- DL manuals

- 3M

- Household Appliance

- APIF100

- Installation And Operating Instructions Manual

3M APIF100 Installation And Operating Instructions Manual

INSTALLATION AND OPERATING

INSTRUCTIONS

APIF SERIES RESDENTIAL

IRON REDUCTION SYSTEMS

Models

APIF100 APIF100J

APIF100M APIF100PT APIF100MPT APIF100MJ

APIF150 APIF150J

APIF150M APIF150PT APIF150MPT APIF150MJ

APIF200 APIF200J

APIF200M APIF200PT APIF200MPT APIF200MJ

APIF300 APIF300J

APIF300M APIF300PT APIF300MPT APIF300MJ

INSTR2188 0710

Installer, please leave with homeowner.

Homeowner, retain for future reference.

Summary of APIF100

Page 1

Installation and operating instructions apif series resdential iron reduction systems models apif100 apif100j apif100m apif100pt apif100mpt apif100mj apif150 apif150j apif150m apif150pt apif150mpt apif150mj apif200 apif200j apif200m apif200pt apif200mpt apif200mj apif300 apif300j apif300m apif300pt ...

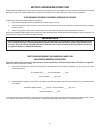

Page 3: Safety Information

Safety information read, understand, and follow all safety information contained in these instructions prior to installation and use of the apif series residential iron reduction system. Retain these instructions for future reference. Failure to follow installation, operation and maintenance instruc...

Page 4: Caution

Caution to reduce the risk associated with property damage due to water leakage: • read and follow use instructions before installation and use of this water treatment system. • installation and use must comply with existing state or local plumbing codes. • protect from freezing, relieve pressure an...

Page 5: Table of Contents

Table of contents section description 1 general information 2 before installation 3 important installation instructions 4 plumbing system clean-up 5 backwashing instructions 6 troubleshooting 7 specification and operating data 8 maintenance 9 limited warranty section 1: general information congratul...

Page 6

Section 2: before installation inspecting and handling your filter: inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection. Handle the fi lter with care. Damage can occur if dropped or set on sharp, uneven projections on the fl oor. D...

Page 7

Tannins (humic acid) tannins (a humic acid), which may be present in some water supplies, are the result of various forms of decaying vegetation (the test for tannins can be performed by your dealer). Tannins can cause problems in the operation of the iron reduction system by forming a sticky coatin...

Page 8

Locate water conditioning equipment correctly: select the location of your iron reduction system with care. Various conditions which contribute to proper location are as follows: 1) locate as close as possible to water supply source. 2) locate as close as possible to a drain. 3) locate in correct re...

Page 9

2-4 facts to remember while planning your installation: 1) all installation procedures must conform to local and state plumbing codes. 2) if lawn sprinkling, a swimming pool, or geothermal heating/cooling or water for other devices/activities are to be treated by the iron reduction system, a larger ...

Page 10

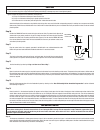

Section 3: important installation instructions proper installation sequence of water conditioning equipment is very important. Refer to the following diagram for your particular water supply. Failure to follow installation, operation, and maintenance instructions may result in property damage due to...

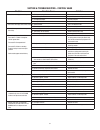

Page 11

3-2 note: have you read “ section 4”, plumbing system cleanup, for instructions on some procedures that may need to be performed fi rst? Gravel and chem-free media schedule unit model number apif100 models (apif100, apif100j, apif100m, apif100pt, apif100mpt, apif100mj) apif150 models (apif150, apif1...

Page 12

3-3 step 4 turn back on the power to the well pump and pressurize the water lines to allow for adjustment of the hydro-charger. Check for leaks and adjust as necessary. Important notes • do not apply heat near hydro-charger , as damage may occur. On badly scaled, older plumbing systems, it may be ad...

