Summary of 22

Page 1

Tanzer 22 owner's guide.

Page 3: Table Of Contents

Table of contents table of contents ...................................................................................................... I launching and rigging .........................................................................................1 rudder and tiller................................

Page 4

Adjustable clew outhaul ................................................................................. 38 mainsheet traveller............................................................................................ 38 genoa gear.....................................................................

Page 5: Launching And Rigging

Launching and rigging rudder and tiller the tiller should be bolted to the rudder with the bolt and lock nut provided as shown in figure 1. The lock nut should be tightened so that the friction between the fibreglass rudder head and the aluminium cheeks of the tiller is sufficient to retain the till...

Page 6

Outboard motor and bracket a 6 h.P. Long shaft outboard motor will provide adequate power for most conditions. A more powerful 7.5 or 9.9 h.P., long shaft motor should only be considered if the boat is to be manoeuvred under power regularly and often in a very swift tidal stream or current where the...

Page 7

6. Check that the valves on all through hull fittings are closed; namely, the sink drain and marine toilet intake and outlet, if one is installed. Check that all hose clamps are tight. 7. If the boat is being launched by a hoist with slings, it should be positioned under the hoist. One sling should ...

Page 8

9. Recover trailer, proceed to dock and rig mast. Rigging kit to rig your boat you will require the following tools: o a pair of vise-grips o an adjustable wrench o a pair of long nose pliers o a marlin spike or awl o a roll of vinyl adhesive tape (white electrical tape available at canadian tire) o...

Page 9

Ref. Figure description fitted with a traveller, different blocks are supplied, and these are described in the section dealing with the mainsheet traveller. -13 2b two aluminum spreaders. -14 7 jib tack shackle. Jib halyard winch handle. Roller-reefing handle. (22a) 2c low profile ventilator insert....

Page 10

2. Select one of the rope tails and secure one end to the thimble (19) at the end of the main halyard (9) (the thinner wire) with a bowline knot or eye space. Fasten the quick release shackle (18) to the large horizontal eye (20) on the foreside of the mast, take up the slack and make up rope tail o...

Page 11

Eye (20) and make up rope tail on the other mast cleat (21) after taking two or three clockwise turns around the winch (22) mounted above the cleat. (see figure 2c) 4. Select forestay (1), backstay (2) and topping lift (5). The swaged eyes on the ends of the forestay and backstay should be secured t...

Page 12

Spreader as shown in figure 2b, using the brass wire provided. The outer ends of the spreaders and the wire should also be covered with adhesive tape. Remove mast hinge bolt (27) taking care not to lose it or the lock nut (28) (figure 2d). 9. Secure the toggle of the turnbuckle (6) on the backstay (...

Page 13

10. The mast is now ready for stepping with the help of another person, place the heel of the mast on the mast step (16). Fasten the mast hinge (16a) to the mast step as shown in figure 2d. Make sure that the self locking nut (28) is tightened. 11. The mast should then be raised to a vertical positi...

Page 14

The mast is now stepped. The barrels of all turnbuckles should be turned to tighten the standing rigging appropriately. The lower shrouds should be taut but not so tight that they twang; nor floppy. The forestay, backstay and upper shrouds should be somewhat tighter than the lowers. It should be kep...

Page 15

Fore and back stay tension is typically set at 15% of breaking strength of the wire, or 495 pounds, to start. Sailing tests can result in this increasing, but in no case should it ever exceed 825 lbs. Or 47 on the loos, and for most boats a maximum of 600 lbs. (45 loos) would be reasonable. The stat...

Page 16

15. Select the main sheet blocks. The fiddle block (12) should be secured to the slot in the strop at the after end of the boom using the shackle provided. The swivel fiddle block (11) with the jamb cleat should be secured to the shackle in the small black rubber cap (40) on the cockpit sole, (see f...

Page 17

Boom vang a boom vang (82) may be installed on the tanzer 22 as shown in figure 9. If you have a boom vang plate (83), then the double block of the boom vang assembly is fitted with a small stainless steel key (84) and this should be inserted in the boom vang plate. The other double block of the boo...

Page 18

Outhaul the outhaul should be secured to the strap (41) on the port side of the boom. The other end should be passed through the cringle in the clew of the mainsail (42) and then made up on the cleat (43) (see figure 6). An adjustable clew outhaul permits adjustment of the tension in the foot of the...

