- DL manuals

- A-Dec

- Medical Equipment

- 3420

- Operation And Maintenance Instructions

A-Dec 3420 Operation And Maintenance Instructions

Summary of 3420

Page 1

Operation and maintenance instructions pac i (portable) model 3420 85068100_2004_05_revj_85068100_2004_05_revh.Qxd 1/22/10 10:54 am page i.

Page 2

Warranty a-dec ™ warrants all products in this catalog against defects in material or workmanship for one year from time of delivery. A-dec’s sole obligation under the warranty is to provide parts for the repair, or at its option, to provide the replace- ment product (excluding labor). The buyer sha...

Page 3

Setup instructions institutional unit: ................................ 1 assemble the u-frame ........................ 1 mount the institutional unit control head 1 field unit:.......................................... 1 assemble the tripod............................ 1 mount the field unit control...

Page 4

Pac 1 field unit pac 1 institutional unit pac 1 self-contained unit pac l (portable) model 3420 85068100_2004_05_revj_85068100_2004_05_revh.Qxd 1/22/10 10:54 am page iv.

Page 5

Setup instructions for field and institutional pac i follow the instructions for your model. Institutional unit assemble the u-frame using a 1/4" hex key, attach the upright support to the u-frame with the 1-1/4" (32 mm) long socket-head screw (see figure 1). Mount the institutional unit control hea...

Page 6

4. If your unit is equipped with the (optional) second tray holder and tray (see figure 6), remove them and set aside. 5. Remove the tripod and the tripod mounting bolt assembly (see figure 7). 6. Adjust the tripod legs to the desired height (see figure 8). We recommend the highest setting for setup...

Page 7

2. Tighten the mounting hub thumbscrew (see figure 12). Go to place the handpiece tubing and syringe in the holders. Place the handpiece tubings and syringe in the holders 1. Lift the control head cover. 2. Remove the two handpiece tubings and the syringe, then place them in the holders (see figure ...

Page 8

Install the tray holder 1. Remove one of the plugs from the control head cover (see figure 16). Install the tray holder as shown in figure 17. If the unit is equipped with an optional sec- ond tray holder, remove the remaining plug from the control head cover and install the second tray holder. 2. P...

Page 9

Pac i field repair kit and (optional) tool kit there should be a field repair kit remaining in your carrying case or box (see figure 20). There is also a tool kit (see figure 21) with your field unit, an option for institutional and self-contained units. Refer to pac i tool and repair kits for a com...

Page 10

About your pac 1 dental unit your a-dec pac i dental unit is engineered to provide many years service, while requiring a minimum amount of attention. However, a cer- tain amount of care is required. Conscientious adherence to these instructions will ensure reli- able service from your pac i. The pac...

Page 11

Control functions unit on/off. To turn your pac i unit on, simply connect the unit supply air tubing (see figure 18) to the compressor or bottled gas (refer to about your pac i). To turn the unit off, disconnect the unit from the compressor or bottled gas. Handpiece selector (see figure 24) controls...

Page 12

Routine adjustments system air pressure the air filter/regulator (see figure 27) controls the system air pressure and is preset to 80 psi (552 kpa). If the system pressure is not 80 psi (552 kpa), simply lift the adjustment knob and turn clockwise to increase pressure and turn counterclockwise to de...

Page 13

Autoclavable syringe your syringe is designed to be easily serviced in the operatory. The syringe parts subject to wear under normal use are provided in a syringe repair kit which is located in the field repair kit. Repair instructions can be found in the maintenance section of this manual. Autoclav...

Page 14

A-dec syringe tips changing the syringe tip to remove the a-dec syringe tip, pull it straight out of the syringe tip retainer assembly (see figure 30). To ensure that the syringe will perform properly, it is important that you install the tip correctly. Push the syringe tip into the syringe tip reta...

Page 15

Handpiece tubing flush system your handpiece control system in equipped with a-dec’s handpiece tubing flush system. The sys- tem flushes more water through the tubings in less time than is normally possible when operat- ing the foot control only. The handpieces should not be connected when flushing ...

Page 16

Tap water if you have confidence in the quality of water delivered by your municipal supply, you may consider using fresh tap water in your self- contained water system. Use of tap water must be done in conjunction with the operation and maintenance procedures prescribed in this manual. Failure to f...

Page 17

Steril-vac your a-dec steril-vac eliminates the need for a central vacuum. It is an air operated oral evacuation system using a-dec’s avs (air vacuum system) handpiece. Vacuum created at the handpiece forces the debris into the one quart (.95 liter) waste container. An (optional) two quart (1.9 lite...

Page 18

Oil collection system the gauze pad (2x2) inside the oil collector jar on your unit needs to be changed once a week for normal usage. Change more often for heavy use. • remove the oil collector jar from the unit and discard the old gauze (see figure 36). • fold in quarters a new two-inch square gauz...

Page 19

General service information parts inspection in the troubleshooting sections in this manual you will find references to the “seal area” as a location for possible defect, which will allow a valve to leak. The seal area is comprised of the seal itself (usually an o-ring), the bore or seat in the valv...

Page 20

Test gauge the test gauge is used to check air pressure at various points while troubleshooting the system. Also required for use of this gauge: • one 1⁄8" (3.2mm) barb, a-dec part no. 023.028.00. • one washer, a-dec part no. 004.005.00. • one plastic tee, a-dec part no. 023.014.00. • two uni-clamps...

