- DL manuals

- WEG

- Inverter

- Easy Drive CFW10

- User Manual

WEG Easy Drive CFW10 User Manual

Summary of Easy Drive CFW10

Page 3: Frequency

04/2015 frequency inverter manual series: cfw-10 software: version 2.Xx language: english document: 0899.5202 / 10 attention! It is very important to check if the inverter software version is the same as indicated above..

Page 4

4 sumarry of revisions revision description section 1 first edition - 2 - addition of the cfw10 mecii and addition of the emc filter for meci. General revision. 3 - addition of the cfw10 size iii and addition of the emc filter for sizes ii and iii. 4 - cfw10 plus and clean versions inclusion. 5 - in...

Page 5

Contents quick parameter reference, fault and status messages i parameters ............................................................ 08 ii fault messages ...................................................... 11 ii i other messages ..................................................... 11 chapter ...

Page 6

Contents 3.3.2 specification of the emission and immunity levels ................................................. 40 3.3.3 inverter and filters ............................................. 41 3.3.4 characteristics of the emc filters ..................... 43 chapter 4 keypad (hmi) operation 4.1 key...

Page 7

Contents chapter 7 diagnostics and troubleshooting 7.1 faults and possible causes .................................... 96 7.2 troubleshooting ...................................................... 98 7.3 contacting weg ..................................................... 99 7.4 preventive maintenan...

Page 8

8 cfw-10 - quick parameter reference software: v2.Xx application: model: serial number: responsible: date: / / . Quick parameter reference, fault and status messages i. Parameters parameter function adjustable range factory unit user page setting setting p000 access parameter 0 to 4, 6 to 999 = read...

Page 9

9 cfw-10 - quick parameter reference parameter function adjustable range factory unit user page setting setting v/f control p136 manual torque boost 0.0 to 100 20.0 (3) % 66 (i x r compensation ) p137 automatic torque boost 0.0 to 100 0.0 % 67 (automatic ixr compensation) p138 slip compensation 0.0 ...

Page 10

10 cfw-10 - quick parameter reference parameter function adjustable range factory unit user page setting setting p231 (1) forward/reverse 0 = forward 2 - 75 selection 1 = reverse 2 = commands analog inputs(s) p234 analog input ai1 gain 0.0 to 999 100 % 75 p235 (1) analog input ai1 signal 0 = (0 to 1...

Page 11

11 cfw-10 - quick parameter reference readonly parameter parameter function adjustable range factory unit user page setting setting fx and ix p288 fx frequency 0.0 to p134 3.0 hz 85 p290 ix current 0.0 to 1.5 x i nom p295 a 85 inverter data p295 rated inverter 1.6 a 85 current (i nom ) 2.6 4.0 7.3 1...

Page 12: Chapter 1

12 chapter 1 safety notices this manual contains necessary information for the correct use of the cfw-10 variable frequency drive. This manual has been written for qualified personnel with suitable training and technical qualification to operate this type of equipment. The following safety notices w...

Page 13

13 chapter 1 - safety notices note! In this manual, qualified personnel are defined as people that are trained to: 1. Install, ground, power up and operate the cfw-10 according to this manual and the local required safety procedures; 2. Use of safety equipment according to the local regulations; 3. ...

Page 14: Chapter 2

14 this chapter defines the contents and purposes of this manual and describes the main characteristics of the cfw-10 frequency inverter. Identification, receiving inspections and storage requirements are also provided. This manual is divided into 9 chapter, providing information to the user on rece...

Page 15

15 chapter 2 - general information 2.3 about the cfw-10 the cfw-10 frequency inverter is fitted with the v/f (scalar) control method. The v/f (scalar) mode is recommended for more simple applications such as pump and fan drives. In thesecases onecan reducethe motor and inverter losses by using the "...

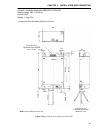

Page 16

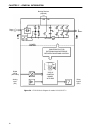

16 chapter 2 - general information figure 2.2 - cfw-10 block diagram for model 7.3 a and 10.0 a/200-240 v (single-phase) and 10.0 a and 15.2 a/200-240 v (three-phase) power supply l/l1 pe analog input (ai1) digital inputs (di1 to di4) power control power supply for eletronicsand interface between po...

