- DL manuals

- WEG

- Engine

- WGM

- Installation, Operation And Maintanance Manual

WEG WGM Installation, Operation And Maintanance Manual

Summary of WGM

Page 1

Motors i automation i energy i transmission & distribution i coatings three phase induction motors cooled by water jacket w line - squirrel cage rotor horizontal and vertical installation, operation and maintenance manual.

Page 3

Installation, operation and maintenance manual document number: 11239449 model: wgm language: english revision: 8 february 2017.

Page 5

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 5 dear customer, thank you for purchasing a weg motor. Our products are developed with the highest standards of quality and efficiency which ensures outstanding performance....

Page 7: Table of Contents

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 7 table of contents 1 introduction ................................................................................................. 11 1.1 safety warnings in the manual ......

Page 8

Www.Weg.Net 8 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4.6.1 cooling system characteristics ........................................................................................................... 25 4.6.2 cooling water cha...

Page 9

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 9 7.9 encoder maintenance ............................................................................................................. 38 7.10 bearing maintenance ............

Page 11: Introduction

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 11 1 introduction this manual contains information regarding low and high-voltage, three-phase induction motors. Motors with special features can be supplied with specific d...

Page 12: General Instructions

Www.Weg.Net 12 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 2 general instructions all the personnel involved with the assembly, operation or maintenance of electrical installations must be permanently informed and updated on the ...

Page 13

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 13 2.4 environmental conditions the motor was designed according to the specific environmental conditions (temperature and altitude) of your application, and are described o...

Page 14

Www.Weg.Net 14 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 3 receiving, handling and storage 3.1 receiving all motors were tested and are in perfect operating conditions. The machined surfaces are protected against corrosion. The...

Page 15

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 15 3.2.1 vertical motor positioning vertical motors are supplied with lifting lugs at the drive end de and non-drive end nde. Some motors are transported in the horizontal p...

Page 16

Www.Weg.Net 16 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 the extended storage instructions are valid for motors that remain stored for long periods (two months or more) before start-up or motors already installed that are in a ...

Page 17

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 17 3.3.3.2 insulation resistance during the storage period, the insulation resistance of the motor windings must be measured and recorded every two months, and before the mo...

Page 18

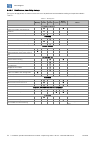

Www.Weg.Net 18 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 3.3.3.9 maintenance plan during storage during the storage period, the motor maintenance must be performed and recorded according to the plan described in table 3.1. Tabl...

Page 19

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 19 3.3.4 preparation for commissioning 3.3.4.1 cleaning the internal and external parts of the motor must be free of oil, water, dust and dirt. Remove the rust inhibitor fro...

Page 20: Installation

Www.Weg.Net 20 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4 installation 4.1 installation site electric motors must be installed in easily accessible places, allowing periodic inspections, on-site maintenance and, if necessary, ...

Page 21

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 21 figure 4.2: connection of the megohmmeter to separate phases if the total winding measurement presents a value below the recommended, the neutral connections must be open...

Page 22

Www.Weg.Net 22 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4.4.7 insulation assessment table 4.2 and table 4.3 present guiding limits of insulation resistance and polarization index for the assessment of the motor insulation cond...

Page 23

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 23 4.5.1.3 alarm and trip temperatures the motor alarm and trip temperatures must be set at the lowest possible value. These temperatures can be determined based on the fact...

Page 24

Www.Weg.Net 24 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4.5.1.4 temperature and ohmic resistance of the pt100 thermoresistance table 4.6 shows the temperature as a function of the ohmic resistance measured across pt100 rtds. T...

Page 25

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 25 4.6 cooling the motor cooling system type may vary according to its application. Only the correct installation of the motor and of the cooling system can ensure its conti...

Page 26

Www.Weg.Net 26 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4.7 electrical aspects 4.7.1 electrical connections attention analyze the electrical connection diagram supplied with the motor carefully before beginning the connection ...

Page 27

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 27 4.7.2 connection diagrams 4.7.2.1 connection diagrams according to iec60034-8 the following connection diagrams show the terminal identification in the terminal box and t...

Page 28

Www.Weg.Net 28 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4.7.2.2 connection diagrams according to nema mg1 4.7.2.2.1 stator connection diagrams 3 terminals 6 terminals 6 terminals - dahlander Δ y Δ lower speed yy higher speed y...

Page 29

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 29 4.8 mechanical aspects 4.8.1 foundations the foundation or structure where the motor will be installed must be sufficiently rigid, flat, free of external vibration and ca...

Page 30

Www.Weg.Net 30 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4.8.3.3 metal base the motor must rest evenly on the metal base in order to prevent deformations of the frame. Occasional errors in the height of the surface that support...

Page 31

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 31 half of the maximum difference among the dial gauge measurements in a complete rotation represents the maximum eccentricity found. The misalignment in a complete shaft ro...