Page 13

3-4 figure 5 step 8 assemble and attach bypass valve to the control valve. See figure 3 if needed. Next locate and assemble the 1” npt connection fi ttings before attaching them to the bypass valve. Use the appropriate method of connection to ensure a permanent connection. Please refer to fi gure 5 ...

Page 14

Caution to reduce the risk associated with property damage due to water leakage: • take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs. Typical examples of proper drain line diameters and lengths are: 1/2” id up to 15 feet when dis...

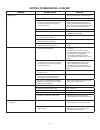

Page 15

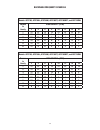

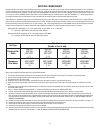

Persons in family iron content - (ppm) 2 4 6 8 10 12 14 16 1 12 12 12 12 12 12 12 12 2 12 12 12 6 6 6 6 6 3 12 12 6 6 6 4 4 4 4 12 12 6 6 4 4 4 3 5 12 12 6 6 4 3 3 3 6 12 6 6 4 3 2 2 2 models: apif100, apif100j, apif100m, apif100pt, apif100mpt, and apif100mj models: apif150, apif150j, apif150m, apif...

Page 16

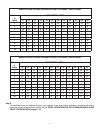

Persons in family iron content - (ppm) 5 10 12 14 16 18 20 22 24 26 28 30 1 12 12 12 12 12 12 12 12 12 12 12 12 2 12 12 12 12 12 12 12 6 6 6 6 6 3 12 12 12 6 6 6 6 6 6 6 4 4 4 12 12 6 6 6 6 6 4 4 4 4 4 5 12 6 6 6 4 4 4 4 4 3 3 3 6 12 6 6 4 4 4 4 3 3 3 2 2 7 12 6 4 4 3 3 3 3 2 2 2 2 8 12 6 4 4 3 3 3 ...

Page 17

3-8 how to set time of day step 1 - press set hour and release. Step 2 - set the clock display to the closest hour by pressing the or . An arrow will appear in the display pointing to pm during pm hours. Step 3 - press set hour to return to the display mode. Note: after an extended power outage the ...

Page 18

How to change days between regeneration step 1 - press and hold set hour and buttons simultaneously for three (3) seconds and release. Step 2 - press set hour button. Step 3 - press or buttons to change the number of days between regenerations. Step 4 - press set hour to return to the display mode. ...

Page 19

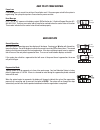

Control valve function and cycles of operation the ac adapter comes with a 15 foot power cord that is designed for use with the control valve. The ac adapter is for dry location use only. If the power goes out, only the time of day needs to be reset. All other settings are permanently stored in the ...

Page 20

How to set timer control set hour regen min. Fill regen hour time - hour pm days to regen power loss if the power goes out, current time of day will need to be reset. If the power goes out while the system is regenerating, the cycle picks up where it was when the power went out. Error message if “e1...

Page 21

Caution to reduce the risk associated with property damage due to water leakage: • installation and use must comply with existing state or local plumbing codes; special instructions for split-stream and public water supply type installation: for split-stream type installation, a secondary pressure t...

Page 22

3-13 figure 10 figure 11 figure 8 figure 9.

Page 23

Section 4: plumbing system clean up the following procedures are guidelines only but have proven successful in most instances. Under no circumstances should any procedure outlined below be followed if contrary to the appliance manufacturer’s instructions. Should there be any questions concerning the...

Page 24

Section 5: backwashing instructions periodic backwashing (regeneration) of the iron reduction system bed is required to fl ush out the entrapped iron that has accumulated. This procedure is performed automatically at 1:00 a.M. For a period of approximately 10 minutes and will not interfere with a so...

Page 25

Problem possible cause solution 1. Timer does not display time of day a. Ac adapter unplugged a. Connect power b. No electric power at outlet b. Repair outlet or use working outlet c. Damaged ac adapter c. Replace c adapter d. Damaged pc board d. Replace pc board 2. Timer does not display correct ti...