Page 17

17 chapter 2 - general information power suplly l/l1 analog input (ai1) digital inputs (di1 to di4) power control power supply for eletronics and interface between powerand control. "ccp10" control board with dsp relay output (rl1) motor u v w rsh ntc pe pe rfi filter n/l2 figure 2.3 - cfw-10 block ...

Page 18

18 chapter 2 - general information figure 2.4 - cfw-10 block diagram for model 4.0 a /110-127 v power suplly l/l1 analog input (ai1) digital inputs (di1 to di4) power control power supply for eletronicsand interface between powerand control "ccp10" control board with dsp relay output (rl1) motor u v...

Page 19

19 chapter 2 - general information 2.4 cfw-10 identification figure 2.5 - description and location of the nameplate lateral nameplate cfw-10 serial number cfw-10 model rated output data (voltage, frequency) software version rated input data (voltage, current, etc) manufacturing date weg part number.

Page 20

20 chapter 2 - general information n o t e ! Th e o pt io n fie ld (s or o )d ef in es if th e c fw -1 0 is a st an da rd ve rs io n or if it w ill be eq ui pp ed w ith an y op tio na ld ev ic es . If th e st an da rd ve rs io n is re qu ire d, th e sp ec ifi ca tio n co de en ds he re . Th e m od e...

Page 21

21 chapter 2 - general information 2.5 receiving and storing the cfw-10 is supplied in cardboard boxes. There is a nameplate on the outside of the packing box that is identical to that one on the cfw-10. Check if the: cfw-10 nameplate data matches with your purchase order. The equipment has not been...

Page 22: Chapter 3

22 chapter 3 installationand connection 3.1 mechanical installation 3.1.1 environment this chapter describes the procedures for the electrical and mechanical installation of the cfw-10. These guidelines and suggestions must be followed for proper operation of the cfw-10. The location of theinverter ...

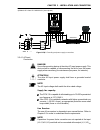

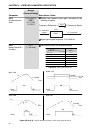

Page 23

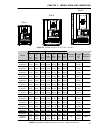

23 chapter 3 - installation and connection figure 3.1 - dimensional of cfw-10 - sizes 1, 2 and 3 size 2 size 3 size 1 table 3.1 a) installation data (dimensions in mm (in)) – refer to section 9.1 dimensions fixing base model width l [mm] (in) height h [mm] (in) depth p [mm] (in) a [mm] (in) b [mm] (...

Page 24

24 chapter 3 - installation and connection table 3.1 b) cold plate version, installation data (dimensions in mm (in)) – refer to section 9.1 the cold plate version was designed in order to allow mounting the “cp” cfw-10 frequency inverter in any heat dissipation surface, since following recommendati...

Page 25

25 chapter 3 - installation and connection figure 3.2 and table 3.2 show free space requirements to be left around the drive. Install the drive on a vertical position, following the recommendations listed below: 1) install the drive on a flat surface. 2) do not install heat sensitive components imme...

Page 26

26 chapter 3 - installation and connection 3.1.3.1 panel mounting when drives are installed inside panels or inside closed metallic boxes, proper cooling is required to ensure that the temperature around the drive will not exceed the maximum allowable temperature. Refer to section 9.1 for power diss...

Page 27

27 chapter 3 - installation and connection 3.2.1power and grounding terminals description of the power terminals: l/l1, n/l2, l3: ac power supply. U, v and w: motor connection. Pe: grounding connection. Br: connection terminal for the braking resistor. Not available for 1.6 a, 2.6a and 4 a/200-240 v...

Page 28

28 chapter 3 - installation and connection 3.2.3 wiring and fuses for power and grounding atention! Provide at least 0.25 m (10 in) spacing between low voltage wiring and drive/motor cables. For instance: plc’s, temperature monitoring devices, thermocouples, etc. Table 3.3 presents minimum cable dia...

