- DL manuals

- A&D

- Analytical Instruments

- Weighing Indicator AD-4401

- Instruction Manual

A&D Weighing Indicator AD-4401 Instruction Manual

Summary of Weighing Indicator AD-4401

Page 1

Ad-4401 weighing indica tor 1 3 8 6 - 2 a - i e.

Page 2

? 1998 a&d company ltd. All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, or translated into any language in any form by any means without the written permission of a&d company ltd. The contents of this manual and the specifications of the instrument cover...

Page 3: Contents

1 contents chapter 1 general description...................................................................................... 3 chapter 2 specifications ................................................................................................... 4 2-1 a/d c onverter b lock .....................

Page 4

2 chapter 7 weighing sequence ....................................................................................... 32 7-1 weighing sequence................................................................................................... 32 7-2 c ustomer p rogrammed c ontrol m ode .................

Page 5

3 chapter 1 general description the ad-4401 is a compact-weighing indicator equipped with high-performance a/d conversion and general-purpose capabilities. It has the following features. User-friendly cabinet design • small din size (panel dimensions: 138+1.0/-0 x 68+0.7/-0 mm) easy to mount in a co...

Page 6: Chapter 2 Specifications

4 chapter 2 specifications 2-1 a/d converter block input sensitivity 0.3 µv/d or more zero correction range 0 to 20 mv ( 0 to 2mv/v) load cell excitation 10vdc +/- 5 %, 230 ma, with remote sensing capability (up to eight 350 ohm load cells can be connected) zero point ±(0.2 µv + 0.0008 % of dead loa...

Page 7: 2-4 Accessories

5 weighing capabilities zero point correcting capability (zero) clears the gross to zero in compliance with a command from the zero keys, control i/o, etc. Capable of enabling or disabling operations at unstable time. Zero correction value is backed up by a battery. Adjustable range: can be freely s...

Page 8: 2-5 Front Panel

6 2-5 front panel main display section a 7-digit 7-segment display. Displays the gross, net weight, etc. Sub display section an 8-digit 7-segment display. The display content can be selected using the “general functions.” the display content is indicated by attaching an accessory label. Status displ...

Page 9

7 status display section (lower) the lower “-” mark indicates a comparison result. In the normal mode, it is illuminated when a setpoint output of an identical name is turned on. In the setpoint setting mode, the “-” mark relevant to the value in the lower numerical display section blinks. Attach an...

Page 10

8 the meaning of each “-” mark differs completely. Attach a different accessory label. There are four kinds of check weighing. [z.Band] illuminated when the gross weight is less than the zero band. [lo-lo] blinks while setting the lo-lo. Illuminated when the comparison result output, lo-lo, is turne...

Page 11

9 key switches [cal] the key used to enter the calibration mode. A cover is provided so that this key can not be operated if used in a certified commercial application. In order to prevent erroneous operation, attach and seal the cover. [setpoint] the key used to set a setpoint. If this key is press...

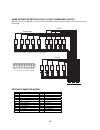

Page 12: 2-6 Rear Panel

10 2-6 rear panel (a) connects the thumbwheel switch or setpoint unit (op-05) to set a setpoint required for a weighing sequence. See 8-2 and 9-4. (b) inputs/outputs the signals such as tare subtraction input, each loading output required for the weighing sequence. The capability of each terminal ca...

Page 13: 3-1 Environment

11 chapter 3 installation and connections this chapter describes the installation environment, and connections to the power terminals and load cell connector. For other external inputs/outputs, see their relevant descriptive chapters. Control i/o, setpoint (setpoint), standard serial output (ser. Ou...

Page 14: 3-3 Load Cell

12 6) to change a blown fuse. Turn the power off and wait 10 seconds or more. Replace the fuse with the accessory fuse without touching other parts. Make sure that no stray material is left in the case, screws, spacer, etc., before closing the case. 3-3 load cell for a load cell cable, the use of a ...

Page 15: Chapter 4 Operation

13 chapter 4 operation 4-1 operation mode this instrument has various “modes” in compliance with its operating conditions. Use the keys to change the mode. You can change the mode in the full-line arrow direction. The broken-line arrow direction indicates only an automatic reset after completion of ...

