- DL manuals

- Waterite

- Water Dispenser

- FCA Series

- Owner's Manual

Waterite FCA Series Owner's Manual

Advanced Water Conditioners

featuring the Custom Control F2CC Valve

OWNER’S MANUAL

FOR ALL FUSION² F SERIES AND FCA SERIES WATER CONDITIONERS

THIS MANUAL IS TO BE LEFT WITH THE OWNER OF THE EQUIPMENT FOR

REFERENCE PURPOSES AND TECHNICAL GUIDANCE. IT IS STRONGLY

RECOMMENDED THAT QUALIFIED DEALER SERVICE PERSONNEL BE

CONTACTED IN THE EVENT OF AN UNKNOWN INTERRUPTION OF SERVICE OR

APPARENT PRODUCT MALFUNCTION. AN ANNUAL PREVENTATIVE

MAINTENANCE INSPECTION BY A WATER PROFESSIONAL IS RECOMMENDED

TO ENSURE TROUBLE-FREE AND CONTINUOUS OPERATION.

www.waterite.com

Waterite Technologies, Inc.

■ 1-885 Keewatin Street, Winnipeg, MB Canada ■ R2X 2S7

Summary of FCA Series

Page 1

Advanced water conditioners featuring the custom control f2cc valve owner’s manual for all fusion² f series and fca series water conditioners this manual is to be left with the owner of the equipment for reference purposes and technical guidance. It is strongly recommended that qualified dealer serv...

Page 2

Page 1 this unit has a control valve which enables the setting of not only the length of each regeneration cycle but also the order in which cycles (steps of regeneration) occur. The following pages instruct how to set the treatment unit’s sequence of cycles, cycle times, salt dose, exchange capacit...

Page 3

Page 2 control valve specifications service flow rate & pressure loss (valve only, including bypass valve, but not including mineral, etc.) 27 gpm (102.2 lpm) @ 15 psi (103 kpa) ∆ ∆ ∆ ∆p backwash flow rate & pressure loss (whole conditioner...Including bypass valve) 27 gpm (102.2 lpm) @ 25 psi (172 ...

Page 4

Page 3 step 1cs cycle sequence cycle sequence instructions allows the setting of the order of the cycle. There are 9 cycles which can be arranged in any order. Later in this book the installer settings allow the setting of how long cycles will last. End must be used as the last cycle option. The ser...

Page 5

Page 4 softener system setup in softener system setup you choose the duration for the cycles selected in cycle sequence and specify other other operating parameters for the system. The upper and lower limits of the allowable values for the cycles are as follows: step 1s step 1s – press next and simu...

Page 6

Page 5 gallons capacity regeneration time option day override result auto normal off reserve capacity automatically estimated. Regeneration occurs when gallons capacity falls below the reserve capacity at the time. Auto normal any number or 14 day default reserve capacity automatically estimated. Re...

Page 7

Page 6 step 8s – set gallons capacity using the or ∆ button. If value is set to: • “auto” ...The gallon capacity will be automatically calculated and reserve capacity will be automatically estimated. • “off”...The regeneration will be based on the day override set (see installer settings step 3i). •...

Page 8

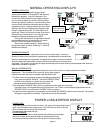

Page 7 figure 1 figure 2 normal operation bypass operation “treated” water exits supply water enters supply water exits supply water enters figure 3 supply water exits supply water enters diagnostic mode figure 4 bypass valve the bypass valve is typically used to isolate the control valve from the p...

Page 10

Page 9 inlet/outlet plumbing: connect to a supply line downstream of outdoor spigots. Install an inlet shutoff valve and plumb to the unit’s bypass valve inlet located at the right rear as you face the unit. There are a variety of installation fittings available. They are listed under installation f...

Page 11

Page 10 note: what follows assumes that auto is set for regeneration mode in step 8s, meaning gallons are automatically calculated. Step 1i - press next and ∆ simultaneously for 3 seconds. Step 2i – hardness: set the amount of hardness in grains per gallon (default 20) using the or ∆ buttons. The al...

Page 12

Page 11 power loss if the power goes out for less than two hours, the system will automatically reset itself. If an extended power outage occurs, the time of day will flash on and off which indicates the time of day should be reset. The system will remember the rest. Error message if the word “error...

Page 13

Page 12 step 1us step 2us step 3us ß ß return to normal mode salt remaining or adding salt if the low salt warning option was factory installed the following screens will be viewed in the user display. Note: the salt used per regeneration setting was set in increments of 0.1 pounds, but the lbs rema...