Page 19

Cunningham most tanzer22 mainsails are fitted with a cringle (86) in the luff a few inches above the tack . This cringle allows the installation of a mainsail cunningham if desired as shown in figure 10. The cunningham tackle (86a), should be secured to the upper hole in the aluminum plate (85) prot...

Page 20

Mainsheet traveller a full cockpit-width mainsheet traveller may be fitted to the tanzer 22 as illustrated in figure 3a and figure 16. If the mainsheet traveller is already installed on your boat, the mainsheet must be rove as shown and not as illustrated earlier for the standard mainsheet arrangeme...

Page 21

Spinnaker gear if your boat is rigged for a spinnaker, the lines comprising the spinnaker halyard (64), topping lift (65) fore guy (66) , after guy (67) , and sheet (68) should be rove through the fittings provided as shown in figs. 18, 19 & 19a..

Page 22

The spinnaker halyard block (69) must be secured to the crane (70) provided on the foreside of the masthead fitting, (see figure 2a) and the spinnaker halyard (64) and the topping lift (65) should be rove through the respective blocks, before stepping the most. The shackle securing the halyard block...

Page 23

When not in use, the spinnaker pole (71) is stowed vertically on the foreside of the mast in the stowage ring (72) provided. Clip one end of the pole to the slide (73) on the spinnaker track (74), attach topping lift (65) and foreguy (66) release the slide and guide the pole into the ring or clip it...

Page 24

The bow pulpit, lifelines and stern rail may be purchased from the factory for owner installation . Figs 13 and 13a show the position in which the stanchion bases should be installed. All bases should be through bolted and all holes caulked. Those bolts visible below decks should be finished with ca...

Page 25: Hoisting Sail

Hoisting sail unless the wind is light, sails should not be hoisted until the boot can be maneuvered head to wind. Mainsail the quick release shackle in the main halyard (18) should be secured to the cringle in the head of the mainsail. Before hoisting the sail, release the main sheet from its jamb ...

Page 26

The quick release shackle (18a) is fastened to the cringle (47) at the head of the sail (figure 7a). Hoist the sail by pulling on the jib halyard. When fully hoisted, three to four clockwise turns of the rope tail should then be taken around the jib halyard winch (figure 2c). By holding the rope tai...

Page 27

The tension in the luff of the jib (or genoa) should be considerably more than that given to the luff of the mainsail; that is why a winch is supplied as standard equipment. Nevertheless tension should be appropriate to the wind strength - very tight for strong winds and less tight for light airs. G...

Page 28

Clockwise around the winch (92) to the cleat (93) . The position of the genoa sheet blocks will require adjustment to suit either the no. 1 or no. 2 genoas. These blocks provide the means with which to adjust the tension in the foot and leech of the genoas. Some no. 1 and no. 2 genoas are fitted wit...

Page 29: Reefing

Reefing roller reefing your tanzer 22 may be equipped with a geared roller reefing gooseneck (81) (see figure 4). In order to rotate the boom, the roller reefing handle should be inserted in one of the square holes in either side of the mechanism and turned. To reef the mainsail while sailing: 1. St...

Page 30: Accessories

Accessories forehatch ventilator the forehatch of your tanzer 22 may be fitted with a circular watertight opaque deck light with a screened opening. This deck light may be removed by inserting a screwdriver in the slot provided. A low profile ventilator may then be inserted. Maximum airflow when und...

Page 31

Cockpit awning figure 13 illustrates the optional tanzer 22 cockpit awning. No additional deck fittings are required in order to install this awning: 1. Unroll and place over boom; battens should be on the underside and the small flaps should be aft. 2. The awning is fitted with four lengths of elas...

Page 32

If your boat has a holding tank, the discharge hose from the toilet leads into the tank, and no through hull fitting or valve is installed on this line. The holding tank has a capacity of approximately 15 gallons and is located immediately forward of the toilet under the berth cushions. The tank is ...

Page 33: Electrical System

Electrical system the standard tanzer 22 electrical system is a 12 volt d.C. System powered by a 40 amp./hr. Wet cell battery. The circuit diagram and location of the battery, switch and fuse panel, conduit, wiring and electrical fixtures are shown in figure 15..