Page 16

14 4-2 confirmation of operations the following outlines the procedure up to displaying a weight value in order to confirm operations after unpacking. Connect a load cell or load cell simulator to the proper terminals on the rear of the indicator. Turning on the power * do load cell wiring before tu...

Page 17: 4-3 Setting A Setpoint

15 step 12 the main display section displays “cal spn”, the subdisplay section displays a weight value (current weighing capacity, set value for calf-04), and the lowest digit of the weight value blinks. Adjust to the calibration weight value that you have on hand, using the [], and [ v ] keys. Step...

Page 18

16 setting with the key switch (spf-01 = 0) this method sets the setpoint using only the keys on the front panel. Step 1 press the [setpoint] key in the normal mode. The indicator will switch to the setpoint setting mode. The “-” mark above final in the subdisplay section blinks and a final value is...

Page 19

17 setting with the 16-digit thumbwheel switch (spf - 01 = 2) this method assigns an exclusive thumbwheel switch to each setpoint. Some setpoints are set with the front panel keys without using the thumbwheel switch. Assignment of the thumbwheel switch and the front panel keys differs depending on t...

Page 20: Chapter 5 Calibration

18 chapter 5 calibration 5-1 general description in the calibration mode, you carry out an operation, which associates a load cell output voltage with a weight value, and operations directly related to weighing. There are the following four kinds. Actual load calibration calibration related function...

Page 21

19 5-2 actual load calibration (cal set) the zero point and span are calibrated using a calibration weight. When making calibration for the first time, it is necessary to set the unit, decimal point position, minimum division, and capacity in advance, using the calibration-related functions mentione...

Page 22

20 5-3 calibration related functions the calibration related functions are designed to set the basic constants for the indicator. They should be carried out first thing upon installation. Step 1 remove the cover from the calibration switch located at the lower left of the front panel and press the [...

Page 23

21 calibration related functions setting calf- name default parameter description 0 none 1 g (international version) 2 kg ( international version and usa version) 3 t (international version) 01 weighing unit 2 4 lb. ( usa version) 0 none 12345 1 10 1 1234.5 2 10 2 123.45 3 10 3 12.345 02 decimal poi...

Page 24

22 setting calf- name default parameter description 08 motion detection time 1.0 0.0 to 5.0 motion is detected in combination with calf-09 motion detection width. It is not detected when set to 0. Its unit is seconds. Motion detection range 2 0 to 9 motion is detected in combination with calf-08 mot...

Page 25

23 15 zero input voltage 0.000000 0.000000 to 2.200000 input voltage (mv/v) from the load cell at "zero", which is determined in "zero calibration" with weights. 16 span input voltage (capacity to zero) 3.200000 0.000000 to 3.200000 input voltage (mv/v) from the load cell at "span", which means the ...

Page 26: 5-4 Calibration Errors

24 5-4 calibration errors err messages causes solutions cerr 0 the minimum graduation is other than 1, 2, 5, 10, 20, and 50. Confirm setting of the minimum graduation, calf-03. Cerr 1 resolution (weighing capacity/minimum graduation) is more than 16000. Confirm the relations between the weighing cap...

Page 27: Chapter 6 General Functions

25 chapter 6 general functions the general functions determine the operations of the ad-4401 and are all stored in the eeprom. Each function is sorted into the groups by capabilities and represented by prefixing a function number (f-xx) with its group name. This chapter describes how to set the gene...

Page 28

26 6-1 basic capabilities related setting fnc f- name default parameter description 0 not disable 01 key switch disable 00000000 00000000 to 11111111 1 disables each bit corresponding to the relevant key. This function is only available in the normal mode. All keys are usable if keys are enabled in ...

Page 29

27 setting fncf- name default parameter description 0 none 1 * discharging 05 “ “ status display capability 0 2 zero tracking "discharging" is exclusively intended for normal batching (built-in automatic program mode). Value of each digit and cutoff frequency 0: none 1: 11.0hz 2: 8.0hz 3: 5.6hz 4: 4...

Page 30

28 6-2 weighing sequence related setting sqf- name default parameter description 1 internal count 01 selection of comparison weight 1 2 display count see 7-6 for details. 0 no automatic accumulation 1 accumulates only acceptable weight see 7-8 for details. 02 automatic accumulation 0 2 accumulates a...

