- DL manuals

- Zamil

- Air Conditioner

- PV036

- Installation, Operation & Maintenance Manual

Zamil PV036 Installation, Operation & Maintenance Manual

Summary of PV036

Page 1

Installation, operation & maintenance manual vertical packaged units 'pv' series models: pv036 - pv060

Page 2: Index

Contents page general model decoding ...................................................................................................................................................... 2 general statement ...............................................................................................

Page 3: Model Decoding

1& 2 basic 3, 4 & 5 nominal cooling c a p acity (mbh) 6 electrical suppl y ( v -ph-hz ) 9 blower mot o r 13 e v apora t o r coil 14 condenser coil 15 fil ter 11 hea t e r 16 unit accessories pv vertical packaged unit 036 048 060 h :208/230-3-60 m :380-3-60 * (4 wire) v :std. Motor a : aluminum fin b...

Page 4: General

General general statement this unit is from the pv series that was designed & built for the optimum performance. However, it is required that you become well acquainted with good practices for the proper installation/operation/and maintenance procedures in order to ensure a safe trouble free operati...

Page 5

Condensate drain connection • use standard pvc pipe with npt connection for the condensate drain. The plastic drain pan has an internal built-in trap. Accord- ingly there will be no need for external 'p' trap. • piping has to be sloped away from the unit. • remember to remove the drain hole plug bef...

Page 6: Dimensions

Front view top view end view condenser coil cond. Air inlet control box evaporator coil supply air return air supply air opening return air opening f 610 [24] h i g mounting flange filter d 5 1 [2] e a c b dimensions pv036 - pv060 notes: 1. All dimensions are in millimeters, (dimensions in brackets ...

Page 7: Access Details

(from side) compressor access left side access (from side) compressor access right side access filter & ele. Controls (from back side) filter & ele. Controls (from back side) access details pv036 - pv060 6.

Page 8: Operation Instructions

Operation instructions start-up inspection & check list after the installation is completed in all respect, the following points should be covered before the system is switched on for operation. 1. Check unit location as per installation instructions. 2. Make sure all electrical fasteners/connection...

Page 9: Electrical Data

Legend: fla – full load amps rla – rated load amps lra – locked rotor amps mocp – maximum over current protection mca – minimum circuit amps * single phase motors electrical data compressor * fan motor fla voltage range power supply (v-ph-hz) model no.: pv036 min. Max. Rla lra 208/230-3-60 187 253 1...

Page 10: Maintenance Instructions

Maintenance instructions crankcase heater the function of crankcase heater is to hold the compressor oil reservoir at higher temperature than the coldest part in the system. • power must be supplied to crankcase heater for a minimum of 12-hours prior to system start-up. If power is off for 6-hours o...

Page 11

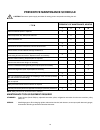

Preventive maintenance schedule 1 x x x x x x x 3 x x x x x 6 x x 12 x x frequency of maintenance, months i t e m clean air filters & replace if required. Clean evaporator coil, drain pan & drain line. Clean condenser coil. Lubricate blower motor/condenser motor. Check/clean electrical connections, ...

Page 12: Trouble Shooting Chart

1. Close start or disconnect switch. 2. Replace fuse. 3. Refer to electrical section. 4. Repair or replace control. 5. Relocate control. 6. Check wiring against diagram. 7. Replace or relocate. 8. Trace control circuit with wiring diagram and repair. 9. Replace the compressor with all precautions. 1...

Page 13: Trouble Shooting Chart

Trouble shooting chart symptom causes check & corrective measure evaporator ices up. Head pressure too high. 1. Restricted airflow. 2. Dirty air filter. 3. Short of refrigerant. 4. Low air volume. 5. Restricted distributor tube. 6. Restricted liquid line/low liquid line pressure. 1. Refrigerant over...

Page 14

Typical schematic wiring diagram legend bm blower motor bmc blower motor contactor cap capacitor cc compressor contactor cb circuit breaker c. Htr crankcase heater comp compressor fm fan motor (condenser) fcs fan cycling switch hps high pressure switch hvtb high voltage terminal block lps low pressu...

Page 15

Typical schematic wiring diagram (for communication shelter applications) legend atb auxiliary terminal block bm blower motor bmc blower motor contactor cc compressor contactor cap capacitor c. Htr crankcase heater comp compressor fm fan motor (condenser) fcs fan cycling switch hps high pressure swi...

Page 16: Parts List

Model number pv036h pv048h pv048m pv060h pv060m compressor 800-674-26 800-674-20 800-674-21 800-674-13 800-674-14 condenser fan motor 800-545-97 800-547-40 800-547-40 800-547-40 800-547-40 fan motor capacitor 800-353-15 800-353-15 800-353-15 800-353-15 800-353-15 blower motor 800-547-52 800-555-29 8...