- DL manuals

- Wallnofer

- Stove

- Walltherm

- Operating Instructions Manual

Wallnofer Walltherm Operating Instructions Manual

progress & innovation

1/46

OPERATING MANUAL:

Instructions for use & maintenance of the

Walltherm®

Version / 12.1

The first natural down-draught wood gasification stove

for the living room.

Dear stove-owner,

You have made an excellent choice purchasing the Walltherm

®

stove/boiler for

your living room. Especially in connection with a heat storage tank, it offers you

all the advantages of a radiant heat stove for the living room and furthermore,

an economical heating system for your whole house. Please study this manual, it

explains how the stove works, how you should operate it and how it has to be

maintained.

For further information, please contact the manufacturer or any authorized

Walltherm dealer

Summary of Walltherm

Page 1

Progress & innovation 1/46 operating manual: instructions for use & maintenance of the walltherm® version / 12.1 the first natural down-draught wood gasification stove for the living room. Dear stove-owner, you have made an excellent choice purchasing the walltherm ® stove/boiler for your living roo...

Page 2

Progress & innovation vers. 12.1 2 /46 ! In any case the laws and norms valid in the installation country have to be respected. This stove has been developed for the following uses: due to the contemporary design and the visible fire it can be perfectly put up in the living room heating of the livin...

Page 3

Progress & innovation vers. 12.1 3 /46 this operating manual is protected by copyright and it (or any part thereof) must not be printed, copied or reproduced without prior consent of wallnöfer h.F. Gmbh. Technical information, graphics, and specifications included in this manual must not be publishe...

Page 4

Progress & innovation vers. 12.1 4 /46 index 1) introduction 1.A. Symbols 1.B. Intended use 1.C. Purpose and contents of the manual 1.D. Keeping the manual 1.E. Updates of the manual 1.F. General information 1.G. Main accident prevention regulations to comply with 1.H. Guarantee 1.I. Manufacturer’s ...

Page 5

Progress & innovation vers. 12.1 5 /46 ! 1. Introduction do not install or use the stove before you have read and understood the contents of this manual. In case of doubt at any time do not hesitate to contact wallnöfer h.F. Gmbh for information. Wallnöfer h.F. Gmbh reserves the right to modify the ...

Page 6

Progress & innovation vers. 12.1 6 /46 contents this manual contains all the information necessary for installation, use and maintenance of the walltherm stove. By complying scrupulously with the contents of this manual you will ensure a high degree of safety and productivity of the stove. 1.D. Keep...

Page 7

Progress & innovation vers. 12.1 7 /46 use use of the stove is subject to compliance with all the safety standards established by the relevant laws in force in the place of installation besides the prescriptions contained in this manual. 1.G. Main accident prevention regulations to comply with a) ee...

Page 8

Progress & innovation vers. 12.1 8 /46 coating: please control the external coating before you install the walltherm, when you find defect parts please contact immediately your reseller. After the installation of the walltherm we can only resolve the problem with sprays. To avoid coating problems du...

Page 9

Progress & innovation vers. 12.1 9 /46 abb.1 .M 1.L. Spare parts use genuine spare parts only! Do not wait until the components are worn from use before changing them. Changing a worn component before it breaks makes it easier to prevent accidents that could otherwise lead to serious harm to people ...

Page 10

Progress & innovation vers. 12.1 10 /46 2. Safety precautions 2.A. Instructions for the installer comply with the indications given in this manual check that the flue and air intake are suitable for the type of installation opted for (12 pa draft) the electrical connections must not be done using te...

Page 11

Progress & innovation vers. 12.1 11 /46 3. Parts list of the stove 3.A. Spare parts/components 1 upper combustion chamber 2 injektor block with secondary air feed 2a secondary air knob 2b grid 3 lower combustion chamber (gas combustion tunnel) 3a door with glass to lower combustion chamber 4 smoke c...

Page 12

Progress & innovation vers. 12.1 12 /46 ! Front view top view parts list of the stove: 4 handling und transport der ofen wird mit allen vorgesehenen teilen geliefert. Der schwerpunkt des heizofens liegt im hinteren bereich. Dies ist auch beim verstellen des heizofens auf seinem transport- untergeste...

Page 13

Progress & innovation vers. 12.1 13 /46 top view front view view from right side backside all dimensions are in mm view from under the stove air intake from under the stove chimney muff.

Page 14

Progress & innovation vers. 12.1 14 /46 a security heat exchanger b sensor thermal safety drain c overpressure valve d thermostat(sensor e forward flow f thermometer g thermostat for air intake h pressure gauge i backflow j fume sensor i forward flow ii backflow iii cold water iv drain for thermal s...