Page 29

29 chapter 3 - installation and connection note! Cable dimensions indicated in table 3.3 are reference values only. Installation conditions and the maximum acceptable line voltage drop shall be considered when sizing the power cables. Table 3.4 - recommended tightening torques for power connections ...

Page 30

30 chapter 3 - installation and connection b) models 7.3 a to 10 a/200-240 v and 4.0 a/110-127 v (single-phase) power supply shielding c) models 1.6 a, 2.6 a, 4.0 a and 7.3 a/200-240 v (three-phase) figure 3.6 b) c) - grounding and power supply connections power supply l/l1 pe pe u v w shielding q1 ...

Page 31

31 chapter 3 - installation and connection shielding braking resistor figure 3.6 d) - grounding and power supply connections d) models 10.0a and 15.2 a/200-240 v (three-phase) danger! Use a disconnecting device at the drive ac-input power supply. This device shall be capable of disconnecting the dri...

Page 32

32 chapter 3 - installation and connection rheostatic braking for the drives with therheostatic braking optional, thebraking resistor shall be installed externally. Refer to figure 8.4 for correct braking resistor installation. Size the braking resistor according to the application and respecting th...

Page 33

33 chapter 3 - installation and connection note! Do not use the neutral conductor for grounding purposes. Attention! The ac input for the drive supply must have a grounded neutral conductor. Electromagnetic interference (emi) shielded cable or metallic conduit shall be used for motor wiring when ele...

Page 34

34 chapter 3 - installation and connection 3.2.5 signal and control connections the signal (analog input) and control connections (digital inputs and relay output) are made on the xc1 connector of control board (see location in figure 3.5). Figure 3.8 - description of the xc1 terminal of the control...

Page 35

35 chapter 3 - installation and connection figure 3.9 - shield connection connect to earth do not ground inverter side insulate with tape 4) for wiring distances longer than 50 m (150 ft), the use of galvanic isolators is required for the xc1:6 to xc1:9 analog signals. 5) relays, contactors, solenoi...

Page 36

36 chapter 3 - installation and connection 3.2.6 typical terminal connections connection 1 with the factory default programming, it is posible to operate the inverter in local mode with the minimum connections shown in figure 3.6 (power) and without control connections. This operation mode is recomm...

Page 37

37 chapter 3 - installation and connection figure 3.11 - wiring for connection 3 note! S1 and s2 are push buttons, no and nc contact, respectively. The speed reference can be realized via analog input ai1 (as in connection 2), via keypad (hmi-cfw10), or via any other source (see description of param...

Page 38

38 chapter 3 - installation and connection connection 4 enabling of the fwd/rev function: set di1 to forward run : p263 = 9 set di2 to reverse run: p264 = 10 make sure the inverter commands are via terminals, i.E., set p229 = 1 to local mode. Note! The speed reference can be realized via analog inpu...

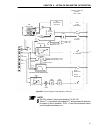

Page 39

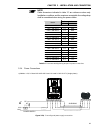

39 chapter 3 - installation and connection figure 3.13 below shows the emc filters connection. 3.3.1 installation figure 3.13 - emc filter connection - general condition the following items are required in order to have an appropriated installation: 1) the motor cable shall be armored, or installed ...

Page 40

40 chapter 3 - installation and connection emc phenomenon emission: conducted emissions (mains terminal disturbance voltage - freq band 150 khz to 30 mhz) radiated emissions (electromagnetic radiation disturbance - freq band 30 mhz to 1000 mhz) immunity: electrostatic discharge (esd) fast transient-...

Page 41

41 chapter 3 - installation and connection 3.3.3 inverter and filters table 3.5.2 shows the inverter models, its respective emc filter and the emc category classification. Refer to section 3.3.2 for emc category description and to section 3.3.4 for external filters characteristics. Table 3.5.1 - lis...

Page 42

42 chapter 3 - installation and connection note: maximum switching frequency is 5 khz. Table 3.5.2 - list of frequency drive models, emc filters and emc categories note! The cfw-10 inverters with three-phase supply do not have emc filters. Inverter model (single-phase) input rfi filter emc class 1.6...

