page 5

Operator manual 5 config key ................................................................................................................................. 3–35 control panel menus ............................................................................................................... 3–36...

Page 6

6 operator manual detect distance ......................................................................................................................... 3–50 vfu category (vertical format units) ................................................................................... 3–51 vfu enable .....

Page 7

Operator manual 7 busy polarity .............................................................................................................................. 3–62 rts function ..............................................................................................................................

Page 8

8 operator manual appendix b: specifications ......................................................................... 3–77 industry and agency standards ............................................................................................... 3–77 electro-magnetic emissions .....................

Page 9

Operator manual preface–9 introduction the 2900 impact printers are designed to handle heavy duty, high volume workloads, with a straight paper path that provides unattended, jam-free print- ing of continuous forms, at high speeds. They have a wide range of printer emulations, network printer manage...

Page 10

Preface–10 operator manual about this manual conventions we use the following conventions throughout this manual: text that is placed in italics draws your attention to additional helpful information. Sometimes your attention is more particularly drawn by the use of this symbol. This symbol marks in...

Page 11

Chapter 1: setting up your printer 1–11 • minimum floor space recommended for your printer is 36" wide x 36" deep (91.4 cm x 91.4 cm) to allow air movement around the printer. Allow space to open printer doors as well. When the doors are fully opened, the printer takes up 6.5 feet (2.0 m) of floor s...

Page 12

1–12 operator manual do not power up your printer before removing the shipping hardware. Careful! Unpacking your printer instructions for unpacking your printer are located on the outside of the shipping container. After you have removed your printer from its container, store the shipping materials ...

Page 13

Chapter 1: setting up your printer 1–13 connecting the i/o after connecting each interface to your printer, run a print job from the host computer to verify proper function of the printer. Serial/parallel interfaces to connect the serial or parallel i/o cable, plug in the cable to the proper connect...

Page 14

1–14 operator manual powering up the power switch is located on the back of the printer, just above the 3-prong power plug connector. Step 1. Make sure the power is off by depressing the "0" side of the rocker power switch. Connect the power cord. Plug the power cord into a proper power outlet. Step...

Page 15

Chapter 1: setting up your printer 1–15 paper system paper system components the tractors, ribbon cartridge, platen and paper iron are all parts of the paper system. The first two can be seen when the lid is raised. The platen and paper iron are hidden inside the housing. Figure 1 - 5. Inside the li...

Page 16

1–16 operator manual figure 1 - 6. Left and right paper tractors tractors the 2900 has two tractors to control paper movement, located on the left and right. A lever on each tractor keeps it locked in place on a horizontal shaft. To reposi- tion a tractor, unlock the tractor and move it to the left ...

Page 17

Chapter 1: setting up your printer 1–17 step 1. Make sure the printer is offline or power is off. Open the printer lid and remove the old ribbon by lifting it straight up off of the ribbon platform. Installing the ribbon cartridge figure 1 - 8. Installing the ribbon cartridge figure 1 - 7. Ribbon ca...

Page 18

1–18 operator manual the front and rear panels of the ribbon shield the ribbon has been carefully positioned between the two panels of the ribbon shield. Figure 1 - 9. Ribbon shield panels installing ribbon cartridge.

Page 19

Chapter 1: setting up your printer 1–19 control panel components the control panel is located on the right front top of the printer housing. It is used to program and direct most printer functions. Figure 1 - 10. Control panel beeper led indicators the green online indicator illuminates whenever the...

Page 20

1–20 operator manual blank page.

Page 21

Chapter 2: loading paper and printing 2–21 introduction this chapter covers how to load the paper and to set the print gap. It also covers how to create saveable configuration settings for your own pre-printed forms. Your printer is designed to use a continuous sheet, sprocket-fed paper. It can hand...

Page 22

2–22 operator manual figure 2 - 1. Inside paper inlet, visible when looking inside the printer cabinet. Loading paper for standard printing mode step 1. Turn off the printer using the power switch on the back, or toggle the "online" button on the control panel until the lcd shows "offline". Step 2. ...

Page 23

Chapter 2: loading paper and printing 2–23 step 6. The column alignment scale is on the top of the ribbon support platform. It is to be used for general guidance in horizontally aligning the form for each print job. The leftmost mark on the scale indicates the location of the first, or leftmost, pri...

Page 24

2–24 operator manual figure 2 - 6. Top of form nubbin fine-tuning the column alignment can be done in two ways: (1) rotate the horizontal vernier wheel, which is located on the right end of the shaft on which the tractors ride. Depending upon the direction the paper needs to move, you will rotate th...

Page 25

Chapter 2: loading paper and printing 2–25 print gap adjustment the 2900 auto-gap feature automatically sets the correct print gap based on form thickness. Dedicated control panel keys also allow the print gap to be adjusted for darker or lighter print based on user preference. For ease of paper loa...

