- DL manuals

- Vola

- Indoor Fireplace

- 860HE

- Installation And User Instructions Manual

Vola 860HE Installation And User Instructions Manual

Summary of 860HE

Page 1

1 vola 860he also known as pinnacle 860 / apex 860 installation and user instructions all instructions must be handed to user for safekeeping this is not a diy product and must be installed by a gas safe registered installer edition d 11/14 country(s) of destination - gb/ie.

Page 2: Installation Instructions

2 these notes must be read before installation this appliance is an inset live fuel effect appliance that provides radiant or combined radiant and convected heat; it cannot and should not be used as the main heating source within a property. The appliance is designed to fit most types of fireplaces ...

Page 3: Opening The Appliance

3 stand the carton the right way up, open the box from the top. Read all the instructions before continuing to unpack or install this appliance. Remove the bags containing ceramic components such as coals or gravel etc. Remove the cardboard packing pieces, and any other bags or boxes containing fitt...

Page 4: Section

4 section contents page no 1 important notes 5 2 installation requirements 6 3 appliance information 7 4 ventilation 8 5 site requirements 8/9 5.1 pre-fabricated flue box 10 6 debris space 10 7 installation of appliance 10 7.1 preparing the opening 13 7.2 fitting the burner tray 14 8 fuel bed 14 9 f...

Page 5

5 this fire is an inset live fuel effect gas fire providing radiant warmth. It is designed to operate on natural gas. It is the law that all gas appliances and fittings are installed by a competent person such as a gas safe registered fitter and in accordance with the gas safety (installation and us...

Page 6

6 this appliance must not be installed into a bathroom or shower room, or where steam may be present. An extractor fan must not be fitted in the same room or space as the appliance as this can affect the safety of the appliance. The fire has been designed to fit into a fireplace or builders opening ...

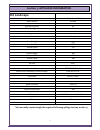

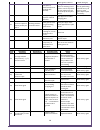

Page 7: H.E Landscape

7 h.E landscape gas group g20 natural gas cat i2h inlet pressure 20 mbar max input (gross) 6.2 min input (gross) 3.4 setting pressure 20 mbar gas inlet connection 8mm compression overall height 532 overall width 1022 overall depth 322 recess height 460 recess width 875 recess depth 300 air vent n/a*...

Page 8: Section 4: Ventilation

8 this appliance does not normally require purpose provided ventilation. However, a second appliance operating within the same room or space must be taken into consideration when assessing ventilation. When commissioning the appliance spillage is detected, then amongst other problems there may be in...

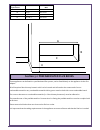

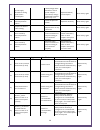

Page 9

9 opening requirements mm a width 875-895mm b height 460-470mm c depth 300mm d from floor 300-450mm these appliances can be fitted to a prefabricated flue system, can be fitted directly to the appliance via the flue adaptor. All will require a false chimney breast in which to be housed and will need...

Page 10: Section 6: Debris Space

10 to any back or infill panel. In accordance with bs 5871 part 2, minimum debris collection volumes are required behind the installed appliance. Clay/cement lines or block flue which is new, unused, or previously only used with a gas fire. Appliance recessed depth + 20mm unlined flue or chimney whi...

Page 11

11 next remove the screws in each corner and the one holding down the access panel, next undo the nut connecting the burner to the isolation valve and tray will now lift free of the firebox. Before installing the fire, check the flue for correct operation using a smoke pellet, all of the smoke shoul...

Page 12

12 next remove the top internal diverter plate from the top of the appliance by unscrewing the screws holding either side of the box keeping the panel in place. Remove the second plate, exposing the opening , at this point fix the fire box into place and pass the liner through the opening in the box...

Page 13

13 before running the gas supply into the opening, offer up the fire box to the fireplace to check the fit is good, ensure that it slides in correctly, the sealing face sits flat and square to the wall and that the base is level, apply the self-adhesive sealing strips around the edge of the rear of ...

Page 14

14 this process is a simple, reverse of the previous instructions on how to remove the burner tray. At this point if you have the slide contoled version then you can place the slide control piece inposition using the two scews supplied. Fit the two brackets supplier to each side of the firebox with ...

Page 15

15 please refer to the instructions supplied separately with each fuel bed option to remove the lining for colour change or replacement, simply with the tray removed the top place can be removed by the two brackets in place then gentle remove the side sections and the back to fit simply reverse the ...

Page 16

16 (see section 16: users instructions) the gap between the spark electrode and the pilot should be 3.5 - 4.5mm to produce a good spark. There should be no need to adjust this. If under any circumstances the electric spark fails, the pilot may be lit manually by proceeding with the ignition sequence...

Page 17

17 if pilot disturbance is not the cause, then the ods safety system may be in operation. Switch the appliance off, check the flue and carry out any remedial work required. Relight the fire and carry out a spillage test, do not allow the appliance to be used if it continues to fail a spillage test. ...

