- DL manuals

- 3M

- Water System

- Aqua-Pure AWS100M

- Installation And Operating Instructions Manual

3M Aqua-Pure AWS100M Installation And Operating Instructions Manual

Summary of Aqua-Pure AWS100M

Page 1

Installation and operating instructions aws series residential water softeners models: aws100m aws150m aws200m aws300m instr2198 0911 installer, please leave with homeowner. Homeowner, retain for future reference..

Page 3: Safety Information

Safety information read, understand, and follow all safety information contained in these instructions prior to installation and use of the aqua-pure ® aws series residential water softener. Retain these instructions for future reference. Failure to follow installation, operation and maintenance ins...

Page 5: Table of Contents

Table of contents section description 1 before installation 2 installation 3 programming 4 service instructions & maintenance 5 performance data sheet 6 troubleshooting 7 parts 8 limited warranty section 1: before installation caution to reduce the risk associated with property damage due to water l...

Page 6

General 1) observe all warning and caution statements that appear in this manual. 2) keep the media tank in the upright position. Do not turn upside down or drop. Turning the tank upside down will cause media to enter the valve. 3) operating temperature is between 40°f (4.4°c) and 110°f (43.3°c). 4)...

Page 7

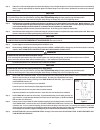

Section 2: installation proper installation sequence of water conditioning equipment is very important. Refer to the following diagram for your particular water supply. Failure to follow installation, operation, and maintenance instructions may result in property damage due to leakage and will void ...

Page 8

2.2 step 1) remove the unit from the shipping box and remove all packaging. Ensure no freight damage has occurred since shipment from our manufacturing facility. Locate the parts package and install the bypass and adapter fi ttings on the control valve to facilitate the connection to the customer’s ...

Page 9

Step 10) make certain bypass valve inlet and outlet knobs are in “bypass” position. After all plumbing connections have been completed, open main water shut-off valve and restore power to well pump. Check for leaks and correct as necessary. Step 11) plug control valve power cord into 110v/60hz, non-...

Page 10: Important Note

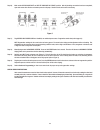

Brine line connection the brine line to the brine tank connects to the valve. Make the connections and tighten (see figure 4). Be sure that the brine line is secure and free from air leak. Even a small leak may cause the brine line to drain out, and the conditioner will not draw brine from the tank....

Page 11: Important Note

2-5 motor the controller uses a standard 12-volt ac motor that works with either 50 hz or 60 hz. Important note water fl ow to the valve can be turned on or bypassed when the controller is powered up for the fi rst time. Variable reserve function the aws metered-demand volumetric controllers are des...

Page 12

2-6 21) shows when water is fl owing through the valve. 22) used with #23, #24, #25. Displays a sequence number or a value. 23) history values. The number displayed by #22 identifi es which history value is currently displayed. 24) parameter. Displayed only in professional programming. The number di...

Page 13: Important Notes

2-7 regeneration modes the aws series controllers can be regenerated either automatically or manually. During a regeneration, the total time remaining of the regeneration, the total time remaining of the regeneration will be displayed on the controller. The current cycle is shown in the lower left o...

Page 14

2-8 manual regeneration action key duration display regen at next time of regen regen p/r recycle icon fl ashes cancel regen regen p/r when recycle icon is fl ashing recycle icon disappears immediate regen regen 5 sec. Recycle icon appears immediate double regen regen 5 sec. When immediate manual re...

Page 15: Important Note

2-9 start-up important note the control valve can be started-up even if power is not yet available to the controller. The valve must be connected to water supply. The motor can be unmounted from the valve, and the camshaft can be indexed manually counterclockwise by hand. This will allow the tank to...

Page 16: Important Note

2-10 important note as you advance through each cycle there will be a slight delay before you can advance to the next cycle. The hourglass icon will light while the camshaft is index- ing. There may be a pause at cycle c4 (system pause). This cycle allows the water/air pressure to equalize on each s...

Page 17: Important Notes

3-1 • when the controller is fi rst plugged in, it may display a fl ashing hourglass and the message err 3, this means that the controller is rotating to the home position (figure 14). If the err 2 is displayed, check that the incoming power frequency matches the controller. See the troubleshooting ...

Page 18

This level of programming is accessible by pressing the set button. The up and down arrows will step through the settings. Time of day day of week time of regeneration number of days between regeneration (99 day calendar override timer) amount of salt used per regeneration system capacity hardness t...

Page 19: Important Notes

3-3 • calendar override the controller can be programmed to regenerate automatically from a 1/2 day to a 99 day frequency. The 1/2 day regeneration mode will regenerate at the “time of regeneration,” as well as 12 hours opposite from that time. For example, the controller will regenerate at 2:00 am ...

Page 20

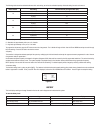

3-4 the following tables show the estimated salt amount for each setting, as well as the estimated capacity of that salt setting for each resin amount. Media volume salt setting total salt amount per regeneration (lbs) 1.0 l (low) 3.5 s (standard) 9 h (high) 15 1.5 l (low) 5.25 s (standard) 13.5 h (...