Page 26

2–26 operator manual step 3 – create the profile select the detect parameter in the print gap category of the operator menu. Press menu => up arrow until detect shows => enter. This will cause the printer to move down the form in 1/6 inch increments, performing a print gap detection operation at eac...

Page 27

Chapter 2: loading paper and printing 2–27 figure 2 - 7. Typical display when print gap mode is set to “auto” 1. This number is for general reference. The precise relationship between the displayed number and physical distance is complex and beyond the scope of this manual. After unlocking the print...

Page 28

2–28 operator manual repeat step 1 and step 2 until the print gap is set just right. This print gap configuration can be saved and may be retrieved every time this particular paper is loaded. What you have just set, though, will not change until someone goes through steps 1 & 2 again, or until a sav...

Page 29

Chapter 3: printer menus and the control panel 3–29 chapter 3 introduction in this chapter you will learn how to use the control panel, how to navigate the menus, and how to select and store parameter values as part of a configuration. You will also learn how to obtain printouts that show all availa...

Page 30

3–30 operator manual control panel display the display during normal operation during normal operation, the top line of the display indicates the current state of the printer, such as online, offline, or a fault message. The second line of the display will indicate which of 10 saved configurations i...

Page 31

Chapter 3: printer menus and the control panel 3–31 table 3 - 1 paper weight & hammer impact indicator indicator paper weight and hammer impact (blank) hammer impact setting is “normal” paper weight setting is “light” h the display when in a menu when a menu is selected, the top line of the display ...

Page 32

3–32 operator manual control panel key functions control panel key functions online key this key toggles the printer between online and offline states, or exits from the menu directly to an online state. When the printer is online, the indicator will light. In the offline state, you may change param...

Page 33

Chapter 3: printer menus and the control panel 3–33 ff key (form feed) continued when in a fault condition pressing the ff key while in a fault condition advances the paper one form. No data prints, and the top of form position is maintained. This allows the use of the ff key to advance paper while ...

Page 34

3–34 operator manual control panel key functions enter key in any of the menus, this key allows you to enter a lower level, to assign a selec- tion to a parameter, or to perform a menu function. When the printer is in a paper out fault condition, and the prnteof parameter is set to off, pressing the...

Page 35

Chapter 3: printer menus and the control panel 3–35 clear key continued config key offline this is a “shortcut” to the load configurations menu item (see later in chap- ter), allowing you to enter a menu where any of ten saved configurations can be loaded into the current configuration. Use the up a...

Page 36

3–36 operator manual using menus control panel menus this section discusses the menus and how to access and select values from them for formatting documents, controlling print operations, or testing the printer. The four main menus are operator, config, test, and help. Categories, parameters and sel...

Page 37

Chapter 3: printer menus and the control panel 3–37 when the printer is offline, no light is on and the display reads: in the offline state, pressing the menu key gives you access to the first level of the menu system. Upon doing this, the display reads: now, in the offline state, you may access one...

Page 38

3–38 operator manual example: changing form length using the menu system if you wanted to change the form length from the default of 66 lines to 65 lines, this is how you do it: 1. Make sure your printer is in an offline state. If it's not, toggle the online key. 2. Press the menu key. The display r...

Page 39

Chapter 3: printer menus and the control panel 3–39 print selections report how to print a control panel selected options report the organization of the multilevel menus is shown on the control panel selected options printout. All of the current selections are marked with an asterisk. 1. Toggle the ...

Page 40

3–40 operator manual operator menu ⇒ font operator menu 1. Toggle the online key once or twice to clear the display and put the printer offline. Offline should be displayed and the green light should be off. 2. Press the menu key. 3. Use the up or down arrow keys until you see operator menu on the d...

Page 41

Chapter 3: printer menus and the control panel 3–41 operator menu ⇒ font ser/par character set this parameter allows you to select a character set that occupies locations hex 80 through ff used by emulations attached to the parallel, serial, and lan ports. The default is code page 437: the details o...

Page 42

3–42 operator manual ser/par style this parameter allows you to select the font style used by emulations attached to the parallel, serial, and lan port. For emulations that support downloaded fonts, you can use this parameter to select the download font. The default option selection is dp. Style opt...

Page 43

Chapter 3: printer menus and the control panel 3–43 operator menu ⇒ font forms category this category is used for setting up the specifics for your individual forms. Use the arrow and enter keys to select menu => operator menu => forms => to get here. Length (lines) if you wish to define the length ...

Page 44

3–44 operator manual left margin you can place the left margin at any column number across the page, using parameter options 1 to 272. The range of options for this parameter depends on the cpi setting. Column 1 is the default option. The left margin must be less than or equal to the right margin. R...

Page 45

Chapter 3: printer menus and the control panel 3–45 print to eof (end of form) continued if print to eof is on: the printer automatically prints to the end of the form then stops. The display reads paper out, the alarm sounds, and the fault indicator illuminates. At this point you can load the machi...