Page 31

29 setting sqf- name default parameter description 09 batch start wait timer 0.0 only effective in built-in-automatic program mode. 10 full-flow comparator inhibiter timer 0.0 only normal batching(built-in automatic program mode) is effective 11 medium-flow comparator inhibiter timer 0.0 12 dribble-...

Page 32

30 6-3 control i/o input related inf-01: capability of input terminal a1 inf-02 : capability of input terminal a2 inf-03: capability of input terminal a3 inf-04: capability of input terminal a4 inf-05: capability of input terminal a5 inf-06: capability of input terminal a6 setting default parameter ...

Page 33

31 6-5 standard serial output related setting sif- name default parameter description 1 displayed weight 2 gross 3 net 4 tare 5 gross/net/tare a & d standard format 6 accumulated weight 7 accumulated counts 01 output data 1 8 accumulated weight /accumulated counts accumulation data format 1 stream m...

Page 34: Chapter 7 Weighing Sequence

32 chapter 7 weighing sequence 7-1 weighing sequence general description weighing sequence, means to output control signals to the units connected to the control i/o, etc., by means of input signals from the load cell and external unit. In order to cope with a wide range of applications, the ad-4401...

Page 35

33 7-2 customer programmed control mode normal batching (weighing mode: calf-14 = 1) output terminal output condition zero band gross ≤ zero band full flow net ≥ final - optional preliminary medium flow net ≥ final - preliminary dribble flow net ≥ final - free fall overlimit net > final + overlimit ...

Page 36

34 loss-in-weight (weighing mode calf-14 = 2) output terminal output condition zero band gross ≤ zero band full (hopper full) gross ≥ full medium flow -net ≥ final – preliminary dribble flow -net ≥ final – free fall overlimit -net > final + overlimit underlimit -net functional description 1. Initial...

Page 37

35 7-3 built-in automatic program mode normal batching / no supplementary flow (weighing mode calf-14 = 3) output terminal output condition zero band gross ≤ zero band full flow net ≥ final - optional preliminary medium flow net ≥ final - preliminary dribble flow net ≥ final – free fall overlimit ne...

Page 38

36 11. When the discharging valve close wait timer completes the set time, the discharging output signal is turned off. 12. When the batch start input signal for the next cycle is input; • the batch finish output signal is turned off. • the judgment result output signal (overlimit or underlimit) is ...

Page 39

37 normal batching/ with supplementary flow (weighing mode calf-14 = 3) supplementary flow automatically turns on the dribble flow for the specified time when the loaded weight is not sufficient. To make supplementary flow, set the “maximum supplementary flow times, sqf-07,” to other than 0, and the...

Page 40

38 13. When the discharging start wait timer completes the set time; • the discharging output signal is turned on, and the discharging time monitor timer starts. 14. When the gross becomes lower than the zero range; • the discharging valve close wait timer starts. • the discharging time monitor time...

Page 41

39 loss-in-weight (weighing mode calf-14 = 4) output terminal output condition zero band gross ≤ zero band full (hopper full) gross ≥ final - full medium flow - net ≥ final - preliminary dribble flow - net ≥ final – free fall overlimit - net > final + overlimit underlimit - net functional descriptio...

Page 42

40

Page 43

41 supplementary description for built-in-automatic program mode to subtract the tare automatically prior to loading set the batch start wait timer to 0.1 second or more and connect the tare subtraction input and the batch start input in parallel. When using with a high-speed packer and it is diffic...

Page 44

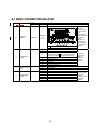

42 7-4 supplementary description for batch weighing when setting the setpoint with the 16-digit thumbwheel switch in batch batching, connection of the 16-digit thumbwheel switch is common. When spf-01 = 2 is set, connect the thumbwheel switch to the set point connector as show in the figure below. S...

Page 45: 7-5 Check Weighing Mode

43 7-5 check weighing mode check weighing mode 1 (weighing mode calf-14 = 5) output terminal output condition zero band gross ≤ zero band hi-hi net > hi-hi limit hi net > target weight + hi limit go target weight + hi limit ≥ net ≥ target weight – lo limit lo net lo-lo net when an output condition i...

