Instruction manual f-18 hornet/super hornet disclaimer 6mmflyrc guarantees our kits to be free from defects in both material and workmanship at the date of purchase. This warranty does not cover any component parts damaged by use or modification. In no case shall 6mmflyrc's liability exceed the orig...

Page 2 this model was designed to be built from either bluecore fan-fold foam or 6 mm depron foam. If using bluecore, note you’ll need to peel the film backing off the fuselage exterior parts to allow sanding the fuselage corners to shape. Leave the film on the wing and empennage parts since it adds...

Page 3 1. Start assembly with the forward fuselage. Lay the two fuselage sides down flat on the work bench and glue the foam corner doublers to the locations shown on the plans. Make sure to make two mirror image parts—a left side and a right side. Either 3m 77 spray adhesive or uhu creativ works be...

Page 4 3. Laminate all of the nosecone pieces together using 3m 77 adhesive. Then glue the nosecone block to the front of the fuselage. Once the glue has dried, sand the nosecone and forward fuselage to shape. Start by tracing the top outline of the nosecone onto the foam and cut to shape with a lon...

Page 5 5. Now begin assembling the aft fuselage. Notice on the plans how the fuselage sides, top, and bottom all have a gentle curve at the aft end of the fuselage that forms the exhaust nozzles. Assembly of these parts goes much easier if you first pre-form these curves into the foam pieces using a...

Page 6 7. Glue on the aft fuselage bottom piece (the centerline should be on the inside as shown). 8. Now glue the forward and aft fuselage assemblies together. Draw a small centerline mark on the inside of the forward fuselage bottom piece, and align that mark with the centerline of the aft fuselag...

Page 7 9. Laminate the two motor mount pieces together (3m 77 spray adhesive recommended). After the glue is dry, glue in the hardwood motor mount with 5 minute epoxy and let it cure. Check the fit of the elevator servo used at this time (before you install the motor mount), and trim or shim the foa...

Page 8 11. Next install the hardware for the pivoting stabilators. The .157” diameter carbon stabilator rod pivots inside three small pieces of 3/16” diameter aluminum, which are supported by four small squares of 1/64” ply glued to the fuselage sides (study the plans carefully here!). Begin by glui...

Page 9 12. Shape the stabilator leading and trailing edges with fine sandpaper (220 grit), sanding a round contour on the leading edge and a tapered contour on the trailing edge. Then glue the left stabilator onto the carbon rod with 5 minute epoxy, making sure the carbon tube is centered in the fus...

Page 10 14. Rudders can be installed on this model as an option. While they do help with directional control at slow speeds, they are generally of limited use and are not required for this model to fly well. If you would like to install rudders, now is the time. Here are some pictures of the recomme...

Page 11 15. Next install the receiver and speed control. The receiver fits inside the compartment in the center fuselage behind the rudder servo, and the esc is installed wherever is most convenient inside the inlet ducts. A small hole must be cut in the foam wall of the receiver compartment to pass...

Page 12 17. Lay the wing down on a flat surface and use 30 minute epoxy to glue the carbon spars in place. Place heavy books over wax paper on top of the wing to hold the wing perfectly flat as the glue cures. Next cut the flaperons free from the wing. Then cut a 45 degree bevel in the leading edge ...

Page 13 19. Sand the wing strakes to the cross section shown on the plans using fine sandpaper (220 grit). Then glue the strakes onto the wing and fuselage. The tabs and slots assure proper alignment. 20. Next the aft fuselage top is installed. As before, this piece should be pre- formed with a heat...

Page 14 21. Glue the 1/32” ply rudder supports into the fuselage. Use 5 minute epoxy and slide the supports into slits in the fuselage sides. 22. Sand the vertical tail leading edges round and the trailing edges tapered. If installing rudders, cut and hinge them at this time. Cut a 20 degree bevel i...

Page 15 23. Install the fuselage turtledeck. First glue the turtledeck sides to the top of the wing, taking care to approximate the curvature shown on the plans and to join the ends on the fuselage centerline (drawing a centerline first will help). After the glue is dry, glue the turtle deck top pie...

Page 16 25. The canopy is removable to allow easy access to the battery compartment. It is held in place with two bamboo skewers forward (toothpicks or carbon rod could also be used) that slide into matching holes in the forward bulkhead, and two small strips of velcro aft that are mounted to short ...

Page 17 27. Attach the motor to the motor mount. This installation shown is the gws eps-350 motor with c gearing. Two screws on top hold the motor onto the wood mounting stick. Plug the motor into the pre-installed leads to the speed control. 28. Test install the battery inside the forward fuselage ...

Page 18 29. Congratulations! Your model is now complete! The model can be flown as is or can be painted using standard acrylic craft paint (available at most craft stores) applied with either a brush or airbrush. Remember to wipe the foam with rubbing alcohol before painting to remove any grease or ...

Page 19 additional photos here are some additional photos of the prototype f-18 park jet to illustrate how the finished model should look:.

Page 20 flight setup 1. This model flies at it’s best with flaperon controls enabled, which requires a transmitter with flaperon mixing. If you don’t have one, this model still flies well with ailerons only. The use of flaps can not only improve takeoff and landing performance, but also maneuverabil...

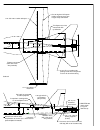

Canopy (make 10 with and laminate together) f-2 f-1 f-4 f-3 wing (make 1) top fwd fuselage (trim to fit) turtledeck sides (make 2) mounting hole for elevator servo (cut to fit selected servo very tightly) .75" x .75" 1/64" ply doublers each side (drill 3/16" hole for pivot bearing tubes) motor mount...

Aft canopy mount (1/4" balsa triangle with velcro on top) bottom outboard sand strake to the cross section shown below (not to scale) canopy and nosecone made from laminated foam sheets and carved to shape removable canopy mounted with two bamboo skewers forward and two velcro strips aft scale in in...

Flaperon servos (with 1/32" music wire pushrods) 3/8" sq. X 4" hardwood motor mount dashed lines indicate foam strip doublers at corners (see parts templates for details) 1/32" ply vertical tail supports (two per side) stabilator servo (with 1/32" music wire pushrod) .75" x .75" 1/64" ply bearing su...