- DL manuals

- A.O. Smith

- Water Heater

- 100 120

- Instruction Manual

A.O. Smith 100 120 Instruction Manual

1

Instruction Manual

PRINTED 0410

317443-000

Keep thIs Manual In the pocKet on heater for future reference

whenever MaIntenance adjustMent or servIce Is requIred.

power vent/power dIrect vent Gas Models

wIth hot surface IGnItIon

all technIcal and warrantY questIons: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, CALL THE TECHNICAL SUPPORT PHONE NUMBER SHOWN ON THE WATER HEATER LABELING.

resIdentIal Gas water heaters

•

for Your safety

•

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

Ashland City, TN 37015

www.hotwater.com

Thank you for buying this energy efficient water heater.

We appreciate your confidence in our products.

Summary of 100 120

Page 1

1 instruction manual printed 0410 317443-000 keep this manual in the pocket on heater for future reference whenever maintenance adjustment or service is required. Power vent/power direct vent gas models with hot surface ignition all technical and warranty questions: should be directed to the local d...

Page 2

2 table of contents table of contents ........................................................................2 safe installation, use and service........................................3 approvals ........................................................................................3 general safe...

Page 3

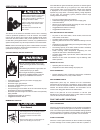

3 the proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of a potential injury hazard. Read and...

Page 4: Caution

4 precautions do not use this appliance if any part has been under water. Immediately call a qualified service agency to inspect the appliance and to make a determination on what steps should be taken next. If the unit is exposed to the following, do not operate heater until all corrective steps hav...

Page 5

5 general safety information.

Page 6: Caution

6 fire hazard do not install water heater on carpeted floor. Do not operate water heater if flood damaged. For continued protection against risk of fire: fire or explosion hazard read instruction manual before installing, using or servicing water heater. Avoid all ignition sources if you smell gas. ...

Page 7

7 thank you for purchasing this water heater. Properly installed and maintained, it should give you years of trouble free service. Abbreviations used abbreviations found in this instruction manual include : • ansi - american national standards institute • asme - american society of mechanical engine...

Page 8

8 * caution harness has 120 vac. In operation. ** see “planning the vent system,” “installation of vent system” and “condensate piping” for more information. Figure 1. Vacuum relief valve *install per local codes m display enclosure ** n exhaust elbow assembly ** o condensate tubing p off/on switch ...

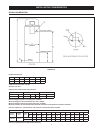

Page 9

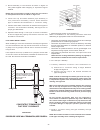

9 rough-in-dimensions units a b c d e f inches 66.75 49.25 22.00 15.75 3.00 8.00 cm 169.5 125.09 55.88 40.00 7.62 20.32 top/side inlet and outlet: 3/4” npt gas inlet: 1/2” npt capacity, gas and electrical characteristics approximate capacity manifold pressure electrical characteristics u.S. Gals. Li...

Page 10: Caution

10 locating the water heater carefully choose a location for the new water heater. The placement is a very important consideration for the safety of the occupants in the building and for the most economical use of the appliance. Property damage hazard all water heaters eventually leak. • do not inst...

Page 11

11 in an alcove or closet, the entire floor must be covered by the panel. Failure to heed this warning may result in a fire hazard. Minimum clearances between the water heater and combustible construction are 0 inch at the sides and rear, 5.5” (14.0 cm) from the front and 18” (45.7 cm) from the top....

Page 12

12 ventilation systems, clothes dryers and fireplaces shall also be considered in determining the adequacy of a space to provide combustion, ventilation and dilution air. Unusually tight construction in unconfined spaces in buildings, infiltration may be adequate to provide air for combustion, venti...

Page 13

13 1. 1 square inch per 3000 btu/hr (700 mm 2 per kw) of the total input rating of all appliances located in the enclosure, and 2. Not less than the sum of the areas of all vent connectors in the space. Outdoor air through two horizontal ducts figure 6. The confined space shall be provided with two ...

Page 14

14 this water heater shall not be connected to any heating systems or component(s) used with a non-potable water heating appliance. All piping components connected to this unit for space heating applications shall be suitable for use with potable water. Toxic chemicals, such as those used for boiler...

Page 15

15 mixing valves water temperature over 125°f (52°c) can cause severe burns instantly resulting in severe injury or death. Children, the elderly and the physically or mentally disabled are at highest risk for scald injury. Feel water before bathing or showering. Temperature limiting devices such as ...

Page 16

16 figure 9. Closed water systems water supply systems may, because of code requirements or such conditions as high line pressure, among others, have installed devices such as pressure reducing valves, check valves, and back flow preventers. Devices such as these cause the water system to be a close...