Page 26

Problem possible cause solution 1. Water clear when drawn, turns red upon standing (stain producing) a. Insuffi cient air-draw by hydro-charger. A. Check hydro-charger adjustment. If unable to adjust for long enough draw, check pumping rate. B. Bypass open or leaking b. Close bypass valve and/or rep...

Page 27

Section 7: valve specification and operating data maximum service flow rate: includes bypass valve 27 gpm (102.2 lpm) @15 psig (103 kpa) drop maximum backwash flow rate: includes bypass valve 27 gpm (102.2 lpm) @15 psig (103 kpa) drop minimum/maximum operating pres- sure: 20 psi (138 kpa) - 125 psi ...

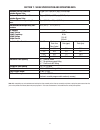

Page 28

Section 7: specification and operating data item apif100 apif100j apif100m apif100pt apif100mpt apif100mj apif150 apif150j apif150m apif150pt apif150mpt apif150mj apif200 apif200j apif200m apif200pt apif200mpt apif200mj apif300 apif300j apif300m apif300pt apif300mpt apif300mj media volume, cu. Ft. (...

Page 29

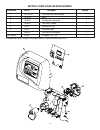

7-3 ref. No. Description apif100 apif100j apif100m apif100pt apif100mpt apif100mj apif150 apif150j apif150m apif150pt apif150mpt apif150mj apif200 apif200j apif200m apif200pt apif200mpt apif200mj apif300 apif300j apif300m apif300pt apif300mpt apif300mj 1 control valve, complete, less bypass valve w2...

Page 30

Section 7: components assemblies iron reduction system assemblies and components drive cap assembly, downflow piston, and space stack assemblies reference no. Part no. Description quantity 1 v3005 spacer stack assembly 1 2 v3004 drive cap assembly 1 3 v3178 drive back plate 1 4 v3001 piston downfl o...

Page 31

Section 7: front cover and drive assembly reference no. Part no. Description quantity 1 v3175tc-01 time clock front cover assembly 1 2 v3107-01 motor 1 3 v3106-01 drive bracket & spring clip 1 4 v3108tc time clock pc board 1 5 v3110 drive gear 12 x 36 1 6 v3109 time clock cover 1 v3002tc time clock ...

Page 32

Section 7: quick connect bypass part number v3006 reference no. Part no. Description quantity 1 v3151 nut 1” quick connect 2 2 v3150 split ring 2 3 v3105 o-ring 2 7-6 1 2 3 3 1 2 v3151 1” quick connect nut 2 v3150 split ring 2 v3105 o-ring 215 2 v3191 vertical bypass adapter 1 not shown part# v3191-...

Page 33

7-7 section 7: installation fitting and assemblies quick connect assemblies part # v3007-02 1” copper brass sweat adapter reference no. Part no. Description: 1” brass sweat assembly quantity 1 v3151 1” quick connect nut 2 2 v3150 1” quick connect split ring 2 3 v3105 1” quick connect o-ring 215 2 4 ...

Page 34

7-8 4 6 5 2 7 1 3 water flow proper dlfc orientation directs water flow towards the washer face with rounded edge. Reference no. Part no. Description quantity 1 h4615 elbow locking clip 1 2 pkp10t58s-blk 5/8” insert sleeve 1 3 v3192 quick connect 3/4” drain elbow nut 1 4 v3158-01 quick connect 3/4” ...

Page 35

Section 8: maintenance depending on your water quality, it may be necessary to perform maintenance on your fi lter system in order to ensure continued performance. This is to both low ph, high manganese and the sacrifi cial nature of the fi lter media. The severity of your ph or the amount of water ...

Page 36

9-1 section 9: limited warranty for any warranty questions, please refer to the enclosed warranty card or call 1-800-222-7880 or mail your request to: 3m purifi cation inc. 400 research parkway meriden, ct 06450 3m is a trademark of 3m company. © 2010 3m company. All rights reserved. 3m purifi catio...