Page 15

Progress & innovation vers. 12.1 15 /46 ! 4. Handling and transport the stove is delivered complete with all the parts specified. Pay attention to the stove’s tendency to oscillate. Bear the above well in mind when moving the stove on the transport stand. Make sure the lifting capacity of the lift t...

Page 16

Progress & innovation vers. 12.1 16 /46 ! 5.C.1. Restriction of space around the stove the figure below (fig. 5.C.1.) shows the minimum distances to flammable materials and other items which have to be kept when installing the stove. A) adjoining wall b) back wall c) side wall d) floor protection ev...

Page 17

Progress & innovation vers. 12.1 17 /46 ! ! ! 5.C.3. Combustion air when working, the stoves takes from the room in which he is installed a certain, small amount of air. Therefore air has to be supplied from outside through an opening to houses that possess controlled airing and ventilation systems....

Page 18

Progress & innovation vers. 12.1 18 /46 right stove side right stove side top view floor floor maintain distance to flammable objects! A external air cover b air inlet from the backside 2 x 100mm a external air cover b air inlet from under the stove (opening of 180mm, tube needs to be 150mm) right s...

Page 19

Progress & innovation vers. 12.1 19 /46 how does the cap for the external air connection work? The channel for the external air is connected from under the stove or from the backside. That air enters the lower part of the stove. From there the air exits, as you can see on the pictures below. If you ...

Page 20

Progress & innovation vers. 12.1 20 /46 ! ! 5.C.4. Chimney and exhaust pipe: please obey the laws and norms valid in the installation country. After having found an appropriate place for installing the stove, please try to install the exhaust pipe, while taking into consideration paragraph 5.C.1. Fo...

Page 21

Progress & innovation vers. 12.1 21 /46 ! ! ! Danger: the connecting of the exhaust-pipe must not be connected with the following pipes: chimney hoods which are already used for other heating systems (boilers, heaters, chimneys etc.); ventilation systems (extractor hoods, ventilations etc.) even if ...

Page 22

Progress & innovation vers. 12.1 22 /46 6. Installation 6.A. Levelling of the wood-gasification stove please level off the stove with the help of a spirit level. 6.B. Different connections 6.B.1. Electricity connection please connect the thermostat, which was delivered together with the stove, with ...

Page 23

Progress & innovation vers. 12.1 23 /46 optional controller: instead of the thermostat you can also install the regulation wal02, with this regulation you can read the temperatures of the storage tank, boiler and the solar system directly in the living room. The regulation wal02 is also configurated...

Page 24

Progress & innovation vers. 12.1 24 /46 wiring of walltherm and solar plant: a1 – solar plant b1 – water tank f1 – walltherm stove r1 – solar pump r2 – stove pump t1 – sensor for solar plant t2 – sensor for tank temperature (inferior part) t3 – sensor for water temperature in the stove t4 – sensor f...

Page 25

Progress & innovation vers. 12.1 25 /46 ! Earthing danger: the system must be earthed and fitted with a circuit breaker as provided for by current laws (fig. Circuit diagram). 6.C. Important indications 6.C.1. The doors the boiler must never be operated with open doors. Eventually out coming glowing...

Page 26

Progress & innovation vers. 12.1 26 /46 6.C.6. Cleaning the stove requires frequent and thorough clean and periodical inspection to guarantee it will work properly and to ensure constant heat efficiency. Use a vacuum cleaner to remove all the ash (when it is cold) that has collected in the stove. 7....

Page 27

Progress & innovation vers. 12.1 27 /46 7.B. Lighting phase before the lighting the turn flap/lever (5) must be opened for the exhaust switch over (lever pointing down) that the smoke is taken up gradually through the flue. Attention: do not leave the exhaust fume flap opened constantly, the opened ...

Page 28

Progress & innovation vers. 12.1 28 /46 spread on the two grills of the filling chamber (upper combustion chamber) about 5-6 sheets of crumpled newsprint (please begin at the front). Do not use cardboard. Then spread highly inflammable kindling (again begin at the front) over the complete width of t...

Page 29

Progress & innovation vers. 12.1 29 /46 if the walltherm® works correct you will see the following conditions: a) the gasification flame remains visible b) the temperature of the exhaust gases dropes down to 120 -150 °c c) the temperature on the reverse flow (pump group) grows to 60 – 75 °c..

Page 30

Progress & innovation vers. 12.1 30 /46 inside the stove: the hot wood gases now draw/pass through the combustion jets into the lower gas combustion tunnel 3, are supplied with secondary air at the injector block 2, and then burn at high temperature. With the help of the secondary air slide bar 2a s...

