- DL manuals

- Zap

- Control Systems

- JACKSHAFT MOTOR-CONTROL SYSTEM 815-RL

- Installation Instructions Manual

Zap JACKSHAFT MOTOR-CONTROL SYSTEM 815-RL Installation Instructions Manual

JACKSHAFT

MOTOR-CONTROL

SYSTEM

FOR

RESIDENTIAL GARAGE DOORS

Model 815-RL

Installation Instructions

WARNING: To reduce the risk of injury to

persons, use this operator only with a

residential sectional door.

FOR INSTALLATION ONLY BY

QUALIFIED

PERSONNEL

ZAP CONTROLS UK

100 Waterloo Boulevard

Anglesey Business Park

Cannock

Staffordshire WS12 1NR

United Kingdom

August 2006

Summary of JACKSHAFT MOTOR-CONTROL SYSTEM 815-RL

Page 1

Jackshaft motor-control system for residential garage doors model 815-rl installation instructions warning: to reduce the risk of injury to persons, use this operator only with a residential sectional door. For installation only by qualified personnel zap controls uk 100 waterloo boulevard anglesey ...

Page 3: Important Installation

Important installation instructions warning: to reduce the risk of injury or death read and follow all installation instructions install only on a properly balanced door. An improperly balanced door has the potential to inflict severe injury. Have a qualified service person make repairs to cables, s...

Page 5: Contents

Contents product overview .............................................................................................. 1 description ........................................................................................................ 2 fitting the super-drive .....................................

Page 6: For Sectional Doors

Control unit model 800-r integrated control unit with case mounted control button. This control unit will power doors up to 15 square metres (160 square feet) in conjunction with model 8472 operator. Manual over- ride model za0093 the manual over-ride drive release mechanism includes a doorframe or ...

Page 7: For

The zap controls’ range of motor-control systems for sectional doors provides a new concept in safety control and the elimination of the inherent problems with a number of features of existing door operators. The zap 815-rl low voltage dc motor-control operates without limit switches and without a s...

Page 8

3 an optional beeper model 850 may be fitted to sound at the start of each door movement and provide audible feedback during programming and door position calibration. Preparation ensure that the door is free to move by hand without any stiffness or misalignment of track sections, which may cause th...

Page 9

Next slide the super-drive assembly onto the door shaft and select a suitable hole in the torque arm to bolt it to the super-drive back plate using the spacer bush, which should pass through the lower slot in the cover back. (pic 7) the cover back will be secured later. The torque arm should be appr...

Page 10

The second allen screw, set at 90 degrees, should then be tightened and secured with the locknut. Now tighten the torque arm screws (pic 10) fitting the manual over-ride lever mechanism the position of the cable post should be assessed next. The cable post, which secures the bowden cable outer sheat...

Page 11

Mark the hole positions for the manual over-ride lever on the door track or frame in a convenient position with the lever held in the horizontal position. Drill two m5 or 7/32nd of an inch size holes. (pic 13). Fit the m5 screws provided with the screw head on the inside of the track or doorframe. F...

Page 12

Fitting the control unit check that the control unit voltage, which is shown on the label on the side of the control unit case, is correct for the available single-phase supply voltage. The control unit model number has a suffix, which relates to the supply voltage. Us is 120 volts eu is 220 volts u...

Page 13

Be strapped to the super-drive bowden cable with cable ties to allow both cables to seat neatly in the slot in the bottom of the motor cover. (pic 20) do not cut or shorten the motor cable. Ensure that any unused cable is coiled and secured away from any moving parts, using the cable ties provided. ...

Page 14

Connecting the main a/c supply the operator should be installed in accordance with local codes and national electric code. To reduce the risk of electric shock, this equipment has a grounding type plug that has a third (grounding pin). This plug will only fit into a grounding type outlet. If the plu...

Page 15

7. The new supply wiring should be terminated to the green connector block. The correct locations for the live, neutral and ground wires are marked on the panel next to the green socket. The new black (live) wire should be terminated in the left hand terminal. The white (neutral) wire should be term...

Page 16

Testing the door operation when the basic wiring is complete the door operation may be tested. It may be helpful to fit an optional plug-in beeper module (part no. 850) (pic 28), which sounds in conjunction with flashes of the acknowledge led. The beeper will sound at the start of each door movement...

Page 17

Door direction assesment the motor direction will depend on which side of the shaft the operator is mounted. In order to assess the correct direction of movement of the door first release the manual over-ride lever and move the door manually to a half open position. Then re-engage the manual over-ri...

Page 18

After the door has stopped in the fully closed position, press the open push button again. When the door has stopped in the open position – press the button to close the door. Complete another door open and close cycle and confirm that when the door has correctly calibrated the door stops and remain...

Page 19

Direction may be adjusted with the close sensitivity preset. (pic 37) if it is required to increase the obstruction sensitivity, thus reducing the door edge pressure required to activate the control unit obstruction sensing circuit, which causes the door to stop and re-open during the close fast spe...

Page 20

See the wiring diagrams on pages 19 and 20. If two or more photo-eyes, or any other safety devices are fitted then each switching circuit should be wired in series. A 24-volt photo-eye or other accessory may be powered from the 24-volt dc accessory radio supply terminals at the lower right hand side...

Page 21

If the safety circuit is interrupted whist the door is closing then the door will stop and reopen. If the safety circuit is interrupted whist the door is operating with the auto-close timer dip switch no. 4 set to on then the timer will reset during each interruption of the safety circuit, whilst th...

Page 22

When the program button is pressed and held, a sequence of flashes of the acknowledge led follows at 4-second intervals. If a bleeper is fitted then the bleeper will sound with the flashes of the led. The first flash or bleep indicates the zap remote control transmitter program mode. The second flas...

Page 23

Auto-close timer programming this function is not available for the north american market. The factory set auto-close timer delay is 15 seconds. In order to confirm the operation of the auto- close timer first set dip switch no. 4 to on. Then press the case push button to open the door. The door wil...

Page 24

19 ; ! " 2 75(6+( $6( (&(,8(4 9,6+ 6+( " 21642//(4 :27 0756 &+$1*( 6+( (&(,8(4 )420 20(16$4: 23(4$6,21 62 2156$16 23(4$6,21 +( -703(4 /,1.,1* 2) 6+( 76376 '74$6,21 6( 40,1$/5 5+27/' %( 64$15)(44(' 62 6+( 6(40,1$/5 1($4(56 6+( 276(4 ('*( 2) 6+(3$1(/ 9+,&+ $4(0$4.(' 23(4$6,21 ,) 6+( $',2 (&(,8(4 '2(5 ...

Page 25

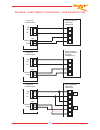

20 zap 800-r – safety wiring connections – zap photo-eyes ! ! ! !.

Page 26

21 """"""""""""""""""""""""""""" """"""""""""""""""""""""""""""""" ! ! ! Zap 800-r – safety wiring connections – non-zap photo eyes.

Page 27

Reason & remedy a. The door movement is stiff due to the door running tight against the door frame in the fully closed position. In which case adjust the position of the roller wheel supports to ease the pressure of the door against the frame. B. The door is badly out of balance. In which case re-te...

Page 28

Zap controls uk 100 waterloo boulevard anglesey business park cannock staffordshire ws12 1nr united kingdom.