Page 34

The terminals should be connected to the battery with the thumbscrews provided. The circuits in the electrical system are labeled on the switch panel as follows: • running lights: this switch operates the 10 point (112m2 degrees) port (red) and starboard (green) navigation lights; and the white 12 p...

Page 35

Of the bow light and spreader lights, check that the deck plugs are properly connected. The conduit and battery box shown in figure 15 are installed in all boots as a standard feature, irrespective of whether the electrical system has been fitted. This conduit allows the installation of electrical w...

Page 36: Maintenance

Maintenance a fiberglass bast requires much less effort to maintain than one built of wood. However, attention should be given to the following: anti-fouling anti-fouling paint should be applied to the bottom of your tanzer 22 if it is to be moored in either fresh or salt water for any length of tim...

Page 37

The interior, including all lockers, ice box, and the bilge, should be washed with warm water and a mild detergent . The bilge in particular should be kept free of dust, fluff and other debris that accumulates there. Gelcoat repairs gelcoat is the pigmented layer of polyester resin that forms the ou...

Page 38

Teak all external teak woodwork should be well oiled at frequent intervals; say twice a month during the sailing season. Use one of the proprietary teak oils that are available for teak furniture. If teak is not oiled regularly, it will, after exposure to sun and rain, weather to a gray colour. To r...

Page 39

Care of sails the sails supplied with your boat by the factory are made of synthetic fibres; all except the spinnaker are of polyester fibre called dacron in north america, and terylene in england. The spinnaker is make of nylon. Contrary to cotton sails, they do not require careful stretching and b...

Page 40

Centerboard assembly on keel/centerboard models, those parts of the centerboard assembly subject to wear should be checked once a year. The stainless steel wire of the centerboard pennant is subject to chafe at the points at which it passes through the cockpit floor and the hull. The upper portion o...

Page 41

At least once every year all winches should be completely dismantled, cleaned and re-lubricated throughout. When not in use, it is recommended that all winches be covered..

Page 42: Additions

Additions adjustable clew outhaul an adjustable clew outhaul may be installed as follows: 1. The aluminum cleat and stainless steel deck strap for the standard clew line should be removed, and the holes plugged with rivets. 2. Nicropress eye and thimble (58) in wire. Secure to boom with rivet. 3. Tu...

Page 43

Track stops (52) should be secured to the cockpit seats (p/s) after the travelier track has been installed. Those portions of the track outboard of the fibreglass support should be bolted directly to the cockpit seats (p/s). Genoa gear the genoa gear as shown in figure 14 may be installed as follows...

Page 44

4. Cheek block (p/s) (91). Install with open end of block forward using bolts. Holes should be caulked. 5. Genoa winch (p/s) (92). Disassemble winches by removing the top retaining screw that is at the bottom of the handle socket. The drum and socket casting may then be fitted together and removed f...

Page 45

Snubbing winches snubbing winches (75) as shown in figure 14. & figure 19 make the handling of the working jib much easier in heavier winds, especially for a light-weight crew. They are also essential for spinnaker handling in anything but light winds. Gibb snubbing winches (75) shown in figure 14. ...

Page 46

Screens screens may be installed as follows: 1. The small teak shelves to support the forehatch screen should be cut to size. These should then be secured to the underside of the teak trim already installed around the hatch opening, with the screws provided. 2. It may also be necessary to cut a rece...

Page 47: Specifications

Specifications l 0.A 22' 6" sail areas sq. Ft. L w.L 19' 9" main 112 beam 7' 10" working jib 110 draft no. 1 genoa 200 fin keel 3' 5" no. 2 genoa 162. Keel-c/b up 2 ' 0" spinnaker (approx) 375. Keel-c/b down 4 ' 0" storm jib 50 displacement fin keel 2,900 lbs keel - c/b 3,100 lbs ballast fin keel 1,...

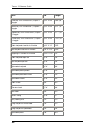

Page 48

Item dia. Length forestay with turnbuckle 2/3 open + toggle 5/32" x lxl9 28'6 3/8" backstay with turnbuckle 1/3 open + toggle 5/32" x lxl9 30'7 1/4" upperstays with turnbuckle 2/3 open + toggle 5/32" x lxl9 27"1 7/8" lowerstays with turnbuckle 1/2 open + toggle 5/32" x lxl9 13"8 1/8" main halyard sh...

Page 49

All cordage should be pre-stressed dacron, either three strand or braided with braided preferred for all sheets..