Page 31

Progress & innovation vers. 12.1 31 /46 7.C. Loading the fuel only open the door of the upper combustion chamber after the wood has burned off and changed into embers. Before putting some more wood on the fire please open the fume flap (5) (lever pointing down), wait a second, and then slowly open t...

Page 32

Progress & innovation vers. 12.1 32 /46 how to set up the secondary air: by turning the round stainless steel knob directly between the upper and the lower combustion chamber, you can adjust the amount of air which enters the injector block of the stove. - attention: mostly this doesn´t change the v...

Page 33

Progress & innovation vers. 12.1 33 /46 c) the pump group we add one of the following pump groups to the stove: temperature of the forward flow pump forward flow stove reverse flow stove positioning of thermal sensor thermal valve, set to at least 60°c deaerator thermal valve, set to at least pos. 6...

Page 34

Progress & innovation vers. 12.1 34 /46 high efficiency pump ecocirc: - max. Power 23 watt - spinning the lever on the pump to 0 will change the backlight color and the operating mode of the pump - for use with the walltherm the pump should be in standard mode where the led is white, not blue! Lever...

Page 35

Progress & innovation vers. 12.1 35 /46 7.D. Permissible and suitable fuels important preconditions: the fuels’ water content should be maximum 20 %. The firewood has to be dry. The natural drying process lasts 1 ½ - 2 ½ years. This process can occur outdoors (covered up) and should be continued in ...

Page 36

Progress & innovation vers. 12.1 36 /46 8. Maintenance and cleaning 8.A. Safety precautions prior to embarking on any maintenance work the following precautions must be taken: a) make sure all parts of the stove are cold. B) make sure the ashes are completely cold and not burning. C) use the individ...

Page 37

Progress & innovation vers. 12.1 37 /46 periodical cleaning: there are two little ash boxes under the two stair grids. Please lightly lift the grids on the side of the jets and clean them. This is very easy when using a ash vacuum cleaner. This should be done every 2 weeks. To prevent the glass from...

Page 38

Progress & innovation vers. 12.1 38 /46 also the grid in the lower combustion chamber and the injector block needs to be cleaned. To get the grid out, you need to lift the injector block! Grid injector block monthly cleaning: the smoke channels should be cleaned every 6 – 8 weeks. For cleaning the s...

Page 39

Progress & innovation vers. 12.1 39 /46 clean all channels with the long brushes! Important: every brush must hit the bottom of the lower combustion chamber to make sure every channel is completely cleaned! Repeat until the channels are free of ash remnants. After cleaning the lower combustion chamb...

Page 40

Progress & innovation vers. 12.1 40 /46 8.B.4. Controlling the sealing the sealing of the doors (upper and lower combustion chamber), the cooking plate (9), the opening with lid for access to smoke channels (4c) and the fume flap for exhaust switchover (5) must be checked yearly. If necessary, they ...

Page 41

Progress & innovation vers. 12.1 41 /46 10. Saving energy the temperatures of the rooms and how long the stove works represent great influences on the consumption of fuels. 1° c lower room temperature can effect an economizing/saving of fuels up to 6 %. Therefore please notice the following: try to ...

Page 42

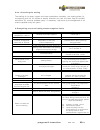

Progress & innovation vers. 12.1 42 /46 11. Concept of waterpipes.

Page 43

Progress & innovation 43/46 indications for the connection to the pipe an emptying tap has to be installed in lowest area of the water circulation. The thermostat for pump’s beginning has to be set when it is in cold state. The stove’s heat exchanger must not be the highest part/point of the system!...

Page 44

Progress & innovation vers. 12.1 44 /46 12 safety functions thermostat at the air inlet with thermostatically controlled flap (6a) a safety thermostat for control of combustion air intake 6b with connection bar and chain is connected with a thermostatically controlled flap for combustion air 6a. If ...

Page 45

Progress & innovation vers. 12.1 45 /46 thermal sfety drain thermal safety drain in case of overheating (8b, 8c, 8e): as further safety precaution the oven has a thermal safety frain consisting of a safety valve 8b, a heat exchanger 8c, and a valve for thermal drain. In any case of over- temperature...

Page 46

Progress & innovation vers. 12.1 46 /46 13 technical features/data heating capacity: 14,9 kw/12.815 kcal room heating capacity: 4,2 kw water heating capacity: 10,7 kw exhaust stream: 0,0107 kg/s average exhaust temperature: 120-150° c operating pressure: 2,5 bar max. 3 bar controlling pressure: 5 ba...