Page 46

3–46 operator manual eject delay this parameter specifies the timeout interval in seconds (after which printing will resume) when quick access is enabled while the printer is online. The default is 30 seconds. Impact this parameter has three options: auto, which is the default, normal, and high. Pap...

Page 47

Chapter 3: printer menus and the control panel 3–47 operator menu ⇒ forms ribnmon thresh this parameter sets the ribbon life threshold of the ribbon monitor feature. The default option is 40, assuming that a 40 million character ribbon is being used. This option should be changed to 60 or 250 if a 6...

Page 48

3–48 operator manual operator menu ⇒ print gap print gap category this category has the parameters for setting the different aspects of the print gap mechanism. Use the arrow and enter keys to select menu => operator menu => print gap to get here. Detect when the enter key is pressed to select this ...

Page 49

Chapter 3: printer menus and the control panel 3–49 reset this parameter resets the gap setting. If detect mode is auto, the next time the tof key is pressed or a print run is started, a print gap detection operation will be performed. If detect mode is manual, the print gap will be set to 190 (the ...

Page 50

3–50 operator manual this parameter sets the vertical distance from the tof to the position where the paper is squeezed during a detect operation. The allowable range is 0 inches to the current form length, with increments in tenths of inches. The default value is 2.0 inches. The print gap is detect...

Page 51

Chapter 3: printer menus and the control panel 3–51 operator menu ⇒ vfu vfu category (vertical format units) use the arrow and enter keys to select menu => operator menu => vfu to get here. Vfu enable a vertical format unit is a means for loading sets of vertical tabs. These vertical tabs define var...

Page 52

3–52 operator manual dump mode this parameter is used to troubleshoot problems that may arise when process- ing data. It places the printer into a hex dump mode. You can select three styles of printouts for use as debugging tools. The selections are: off: dump mode is disabled. (default selection) s...

Page 53

Chapter 3: printer menus and the control panel 3–53 config menu ⇒ printer style3: control codes and spaces are printed in hexadecimal format. Ascii characters are printed as is and escape sequences force a new line. Io hold this parameter allows you to set the amount of time the printer remains lock...

Page 54

3–54 operator manual config menu ⇒ printer beeper mode when a fault event occurs, the beeper will sound. There are two options: single or persistent. In the single mode, each fault event will cause the fault alert beeper to produce just one short-duration audio tone and then to remain silent. In the...

Page 55

Chapter 3: printer menus and the control panel 3–55 config menu ⇒ codes codes category in this category are choices that allow you to determine the printer’s response to certain conditions and to assign values to parameters that are used by other commands or escape sequences. Use the arrow and enter...

Page 56

3–56 operator manual print on cr this parameter is intended for use by customers whose applications embolden characters by using a cr-only method to selectively reprint all or parts of a line. Off: ignore bolding, print as regular text (default setting) double strike: print line, then backup to repr...

Page 57

Chapter 3: printer menus and the control panel 3–57 config menu ⇒ codes code 7f this parameter allows you to dictate how the printer will react when it receives a hexadecimal code 7f. The default value depends on the emulation. (see the emulation parameter, presented earlier in this chapter.) ignore...

Page 58

3–58 operator manual configurations category the 6300 series printer can save up to ten personalized configurations, so you don't have to recreate configurations you use frequently. In addition, each configu- ration you save can be tagged with a label of up to 15 characters. When you first receive y...

Page 59

Chapter 3: printer menus and the control panel 3–59 how to label a configuration slot • make sure the printer is offline. • press the menu key to enter menu mode. • use the up and down arrow keys to get to the config menu, and then press enter. • use the up and down arrow keys until the display read...

Page 60

3–60 operator manual serial i/o category serial interface is a style of host com- puter-to-printer i/o communications. It requires certain parameters to be prop- erly set in order for the printer and host computer to communicate. Use the arrow and enter keys to select menu => config menu => serial i...

Page 61

Chapter 3: printer menus and the control panel 3–61 status enquiry when this parameter is enabled, the host may send an enquiry packet to the printer requesting status. The printer will then send back a 1 byte packet denoting the status of the printer. If this option is set to off (the default), no ...

Page 62

3–62 operator manual dtr function continued... Offline: when this option is active, the dtr line is used to signal only that the printer is online or offline. Unlike the busy option, the offline option will not interfere with operation of the xon/xoff communication protocol. Power: when this option ...

Page 63

Chapter 3: printer menus and the control panel 3–63 parallel i/o category the parallel category on your printer has three parameters that can be changed according to user needs. Use the arrow and enter keys to select menu => config menu => parallel i/o to get here. Popc (print on paper command) the ...

