W-tech s.R.L. Via moglio, 18/2 - 40037 sasso marconi - (bo) italy t: +39 051 6783010 f: +39 051 6784941 info@w-tech.It - www.W-tech.It reg. Imp. Bo c/f - p.Iva: 03079111203 - rea bo 490312 - cap. Soc. 32.000 € i.V. Installation and maintenance manual closed circuit evaporative cooler axial type seri...

Pag 1 table of contents 1. Machinery description 2 1.1 general safety use 1.2 general description 2 1.3 primary circuit. 2 1.4 secondary circuit 2 1.4.1 water pumping system 2 1.4.2 water distribution system 2 1.5 air induction system 2 1.6 casing and water collection basin. 3 2. Delivery and handli...

Pag 2 1. General safety rules and machinery description 1.1 general safety use: the content of this manual is to be considered as an integration to the general safety rules applied in your country, in the environment you are working in and also to the rules to be followed by law. In case of conflict...

Pag 3 1.6 casing and water collection basin the body of the unit is manufactured in “sendzimir” galvanised steel covered with 300 g/m 2 zinc layer. As a standard, a minimum 80µ complete paint of epoxy-polyester layer is applied on each side of the panels. The application is done by electrostatic pro...

Pag 4 2. Delivery and handling 2.1 delivery method all models of this series are delivered with the maximum possible elements mounted in our factory. Depending on the height of parts, the unit will be divided in order to lower the transport costs. Generally the deliveries are carried out in two or m...

Pag 5 3. Installation 3.1 tower foundation and anchoring our units have no needs of any special foundation. They can be placed directly onto a concrete slab or onto concrete coated ground, making sure in all cases that the anchoring is capable of resisting the operating load distributed by the tower...

Pag 6 3.3 assembly of the bodies before beginning the assembly on site, check that all elements delivered inside the basin have been removed. To access the basin, the bolts used to capture the angle that is used to hold the louvers panels have to be eased. Then the angle is to be removed, as well as...

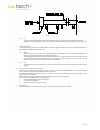

Pag 7 the assembly could he helped by means of pointers, which will be inserted in the holes in the lower body just before the upper one is allowed to rest on it. Please see fig. 7. Fig. 7 3.4 electrical connection our units are normally supplied with the electrical motors already cabled and the wir...

Pag 8 4. Operations to be carried out before the start up 4.1 cleaning • make sure that the distribution system is clean and that the distribution nozzles are correctly positioned and free of any kind of blockage. • check if the water basin is completely clean, if not, clean it using water under pre...

Pag 9 • ryznar index = 2 phs - phc between 6 and 7. Where phs is the ph of saturation and phc is the true level measured in the circuit. • the product of sulphates and calcium concentration in the circuit water, (both expressed in mg/l co3 ca), should be less than 500,000. • silica content should be...

Pag 10 7. General maintenance instructions due to the quality of these units, maintenance requirements are minimal. Nevertheless, they will be inspected fully on a monthly basis. In the same way, the entire circuit should be cleaned every year. It is advisable to carry out certain actions regularly ...

Pag 11 fig. 10 7.1.6 coil the coil has to be observed regularly. It has to be considered that this is a key element in the performance of the tower. Therefore, due to the possibilities of scaling, a monthly check is recommended and a daily purge of part of the spraying water. 7.2 in the air flow sys...

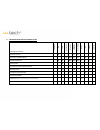

8.- preventive maintenance summary chart operations to be carried out blo w do w n g rid bas in wa te r m ak e- up el ect ri c p u m p wa te r di st ri bu ti o n dr if t e li m in at o r m o to r fa n ca si ng co ld w ea th er o pe ra ti o n inspection for fouling m m m inspection of the general con...

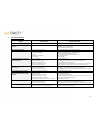

Pag 1 9. Troubleshooting chart defect possible cause action to be taken motor rotates in opposite direction error in connection. Change two phases in the power supply to the motor. Abnormal vibration in mechanical equipment fan / fan motor. Check state of blades and that they are correctly secured. ...

W-tech s.R.L. Direzione e amministrazione: via moglio 18/2 – 40037 sasso marconi (bo) – italy t: +39 051 6783010 f: +39 051 6784941 info@w-tech.It - www.W-tech.It.