Page 32

Www.Weg.Net 32 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 4.8.8.1 direct coupling because of issues about cost, space economy, problems with belt sliding and more safety against accidents, direct coupling must be used whenever p...

Page 33: Starting

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 33 5 starting 5.1 direct on-line starting it is the simplest and most economically feasible method; however, it must only be used when the starting current does not affect t...

Page 34: Commissioning

Www.Weg.Net 34 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 6 commissioning when the motor is started for the first time or after a prolonged standstill, several aspects must be considered besides the regular operation procedures....

Page 35

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 35 6.3.1 general after a first successful starting test, couple the motor to the driven load, and then the starting procedure can be reinitiated, as follows: start the motor...

Page 36

Www.Weg.Net 36 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 6.4 operation as asynchronous generator for operation as asynchronous generator, besides the procedures mentioned in section 6.3, it is necessary to consider the followin...

Page 37: Maintenance

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 37 7 maintenance 7.1 general a proper maintenance program for electric motors includes the following recommendations: keep the motor and the associated equipment clean; meas...

Page 38

Www.Weg.Net 38 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 7.4.2 reimpregnation if any layer of resin on the windings is damaged during cleaning or inspection, such parts must be corrected with adequate material (in this case, co...

Page 39

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 39 7.10 bearing maintenance 7.10.1 grease-lubricated rolling bearings 7.10.1.1 instructions for lubrication the lubrication system was designed in such a way that during the...

Page 40

Www.Weg.Net 40 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 7.10.1.5 alternative greases if it is not possible to use the original grease, alternative greases listed in table 7.3 can be used, under the following conditions: 1. The...

Page 41

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 41 table 7.3 shows the most common rolling bearings used in horizontal motors, the quantity of grease and the speed limit for using optional greases. Table 7.3: application ...

Page 42

Www.Weg.Net 42 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 7.10.1.6 procedure for changing the grease in order to replace the polyrex em103 grease by one of the alternative greases, the bearings must be opened to remove the old g...

Page 43

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 43 de bearing disassembly in order to disassemble the bearing, proceed according to the following guidelines: 1. Remove the screws (4), protection disc (5) and the labyrinth...

Page 44

Www.Weg.Net 44 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 7.10.1.10.2 lower bearing disassembly in order to disassemble the bearing, proceed according to the following guidelines: 1. Place the motor in the horizontal position; 2...

Page 45

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 45 7.10.3 bearing protection 7.10.3.1 protection settings attention the following temperatures must be set on the bearing protection system: alarm 110 ºc – trip 120 ºc the a...

Page 46

Www.Weg.Net 46 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 8 motor disassembly and assembly attention all the repair, disassembly and assembly services must be performed only by properly qualified and trained professionals; other...

Page 47

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 47 8.2 vertical motors figure 8.2: vertical motor figure 8.2 legend: 1. Flange 2. Stator 3. Rotor 4. Internal fan 5. Shaft 6. Lower bearing 7. Lower end shield 8. Upper end ...

Page 48

Www.Weg.Net 48 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 8.3 air-gap measurement after disassembling and assembling the motor, it is necessary to measure the air gap in order to check the concentricity between rotor and stator....

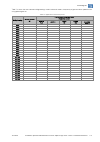

Page 49: Maintenance Plan

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 49 9 maintenance plan the maintenance plan described in table 9.1 is only referential, and the intervals between each maintenance intervention may vary according to the moto...

Page 50

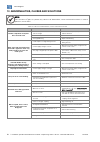

Www.Weg.Net 50 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 10 abnormalities, causes and solutions note the instructions of table 10.1 present only a basic list of abnormalities, causes and corrective actions. In case of questions...

Page 51

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 51 abnormality possible causes correction stator winding becomes very hot under load insufficient cooling due to dirty water channels clean the water passage channels overlo...

Page 52: Declaration of Conformity

Www.Weg.Net 52 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 11 declaration of conformity.

Page 53: Environmental Information

Www.Weg.Net 11239449 installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical l 53 12 environmental information 12.1 package electric motors are supplied in cardboard, polymer, wood or metallic material packages. These materials are recyclable or reusab...

Page 54: Warranty Term

Www.Weg.Net 54 l installation, operation and maintenance manual – squirrel cage motor – w line - horizontal and vertical 11239449 13 warranty term these products, when operated under the conditions stipulated by weg in the operating manual for such product, are warranted against defects in workmansh...

Page 55

Argentina weg equipamientos electricos s.A. Sgo. Pampiglione 4849 parque industrial san francisco 2400 - san francisco phone: +54 (3564) 421484 www.Weg.Net/ar australia weg australia pty. Ltd. 14 lakeview drive, scoresby 3179, victoria phone: +03 9765 4600 www.Weg.Net/au austria watt drive antriebst...