Page 21

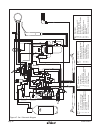

How your pac i works your pac i is engineered to provide many years of reliable service, even under the “less than ideal” conditions a portable dental delivery system may encounter. An important part of that engineering is the uncomplicated, straightforward design. Refer to the schematic on the oppo...

Page 22

Page 18 85.0681.00 rev j figure 47. Pac i schematic diagram re f. N o. D es cr ip ti on 18 q d f or s te ri l va c or a se 19 a ut oc la va bl e sy ri ng e 20 c oo la nt w at er o n/ o ff t og gl e 21 fo ot c on tr ol 23 po w er s up pl y (o pt io na l) 24 q d f or s up pl y a ir 25 fl us h va lv e ...

Page 23

Basic troubleshooting given proper care, your pac i will provide years of reliable service. In the event that something does go wrong with the unit, this troubleshoot- ing section tells what can be done in the opera- tory before removing the unit for repair. This detail is not intended to isolated e...

Page 24

Air filter/regulator the supply air passes through the filter before entering the regulator. The filter element should be serviced when it becomes sufficiently clogged to impede the flow to the regulator. Servicing the air filter/regulator the air filter/regulator assembly (24.0030.00) used in the p...

Page 25

Century ii control blocks the century ii control blocks control the routing of drive air, coolant air and coolant water to the handpieces. The control blocks are used in conjunction with the century ii manifolds, a manual selector valve, and a coolant flow con- trol valve to make a complete control ...

Page 26

Coolant water for the handpiece is controlled by an integral water valve in the century ii control block (see figure 53). The water is supplied through a passage from the manifold. This passage intersects with the coolant water flow control needle valve bore (see figure 53). After passing the needle...

Page 27

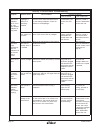

85.0681.00 rev j page 23 century ii control block troubleshooting symptom possible cause test procedure corrective action if test is normal if test is abnormal audible air leakage from the control block area loose connec- tions locate the exact point of leakage, use a soap solution if necessary. Tig...

Page 28

Page 24 85.0681.00 rev j century ii control block troubleshooting symptom possible cause test procedure corrective action if test is normal if test is abnormal air or water leaks from a handpiece that is not in use, only when another handpiece is being used the holdback diaphragm is defective or imp...

Page 29

85.0681.00 rev j page 25 century ii control block troubleshooting symptom possible cause test procedure corrective action if test is normal if test is abnormal no coolant air from one handpiece clogged tube in the handpiece switch the handpieces around and test each one, to determine whether the pro...

Page 30

Foot control iii valve the a-dec foot control iii valve is actuated by foot pressure on the disc, which depresses the piston assembly in the valve bore. This displaces the poppet allowing air to flow to the outlet. When foot pressure is released, the piston returns, seal- ing the inlet at the poppet...

Page 31

Signal relay valve the signal relay valve is a pilot operated three-way valve that mounts on the foot control valve body to provide handpiece coolant air and the handpiece water coolant signal. The valve is actuated by air pressure from the foot control valve outlet. This deflects the diaphragm and ...

Page 32

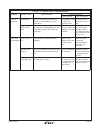

Page 28 85.0681.00 rev j signal relay valve troubleshooting symptom possible cause test procedure corrective action if test is normal if test is abnormal no signal from the signal relay valve the signal relay valve is installed upside down visually check the signal relay valve. It must be positioned...

Page 33

Servicing the flush valve a defective flush valve can cause two problems: • water leakage from around the flush valve toggle • water dripping from the handpieces. To service the flush valve, first locate the century ii, pac 1 service kit (90.0043.00), which is in you field repair kit. Included in th...

Page 34

Autoclavable syringe service replacement parts the autoclavable syringe service kit, located in the field repair kit, contains all the syringe parts subject to wear during normal use. Service kit parts, designated by an asterisk*, are shown in figure 59. Page 30 85.0681.00 rev j figure 59. Autoclava...

Page 35

Repair instructions your syringe is designed to be easily serviced in the operatory. The syringe parts subject to wear under normal use are provided in your syringe service kit, located in the field repair kit. Relieve system air and water pressure 1. Disconnect the air supply. Use the syringe to bl...

Page 36

6. While holding the new valve retaining screw and hex key in place, use the tip of a small flat-blade screwdriver and gently press down on the brass spools of the valve assemblies until they are no longer flush with the syringe (see figure 63). 7. Tighten the valve retaining screw into the syringe ...

Page 37

Steril-vac service button replacement if air leakage develops around the avs oral evacuator button, install a new button assembly. Your avs non-locking button service kit (10.0601.00) is in the field repair kit. It con- tains the new button with o-rings, a spring, a tool for removing the old spring,...

Page 38

Field repair kit p/n 45.0439.00: avs non-locking button service kit, p/n 10.0601.00 10.0109.00 non-locking on-off button assembly 10.0440.00 compression spring 85.0040.00 install avs button kit 98.0030.00 spring removal tool autoclavable syringe service kit, p/n 23.1099.00 008.003.00 hex key, .050 0...

Page 39

85.0681.00 rev j page 35 regulatory information regulatory information is provided with a-dec equipment as mandated by agency requirements. This information is delivered in the equipment’s instructions for use or the separate regulatory information and specifications document. If you need this infor...

Page 40

Contact information a-dec inc. 2601 crestview drive post office box 111 newberg, oregon 97132 usa telephone 1-800-547-1883 (503)-538-7478 designated e.U. Authorized representative: a-dec dental u.K. Ltd. Austin house 11 liberty way nuneaton, warwickshire england cv116rz phone: 0800-adecuk (233285) w...