Page 64

3–64 operator manual intellifilter category use the arrow and enter keys to select menu => config menu => intellifilter to get here. Intellifilter is a programmable feature, standard on tallygenicom line printers. Without having to touch an otherwise well-working host system, intellifilter permits u...

Page 65

Chapter 3: printer menus and the control panel 3–65 tcp/ip menu (lan interface only) tcp/ip menu the tcp/ip menu only appears if a tcp/ip lan network interface card is installed in the printer. Ip addr category this lets you to set up the four octets of the ip address. Use the arrow and enter keys t...

Page 66

3–66 operator manual subnet category this option allows you to set up the four octets of the subnet mask. Use the arrow and enter keys to select menu => tcp/ip => subnet to get here. Parameter option ip octet 1 0-255 ip octet 2 0-255 ip octet 3 0-255 ip octet 4 0-255 make sure that the lan cable is ...

Page 67

Chapter 3: printer menus and the control panel 3–67 test menu in test menu you will find diagnostic test print patterns used to check printer functions and a parameter that allows you to control paper mo- tion sensing. Use the up and down arrow keys to scroll to the desired selection. Testmenu ⇒ pat...

Page 68

3–68 operator manual fault override category this category deals with the configura- tion of fault information from the engine manager and the control processor. If the option is set to on, then the fault is overridden and won't be reported on the panel. If the option is set to off, then the overrid...

Page 69

Chapter 3: printer menus and the control panel 3–69 navigations within operator, config, and test menus menu categories category parameters parameter settings online offline online offline online offline online offline operator menu offline online config menu test menu help menu menu clear clear cle...

Page 70

3–70 operator manual blank page.

Page 71

Appendix a: troubleshooting a–71 introduction this chapter deals with troubleshooting problems on a 6300 series printer. Messages that indicate printer faults and errors are explained and corrective action given. The few paper handling and print quality problems that may occur are also explained. Me...

Page 72

A–72 operator manual step 4. If any other faults appear on the display after you have corrected the original problem, go back to step 1 and perform required corrective actions for the new problem. Otherwise place the printer back online and test it during normal print operations. Table a - 1. Displa...

Page 73

Appendix a: troubleshooting a–73 this message indicates that the printer has received an unprintable graphic. This message only appears if the set graphic error action command has been set properly. Clear the message (clear key), then place the printer back online. Confirm with host why graphic chec...

Page 74

A–74 operator manual offline data in explanation: corrective action: offline dump on explanation: corrective action: online download explanation: corrective action: online dump on explanation: corrective action: overflow vfu explanation: corrective action: paper motion flt explanation: corrective ac...

Page 75

Appendix a: troubleshooting a–75 ribbon fault explanation: corrective action: setup address explanation: corrective action: shuttle fault explanation: corrective action: testing hardware explanation: corrective action: the ribbon fault detector is not reading any movement in the printer ink-ribbon. ...

Page 76

A–76 operator manual paper problems table a - 2. Paper/printing corrective action the paper holes are wider than normal after passing through the tractors. Horizontal paper tension is too tight. Unlock and readjust the tractors so that the paper holes line up evenly with the tractor pins. Printed ch...

Page 77

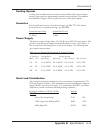

Appendix b: specifications b–77 industry and agency standards the 2900 printer is designed to meet the requirements of several industry and government agency standards. Electro-magnetic emissions emi: fcc part 15, subpart j, class a and en55022 class b harmonics: en 61000-3-2 flicker: en 61000-3-3 e...

Page 78

B–78 operator manual physical configurations weight 115.4 lbs. Dimensions width: 28.3 inches height: 13.0 inches depth: 14.4 inches depth with paper exit guide assembly: 23.4 inches preventive maintenance this printer is designed to eliminate the requirement of scheduled mainte- nance procedures, su...

Page 79

Appendix b: specifications b–79 cooling system cooling system malfunctions are detected and a failure will result in shuttle motion, paper motion, and printing functions being inhibited. The malfunc- tion hammer voltage1 will be reported on the control panel display. Acoustics the sound power level ...

Page 80

B–80 operator manual emulations emulations available on the 2900 series: epson dfx-9000, ibm proprinter iii xl, mtpl characters per inch seven basic characters per inch (cpi) settings are available through the con- trol panel. They include 10, 12, 13.33, 15, 16.67, 17.14, and 20. These character mat...

Page 82

B–82 operator manual nonvolatile memory your printer stores up to 10 printer configurations in nonvolatile memory. Paper description the printer uses continuous, sprocket-fed type paper, 2.5 inches (64 mm) to 18 inches (457 mm) outside width and 3.0 inches (76 mm) to 12.0 inches (305 mm) in length. ...

Page 83

Appendix b: specifications b–83 blank page.

Page 84

4500 daly drive, suite 100 t 703.833.8700 chantilly, va 20151 f 703.222.7629 www.Tallygenicom.Com 255069-001a.