Page 18: Section 15: Servicing

18 all instructions must be handed to the user for safekeeping. Show the customer how to light and operate the fire. After commissioning the appliance, the customer should be instructed on the safe use of the appliance and the informed for the need of regular servicing. Frequency of service depends ...

Page 19

19 important notes the installation of this fire must only be carried out by a competent person (such as a gas safe registered fitter) in accordance with the gas safety (installation and use) regulations 1998, the relevant british standards, codes of practice, the building regulations and the manufa...

Page 20: The Factory

20 the remote control with this appliance has already been paired at the factory quick start user instructions fire control this control is situated on your fire. The drawing shows the main features of the control. The control required 3 x aa size alkaline batteries to be inserted under the battery ...

Page 21

21 the valve and handset have already been paired first set up the hand set, cup the handset the green unlock light will illuminate. Keep it held to keep the control unlocked, to enable operation of the buttons. 3) setting the time the display will be as shown, as the time is not set yet and will pr...

Page 22

22 4) setting the display for 12 or 24 hour display as always when pressing the remote control buttons keep the control held to keep the green light on and therefore handset safety feature, unlocked. The h indicates that it is time to set the timer to either 24 hour display or 12 hour (am or pm) dis...

Page 23

23 setting the temperature display to celsius or fahrenheit . Press and release the + or - button to toggle between c and f. When the display shows the desired symbol, press and releases the “set” button to store. As the important settings above have now been done. Press and hold (not releasing stra...

Page 24

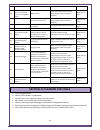

24 mode man = manual zzz = snooze therm = thermostat timed day of the week time (12 or 24hr) fire status battery indicator rc = handset fc = fire control light sensor (for display backlight) to change mode press to decrease flame power button in range of the fire if missing out of range or fire swit...

Page 25

25 operating instruction (detailed) 1) upon successful insertion of the batteries in the handset (if the handset has not previously paired) the display will be as shown if it has been paired already then go to no 3. 1a) if display is not as above the handset may well need to be reset before pairing....

Page 26: Section 17:

26 control and to enter to setup the time of day on the handset. N.B. If the display returns to the one shown above with the word “tesc” shown, then too much time has passed before pressing “set” and so the handset has not paired yet. Simply repeat pairing again. Advanced settings menu in the event ...

Page 27

27 2. Release the pressure and the pilot light should now be established (if this fails repeat step 1 and hold down for 20 seconds). 3. Slide the control to the left to increase the flame size to the desired effect. 4. To switch the fire off simple slide the control all the way to the left, passed t...

Page 28

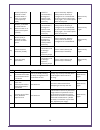

28 no spark at electrode (fire not igniting pilot burner) check ignition cable for damage and listen and watch for tracking out of spark to see if it is present but not making it to the electrode tip on the pilot burner. If cable damaged, replace cable. Reset error by performing a normal start cycle...

Page 29

29 e07 power supply breakdown during peak current consumption check/change all the batteries or check power adaptor. : note always change all batteries together never only 1 or 2 replace batteries / power adaptor reset and try again e08 error caused by external pressure switch check the pressure swi...

Page 30

30 e16 button (on/off) is shorted to other buttons either on tesc or on wired control panel (if used) check for contamination / damage and replace wired switch panel if necessary clean as necessary. Replace switch panel as necessary if damaged or too contaminated. Disconnect wired control panel and ...

Page 31

31 e24 thermocouple doesn't reach final current - damaged or aged replace pilot check and correct thermocouple wiring. Replace thermocouple if necessary reset and try again check pilot connections check and correct thermocouple wiring. Replace thermocouple if necessary reset and try again pilot pipe...

Page 32: End User

32 before carrying out any of the following operations, ensure that the fire is off and completely cold. Debris that may form on the fire bed should be periodically removed by a competent person. Large deposits could indicate deterioration of the flue. This should be repaired by a competent person, ...

Page 33: 0843 289 4268

33 please ensure you have the following information at hand when you contact sirocco; the full serial number which is located on the data badge of the appliance your receipt of purchase showing the date and where purchased from your installers details you can contact sirocco`s representative in the ...

Page 34: Our Warranty Statement

34 nad lasem 8, zabia wola 96-321 zelechow poland technical help line speak to a sirocco trained engineer 0904 0843473 (0904 084 fire) this is a premium rate number charged at 1.00 plus vat per minute from bt lines mon to fri 9:00 to 17:00 warranty and service for warranty registration or for a home...

Page 35

35 10. Any installation labour transportation or other related costs/expenses arising from defective parts/rapier replacement or otherwise of same will not be covered by this guarantee nor shall the company assume responsibility for same. Furthermore the company shall not be responsible for any indi...

Page 36

36 30 warranty in addition the flame failure devise or ods and ceramics on some models will need to be replaced in the 3rd year service as part of the conditions of your 5 year warranty, these items are purchased from the sirocco internet website “spares shop” and are shown as 3 rd year service pack...