- DL manuals

- A.O. Smith

- Water Heater

- ***81-140

- Installation, Service, Maintenance

A.O. Smith ***81-140 Installation, Service, Maintenance

1

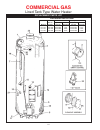

COMMERCIAL GAS

Lined Tank Type Water Heater

•

Installation

•

Service

•

Maintenance

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED IN U.S.A. 1102

PART NO. 195091-000

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE INSTALLING AND USING THIS

APPLIANCE.

Summary of ***81-140

Page 1

1 commercial gas lined tank type water heater • installation • service • maintenance place these instructions adjacent to heater and notify owner to keep for future reference. Printed in u.S.A. 1102 part no. 195091-000 caution text printed or outlined in red contains information relative to your saf...

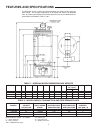

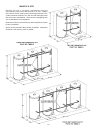

Page 2: Features and Specifications

2 the illustration shows a typical gas-fired commercial gas power burner, tank-type water heater. The principal components of the heater are shown and identified here. By referring to the plate on the heater jacket the unit may be identified in the specifications presented in table 1 and 2. Features...

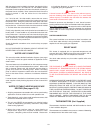

Page 3: Foreword

3 foreword these designs comply with the latest version of the american national standard for gas water heaters, volume iii, ansi z21.10.3 - csa 4.3. Detailed installation diagrams are found in this manual. These diagrams will serve to provide the installer with a reference for the materials and met...

Page 4

4 spray can propellants, cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium chloride (water softener salt), waxes, and process chemicals contain typical compounds which are potentially corrosive. Do not store products of this sort near the ...

Page 5: Features

5 the input reduction is primarily achieved by reducing the size of the main burner orifices. To do this, the main burner orifices require replacement with orifices sized for the particular installation elevation. Correct orifice sizing and parts may be obtained from the manufacturer. See the replac...

Page 6

6 are heavy and travel along the floor and may be ignited by the heater’s ignition system or main burner flames causing fire or explosion. Some local codes permit operation of gas appliances in such areas if they are installed 18 inches or more above the floor. This may reduce the risk if location i...

Page 7

7 carboning or sooting of the combustion chamber, burners and flue tubes and creates a risk of asphyxiation. Mechanical exhausting of room air where an exhaust fan is installed in the same room with a heater, sufficient openings for air must be provided in the walls. Undersized openings will cause a...

Page 8

8 in venting systems where a continuous or intermittent back (positive) draft is found to exist, the cause must be determined and corrected. In some cases, a special vent cap may be required. Do not install this unit on the positive draft side of a venting system being served by a power exhauster. D...

Page 9

9 warning the heater is not intended for operation at higher than 10.5" w.C. - natural gas, 13.0" w.C. - propane gas (1/2 pound per square inch gauge) supply gas pressure. Higher gas pressures require supplemental reducing service regulation. Exposure to higher gas supply pressure may cause damage t...

Page 10

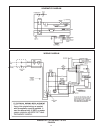

10 with the power burner installed in the heater, the electrical wiring can be completed. On ***81-140 and ***81-199 models, remove the power burner backplate and fasten the conduit assembly to the power burner assembly. Next, connect the black wire to the terminal marked “1” and the white wire to t...

Page 11

11 wiring for ***81-140 thru ***81-370 figure 9 schematic diagram wiring diagram.

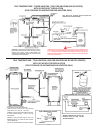

Page 12: Installation Diagrams

12 installation diagrams one temperature - one heater vertical storage tank forced circulation with or without building recirculation one temperature - one heater horizontal storage tank forced circulation with or without building recirculation scald prevention hot water can scald if used carelessly...

Page 13

13 danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control section on page 17 & 19. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti- scald valve for hot water supplied to fixtures. One or two temperature...

Page 14

14 two temperature - three heaters (two pre-heaters/one booster) with or without circulation (for storage or instantaneous heaters only) two temperature - two heaters (one pre-heater/one booster heater) with or without recirculation (for storage or instantaneous heaters only) caution: if building co...

Page 15

15 danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control section on page 17 & 19. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water supplied to fixtures. One or two temperature ...

Page 16

16 manifold kits precision cut type “l” all copper manifold kits from your manufacturer assure water flow balance of all units. Without this balance, the full water heating and storage potential of the system cannot be achieved. Plus, the units with the higher water flow may have a shortened life. U...

Page 17: Prior To Start Up

17 prior to start up important it is required that a qualified person perform the initial firing of the heater. At this time the user should not hesitate to ask the individual any questions which he may have in regard to the operation and maintenance of the unit. A checklist and service information ...

Page 18

18 operational and adjustment procedure (initial start up) for your safety read before lighting warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance does not have a pilot. It is equipped w...

Page 19

19 table 5 temperature time to produce 2nd & 3rd setting degree burns on adult skin o 180°f (82°c) nearly instantaneous 170°f (77°c) nearly instantaneous 160°f (71°c) about 1/2 second 150°f (65°c) about 1-1/2 seconds 140°f (60°c) less than 5 seconds 130°f (54°c) about 30 seconds 120°f (49°c) more th...

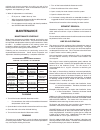

Page 20: Maintenance

20 6.Check main burner operation by cycling on and off the thermostat dial several times. Wait 1 minute between cycles for regulators and sequencing to reset. 7. When all adjustments are satisfactory: • fill in part no. 170037 “start-up” form. • adjust thermostat temperature dial to deliver desired ...

Page 21

21 to clean heater through cleanout opening, proceed as follows: 1. Turn off water inlet valve, the heater electrical disconnect switch and open drain valve. 2. Remove outer cover plate from lower side of heater jacket. 3. Remove cover from cleanout opening. 4. Remove lime, scale or sediment using c...

Page 22: Checklist and Service

22 to test gate for operation gently tap gate and observe. Do not attempt to adjust this control. Do not oil. Anode rod inspection the heater tank is equipped with anode rods to provide corrosion control. At least once a year the anode rods should be checked to determine if replacement is necessary....

Page 23: Troubleshooting

23 • installation of a second relief valve with lower setting than the primary relief valve. • an expansion tank of suitable size and pressure rating and provision to avoid water logging. Hot water odor on occasion, hot water may develop a strong odor. If this occurs, drain the heater completely, fl...

Page 24: Commercial Gas

24 natural gas propane gas burner wayne c.S. Wayne c.S. Models number part no. (decimal) part no. (decimal) ***81-140 hsg-200 62459-001 0.24 62459-001 0.209 ***81-199 hsg-200 62459-001 0.38 62459-001 0.257 ***81-270 hsg-400 62459-002 0.368 62459-002 0.302 ***81-370 hsg-400 62459-002 0.532 62459-002 ...

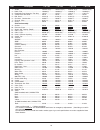

Page 25

25 *items not illustrated. ( ) reflects quantities. Part numbers underlined are recommended stock items for emergency replacement. (consider gas used in your area only). All information such as model and series number, type of gas and specifications must tobe supplied to state water heaters. Item de...

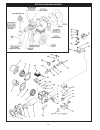

Page 26

26 model hsg 200/400 gas burner.

Page 27

27 1 .... Burner housing ......................................................................................... 6206 2 .... Air tube-hsg200 6” .................................................................................. 6206-1 ..... Air tube-hsg400 6 1/4” ......................................

Page 28

28.