Page 14

Page 13 start up instructions • after installation is completed rotate the bypass handles to the bypass position (see bypass valve diagram page ). • turn on water and check for leaks. • fully open a cold water faucet. • allow water to run until clear to rid pipes of debris which may have occurred du...

Page 15

Page 14 e d replacement parts 1 4 3 2 6 5 front cover and drive assembly item no. Part no. Description qty. 1 v3175cc-01 front cover assy., cc 1 2 v3107-1 motor 1 3 v3106-01 drive bracket & spring clip 1 4 v3108cc pc board, cc 1 5 v3110 drive gear, 12x36 3 6 v3109 drive gear cover 1 2-6 v3002cc driv...

Page 16

Page 15 injector assembly with cap, plug, screen and o-ring item no. Part no. Description qty. 1 v3176 injector cap 1 2 v3152 o-ring 135 1 3 v3177 injector screen 1 4 v3010-1z injector assy. Plug 1 5 v3010-1a a injector assy., black 1 v3010-1b b injector assy., brown v3010-1c c injector assy., viole...

Page 17

Page 16 water flow proper dlfc orientation directs water flow towards the washer face with rounded edge and lettering. 3/4" npt drain line assembly, 3/4" item no. Part no. Description qty. 1 h4615 locking clip, elbow 1 2 pkp10ts8-bulk insert, 5/8" tube optional 3 v3192 nut, æ" drain elbow optional 4...

Page 18

Page 17 replacement parts water flow proper dlfc orientation directs water flow towards the washer face with rounded edge and lettering. 1" npt drain line assembly, 1" item no. Part no. Description qty. 1 h4615 locking clip, elbow 1 2 v3008-02 drain fitting, 1" straight 1 3* v3166 drain fitting body...

Page 19

Page 18 water meter and meter plug item no. Part no. Description qty. 1 v3151 nut, 1" qc 1 2 v3003 meter assy., includes items 3 and 4 1 3 v3118-01 turbine assy. 1 4 v3105 o-ring 215 1 5 v3003-01 meter plug assy. 1 bypass valve item no. Part no. Description qty. 1 v3151 nut, 1" quick connect 2 2 v31...

Page 20

Page 19 /rrvhqv'udlq1xw,q 3ro\wxeh$ssolfdwlrqv /rrvhqv,qmhfwru$qg %\sdvv&dsv /rrvhqv4xlfn &rqqhfw1xwv /rrvhqv'ulyh&ds loosens drain nut in polytube applications service wrench (part no. V3193) although no tools are necessary to assemble or disassemble the valve, the service wrench, part no. V3193, (...

Page 21

Page 20 drive assembly remove the valve cover to access the drive assembly by pulling out slightly on the two tabs centered on the side. Disconnect the power source plug (black wire) from the pc board prior to disconnecting the motor or water meter plugs from the pc board. The motor plug connects to...

Page 22

Page 21 replace the motor if necessary. Do not lubricate the motor or the gears. When reinstalling the motor gently turn the motor while inserting so that the gear on the motor meshes with the gears under the drive gear cover and the small plastic bulge engages one of the slots on the motor housing....

Page 23

Page 22 the regenerant piston (the small diameter one behind the main piston) is removed from the main piston by pressing straight sideways to unsnap it from its latch. Chemically clean in dilute sodium bisulfite or vinegar or replace the regenerant piston if needed. To remove the main piston, fully...

Page 24

Page 23 two holes are labeled dn and up. Check for compliance with one of the following: a. For down flow systems, the appropriate size injector is located in the “dn” hole, a plug is in the “up” hole and that the piston is a combination of the main piston and the regenerant piston; b. For backwash ...

Page 25

Page 24 bypass valve the working parts of the bypass valve are the rotor assemblies that are contained under the bypass valve caps. Before working on the rotors, be sure that there is a closed shut-off valve ahead of the unit and the system is depressurized. Turn the red arrow shaped handles towards...

Page 26

Page 25 troubleshooting procedures 1 problem cause solution 1. Timer does not display time of day a. Transformer unplugged a. Reconnect transformer b. No power at outlet b. Repair or use working outlet c. Defective transformer c. Replace transformer d. Defective pc board d. Replace pc board 2. Timer...

Page 27

Page 26 troubleshooting procedures 2 problem cause solution 6. Valve stalled in regeneration a. Motor not operating a. Replace motor b. No power at outlet b. Repair outlet or use working outle c. Defective transformer c. Replace transformer d. Defective pc board d. Replace pc board e. Broken drive g...