Page 43

43 chapter 3 - installation and connection 3.3.4 characteristics of the emc filters footprint / booksize model b84142a0012r212 (epcos) supply voltage: 250 v, 50/60 hz current: 12 a weight: 0.95 kg (2.1 lb) a) model footprint/booksize b84142a0012r212 (epcos) figure 3.14 a) - drawing of the footprint ...

Page 44

44 chapter 3 - installation and connection figure 3.14 b) - drawing of the footprint / booksize filter footprint / booksize model b84142b18r212 (epcos) supply voltage: 250 v, 50/60 hz current: 18 a weight: 1.3 kg (2.9 lb) b) footprint/booksize model b84142b18r212 (epcos) terminals 2.5 mm 2 tightgnin...

Page 45

45 chapter 3 - installation and connection figure 3.14 c) - drawing of the footprint / booksize filter footprint / booksize model b84142b22r212 (epcos) supply voltage: 250 v, 50/60 hz current: 22 a weight: 1.4 kg (3 lb) c) footprint/booksize model b84142b22r212 (epcos) terminals 6 mm 2 tightgning to...

Page 46

46 chapter 3 - installation and connection standard model: b84142 - a20-r supply voltage: 250 v, 50/60 hz current: 20 a weight: 1 kg (2.2 lb) figure 3.15 a) b) - drawing of the standard filter a) standard model: b84142-a20-r (epcos) standard model: b84142 - a30-r supply voltage: 250 v, 50/60 hz curr...

Page 47: Chapter 4

47 chapter 4 keypad (hmi) operation this chapter describes the cfw-10 operation via human-machine interface (hmi), providing the following information: general keypad description (hmi); use of the keypad (hmi); inverter parameters arrangement; alteration mode parameters (programming); description of...

Page 48

48 chapter 4 - keypad (hmi) operation the keypad (hmi) is a simple interface that allows inverter operation/ programming. This interface has the following functions: indication of the inverter status and operation variables; fault indication and diagnostics; viewing and programming parameters; inver...

Page 49

49 chapter 4 - keypad (hmi) operation reference backup the last frequency reference, set by the keys the and , is stored when inverter is stopped or the ac power is removed, provided p120 = 1 (reference backup active is the factory default). To change the frequency reference before inverter is enabl...

Page 50

50 chapter 4 - keypad (hmi) operation 4.2.4 parameter viewing and programming all inverter settings are made through parameters. Parameters and their contents are shown on the display through the led´s " parameter" and "value". The identification is made between parameter number and its value. Examp...

Page 51

51 chapter 4 - keypad (hmi) operation note! (1) for parameters that can be changed with the running motor , the inverter will use the new value immediately after it has been set. Forparameters that can be changed only with stopped motor , the inverter will use this new value only after the key is pr...

Page 52: Chapter 5

52 chapter 5 5.1 pre-power checks this chapter provides the following information: how to check and prepare the inverter before power-up; how to power-up and check for proper operation; how to operate the inverter when it is installed according to the typical connections (see electrical installation...

Page 53

53 chapter 5 - start-up 5.3 start-up danger! Even after theac power supply has been disconnected, high voltages may be still present. Wait at least 10 minutes after powering down to allow full discharge of the capacitors. The sequence below is valid for the connection 1 (refer to section 3.2.6). Inv...

Page 54

54 chapter 5 - start-up 5.3.2 start-up operation via terminals connections according to figures 3.6 and 3.10. Notes! (1) if the direction of roation of themotor rotation is not correct, switch off the inverter. Wait 10 minutes to allow a complete capacitor discharge and the swap any two wires at the...

Page 55: Chapter 6

55 this chapter describes in detail all cfw-10 parameters and functions. 6.1 symbols please find below some symbols used in this chapter: aix = analog input number x. Ao = analog output. Dix = digital input number x. F* = frequency reference. This is thefrequency value(or alternatively, of speed) th...

