- DL manuals

- WarmingTends

- Burner

- CFB120LP

- Installation Manual

WarmingTends CFB120LP Installation Manual

Summary of CFB120LP

Page 2

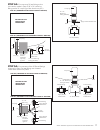

2 certified models match lit model # cfb60lp as match lit model # cfb60ng as match lit model # cfb120lp as match lit model # cfb120ng as match lit model # cfb180lp as match lit model # cfb180ng as match lit model # cfb290lp as match lit model # cfb290ng as match lit 3v battery operated units model #...

Page 3

3 general information carefully follow the instructions in this manual to prevent personal injury or property loss. Instructions are updated as needed. It is the installer’s respon- sibility to periodically review instructions for applicable updates. Warning: this owner’s manual contains critical in...

Page 4

4 construction of enclosure warning: all fire pits must have a gas shutoff on the outside of the fire pit to allow for emergency shut off and maintenance. Warning: for electronic ignition models, there must be an electrical shut off (wall switch or breaker) on the exterior of the fire pit or on adja...

Page 5

5 media installation warning: only use approved decorative media (glass, lava rock, ceramic log sets, etc.) that have been manufactured for specific use in fire features. Warning: media must be ½” or larger in size to prevent media from falling into gas orifices and blocking flow of gas out of jets....

Page 6

6 fire feature operation warning: if you do not follow these instructions exactly, a fire or explo- sion may result causing property damage, personal injury, or loss of life. Warning: before use, be sure to test all gas connections for leaks. Do not use fire pit if there is any evidence of leaking g...

Page 7

7 troubleshooting – manual lit / push button below are some potential causes and countermeasures to the symptoms listed: no flame • make sure the key valve is on. Turn key counterclockwise to open valve and allow gas flow. Low or weak flame • verify correct gas pressure. One or more jets will not li...

Page 9

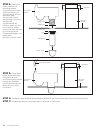

9 step 2: remove 1/2” flared fittings from each end of 1/2” flex line. Step 3a: (for match lit system) connect one of your 1/2” flared fittings removed in step 2 to the ½” coupling located on the bottom of the aluminum plate with flared end on bottom. Tighten. Apply thread sealant here plate couplin...

Page 10

10 step 5 step 5: locate the other 1/2” flared fitting removed in step 2 and connect into the 1/2” key valve, placing the non-flared end into the key valve. Tighten.. Apply thread sealant here flared fitting key valve step 4a: (match lit system) connect the 1/2” flex line to the fitting now located ...

Page 11: Final Set Up

11 step 6 questions? Contact warming trends at 303.346.2224 step 6a: (match lit system) connect 1/2” flex line into the fitting connected in step 5 to key valve. Tighten. Step 7: (standard 24 volt and premium 24 volt ignition systems only) plug ignition into three prong, above grade, nema rated, out...

Page 13

13 apply thread sealant here plate coupling flared fitting 1/2" x 2" nipple (fit180) step 4a: (match lit system) connect the new fitting created in step 4 to the 1/2” coupling located on the bottom of the aluminum plate. Tighten. Step 4c drip leg step 4b: (standard 24 volt ignition) apply thread sea...

Page 14: Final Set Up

14 questions? Contact warming trends at 303.346.2224 step 7a: match lit system connect 3/4” flex line into the fitting connected in step 7. Tighten. Final set up 1/2" x 2" nipple (fit180) step 8: (standard 24 volt and premium 24 volt ignition systems only) plug ignition into three prong, above grade...

Page 16

16 step 3a: connect 1/2” x 3/4” reducing fitting to the ½” coupling located underneath the aluminum plate. Apply thread sealant here 1/2" x 3/4" reducing fitting (fit250) 1/2" x 3/4" reducing fitting (fit250) coupling plate step 3b: (standard 24 volt high capacity ignition) see page 20 for installat...

Page 17

17 step 5b: (standard 24 volt high capacity ignition) see page 20 for installation instruction step 5a: connect two of the 3/4” flared fittings removed in step 2 to tee fitting now located underneath aluminum plate. Coupling flared fitting flared fitting apply thread sealant here apply thread sealan...

Page 18

18 step 6c step 6a: connect both 3/4” flex lines to the 3/4” flared fittings connected in step 5. Tighten. Coupling flex line flex line 3/4” tee (fit250) flared fitting flared fitting drip leg plate flex line flex line step 6c: (premium 24 volt standard capacity ignition) coupling flared fitting pre...

Page 19: Final Set Up

19 questions? Contact warming trends at 303.346.2224 step 10a: connect available ends of 3/4” flex lines (connected to aluminum plate in step 6) to 3/4” flared fittings connected in step 10. Step 10c: (premium 24 volt standard capacity ignition) 3” x 3/4” nipple (fit250) drip leg coupling premium 24...

Page 21

21 300k+ btu systems with dflkv34 and dflkv34fit300 step 3a: connect 3/4” x 3” pipe nipple fitting to the coupling located underneath the aluminum plate. Apply thread sealant here coupling plate 3/4" x 3" nipple (fit300) step 3b: (standard 24 volt ignition) step 3c: (premium 24 volt ignition) coupli...

Page 22

22 300k+ btu systems with dflkv34 and dflkv34fit300 step 5a: connect two of the 3/4” flared fittings removed in step 2 to tee fitting now located underneath aluminum plate. Coupling flared fitting flared fitting apply thread sealant here apply thread sealant here 3/4" tee (fit300) 3/4" x 3" nipple (...

Page 23

23 step 7: connect 3/4” x 3” pipe nipple (fit300) to the 3/4” key valve. Apply thread sealant here key valve 3/4" x 3" nipple (fit300) step 8: connect remaining 3/4” tee fitting (fit300) to the connection made in step 7. Key valve 3/4" x 3" nipple (fit300) apply thread sealant here 3/4" tee (fit300)...

Page 24: Final Set Up

24 300k+ btu systems with dflkv34 and dflkv34fit300 step 10 step 10a: connect available ends of 3/4” flex lines (connected to aluminum plate in step 6) to 3/4” flared fittings connected in step 10. Flared fittings flared fittings 3/4” tee (fit300) coupling 3/4” x 3” pipe nipple (fit300) 3/4” x 3” pi...

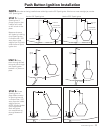

Page 25: Note

25 push button ignition installation plate crossfire brass burner straight jet drill here .125" crossfire brass burner tilted jet drill here .125" plate step 2: place wires through drilled hole and pull through until spark igniter bracket is in place on plate. Step 2 - side view, tilted jet spark ig...

Page 26

26 step 6: test spark igniter and push button module without gas, making sure spark arcs from electricity to jet. Step 7: test with gas. Burner should light within 5 seconds or a few clicks. Step 5: crimp spark igniter wires, then slide crimped wires on to connections using needle nose pliers. Be ca...

Page 27: Parts Glossary

27 4” key (kv12 or kv34) 12” key (key12) key valve (kv12 or kv34) pressure face plate (kv12 or kv34) flex line (fl3612 or fl3634) flared fitting flared fitting parts glossary spark igniter (pb-si) push button module (pb-cm) mounting bracket (pbmbr).

Page 28: Replacement Parts

28 flkv12 for use with any burner up to 120k btu’s. Kit includes: (1) 36” l x ½” diameter flex line + ½” key valve + 4” and 12” key flkv34 for use with any 121k - 249k btu burner. Kit includes: (1) 36” l x 3/4” diameter flex line + 3/4” key valve + 4” and 12” key flkv34fit180 for use with any 121k -...