Page 46

44 when setting the setpoint with a 15-digit thumbwheel switch when spf-01 = 2 is set, connect the thumbwheel switch to the set point connector as show in the figure below. Setpoint connector wiring pin # pin # a1 1 b1 hi limit. 10 3 a2 2 b2 hi limit. 10 4 a3 4 b3 lo limit 10 0 a4 8 b4 lo limit 10 1...

Page 47

45 check weighing mode 2 (weighing mode calf-14 = 6) output terminal output condition zero band gross ≤ zero band hi-hi net > hi-hi limit hi target weight + hi-hi limit ≥ net > target weight go target weight + hi limit ≥ net ≥ target weight – lo limit lo target weight – lo-lo limit ≤ net lo-lo net w...

Page 48

46 when setting the setpoint with a 15-digit thumbwheel switch when spf-01 = 2 ( 16-digit mode ) is set, connect the thumbwheel switch to the set point connector as show in the figure below. Setpoint connector wiring pin # pin # a1 1 b1 hi limit. 10 3 a2 2 b2 hi limit. 10 4 a3 4 b3 lo limit 10 0 a4 ...

Page 49

47 check weighing mode 3 (weighing mode calf-14 = 7) output terminal output condition zero band gross ≤ zero band hi-hi net > hi-hi limit hi net > hi limit go hi limit ≥ net ≥ lo limit lo net lo-lo net when an output condition is established, a relevant output terminal is turned on (power continuity...

Page 50

48 when setting the setpoint with a 10-digit thumbwheel switch when spf-01 = 2 (16-digit mode) is set, connect the thumbwheel switch to the set point connector as show in the figure below. Setpoint connector wiring pin # pin # a1 1 b1 hi limit. 10 3 a2 2 b2 hi limit. 10 4 a3 4 b3 lo limit 10 0 a4 8 ...

Page 51

49 check weighing mode 4 (weighing mode calf-14 = 8) output terminal output condition zero band gross ≤ zero band hi-hi net > hi-hi limit hi hi limit > net ≥ hi limit go hi limit ≥ net ≥ lo limit lo lo limit > net ≥ lo-lo limit lo-lo net when an output condition is established, a relevant output ter...

Page 52

50 when setting the setpoint with a 16-digit thumbwheel switch when spf-01 = 2 (16-digit mode) is set, connect the thumbwheel switch to the set point connector as show in the figure below. Setpoint connector wiring pin # pin # a1 1 b1 lo limit 10 0 a2 2 b2 lo limit 10 1 a3 4 b3 lo limit 10 2 a4 8 b4...

Page 53: 7-6 Comparison Weight

51 7-6 comparison weight although the weight compared with the setpoint is mainly the net, the gross is partially compared. Since the net assumes a negative value in loss-in-weight, setpoint is made with the polarity reversed. Setpoint of the weight with the setpoint allows you to select the display...

Page 54

52 7-9 automatic free fall compensation automatic free fall compensation is the capability to reduce a loading error in batch weighing. The following two kinds can be selected depending on the functioning of the automatic free fall compensation (sqf-03). 1) automatically setting the “moving average ...

Page 55: Chapter 8 Interface

53 chapter 8 interface 8-1 control i/o the control i/o is intended for inputting/outputting weighing control signals to an external unit. It consists of 6 inputs and 8 outputs. The capability of each input/output terminal can be selected, except com (see 6-3, 6-4 for selection method). Upon shipment...

Page 56

54 input terminal function (inf-01 to inf-06) the capabilities of the input terminals a1 through a6 can be optionally selected with the “general functions inf-01 through inf-06.” (see 6-3 for method of selection) set value terminal no. Function name description 0 function> n/a n/a 1 zero edge clears...

Page 57

55 output terminal function (outf-01 to outf-08) output terminals b1 through b6 can be optionally selected with the “general functions outf-01 through outf-08.” (see 6-4.) set value function name description 0 no function n/a 1 zero range turned on when the gross is close to the zero range. Underlim...

Page 58: 8-2 Setpoint

56 8-2 setpoint the setpoint refers to a weight setting such as the reference value and final required for the weighing sequence. Connect the thumbwheel switch which makes this setting to the set point connector. Connection of the setpoint differs depending on the general function, “setpoint read mo...