Page 56

56 chapter 6 - detailed parameter description the frequency reference (i.E., the desired output frequency, or alternatively, the motor speed) can be defined in several ways: the keypad - digital reference that can be changed through the keypad (hmi), by using the keys and (see p221, p222 and p121); ...

Page 57

57 chapter 6 - detailed parameter description note! Dis on (status 1) when connected to 0 v (xc1:5). When f* of rotation (if this is possible - p231 = 2 and if the selected control is not forward run/reverse run. Keypad reference (p121) p124 to p131 p265 = 7/8 p266 = 7/8 multispeed di4 di3 di2 1 2 3...

Page 58

58 chapter 6 - detailed parameter description note! In v/f control mode (p202 = 0 or 1), fe = f* (see fig. 6.1) if p138 = 0 (slip compensation disabled). If p138 0, see figure 6.9 for the relation between fe and f*. Figure 6.2 - inverter block diagram fe command via digital input (di) acceleration...

Page 59

59 chapter 6 - detailed parameter description 6.2.3 commands the inverter has the following commands: pwm pulse enabling/ disabling, definition of the direction of rotation and jog. As the frequency reference, also the inverter commands can de defined in several ways. The main command sources are: v...

Page 60

60 chapter 6 - detailed parameter description 6.3 parameter listing in order to simplify the explanation, the parameters havebeen grouped by characteristics and functions: read-only parameters variables that can be viewed on the display, but can not be changed by the user. Regulation parameters prog...

Page 61

61 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p000 0 to 999 access [ 0 ] parameter 1 6.3.1 access and read only parameters - p000 to p099 p002 0 to 999 frequency [ - ] proportional value 0.01 ( 0.1 ( 1 (> 99.9) p003 0 to 1.5 x i nom motor current...

Page 62

62 chapter 6 - detailed parameter description range [factory setting] parameter description / notes 0.1 to 999 s [ 5.0 s ] 0.1 s ( 1 s (> 99.9) 0.1 to 999 s [ 10.0 s ] 0.1 s ( 1 s (> 99.9) 0.1 to 999 s [ 5.0 s ] 0.1 s ( 1 s (> 99.9) 0.1 to 999 s [ 10.0 s ] 0.1 s ( 1 s (> 99.9) this set of parameters...

Page 63

63 chapter 6 - detailed parameter description range [factory setting] parameter description / notes output frequency (motor speed) linear t (s) t accel. Time (p100/102) t decel. Time (p101/103) 50 % s ramp 100 % s ramp figure 6.4 - s or linear ramp it is recommended to use the s ramp with digital fr...

Page 64

64 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p121 p133 to p134 frequency [ 3.0 hz ] reference by 0.1 hz ( key and 1 hz (> 99.9 hz) defines the keypad reference value that can be set by using the keys and when the parameters p002 or p005 are bein...

Page 65

65 chapter 6 - detailed parameter description the frequency reference is defined by the status of the digital inputs programmed to multispeed as shown in table below: if a multi-speed reference (p124 to p131) is set to 0.0 hz and this same reference is selected, the drive will decelerate to 0.0 hz a...

Page 66

66 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p133 (1) 0.0 to p134 minimum [ 3.0 hz ] frequency 0.1 hz ( (f min ) 1 hz (> 99.9 hz) p134 (1) p133 to 300 maximum [ 66.0 hz ] frequency 0.1 hz ( (f max ) 1 hz (> 99.9 hz) defines the maximum and minim...

Page 67

67 chapter 6 - detailed parameter description range [factory setting] parameter description / notes figure 6.6 b) cont. - v/f curve and details of the manual torque boost (i x r compensation) p137 0.0 to 100 % automatic torque [ 0.0 ] boost - (automatic i x r compensation) the automatic torque boost...

Page 68

68 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p138 0.0 to 10.0 slip [ 0.0 ] compensation 0.1 % the parameter p138 is used in the motor slip compen- sation function. This function compensates the drop of themotor speed due to load, which is a inhe...

