- DL manuals

- Zamil

- Air Conditioner

- CX SERIES

- Installation, Operation & Maintenance Manual

Zamil CX SERIES Installation, Operation & Maintenance Manual

Summary of CX SERIES

Page 1

Installation, operation & maintenance manual air cooled condensing units cx series (cx150 - cx360) part number: 800-213-58 (rev.-02).

Page 2: Index

Contents page model decoding ........................................................................................................................................ 2 general statement .....................................................................................................................

Page 3: Model Decoding

1& 2 basic 3, 4 & 5 nominal cooling capacity (mbh) 7 refrigera- tion circuit 6 electrical supply ( v-ph-hz ) 9 mode 11 condenser coil cx classic condensing unit 150 180 220 240 300 360 s : single * d : dual h : 208/230-3-60 m : 380-3-60 (4 wire) f : 460-3-60 c : cool only h : heat pump + a : aluminu...

Page 4: Installation Procedures

Installation procedures general these units are shipped completely assembled, charged with refrigerant (r-22) and wired. They will require external power & thermostat wiring in the field. Selection of the condensing unit and its corresponding matching indoor unit should be based on a heat calculatio...

Page 5: Dimensions

Dimensions cx150 - cx220 note: 1. All dimensions are in mm (dimensions in brackets are in inches). 4.

Page 6: Dimensions

Dimensions cx 240 - cx 300 note: 1. All dimensions are in mm (dimensions in brackets are in inches). 5.

Page 7: Dimensions

Dimensions cx 360 note: 1. All dimensions are in mm (dimensions in brackets are in inches). 943 [37.13"] 943 [37.13"] 2032 [80.0"] 73 [2.88"] 2197 [86.50"] 2121 [83.50"] 15 50 [61. 0" ] 20 3 [8 .0 "] 6.

Page 8

Rigging & mounting these units are suitable for overhead rigging. See below rigging instructions. Attention to riggers: 1. Hook rigging sling through holes/insert 3" nominal pipe through holes in the base rail, as shown below. 2. Holes in base rail are centered around the unit center of gravity. 3. ...

Page 9

Refrigerant piping connections piping connections: outdoor units should be connected to indoor units using field-supplied piping of refrigerant grade and correct size. The liquid and suction line diameters can be determined from the physical data table. For piping applications beyond 25 feet (7.62 m...

Page 10

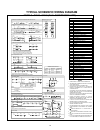

Typical schematic wiring diagram note: 1. Refer to next page for legend, notes & wiring diagram for optional items. 2. Refer to unit control box (inside panel) for exact wiring diagram. Models : cx150 (single compressor units) 9 close(psig) open(psig) name fcs 190 ± 15 290 ± 10 45 lps1 hps 450 ± 10 ...

Page 11

Typical schematic wiring diagram 15 unit off fr comp 17 ar1-1 46 ar1 47 17 conn.For oil pressure switch option cr-1 1 28a 26a/27a ops 2 2 240 28c ops sr 2 (pls. Connect lps accordingly) 5a note: ar8 one unloader lps1 3a 6a ul ar8-1 1 2 2 1) uvm option options 2) smoke detector option uvm-1 8 1 remov...

Page 12

Typical schematic wiring diagram 11 1 lps1 jp1 1a 2a atb1 jp2 1b f1 t3 a comp 1 t2 a t1 a cc1 fm1 36 a 35 a 37 a t2 b t1 b fmc1 sr1-1 [ssps2] jp7 25b [ssps1] 230vac jp4 l1 25a l2 3a jp8 * 26b 4a jp6 see note-8 * f2 26a t3 b fm2 35 b 37 b 36 b cc2 fmc2 c1-contactor c1-safety relay c2-safety relay c1-...

Page 13

Legend ahu air handling unit ai anti ice thermostat ar auxiliary relay atb auxiliary terminal block cap capacitor cc compressor contactor cb circuit breaker c. Htr crankcase heater comp compressor cr control relay fm fan motor (condenser) fmc fan motor contactor fr fault relay fcs fan cycling switch...

Page 14

Typical schematic wiring diagram note: 1. Refer to next page for legend, notes & wiring diagram for optional items. 2. Refer to unit control box (inside panel) for exact wiring diagram. Models : cx240 - cx360 (dual compressor units) 13 27b olr2-1 olr1-1 27a c1-safety relay to ahu [ai2] for fan motor...

Page 15

Typical schematic wiring diagram models : cx240 - cx360 (dual compressor units) legend ahu air handling unit ai anti ice thermostat ar auxiliary relay atb auxiliary terminal block cap capacitor cc compressor contactor cb circuit breaker c. Htr crankcase heater comp compressor cr control relay fm fan...

Page 16: Operation Instructions

Operation instructions pre-startup inspection and check list after the installation is completed in all respect, the following points should be covered before the system is switched on for operation. 1. Remove straps & wooden pieces that hold the compressor in place during transportation. 2. Make su...

Page 17

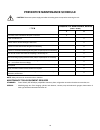

Preventive maintenance schedule 12 x x x x x x x x x x frequency of maintenance, months (first 4 years) i t e m caution: disconnect power supply and allow all rotating parts to stop before servicing the unit. 6 x check all electrical controls, components, wiring terminals, etc..., for sparks, over h...

Page 18: Trouble Shooting Chart

1. Close start or disconnect switch 2. Replace fuse 3. Refer to electrical section 4. Repair or replace control 5. Relocate control 6. Check wiring against diagram 7. Replace or relocate 8. Trace control circuit with wiring diagram & repair 9. Replace the compressor with all precautions 1. Check wir...

Page 19: Trouble Shooting Chart

Trouble shooting chart symptom causes check & corrective measure head pressure too high head pressure too low high suction pressure loss of oil pressure relay defective or burned out space temperature too high suction line frosted or sweating liquid line frosted or sweating unit noisy 1. Correct the...

Page 20: Parts List

Parts list model number cx150h cx150m cx150f cx180h cx180m cx180f compressor (single),scroll 800-674-17 800-674-18 800-674-19 n.A. N.A. N.A. . Compressor (dual), scroll 800-674-23 800-674-24 800-674-25 800-674-79 800-674-80 800-674-81 fan motor 800-545-58 800-545-58 800-545-63 800-545-68 800-545-68 ...