Page 59

57 8-3 standard serial output (ser. Out) the standard serial output is a 20 ma current loop. It is located on the rear panel of the indicator, and is used to connect a remote indicator or printer. This output does not have a power supply. Therefore, the external unit must supply the power. Setting o...

Page 60

58 output data there are two kinds of transmission formats; “a & d standard format” and “accumulation data format”. The a & d standard format has been used for our weighing indicators. It consists of two headers, data, unit, and terminator. The accumulation data format outputs a simple header, numer...

Page 61

59 header- 1 8 digits including data, polarity, and decimal point unit terminator accumulated weight t w , + 0 1 2 3 4 5 6 . 7 8 k g cr lf header is "tw" weight + overflow t w , + sp sp sp sp sp sp sp . Sp sp k g cr lf "sp" value weight - overflow t w , - sp sp sp sp sp sp sp . Sp sp k g cr lf "sp" ...

Page 62: Chapter 9 Options

60 chapter 9 options there are the following external input/output options. Note) the 4401 has only one slot for op-01, op-03 or op-04. Therefore only one of them can be installed. • op-01 bcd output • op-03 rs-422/-485 input/output • op-04 rs-232c input/output • op-05 setpoint unit (setpoint settin...

Page 63

61 interface specification output open collector (common is connected to the npn transistor emitter sides) output data: 6-digit bcd code, overflow, polarity, motion, strobe input dry contact (pulled up to +5 v by a resistor) input data: hold • in case of negative logic, each terminal is turned on at...

Page 64

62 data transfer mode there are three kinds of data transfer modes for the bcd output; “stream,” “auto print,” and “manual print.” [stream], [auto print], and [manual print] the functions of these transfer modes are the same as described in {8-3 standard serial output}. Timing strobe pulses are turn...

Page 65

63 note: • the polarity of signal a and b vary from computers. • not necessary to ground the sg terminal for the computer without a signal ground terminal. • wait 8 ms or more before selecting a unit by sda and sdb..

Page 66

64 the following is a program for connecting two ad-4401s and a computer by rs-422. Setting item computer ad-4401 baud rate 960 0 bps rsf-03 = 5 parity bit even rsf-04 = 2 character bit 7 bits rsf-05 = 7 stop bit length 1 bit rsf-06 = 1 terminator cr, lf rsf-07 = 2 output data (display weight) rsf-0...

Page 67

65 setting rsf- name default parameter description 1 displayed weight 2 gross 3 net 4 tare 5 gross/net/tare a&d standard format 6 accumulated weight 7 accumulated counts 01 output data 1 8 accumulated weight/ accumulated counts accumulated data format 1 stream 2 auto print 3 manual print 4 command 5...

Page 68

66 data transfer mode there are five kinds of data transfer modes for rs-232c/422/485; “stream,” “auto print,” “manual print,”,“command”, and “output per sampling.” [stream], [auto print], and [manual print] the functions of these transfer modes are the same as described in 8-3 standard serial outpu...

Page 69

67 accumulation data format example header -1 8 digits including data, polarity, and decimal point unit terminator accumulated weight t w , + 0 1 2 3 4 5 6 . 7 8 k g cr lf header is "tw" weight + overflow t w , + sp sp sp sp sp sp sp . Sp sp k g cr lf "sp" value weight - overflow t w , - sp sp sp sp...

Page 70

68 how to use the command mode in the command mode, a “command” is transmitted from an external unit to the ad-4401, the ad-4401 operates in compliance with the command and responds with a result. When the command is not accepted due to an error (improper command or faulty data), a “negative acknowl...

Page 71

69 type of response description acknowledgment communication procedure a: repeats the command as it is. Communication procedure b: returns the data. Communication procedure c: returns the command as it is and waits to receive the data. Negative acknowledgment (beyond condition): ad-4401 in non-recei...

Page 72: 9-4 Op-05 Setpoint Unit

70 9-4 op-05 setpoint unit the op-05 setpoint unit is a thumbwheel switch unit designed for setting the setpoints exclusive for batch weighing and loss-in-weighting use. By connecting this option to the ad-4401, each setpoint can be set with the thumbwheel switch on the panel or the bcd input. Since...