Page 69

69 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p142 (1)(2) 0 to 100 maximum output [ 100 ] voltage 0.1 % p145 (1)(2) p133 to p134 field weakening [ 60.0 hz ] frequency 0.01 hz ( (rated 1 hz (> 99.9 hz) frequency) define thev/f curveused in v/fcont...

Page 70

70 chapter 6 - detailed parameter description range [factory setting] parameter description / notes figure 6.12 - deceleration curve with dc link voltage regulation by this function an optimized deceleration time (minimum) is achieved for the driven load. This function is useful in applications with...

Page 71

71 chapter 6 - detailed parameter description range [factory setting] parameter description / notes prevents motor stalling during an overload. If motor load increases its current will increase too. If the motor current attempts to exceed the value set at p169, the motor speed will be decreased by f...

Page 72

72 chapter 6 - detailed parameter description range [factory setting] parameter description / notes output voltage p136 = 0 p142 0 p145 output frequency a) linear v/f recommended for belt conveyors, extruding machines, etc. - quadratic v/f control: in this control mode the flux in the motor air gap ...

Page 73

73 chapter 6 - detailed parameter description range [factory setting] parameter description / notes programs all parameters to the standard factory default, when p204 = 5. P204 (1) 0 to 999 loads [ 0 ] factory - setting in the event of a fault trip, except for e09, e24, e31 and e41, theinverter can ...

Page 74

74 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p221 (1) 0 to 7 local reference [ 0 - keys ] selection - p222 (1) 0 to 7 remote reference [ 1 - ai1 ] selection - defines thefrequencyreferenceselectionin thelocal and remote mode. P221/p222 0 1 2 3 4...

Page 75

75 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p231 (1) 0 to 2 forward/reverse - [ 2 - commands] local/remote modes defines the direction of rotation. P231 0 1 2 direction of rotation always forward always reverse commands as defined in p229 and p...

Page 76

76 chapter 6 - detailed parameter description range [factory setting] parameter description / notes this is shown in the block diagram below: gain p234 ai1' offset (p236) p235 ai1 figure 6.18 a) - block diagram of the analog input a1 following situation as example: ai1 is thevoltage input (0-10 v - ...

Page 77

77 chapter 6 - detailed parameter description range [factory setting] parameter description / notes note that there is always a dead zone at the starting of the curve where the frequency reference remains at thevalue of the minimum frequency (p133), even when the input signal is changed. This dead z...

Page 78

78 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p235 (1) 0 to 1 analog input ai1 [ 0 ] signal defines the signal type of the analog input, as shown in table below: p236 -120 to +120 analog input ai1 [ 0 ] offset 1 % see p234. P235 0 1 signal type (...

Page 79

79 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p266 (1) 0 to 27 digital input di4 [4 - not used (hmi) function or start/stop (terminals) ] - functions activated with 0 v at digital input. Notes! 1) local/remote = open/0 v at the digital input resp...

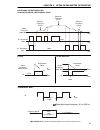

Page 80

80 chapter 6 - detailed parameter description range [factory setting] parameter description / notes a) general enable b) start/stop open output frequency (motor speed) motor runs freely time time 0 v accel. Ramp d i output frequency (motor speed) decel. Ramp time time accel. Ramp open d i c) wire st...

Page 81

81 chapter 6 - detailed parameter description d) forward run / reverse run open time time time open di1 - rev di1 - fwd output frequency (motor speed) cw ccw open time time output frequency (motor speed) di - fwd/ rev cw ccw f) fwd / rev g) ramp 2 di - decrease pe time output frequency (motor speed)...

Page 82

82 chapter 6 - detailed parameter description time output frequency (motor speed) start/stop jog frequency (p122) decel. Ramp di - jog general enable open open open accel. Ramp h) jog time time time open time time output frequency (motor speed) di - no external fault i) no external fault motor runs ...

Page 83

83 chapter 6 - detailed parameter description output frequency (motor speed) di - accelerate / start di - decelerate / stop open open minimum frequency (p133) maximum frequency (p134) minimum frequency (p133) time time time k) eletronic potentiometer (ep) (start/accelerate) - (decelerate / stop) m) ...

