- DL manuals

- 3M

- Power Tool

- Scotch-Weld

- Owner's Manual

3M Scotch-Weld Owner's Manual

3

Scotch-Weld

™

Hot Melt Applicator PG II Owner’s

Manual

Manuel de l’utilisateur – Applicateur d’adhésif

thermo-fusible PG II 3M

™

Scotch-Weld

™

Aplicador por fusión al calor de Scotch-Weld

™

PG

II de 3M

™

Manual del usuario

Use with 3M™ Scotch-Weld™ Hot Melt Adhesives

À utiliser avec les adhésifs thermo-fusibles 3M™ Scotch-Weld™

Úselo con adhesivos de fusión al calor Scotch-Weld™ de 3M™

Summary of Scotch-Weld

Page 1

3 scotch-weld ™ hot melt applicator pg ii owner’s manual manuel de l’utilisateur – applicateur d’adhésif thermo-fusible pg ii 3m ™ scotch-weld ™ aplicador por fusión al calor de scotch-weld ™ pg ii de 3m ™ manual del usuario use with 3m™ scotch-weld™ hot melt adhesives À utiliser avec les adhésifs t...

Page 2: Contents

General information ...............................................................................Page 3 set up and installation...........................................................................Page 4 operation ..................................................................................

Page 3: General Information

General information © 3m 2006 3 the 3m™ scotch-weld™ hot melt applicator pg ii is designed to be a simple, reliable tool for dispensing 3m™ scotch-weld™ hot melt adhesive sticks. It is self-contained and hand held, designed for multi-station or intermittent manual adhesive application. The 3m scotch...

Page 4: Set Up and Installation

© 3m 2006 4 set up and installation remove the 3m™ scotch-weld ™ hot melt applicator pg ii from its shipper and inspect for obvious damage. 1. Connect air and electrical service select a work station where 120 vac grounded receptacle and compressed air service are available. Electrical outlet should...

Page 5: Operation

Operation © 3m 2006 5 warm up make certain that the 3m™ scotch-weld ™ hot melt applicator pg ii is fully loaded with adhesive. Set the off/on switch to the “on” position, switch should light up, and set 3m scotch-weld hot melt applicator pg ii in the bench stand for 15 minutes. During this warm-up p...

Page 6: Caution:

Before operation caution: always remember the tip and valve are extremely hot. 1. Make sure filtered compressed air is available, regulated to a maximum of 80 psi or to a minimum of 50 psi. Do not operate 3m™ scotch-weld™ hot melt applicator pg ii below 40 psi. If low flow is experienced at 40 psi s...

Page 7: Preventive Maintenance

Preventive maintenance © 3m 2006 7 during operation always use the bench stand provided when 3m™ scotch-weld™ hot melt applicator pg ii is not in use. Do not lay the applicator on its side. This impedes cooling process and may cause plugging problems. Open adhesive stick container only when necessar...

Page 8: Troubleshooting

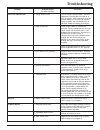

© 3m 2006 8 troubleshooting problem probable cause correction (in order of priority) low or no adhesive flow 1. Hung adhesive stick turn on the 3m™ scotch-weld™ hot melt applicator pg ii and allow it to heat for at least 60 minutes. With incoming air at 80 psi extrude adhesive. If unsuccessful remov...

Page 9: Troubleshooting

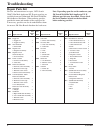

# of items/ kit # repair part kit kit 9200 trigger kit a. Trigger pin 1 b. Trigger assembly 1 9203 heat shield kit a. Heat shield 1 9204 regulator kit a. Regulator assembly 1 9205 regulator hose sub-assembly kit a. Hose assembly 1 9207 power cord kit a. Power cord assembly 1 b. Cable ties 5 9209 the...

Page 10: Troubleshooting

© 3m 2006 10 troubleshooting your 3m™ scotch-weld™ hot melt applicator pg ii has been engineered for durability and reliability. However, as with any electrical-mechanical device, parts will wear with use and require replacement for maximum performance. We have listed below certain part kits that yo...

Page 11: Repair Procedures

© 3m 2006 11 repair procedures a. Handle kit disconnect electrical and compressed air service. To replace applicator handles, first follow “handle disassembly instructions.” next remove the electrical wiring from the terminal strip on the left handle, replacing them to the same terminals on the repl...

Page 12: Repair Procedures

© 3m 2006 12 repair procedures disconnect electrical and compressed air service. First follow “handle disassembly instructions” then remove the two large phillips head screws to the rear of the wire terminals on the right hand side of the handle. This allows the regulator assembly to swing free, con...

Page 13: Repair Procedures

© 3m 2006 13 repair procedures g. Trigger kit disconnect electrical and compressed air service. Follow “handle disassembly procedures”. Lift the trigger assembly off the trigger pin and replace. Re- assemble following reverse procedure. Heat shield disassembly instructions h. Heat shield kit disconn...

Page 14: Repair Procedures

© 3m 2006 14 repair procedures j. Thermostat/tco kit disconnect electrical and compressed air service. Remove the heat shield assembly by removing the two phillips head screws from either side of the heat shield and the one phillips head screw on the heat shield immediately above the loading chamber...

Page 15: General Assembly

© 3m 2006 15 general assembly please check serial number located on the heat block before ordering part kits. A g e a e d f b l k m n o i j j c h a. 9221 handle kit b. 9204 regulator kit c. 9223 valve kit d. 9220 hose kit e. 9207 power cord kit f. 9219 switch kit g. 9200 trigger kit h. 9203 heat shi...

Page 16: General Assembly

© 3m 2006 16 general assembly wiring arrangement electrical control.

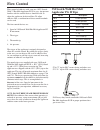

Page 17: Flow Control

© 3m 2006 17 flow control flow control of adhesive with your new 3m™ scotch- weld ™ hot melt applicator pg ii is easy. An operator familiar with the control devices should be able to adjust the applicator for desired flow. To adjust adhesive flow, a combination of these control methods can be used. ...

Page 18: Accessories

© 3m 2006 18 accessories bench mount for 3m™ scotch-weld™ hot melt applicator pg ii a special bench mount assembly is available which allows the 3m scotch-weld hot melt applicator pg ii to be mounted in a 45° position and operated with a foot pedal. It is adjustable to allow positioning of the nozzl...

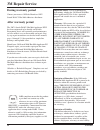

Page 19: 3M Repair Service

© 3m 2006 19 3m repair service during warranty period contact your nearest 3m sales branch or 3m™ scotch-weld ™ hot melt adhesives distributor after warranty period the 3m™ scotch-weld™ hot melt applicator pg ii has been engineered to be durable and reliable. Recognizing that it will eventually need...