Page 73

71 connection when the power supply is not connected, this instrument can be set with the thumbwheel switch on the front panel. When this is done, set the int/ext selector switches to int. When the bcd input or serial connection is required, connect the power supply and short the cont terminal. This...

Page 74

72 using the external setting input external setting input for final, free fall, and preliminary is enabled by setting their respective int/ext selector switches to ext. It is of bcd code and negative logic, and its level is about 10 v. Drive it with an open collector input or no-voltage (shorting t...

Page 75: 9-5 Op-07 Analog Output

73 9-5 op-07 analog output the op-07 analog output option is for sending the weight data to an analog input unit. The output is a 4 to 20 ma current output proportional to the display reading. The output data is updated in synchronization with the display update. Setting anf- name default parameter ...

Page 76: Chapter 10 Maintenance

74 chapter 10 maintenance 10-1 check mode entering check mode the check mode is intended to check the operations of the indicator, key switches, and external input/output. Step 1 with the [enter] key pressed and held, press the [setpoint] key. “fnc” is displayed to indicate that the indicator is ent...

Page 77

75 item checked checking procedures display key switches (o) mark of the pressed key moves upward. Control i/o (o) mark of the on-terminal moves upward. The terminal of the displayed number is on. Standard serial output pressing the [enter] key sends “1 2 3 ” at the baud rate set in the general func...

Page 78: 10-2 Initialization

76 10-2 initialization initialization is the operation to return the contents of the ram and eeprom to the initial factory values. There are three kinds of initialization modes, depending upon their ranges. Ram initialization mode initializes the ram only. Since the zero compensation value, tare val...

Page 79: Chapter 11 Setting Lists

77 chapter 11 setting lists use the settings list as a quick reference for maintenance of your ad-4401. When consulting with your a & d representative, let them know the user set values. 11-1 general functions basic functions setting fncf- name user’s default parameter description 0 not disable 01 k...

Page 80

78 weighing sequence functions setting sqf- name user’s default parameter description 1 internal count 01 selection of comparison weight 1 2 display count 0 no automatic accumulation 1 accumulates only acceptable weight 02 automatic accumulation 0 2 accumulates all values 0 no automatic free fall co...

Page 81

79 setting sqf- name user’s default parameter description 12 dribble-flow comparator inhibitor timer 0.0 n/a 13 judgment wait timer 0.1 0:until next batch start 14 batch finish output width 0.0 0.0 to 25.5 (in step of 0.1 second) non-0: set time 0: unused 15 batch monitoring timer 0 0.0 to 25.5 (in ...

Page 82

80 control i/o input functions inf-01: capability of input terminal a1 inf-02 : capability of input terminal a2 inf-03: capability of input terminal a3 inf-04: capability of input terminal a4 inf-05: capability of input terminal a5 inf-06: capability of input terminal a6 setting default parameter de...

Page 83

81 standard serial output functions setting sif- name user’s default parameter description 1 displayed weight 2 gross 3 net 4 tare 5 gross/net/tare a & d standard format 6 accumulated weight 7 accumulated counts 01 output data 1 8 accumulated weight /accumulated counts accumulation data format 1 str...

Page 84

82 op-03 rs-422 / op-04 rs-232c functions setting rsf- name user’s default parameter description 1 displayed weight 2 gross 3 net 4 tare 5 gross/net/tare a&d standard format 6 accumulated weight 7 accumulated counts 01 output data 1 8 accumulated weight/ accumulated counts accumulated data format 1 ...

Page 85

83 11-2 calibration related functions setting calf- name user’s default parameter description 0 none 1 g (international version) 2 kg ( international version and usa version) 3 t (international version) 01 weighing unit 2 4 lb ( usa version) 0 none 12345 1 10 1 1234.5 2 10 2 123.45 3 10 3 12.345 02 ...

Page 86

84 setting calf- name user’s default parameter description 0 1 does not output when the weight value is overflowing or unstable 0 12 standard serial output; output when weight value is overflowing or unstable 1 1 outputs even if the weight is overflowing or unstable 0 does not output when the weight...

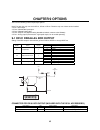

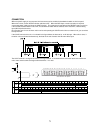

Page 87: Appendix Dimensions

85 appendix dimensions ad-4401 op-05.

Page 88

86.

Page 89

87.

Page 90

88.