Z Corporation Spectrum Z 510 Maintenance Manual

85063 Spectrum Z510 Preventative Maintenance Procedure 1/12

80563

Spectrum Z510 Preventative Maintenance Procedure

Rev D

Description:

This procedure is for the purpose of preventative maintenance on the Spectrum 510.

Prerequisites:

• Printers should be inspected for bulletin updates before ordering parts for maintenance.

• Bulletins can be found on the Z Corp Website.

Equipment / Parts Required:

• 50342 Dealer Recommended Toolkit.

• 50355 Spectrum Z510 Maintenance Kit.

• 10674 Syringe, Luer-Lock, 20cc (Accessories Kit)

• 06775 PL Needle Tubing Assy (Accessories Kit)

• 09947 Fluid clean out procedure

• Clamp or hemostats (15237 or equivalent)

• Paper

towels

• Can of compressed air (to clean powder from fan

Procedure

• Perform the items on the checklist below.

• Give Customer a copy of the completed checklist for reference.

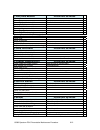

Spectrum Z510 Preventative Maintenance Kit #50355

06419

Toucan Septum Assy

4

each

30011

Service Station Wiper

1

each

30052

Toucan Roller Scraper

1

each

30550

Toucan Gantry Anti-Rotate Bearing

1

each

15055

Inline

Filter

4 each