Summary of TL 2.0

Page 1

Part number: 21-man-00 revision no: 1 tube lathe model tl 2.0 & tl 4.0 21-000-02, 04, 22, 24 revised: jan. ‘98 i e.H. Wachs companies 100 shepard st. Wheeling il. 60090 patent pending pipe & tube cut-off machines mod. Tl 2.0, 4.0 s/n:.

Page 2: Tube Lathe

Tube lathe table of contents section i standard equipment.......................................................................................5 section ii safety instructions....................................................................................6-9 section iii ec declaration of confor...

Page 3: Tube Lathe

Tube lathe 5 section i standard equipment 21-000-02 wachs model tl 2.0 portable tube cut-off lathe for 1/4” to 2” (6.35-50.8 mm) diameter, complete with split- type rotating and stationary frames, adjustable sealed bearing system, starwheel feed radial tool slide, metabo 110v 50 hz/60hz electric dri...

Page 4: Tube Lathe

Tube lathe 6 for your safety and the safety of others, read and understand these safety recommendations and op- erating instructions before operating. Section ii safety instructions the e. H. Wachs company takes great pride in manu- facturing safe, quality products with user safety a priority. The e...

Page 5

7 1. Die betriebsanleitung lesen! Bedienungsmänner können wertvolle zeit einsparen und verletzungen und beschädigungen der maschine vermeiden, wenn sie die aufbau- und betriebsanleitungen vor dem aufbau durchlesen. 2. Maschine und zusatzgerÄte ÜberprÜfen! Vor dem aufbau der maschine sollte diese und...

Page 6

8 eh wachs har sedan 1883 etablerat ett gott anseende när det gäller kvalitet och kundtillfredsställelse. Wachs känner sig därför förpliktigat att göra sitt yttersta för att garantera säkrast möjliga användning av wachs- utrustning. Vi har ställt samman en lista av säkerhetsanvisningar som ett led i...

Page 7

9 1. LÆs brugsanvisningen!! Hvis man læser anvisningerne i klargøring og drift, inden man begynder at gøre maskinen klar, kan man spare tid og forhindre person- og maskinskade. 2. InspicÉr maskine og udstyr! Inden maskinen gøres klar, skal man inspicere maskinen og udstyret. Se efter slidte fittings...

Page 8: Tube Lathe

Tube lathe 10 e.H. Wachs company 100 shepard st. Wheeling, il 60090 usa name and address of manufacturer (if different) distributed in the ec by: business address: machine title: model number: machine description: serial number: harmonized standards used: other safety standards used: name of person ...

Page 9: Tube Lathe

Tube lathe 11 section iv machine specifications machine noise levels: note: noise levels have been measured at 1 meter high and 1.6 meters away. Capacity: tl 2.0: 1/4” to 2” (6.35-50.8 mm) o.D. Tube tl 4.0: 1” to 4” (25.4-101.6 mm) o.D. Tube function: tube cut-off material: stainless steel/alloy wal...

Page 10: Tube Lathe

Tube lathe 12 section v set-up and operation tube lathe components (all models) a. Clamping handle i. Tool bit b. Retaining pin j. Allen wrench c. Star wheel k. Stationary frame d. Tool slide assembly l. Rotating frame e. Clamp shoe m. Thumb screws f. Trip handle (hidden) n. Drive motor g. Pinion ho...

Page 11: Tube Lathe

Tube lathe 13 section v set-up and operation (cont.) a. Assembly of machine from case 1. Remove tube lathe, drive motor and bench plate from storage case. 2. Install two fhcs through bench plate into pinion housing using supplied allen wrench. 3. Install drive motor into the pinion housing and ten- ...

Page 12: Tube Lathe

Tube lathe 14 figure 4 figure 5 f. Tool bit installation 1. Follow steps 1-3 in section “e” to bring tool slide to its uppermost position. 2. Loosen center bolt on tool slide cover plate. 3. Slide tool bit in from top and position cutting edge approximately 1/16” off of workpiece o.D. 4. Tension cen...

Page 13: Tube Lathe

Tube lathe 15 section v set-up and operation (cont.) h. Drive motor speed settings speed settings-tl 2.0 tube diameter speed dial setting 1/4” d 3/8” c 1/2” c 3/4” b 1 b 1-1/2” a 2” a speed settings-tl 4.0 tube diameter speed dial setting 1” c 1-1/2” c 2” b 2-1/2” b 3 a 4” a caution: always start th...

Page 14: Tube Lathe

Tube lathe 16 section vi maintenance-machine adjustments tube lathe maintenance is required periodically for cleaning and inspection of worn or damaged parts. The following steps should be followed before placing machine back in its storage case: 1. The power cord should be inspected for damage and ...

Page 15: Tube Lathe

Tube lathe 17 section vii miscellaneous charts and graphs tl 2.0 stainless steel shoe sets part number description 21-402-10 tl 2.0 shoe set for 1/4” o.D. 21-402-20 tl 2.0 shoe set for 3/8” o.D. 21-402-30 tl 2.0 shoe set for 1/2” o.D. 21-402-40 tl 2.0 shoe set for 3/4” o.D. 21-402-50 tl 2.0 shoe set...

Page 16: Tube Lathe

Tube lathe 18 section ix trouble shooting trouble possible cause remedy machine won’t run. Power cord not connected. Check power cord. Workpiece shifts during loose shoe clamp. Check tension on cuttind operation. Shoe clamp handle. Poor end quality. Dull or damaged tool bit. Replace tool bit. Machin...

Page 17: Tube Lathe

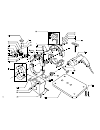

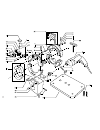

Tube lathe section x parts lists & exploded view drawings.

Page 18: Tube Lathe

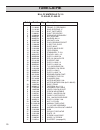

Tube lathe 20 ref. # part # qty. Description 1 21-100-02 1 frame, 2" stationary 2 21-101-02 1 ring, rotating - 2" 3 52-113-00 4 bolt, captivated 4 21-006-01 4 shaft, eccentric 5 43-006-00 4 bearing,guide wheel* 6 90-045-01 4 nut,10-32 jam 7 90-055-54 4 washer,an 1/4 8 90-055-02 4 hex nut,1/4-28 9 21...

Page 19

21.

Page 20: Tube Lathe

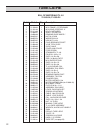

Tube lathe 22 ref. # part # qty. Description 1 21-100-04 1 mch frame, 4" stationary 2 21-101-04 1 mch ring, rotating - 4" 3 52-113-00 4 bolt, captivated 4 21-006-01 8 shaft, eccentric 5 43-006-00 8 bearing,guide wheel* 6 90-045-01 8 nut,10-32 jam 7 90-055-54 8 washer,an 1/4 8 90-055-02 8 hex nut,1/4...

Page 21

23.

Page 22: Tube Lathe

Tube lathe 24 to place an order or to get more detailed information on any e.H. Wachs products, call us at: 1-800-323-8185. Ordering replacement parts please use parts list provided in manual. Have part description and part number of required replacement part or parts to help expedite order and insu...