Page 17: Caution

17 fit pipe insulation over the incoming cold water line and the hot water line. Make sure that the insulation is against the top cover of the heater.Fit t & p valve insulation over valve. Make sure that the insulation does not interfere with the lever of the t & p valve. Secure all insulation using...

Page 18

18 gas piping make sure gas supplied is same type listed on model rating plate. The inlet gas pressure must not exceed 14 inch water column (3.5 kpa) for natural and propane gas (l.P.). The minimum inlet gas pressure shown on rating plate is that which will permit firing at rated input. All gas pipi...

Page 19

19 high altitude installations this high efficiency water heater is certified for use without modification for an altitude of 10,000 feet (3,079 meters). Consult the factory for installation at altitudes over 10,100 feet (3,079m). Some gas utility companies derate their gas for altitude, making it u...

Page 20

20 venting never operate the water heater unless it is vented to the outdoors. The instructions in this section of the manual must be followed to avoid choked combustion or recirculation of flue gases. Such conditions cause sooting of the combustion chamber, burners and flue tubes and creates a risk...

Page 21

21 pvc materials should use astm d-2564 grade cement; cpvc materials should use astm f-493 grade cement and abs materials should use astm d-2235 grade cement. If the water heater is being installed as a replacement for an existing power vented heater in pre-existing venting, a thorough inspection of...

Page 22

22 commonwealth of massachusetts for all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the co...

Page 23

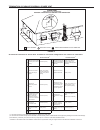

23 termination clearances sidewall power vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l power vent (using room air for combustion) exterior clearances for sidewall vent...

Page 24

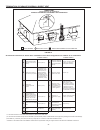

24 termination clearances sidewall direct vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l direct vent (using outdoor air for combustion) exterior clearances for sidewall...

Page 25

25 sequence of installations, figure 15a cut a length of pvc pipe about 3.5 inches (8.9 cm) longer than the wall thickness at the opening. Glue the vent terminal to this section of pipe. Slide the wall plate over the pipe to stop against the vent terminal. Place a bead of caulking (not supplied) aro...

Page 26

26 vertical vent terminal installation when terminating through a roof, the following specifications pertaining to terminal location must be followed. 1. Proper support must be provided for all pipe protruding through the roof. 2. The vertical roof terminations should be sealed with a plumbing roof ...

Page 27

27 concentric vent installation this appliance is certified for concentric venting with concentric vent kit #9003910105 and #9006328005. Follow instructions below for proper installations. Kit components each kit is comprised of the following: item description qty. Rain cap 3 in. 1 sdr-26 pipe 4 in....

Page 28

28 5. Secure assembly to roof structure as shown in figure 23 using field supplied metal strapping or equivalent support material. Note: ensure termination height is above the roof surface or anticipated snow level as shown in figure 23. 6. Install rain cap and small diameter pipe assembly in roof p...

Page 29

29 5. Install rain cap and small diameter pipe assembly in y concentric fitting and large pipe assembly. Ensure small diameter pipe is bottomed and cemented in y concentric fitting. 6. Secure assembly to structure as shown in figure 24 using field- supplied metal strapping or equivalent support mate...

Page 30

30 12” minimum clearance above highest anticipated snow level 12” minimum clearance above highest anticipated snow level 24” minimum separation. Exhaust must be at same level or above intake terminal. Direct vent diagram figure 28. Figure 30. Figure 31. Figure 32. Figure 29. When direct venting thro...

Page 31

31 vent pipe preparation 1. Initial preparation. A.) make sure the solvent cement you are planning to use is designed for the specific application you are attempting. B.) know the physical and chemical characteristics and limitations of the pvc and cpvc piping materials that you are about to use. C....

Page 32

32 b. Deburring use a knife, plastic pipe deburring tool, or file to remove burrs from the end of small diameter pipe. Be sure to remove all burrs from around the inside as well as the outside of the pipe. A slight chamfer (bevel) of about 10°-15° should be added to the end to permit easier insertio...

Page 33

33 controls and switches this model is provided with three pressure switches. These switches are essential to the safe and proper operation of the unit. All switches are wired in series. The controller is set up to shut the unit down whenever there is a failure of any of the switches. It is importan...

Page 34

34 caution label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Power vent wiring schematic - figure 34. This water heater is polarity sensitve. Before applying electricity to this heater be...

Page 35

35 warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to light the burner ...

Page 36

36 for the lowest temperature which satisfies your hot water needs. This will also provide the most energy efficient operation of the water heater and minimize scale formation. Valves for reducing the point-of-use temperature by mixing cold and hot water are available, see figure 8. Also available a...