Page 84

84 chapter 6 - detailed parameter description range [factory setting] parameter description / notes p277 (1) 0 to 7 relay output rl1 [ 7 - no fault ] function table below shows the available options. Output/parameter function fs > fx fe > fx fs = fe is > ix not used run (inverter enabled) no fault p...

Page 85

85 chapter 6 - detailed parameter description figure 6.20 e) f) - details about the operation of the relay output fucntions e) run stopped motor or running by inertia time off relay on motor running f) no fault time off relay fault state (exy) ready/run state on range [factory setting] parameter uni...

Page 86

86 chapter 6 - detailed parameter description range [factory setting] parameter unit description / notes p297 (1) 2.5 to 15.0 switching [ 5 khz ] frequency 0.1 khz for the 15.2 a model the factory adjustment is [2.5 khz] defines the switching frequency of the igbts in the inveter. The switching freq...

Page 87

87 chapter 6 - detailed parameter description range [factory setting] parameter unit description / notes before dc braking starts, there is a "dead time" (mo- tor runs freely) required for themotor demagnetization. This time is function of the motor speed at which the dc braking occurs (output frequ...

Page 88

88 chapter 6 - detailed parameter description 6.3.4 special functions parameters – p500 to p599 6.3.4.1 introduction other application examples: level control, temperature, dosing, etc. The cfw-10 is fitted with pid regulator function that can be used for closed loop process control. This function w...

Page 89

89 chapter 6 - detailed parameter description the p040 parameter indicates the process variable value (feedback) in the selected scale at p528, which is set according to the following equation: p528 = full scale of used sensor x 100 p234 example: consider the previous example data (pressure sensor o...

Page 90

90 chapter 6 - detailed parameter description s e t p o in t d e fi n it io n (p ro ce ss va ria bl e re fe re nc e) h m ip ot en tio m et er (p lu s ve rs io n) p2 40 (o ffs et ) g ai n p5 25 3- h m i po te nti om ete r 0- k ey p2 21 (l oc al )o r p2 22 (r em ot e) se tp oi nt pi d (k ey ) se t po ...

Page 91

91 chapter 6 - detailed parameter description note! When pid (p203 = 1) function is enabled: program one of the digital inputs dix (p263 to p266 = 27). In this manner, with closed dix it operates in manual mode(without closing the loop control – feedback) and opening the dix the pid regulator starts...

Page 92

92 chapter 6 - detailed parameter description signal type: set p235 according to transducer signal (4-20 ma, 0-20 ma or 0-10 v). Set p234 according to the variation range of the used feedback signal (for more details see parameters descriptions p234 to p240). Example: suppose the following applicati...

Page 93

93 chapter 6 - detailed parameter description 2) automatic operation: open the di and make the dynamic setting of the pid regulator, i.E., set the proportional gain (p520), integral gain (p521) and differential gain (p522). Note! The inverter setting must be correct in order to obtain a good perform...

Page 94

94 chapter 6 - detailed parameter description range [factory setting] parameter unit description / notes p520 0.0 to 999 % pid proportinal [ 100 ] gain 0.1( 1 (> 99.9) p521 0.0 to 999 % pid integral [ 100 ] gain 0.1( 1 (> 99.9) p522 0.0 to 999 % pid differential [ 0 ] gain 0.1( 1 (> 99.9) the integr...

Page 95

95 chapter 6 - detailed parameter description range [factory setting] parameter unit description / notes p528 0.0 to 999 process [ 100 ] variable scale 0.1( factor 1 (> 99.9) defines the process variables scale. It makes the conversion between percentage value (internally used by the inverter) and t...

Page 96: Chapter 7

96 chapter 7 diagnosticsand troubleshooting this chapter assists the user to identify and correct possible faults that can occur during the cfw-10 operation. Also instructions about required periodical inspections and cleaning procedures are also provided. When a fault is detected, the inverter is d...

Page 97

97 chapter 7 - diagnostics and troubleshooting note: (1) in case of e04 fault due to inverter overtemperature, allow the inverter to cool down before trying to reset it. Note! The faults act as follows: e00 to e06: switches off the relay that has been programmed to “no fault”, disables the pwm pulse...