Page 21: Important Note

3-5 history data description range h0 resin volume initial setting value cubic feet h1 days since last regeneration 0-255 h2 current fl ow rate 0-47 gpm h3 water used today in gallons since time of regeneration 0-65536 gallons h4 water used since last regeneration in gallons 0-65536 gallons h5 total...

Page 22

4-1 section 4: service instructions & maintenance valve service cover the cover provides protection for the controller, wiring, and other components. This cover will be removed for most service and maintenance. To remove cover: 1) grasp side edges toward rear of the valve. 2) pull outwards until the...

Page 23: Important Note

4-2 drive motor the drive motor is open loop and receives commands from the control module. The motor has a pinion gear that meshes with the camshaft gear to drive (rotate) the camshaft. During operation, rotation forces the motor into its mounting position and screws or bolts are not needed. Note: ...

Page 24: Important Note

4-3 camshaft the camshaft has several lobes that push open the valve discs as the camshaft rotates. Rotation is controlled by a drive motor that drives a gear at the rear of the camshaft. The front end has a cup with markings and slots. Important note the camshaft slots are molded to exact dimension...

Page 25: Important Note

4-4 wiring harnesses the wiring harnesses are designed to fi t one way. The connectors are unique to the port they plug into. The wires are held in place by clips and the connectors latch in place. To remove a wiring harnesses: 1) disconnect power to the unit. 2) remove cover. 3) remove controller. ...

Page 26: Important Note

4-5 spring (valve discs) this spring is a one-piece metal spring that applies pressure to the valve discs holding them closed. The rotating camshaft overcomes this pressure to open the valve discs as needed. The shape of the spring is critical for proper operation. Important note do not attempt to s...

Page 27: Important Note

Top plate the top plate holds the valve discs in place during operation. This plate is removed to allow cleaning and replacing the valve discs. Important note the valve discs are made from a chloramine resistant severe service rubber. The valve discs will usually not need to be changed. Before remov...

Page 28: Caution

4-7 10) replace camshaft and motor. 11) replace controller and wiring harnesses. Maintenance important note: many of the maintenance procedures involve o-rings. When reassembling two parts with an o-ring seal, care must be taken with the placement of the o-ring. To properly install o-rings, they sho...

Page 29

Water meter maintenance demand systems the valve metering devices are used with the demand controls, and may require simple maintenance. In rare instances, the turbine wheel of the water meter can collect small particles of oxidized iron, eventually preventing the wheel from turning. 1) shut off the...

Page 30

4-9 after service start-up whenever the controller is unplugged or the system is put in bypass for maintenance, a start-up is required. This start-up is not normally as extensive as the new system start-up procedure needs to be followed. The initial power-up procedure should be used if a new control...

Page 31

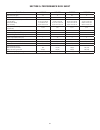

Section 5: performance data sheet 5-1 model number aws100m aws150m aws200m aws300m rated service flow (gpm) 11.2 14 12.7 17 pressure drop at rated service flow rate (psi) 15 15 15 15 rated softening capacity (grains) low salt setting standard salt setting high salt setting 15,115 @ 3.5 lbs salt 27,4...

Page 32

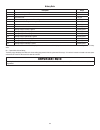

6-1 section 6: troubleshooting problem cause solution 1. Err 1 displayed a. Controller power has been connected and the control is not sure of the state of operation. A. Press the up arrow and the control should reset. 2. Err 2 displayed a. Controller power does not match 50 or 60 hz. A. Disconnect ...

Page 33

6-2 9. Clock does not display correct time of day. A. Electrical outlet operated by switch. A. Use electrical outlet not controlled by switch. B. Incorrect voltage or frequency (hz). B. Replace timer with one of correct voltage and frequency (hz) (contact dealer). C. Power outages. C. Reset clock. 1...

Page 34

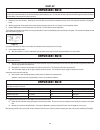

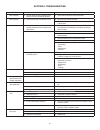

7-1 section 7: parts 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1a component parts list metered softener models (aws series) ref description aws100m aws150m aws200m aws300m 1 control valve, timer & cover (aws-m) vam-x-7sb-c vam-x-5sb-c vam-x-5sb-c vam-x-8sb-c 1a o-ring 43f 43f 43f 43f 2 media tank w/bas...

Page 35

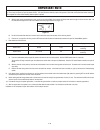

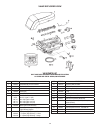

7-2 valve exploded view valve parts list only those parts referenced in drawing are stock items all others are special order, non-returnable ref part no. Description 1 1035807 valve assembly w/o flow controls 2 1235338 top plate (not shown) 3 1235339 valve disc spring, one piece 4 1236246 valve cove...

Page 36

Section 8: limited warranty limited warranty: 3m purifi cation inc. Warrants this product to be free from defects in material and workmanship during normal use for the warranty period set forth below. The warranty period commences from the date of purchase. This warranty does not cover failures resu...