Page 37

37 user input buttons • the up and down buttons are used to navigate menus and adjust user settings. • the operational buttons are used to enter/exit menus, select menu items, activate adjustment modes and confirm or cancel new user settings. The operational buttons are multifunctional, their curren...

Page 38

38 status icons the status icons are displayed on the desktop screen and convey operational and diagnostic information. The icons are described in the table below. Table 3. Icon description water temperature in the tank has fallen. Shaded area of the animated thermometer icon will rise and fall in r...

Page 39

39 operating states the current operational state of the water heater is displayed on the desktop screen as the "status." the common operational states are described in the table below. Table 4. State description standby the water heater is not in an active heating cycle. Ie: the tank temperature is...

Page 40

40 user settings & control system menus temperatures operating set point and differential adjustment the operating set point is adjustable from 90°f (42°c) to 180°f (82°c) for commercial and 160°f (71°c) on residential models. The factory setting is 120°f (49°c). The differential is adjustable from ...

Page 41

41 temperatures (cont) description/action display tank temperature • - non adjustable - control system sensed temperature from the temperature probe. Tank probe offset • - adjustable user setting, range -5° to +5° (factory setting 0°). The tank probe offset is used to calibrate control system temper...

Page 42

42 display settings description/action display select display settings from the main menu and press the operational button under "select" to enter this menu. This menu contains adjustable display options for viewing information on the lcd screen. Use the up & down buttons to navigate the menu. Tempe...

Page 43

43 current fault description/action display select current fault from the main menu and press the operational button under "select" to enter this menu. This menu contains non adjustable operational information. Use the up & down buttons to navigate the menu. This menu contains the current fault or a...

Page 44

44 service contact information the control system has a discrete menu that installing contractors and/or service agents can access to enter contact information for their customers. This contact information will be displayed with all fault and alert messages. Description/action display from the deskt...

Page 45

45 start up conditions smoke/odor it is not uncommon to experience a small amount of smoke and odor during the initial start-up. This is due to burning off of oil from metal parts, and will disappear in a short while. Thermal expansion water supply systems may, because of such events as high line pr...

Page 46

46 venting system inspection at least once a year a visual inspection should be made of the venting system. You should look for: 1. Obstructions which could cause improper venting. The combustion and ventilation air flow must not be obstructed. 2. Damage or deterioration which could cause improper v...

Page 47

47 burn harzard. Hot water discharge. Keep hands clear of drain valve discharge. To drain the water heater storage tank: 1. Turn off the electrical supply to the water heater. 2. Turn off the gas supply at the main gas shutoff valve if the water heater is going to be shut down for an extended period...

Page 48

48 maintenance temperature-pressure relief valve test burn hazard. Hot water discharge. Keep clear of temperature- pressure relief valve discharge outlet. It is recommended that the temperature-pressure relief valve should be checked to ensure that it is in operating condition every 6 months. When c...

Page 49

49 never use this water heater unless it is completely filled with water. To prevent damage to the tank, the tank must be filled with water. Water must flow from the hot water faucet before turning “on” gas to the water heater. A *condensation may be seen on pipes in humid weather or pipe connection...

Page 50

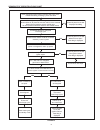

50 troubleshooting flow chart. 1. When the control system is first powered, during boot up, it will display water heater model information during initialization. After a few moments the control system lcd which is part of the uim (user interface module) will display the default screen known as the "...

Page 51

51 sequence of operation flow chart yes no water is heated to set point 24 v gas valve de-energized approximately 30 second inter-purge cycle 24 v gas valve de-energized retries up to two more times approximately 30 second post-purge cycle control system locks out “ignition failure” fault msg is dis...

Page 52: Caution

52 if the main burner ignites momentarily but does not sustain ignition allow the water heater to try to ignite up to two more times until control system locks out and the ignition failure fault message is displayed on the control system's lcd. If the water heater is experiencing rough starts - see ...

Page 53

53 note: if you are not qualified and licensed or certified as required by the authority having jurisdiction to perform a given task do not attempt to perform any of the diagnostic or service procedures described in the following section. If you do not understand the instructions in the following se...

Page 54

54 fault and alert messages call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent in your area. Possible causes - check/repair displayed fault/alert message the water heater’s control system is polarity sensitive and ...

Page 55

55 fault and alert messages (cont) call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent in your area. Possible causes - check/repair displayed fault/alert message the control system has detected the blower prover swi...

Page 56

56 notes.

Page 57

57 notes.

Page 58

58 notes.

Page 59

59 limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. The tank 1. If the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water ther...

Page 60

60 500 tennessee waltz parkway, ashland city, tn 37015 phone: 800-527-1953 fax: 800-433-2515 www.Hotwater.Com.