Page 98

98 chapter 7 - diagnostics and troubleshooting 7.2 troubleshooting problem point to be corrective action checked motor does incorrect wiring 1.Check the power and the control connections. For example, not run the digital inputs dix programmed for start/stop or general enable or no external fault mus...

Page 99

99 chapter 7 - diagnostics and troubleshooting note! When contacting weg for services, please have the following data on hand: inverter model; serial number, manufacturing date and hardware revision, as indicated on the inverter nameplate (refer to section 2.4); software version (refer to section 2....

Page 100

100 chapter 7 - diagnostics and troubleshooting table 7.1 - periodic inspection after start-up 7.4.1 cleaning instructions when required to clean the inverter, flow the instructions below: a) cooling system: remove ac power from the inverter and wait 10 minutes. Remove all dust from ventilation open...

Page 101: Chapter 8

101 chapter 8 optionsandaccessories this chapter describes the optional devices that can be used internal or external with the cfw-10. Note! The cfw-10 inverter line has filters only for the models with single- phase power supply. 8.1 rfi filter the installation of frequency inverters requires some ...

Page 102

102 chapter 8 - options and accessories 8.2.1 application criteria in a general manner, the cfw-10 series inverters can be connected directly to the power supply line without line reactors. But in this case, ensure the following: to ensure the inverter expected life, a minimum line impedance that in...

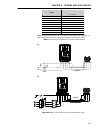

Page 103

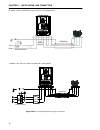

103 chapter 8 - options and accessories rede blindagem table 8.1 - minimum line impedance for several load conditions note: these values ensure a life of 20 . 000 hour for the dc link capacitors, i.E., they can be operated during 5 years with operation of 12 hours per day. Line l/l1 pe pe u v w shie...

Page 104

104 chapter 8 - options and accessories theuse of a three-phase load reactor, with an approximate 2 % voltage drop, adds an inductance at the inverter output to the motor. This decreases the dv/dt (voltage rising rate) of the pulses generated at the inverter output. This practice reduces the voltage...

Page 105

105 chapter 8 - options and accessories in any case, the rms current capacity and the maximum peak current shall be respected. The maximum peak current defines the minimum resistance value (ohms) of the braking resistor. Refer to table 8.3. The dc link voltage level at which the rheostatic braking i...

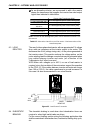

Page 106

106 chapter 8 - options and accessories connect the braking resistor between the +ud and br power terminals (refer to section 3.2.1 and fig. 3.6); make this connection with a twisted pair. Run this cable separately from any signal or control wire. Size the cable cross section according to the applic...

Page 107

107 chapter 8 - options and accessories figure 8.4 - braking resistor connection (only for the models 7.3 and 10.0 a/200-240 v and 4.0 a/110-127 v single-phase and 10.0 a and 15.2 a/200-240 v three-phase) motor input power supply contactor control voltage thermal relay thermostat braking resistor u ...

Page 108: Chapter 9

108 chapter 9 technicalspecifications this chapter describes the technical specifications (electrical and mechanical) of the cfw-10 inverter series. 9.1 power data ac input specifications: voltage: -15 %, +10 % (with loss of motor efficiency); frequency : 50/60 hz (± 2 hz); overvoltage: category iii...

Page 109

109 chapter 9 - technical specifications the values shown in the tablewere calculated by considering the rated inverter current, input voltage of 220 v. (2) rated current is valid for the following conditions: relative air humidity: 5 % to 90 %, non condensing. Altitude: 1000 m up to4000 m (3.300 ft...

Page 110

110 chapter 9 - technical specifications 9.2 electronic/general data applied voltage v/f (scalar) 0 to 300 hz, resolution: 0.01 hz. Speed regulation: 1 % of the rated speed. 1 isolated input, resolution: 7 bits, (0 to 10) v or (0 to 20) ma, or (4 to 20) ma, impedance: 100 k [(0 to 10) v], 500 [(0...